Automatic stillage air-drying machine

An automatic technology of drying machine, applied in the preparation of alcoholic beverages, etc., can solve the problems of difficult control of cooling temperature, need to regularly clear blockage, affect cooling effect, etc., and achieve good uniform mixing effect, good cooling effect, and floor space. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

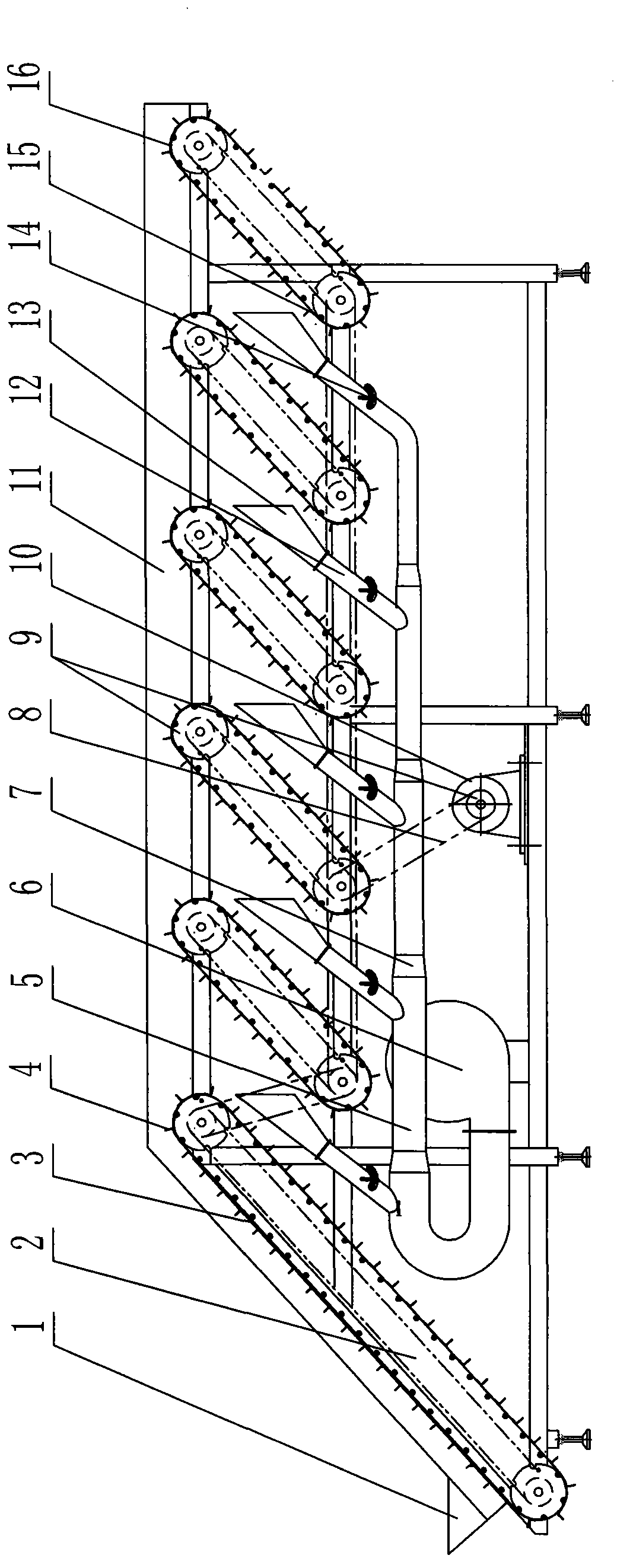

[0012] Such as figure 1 As shown, the present invention comprises a frame 11, a hopper 1 arranged on the frame 11, an inclined conveyor 2, an air supply device 5 and a driving motor 10, and the driving motor 10 is connected with the inclined conveyor 2 by a sprocket 9, a chain 8 , There are multiple inclined conveyors 2, and the feed end 15 of the latter inclined conveyor 2 is arranged below the discharge end 16 of the previous inclined conveyor 2. The number of inclined conveyor 2 machines is preferably 5-6. The inclined conveyor 2 includes a sprocket 9 arranged on the frame 11 and a chain plate 3 surrounding the upper sprocket. The chain plate 3 is evenly provided with baffle plates 4 to prevent materials from sliding down. The feed end 15 of the first inclined conveyor 2 is close to the ground, and the hopper 1 is arranged above the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com