Shallow underground excavation unsymmetrial loading tunnel roof caving in-hole forepoling method

A technology of shallow buried excavation and advanced support, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve problems such as secondary roof fall, damage to initial support, and inability to achieve the effect of large inclination angle and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

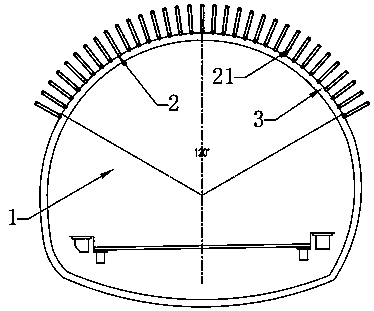

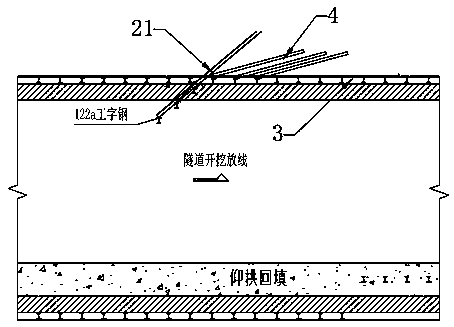

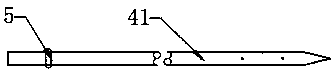

[0022] As shown in the figure, the advanced support method in the cave at the roof fall of the shallow buried excavation bias tunnel provided by this embodiment includes the following steps: S1, advanced geological prediction, using TSP tunnel seismic wave advanced geological prediction system and geological radar two-way control, and compare and analyze the results to determine the condition of the rock mass; S2, backfill the cave with soil backpressure, and then use sand and gravel materials and cement to backfill the collapsed hole above the roof. One-step construction; S3, set up a guide frame on the tunnel face 1 (not shown in the figure), and fix the guide frame with locking anchors at the arch foot and arch waist; S4, use a guide frame above the tunnel face 1 In order to support the advanced pipe shed 2 along the design shape of the tunnel, the said pipe shed is made of φ108mm seamless steel pipe 21 with a circumferential spacing of 40cm. The angle is 10~30°; S5, insert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com