Patents

Literature

42results about How to "New design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

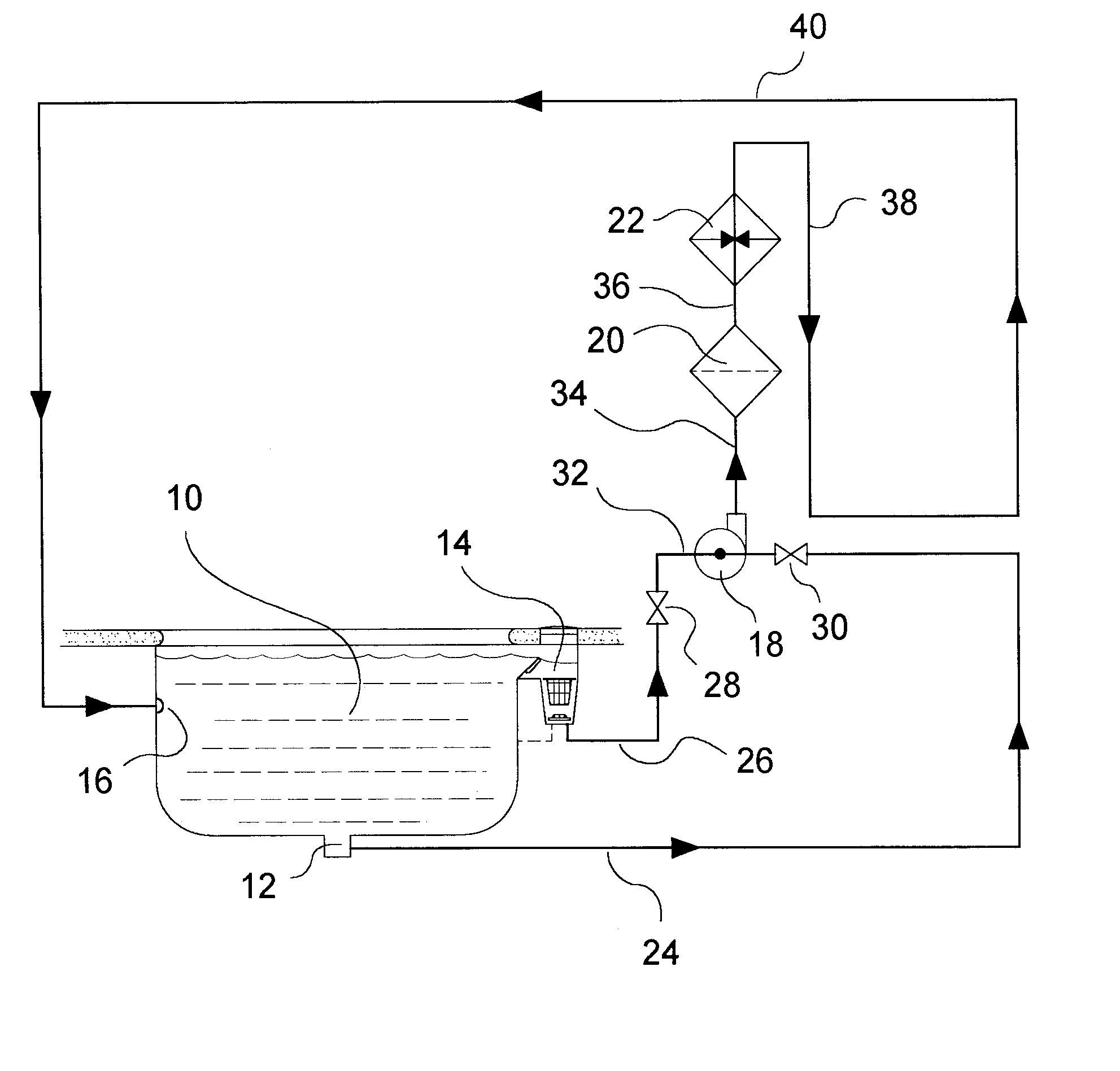

