Vortex air outlet device

A technology of tuyere device and air outlet, which is applied in the field of air outlet device, which can solve the problems of increasing the guiding degree of the blade body, increasing the cost, complicated mechanism, etc., and achieve the effect of increasing the diffusion range, improving the effect and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

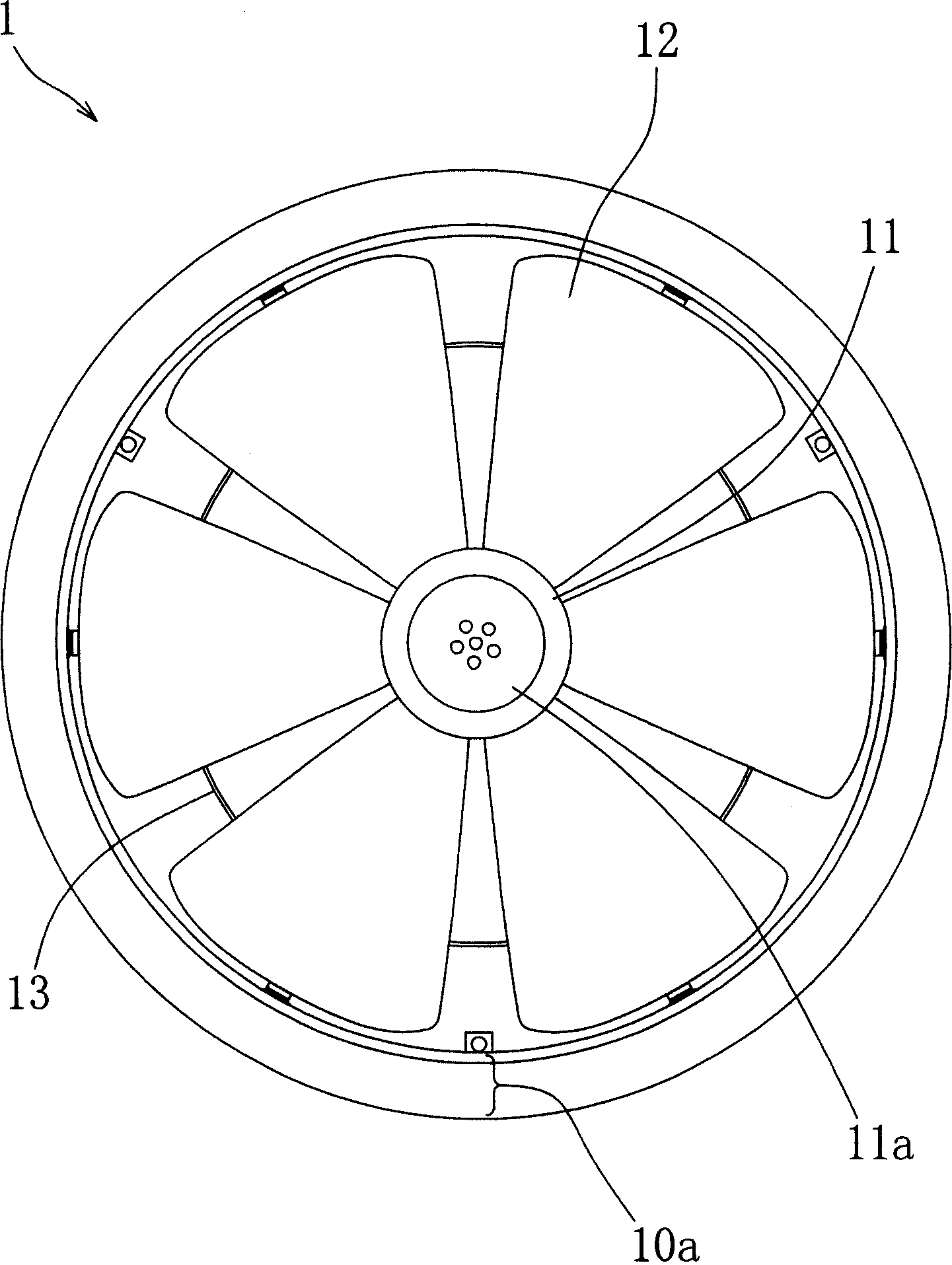

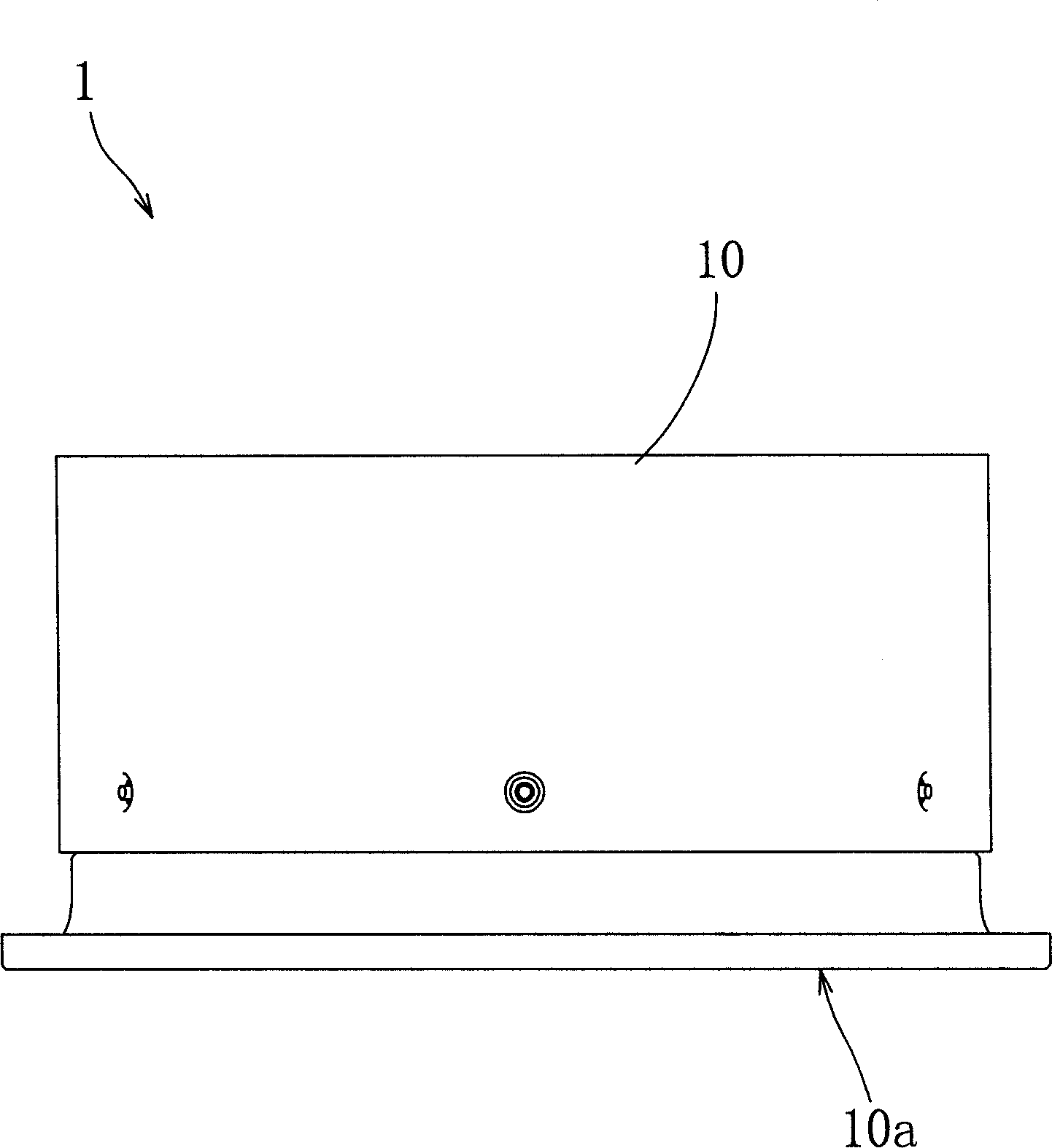

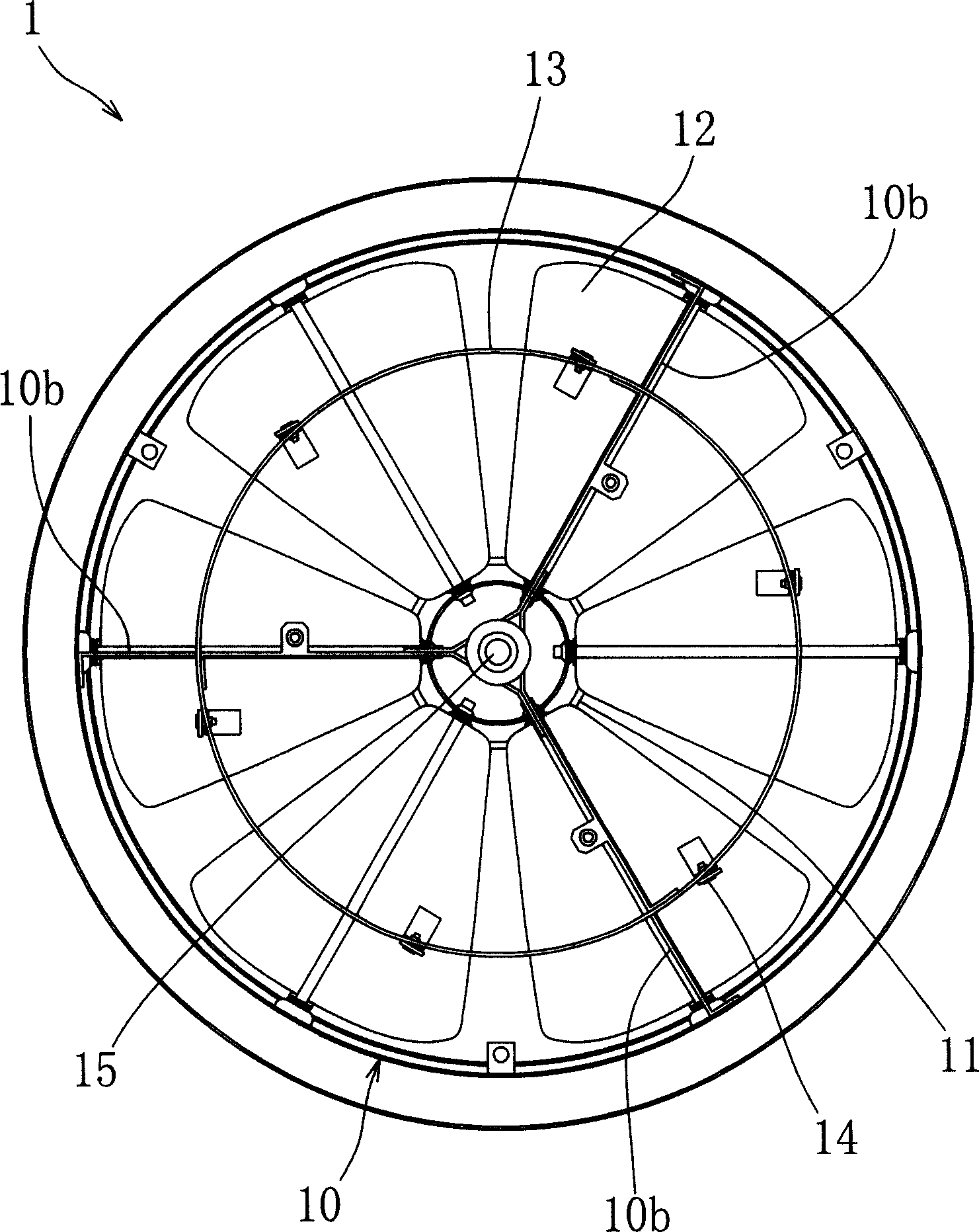

[0034] Below, based on Figure 1 to Figure 5 , illustrating the swirl air outlet device related to one embodiment of the present invention. figure 1 It is a bottom view of the swirl air outlet device related to this embodiment, figure 2 It is a right side view of the swirl air outlet device related to this embodiment, image 3 It is a top view of the swirl air outlet device related to this embodiment, Figure 4 It is an explanatory diagram of the horizontal discharge state and the vertical discharge state in the swirl air outlet device related to this embodiment, Figure 5 It is an explanatory diagram of the inclination state of the blade body in the horizontal discharge state and the vertical discharge state in the swirl air outlet device related to the present embodiment.

[0035] In each of the above-mentioned figures, the swirl air outlet device 1 related to the present embodiment has a structure including a substantially cylindrical air outlet main body 10, and one f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com