Micro camera lens

A miniature camera and lens technology, applied in the field of camera lenses, can solve the problems of increasing the size of the camera lens, the size of the chip, and the difficulty of processing, and achieves the effects of small size, reduced tolerance loss, and high-quality resolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

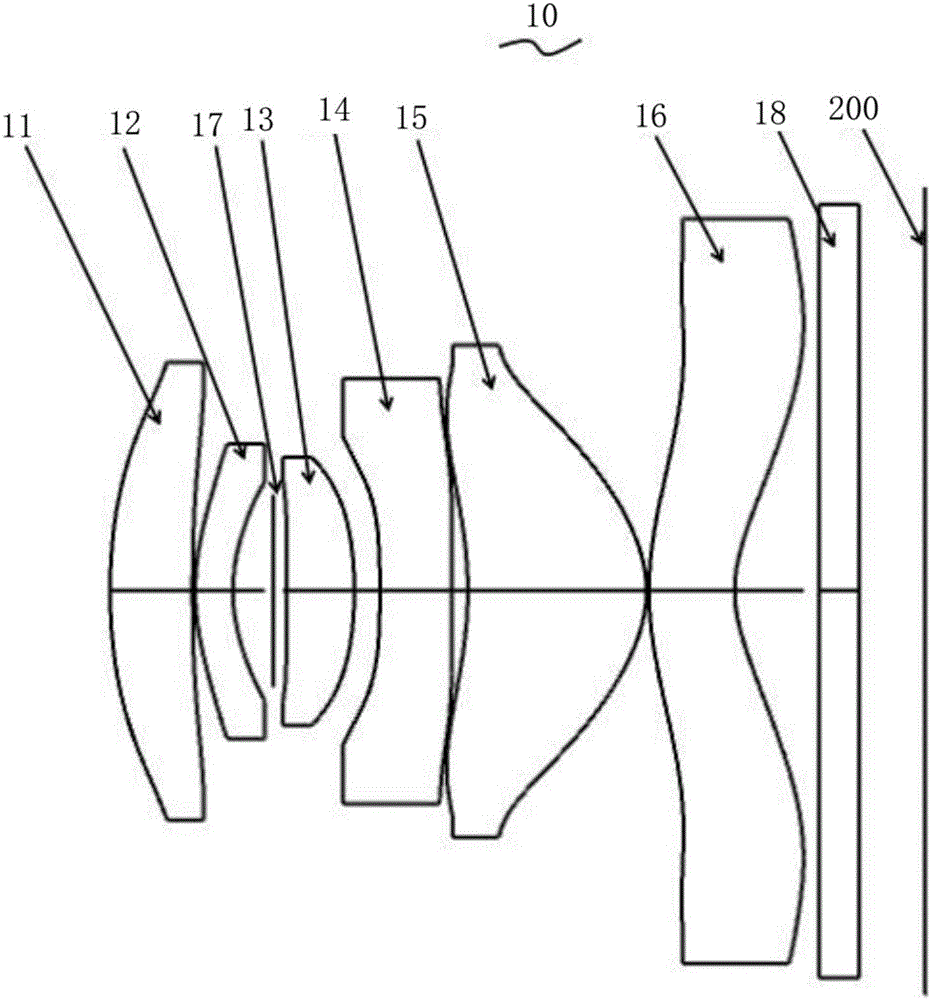

[0084] The relevant parameters of each lens in the miniature camera lens of this embodiment are shown in Table 1.

[0085] Table 1

[0086]

[0087]

[0088] Table 2 shows the aspherical parameters of each lens in the miniature camera lens of this embodiment.

[0089] Table 2

[0090]

[0091]