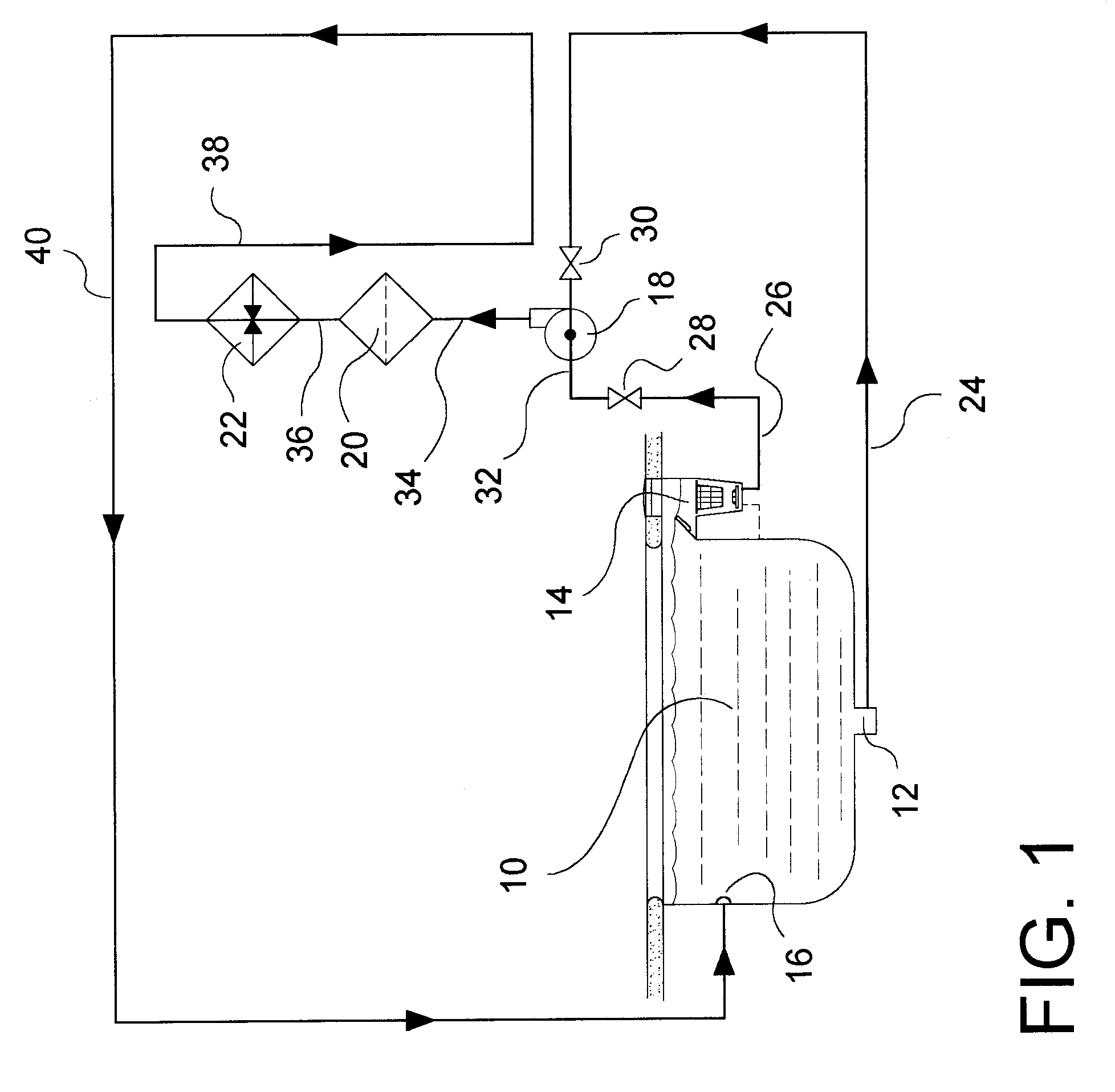

