Engine lubricating system and engine

A lubrication system and engine technology, which is applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve the problems of reducing system reliability and safety, increasing the complexity of the shaft drive system, and the oil return pump cannot be smaller than the main oil pump. Achieve the effect of light weight, less parts, and reduce the pressure of space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

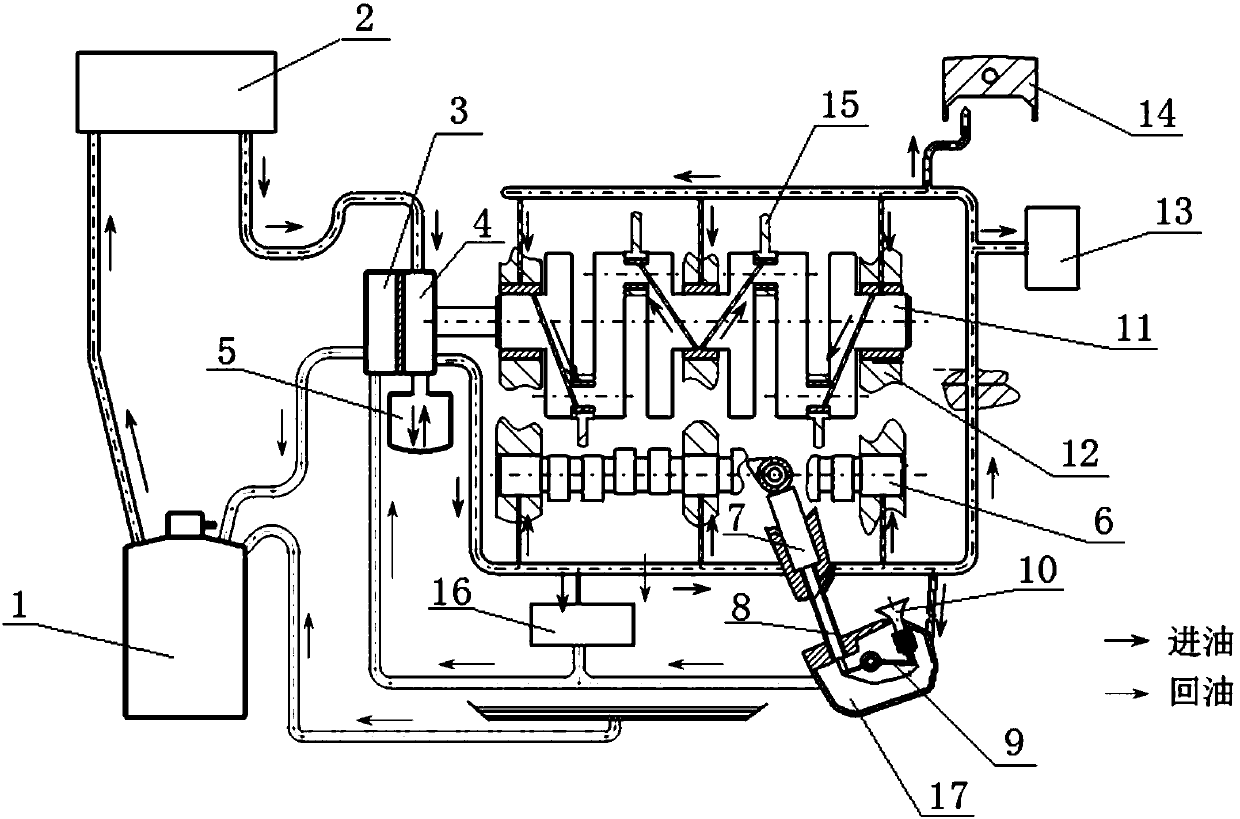

[0019] figure 1 It is a schematic diagram of the engine lubrication system of the present invention. This engine lubrication system includes two parts: oil suction and oil return. At one end of the crankshaft 11, the main oil pump 4, driven by the crankshaft 11, sucks the lubricating oil in the lubricating oil tank 1 into the air-cooled oil cooler 2 for cooling, and the cooled lubricating oil enters the main oil passage under the action of the main oil pump 4 , the lubricating oil entering the main oil passage is divided into five parts, the first part enters the crankshaft 11 main journal, the camshaft 6 journal and the connecting rod 15 journal through the inclined oil passage, the second part enters the hydraulic tappet 7 through the main oil passage, Along the gap between the outer tube of the tappet 8 and the tappet, it enters the corresponding friction part of the rocker arm 9, and the third part of lubricating oil enters the valve cover 17 from the main oil passage thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com