Packaging shell and packaging structure of edge type light emitting component

A technology of light-emitting components and packaging structures, applied in electrical components, laser devices, laser parts, etc., can solve the problems of light length, affecting light output efficiency, and easy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

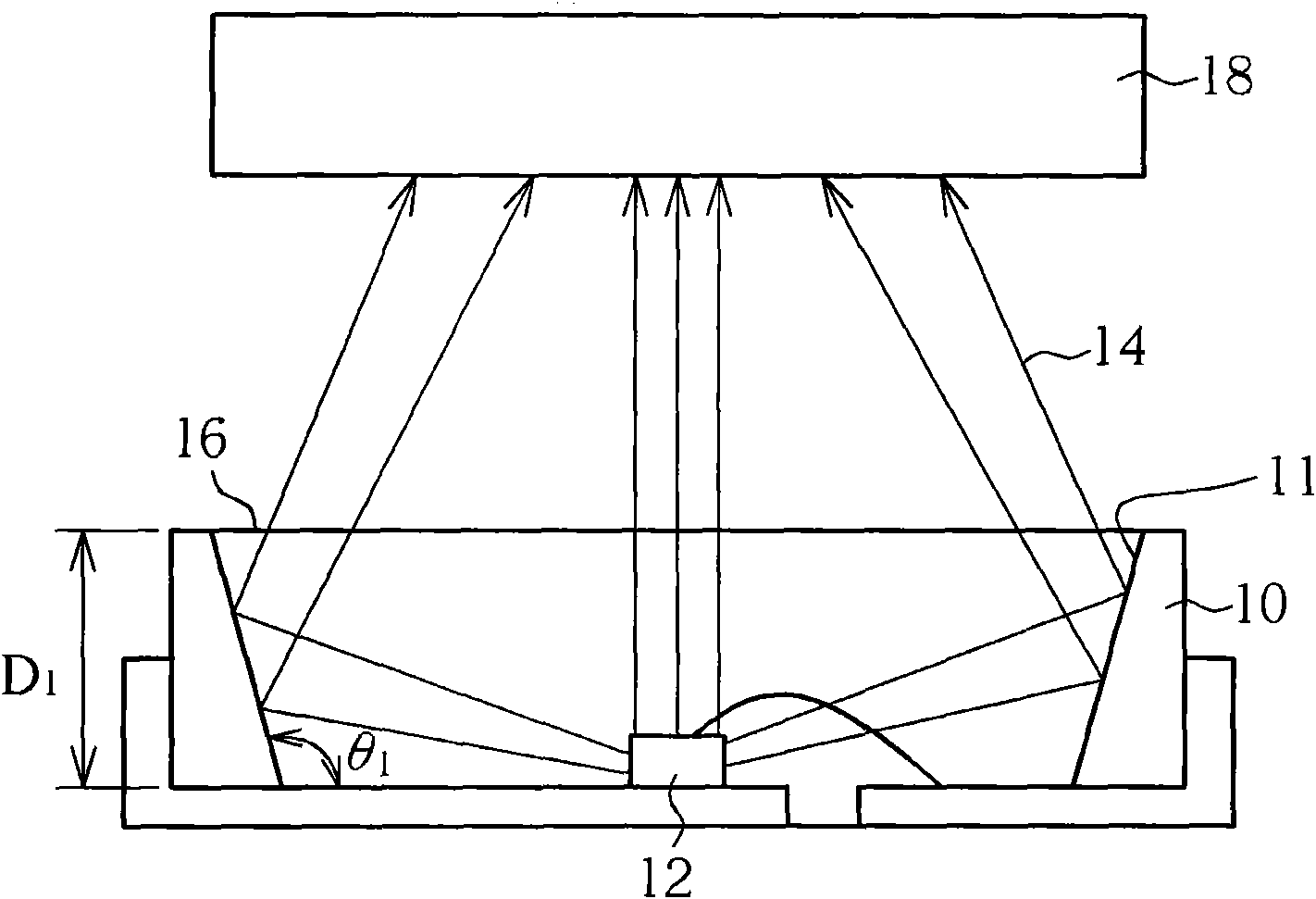

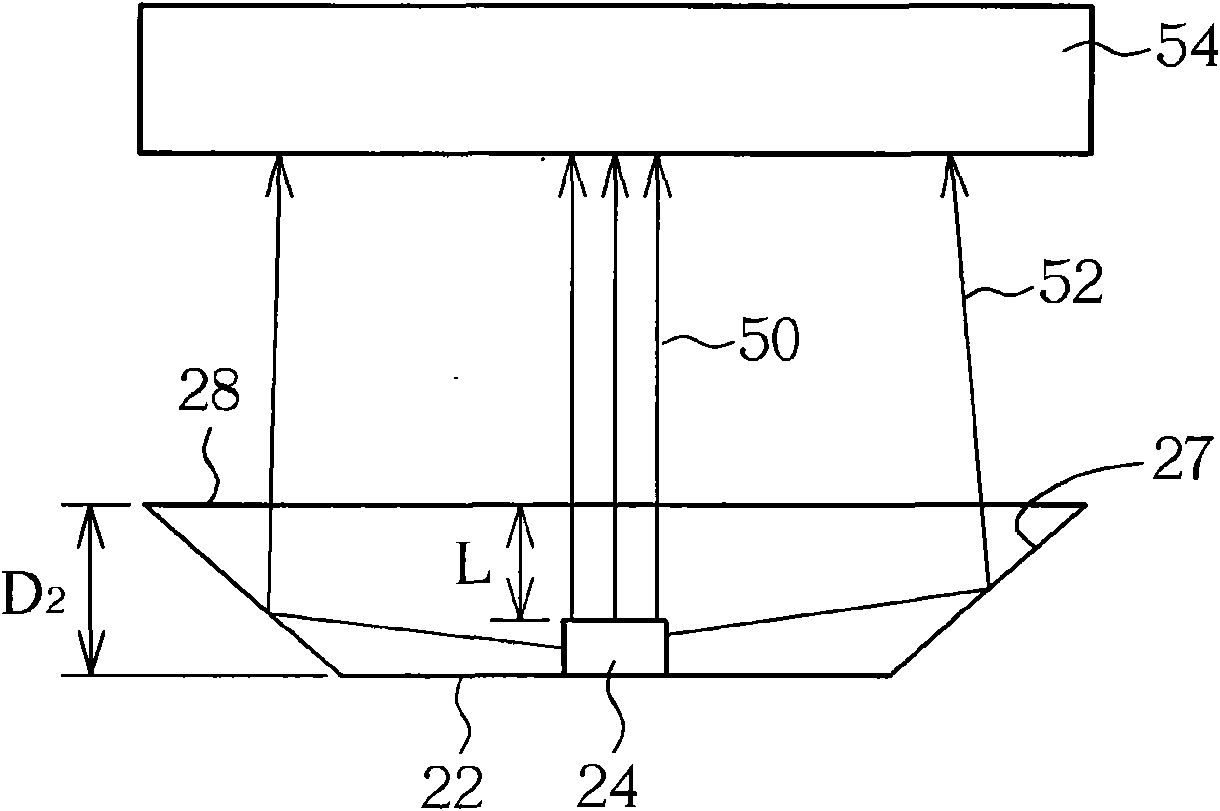

[0032] The light-emitting element of the side-light light-emitting element packaging structure of the present invention is located in a cup-shaped substrate, wherein the cup shell of the cup-shaped substrate is inclined outward so that the side wall and the base form an included angle of 140 to 150 degrees, and the cup shell has a The depth perpendicular to the base is 0.25mm to 0.3mm, and the mouth of the cup shell is a light-emitting surface, and the area of the light-emitting surface is 1.5 to 2 times the area of the base.