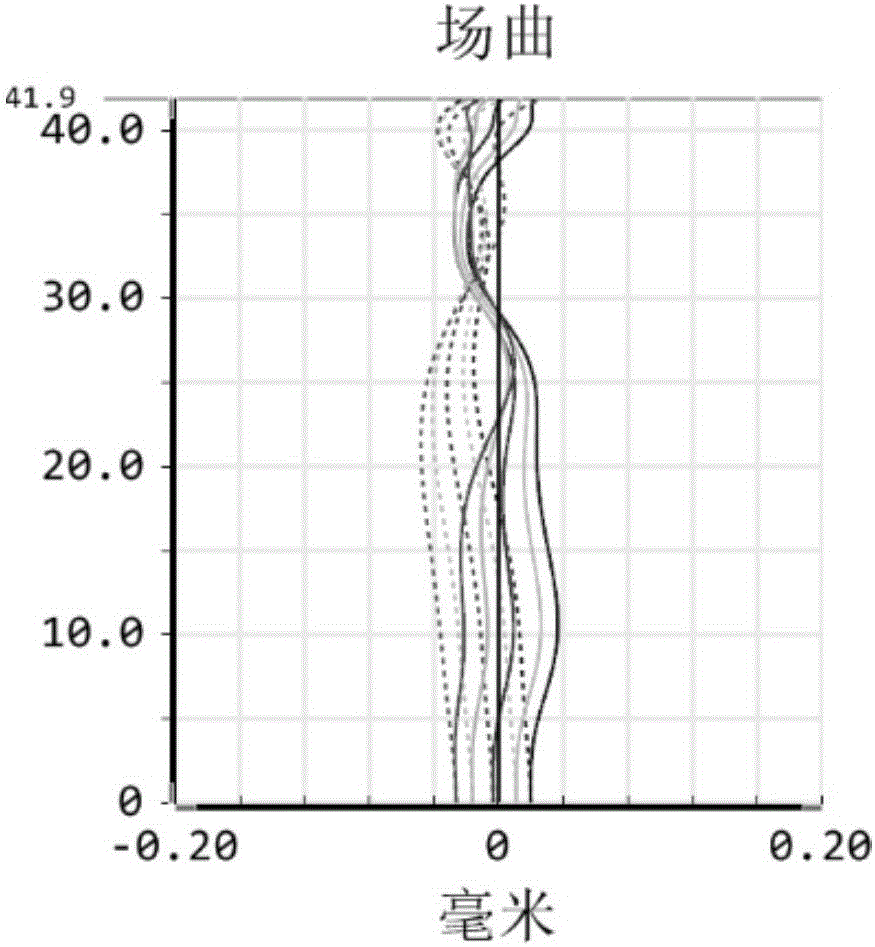

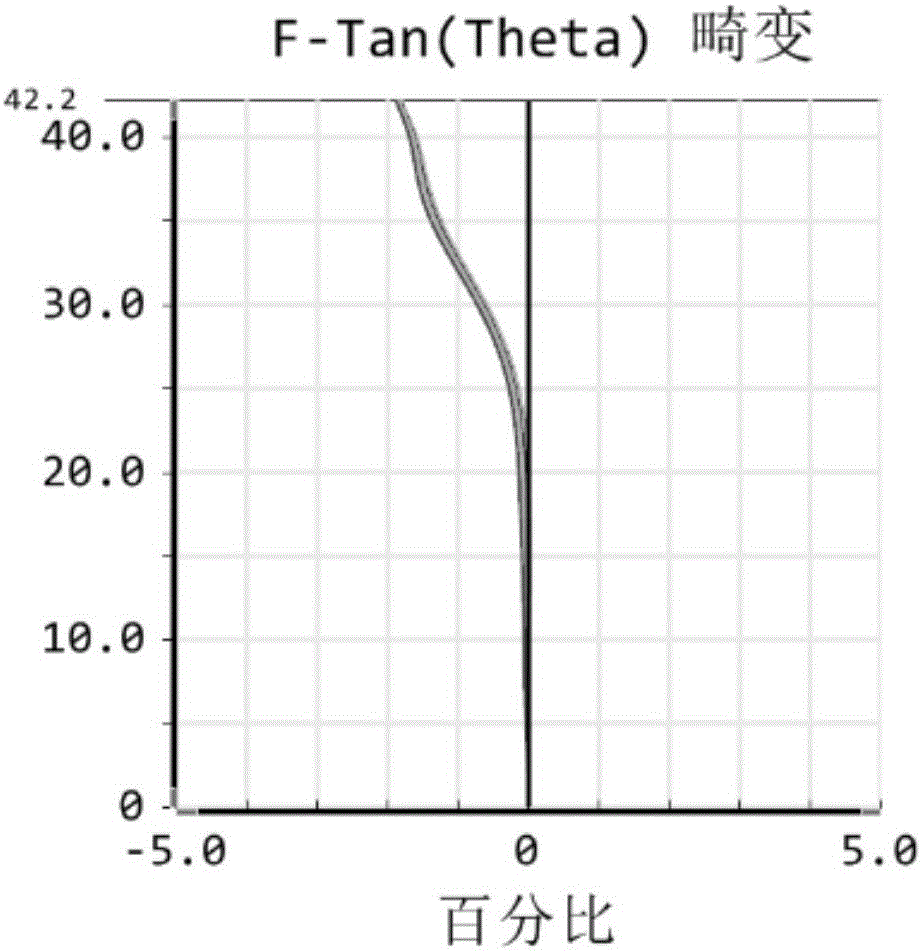

[0092] In this embodiment, the curvature of field, distortion and on-axis spherical aberration of the miniature camera lens are as follows: Figure 2a , Figure 2b and image 3 As shown, it can be seen from the figure that the curvature, distortion and on-axis penalty of this embodiment can be well corrected.

Embodiment 2

[0094] The relevant parameters of each lens in the miniature camera lens of this embodiment are shown in Table 3.

[0095] table 3

[0096] Surface serial number structure radius of curvature thickness Refractive index Abbe number 0 thing unlimited 2000.0000 1 first lens 13.8255 1.7956 1.882 37.221 2 641.7909 0.0500 3 second lens 5.3181 0.8962 1.65 21.5 4 3.6094 0.9240 5 aperture unlimited 0.2247 6 third lens -321.4642 1.2770 1.54 56.0 7 -9.3533 0.6792 8 fourth lens -32.7861 1.5208 1.65 21.5 9 30.9952 0.1478 10 fifth lens -14.5217 3.9087 1.54 56.0 11 -2.2506 0.0500 12 sixth lens 6.2109 1.5555 1.75 29.4 13 2.3388 1.4704 14 filter unlimited 0.8000 15 unlimited 1.7031 16 imaging surface unlimited 0.0000

[0097] The aspherical parameters of each lens in the miniat...

Embodiment 3

[0103] The relevant parameters of each lens in the miniature camera lens of this embodiment are shown in Table 5.

[0104] table 5

[0105]

[0106]

[0107] Table 6 shows the aspherical parameters of each lens in the miniature camera lens of this embodiment.

[0108] Table 6

[0109]

[0110] In this embodiment, the curvature of field, distortion and on-axis penalty of the miniature camera lens are as follows: Figure 6a , Figure 6b with Figure 7 As shown, it can be seen from the figure that the curvature, distortion and on-axis penalty of this embodiment can be well corrected.

[0111] In addition, Table 7 is the above-mentioned 3 embodiments and their corresponding optical characteristics, including the focal length f of the miniature camera lens, the number of apertures F#, the total optical length T of the miniature camera lens L And the angle of view 2θ, and the value corresponding to each of the previous conditional expressions.

[0112] Table 7

[011...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com