Emulsion type crude oil viscosity-reduction drag reduction agent applied to high-wax-content pure oil pipe transportation

A technology of drag reducer and emulsion type, which is applied in the field of emulsion type crude oil viscosity reducer and drag reducer, which can solve the problems of increased back pressure and reduced pipeline transportation capacity, and achieve the effects of low freezing point, safe low temperature transportation and good storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

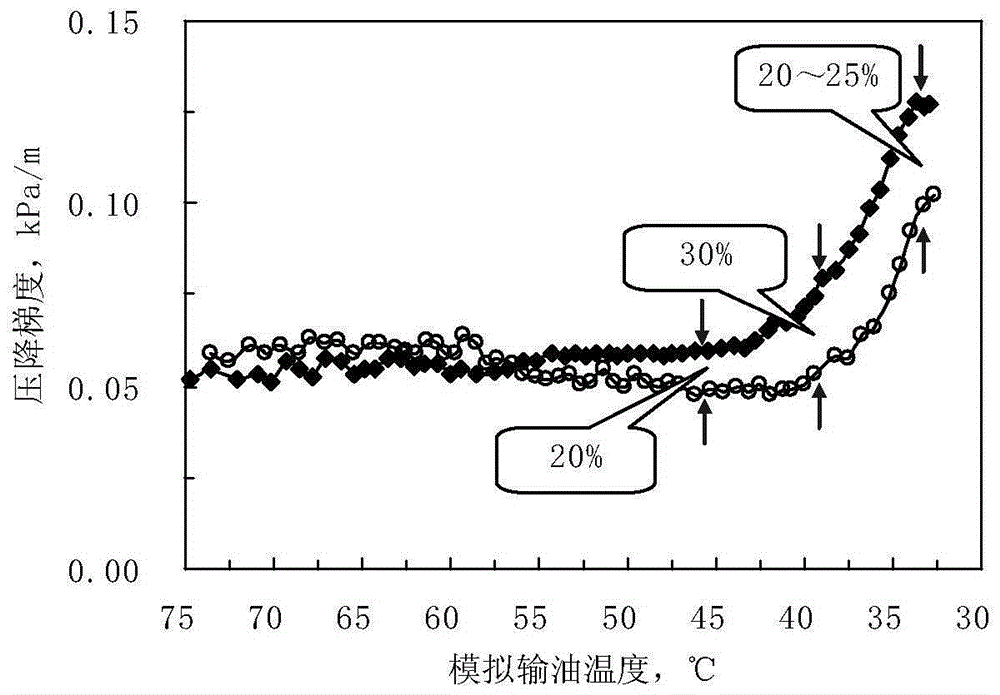

Image

Examples

Embodiment 1

[0017] Weigh 2g of MSA, 3.5g of polyolefin drag reducer polyalphaolefin, 3.6g of octanol, 0.32g of S-80, 0.18g of T-60, 0.4g of ethylene glycol monobutyl ether, mix and prepare emulsion type crude oil Viscosity reducer.

Embodiment 2

[0019] Weigh 3g of EVA, 2g of polyolefin drag reducer polyalphaolefin, 3.6g of 2-hexanol, 0.64g of S-80, 0.36g of T-60, 0.4g of ethylene glycol monobutyl ether, and mix to prepare the emulsion Viscosity and drag reducer for crude oil.

[0020] Indoor experiment effect:

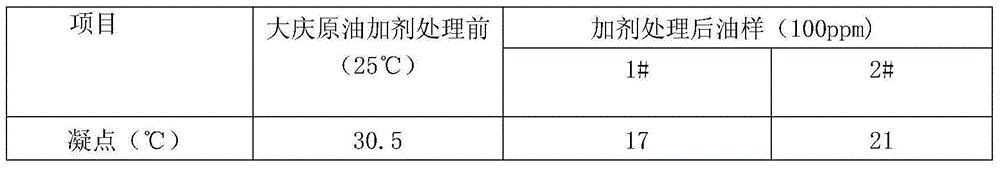

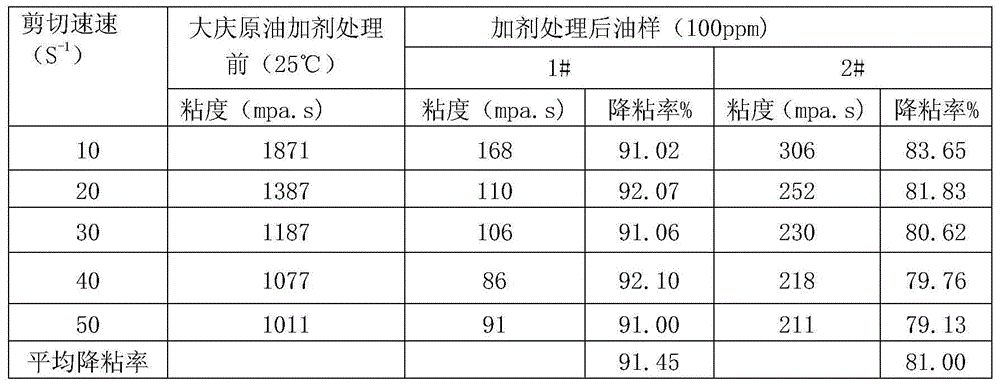

[0021] 1. Performance evaluation of viscosity reduction and pour point reduction

[0022] Experimental procedure: the products obtained in the above-mentioned Examples 1 and 2 are respectively defined as 1# and 2# viscosity-reducing and drag-reducing agents; Daqing crude oil samples are respectively added with 100 ppm each of 1# and 2# viscosity-reducing and drag-reducing agents, and after 70 After treatment at ℃, the temperature was lowered to 25℃ at a cooling rate of 0.5℃ / min, and the results of freezing point and viscosity were compared as shown in Table 1 and Table 2.

[0023] Table 1 Comparison of freezing points of Daqing crude oil samples before and after adding viscosity-reducing agent

[0024]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com