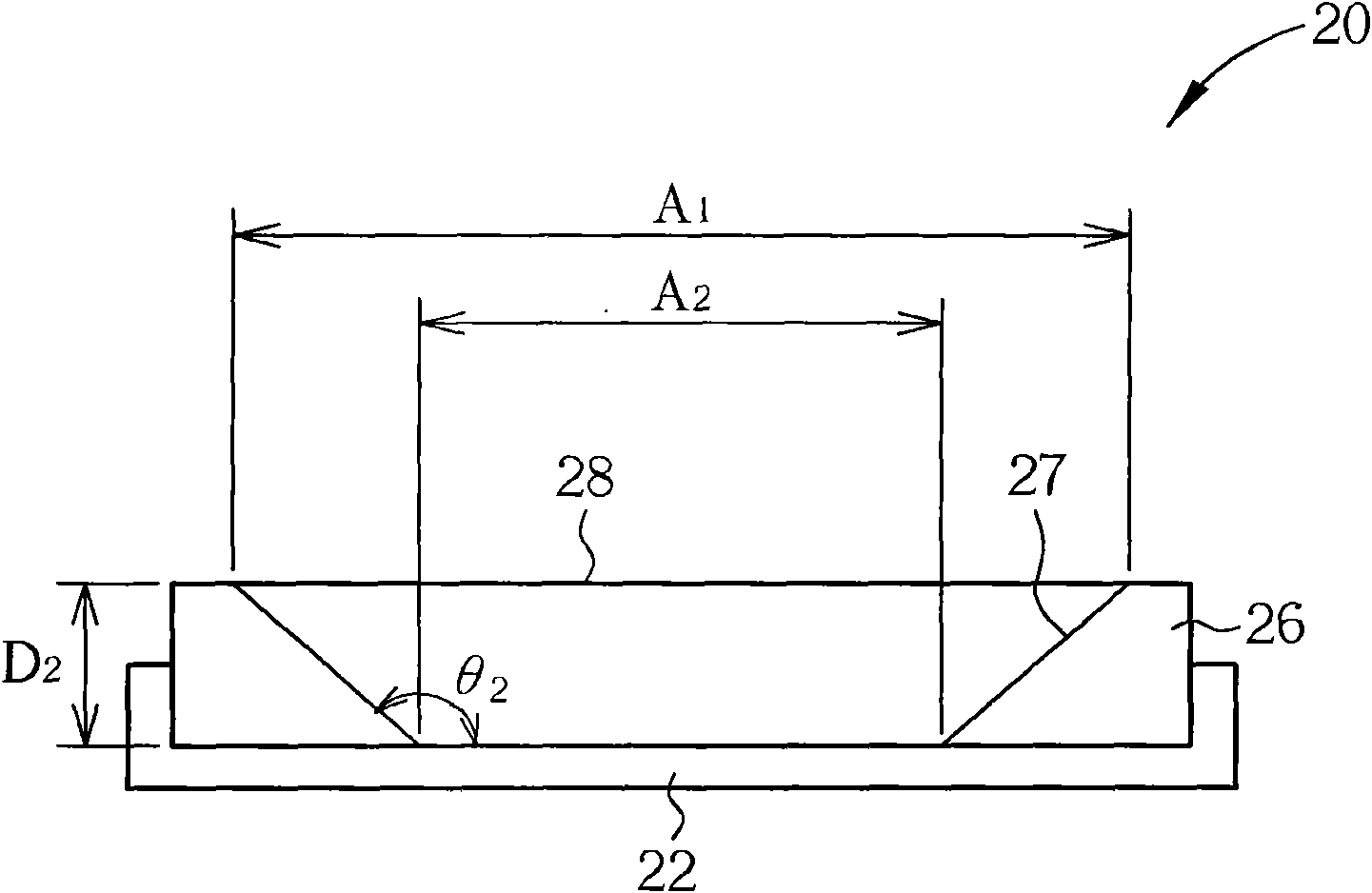

[0033] Such as figure 2 A schematic cross-sectional view of a specific embodiment is shown, and the package case 20 of an edge-lit light-emitting element includes the following: a base 22 . The base 22 can carry a light emitting element. The light emitting element can be, for example, a light emitting diode (LED), an organic light emitting diode, a resonant cavity light emitting diode, or a laser semiconductor chip. The cup shell 26 is combined w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com