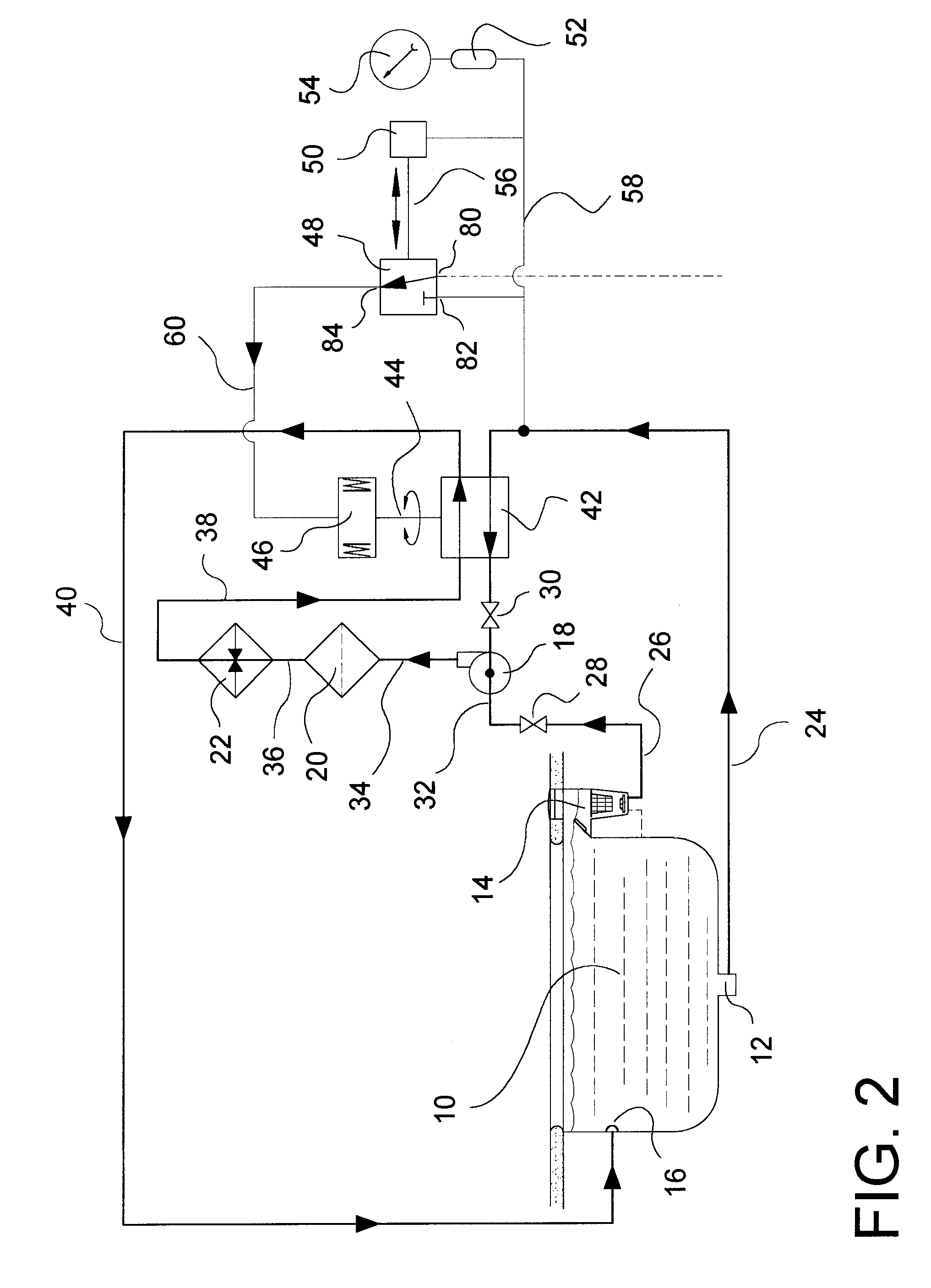

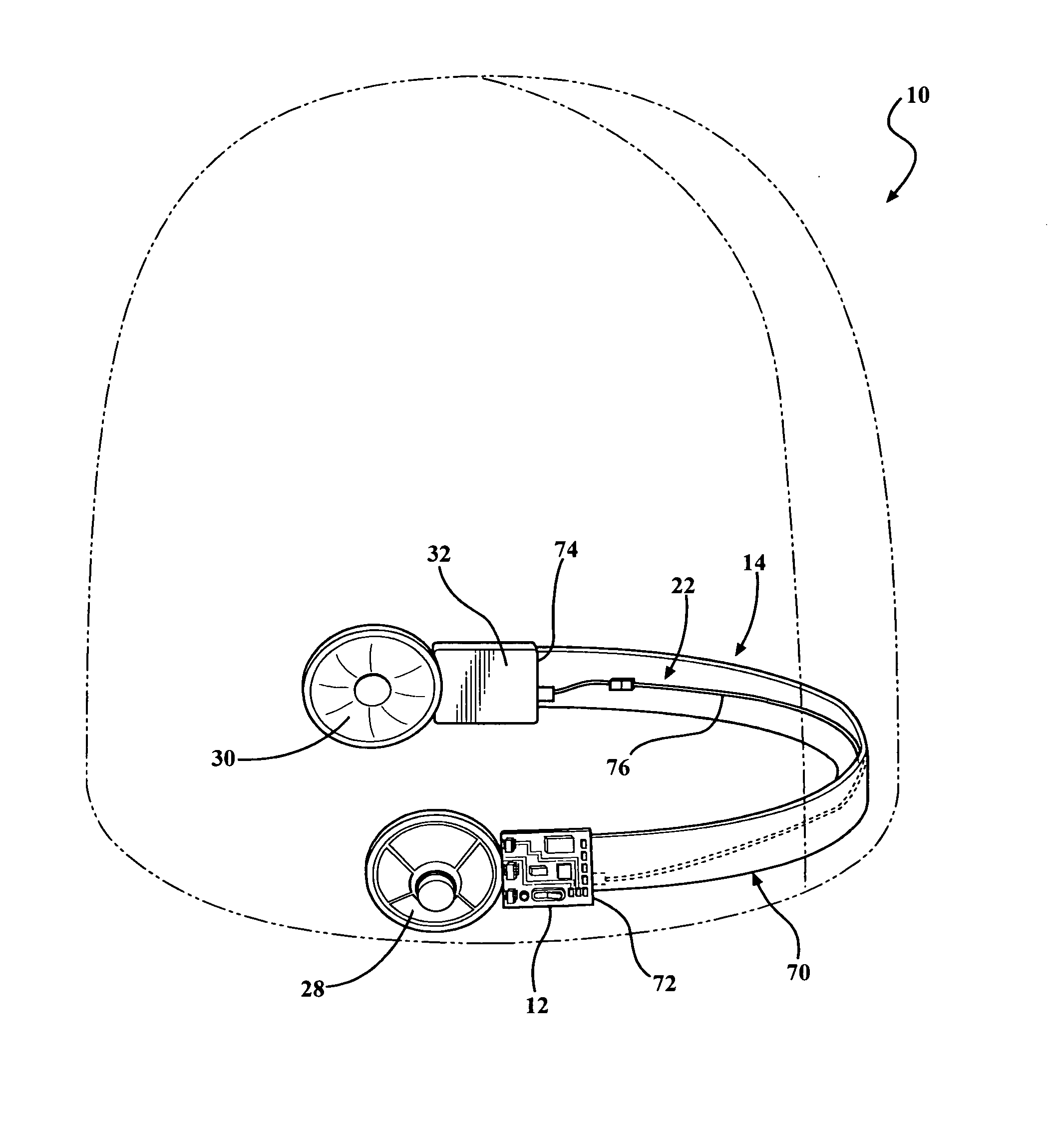

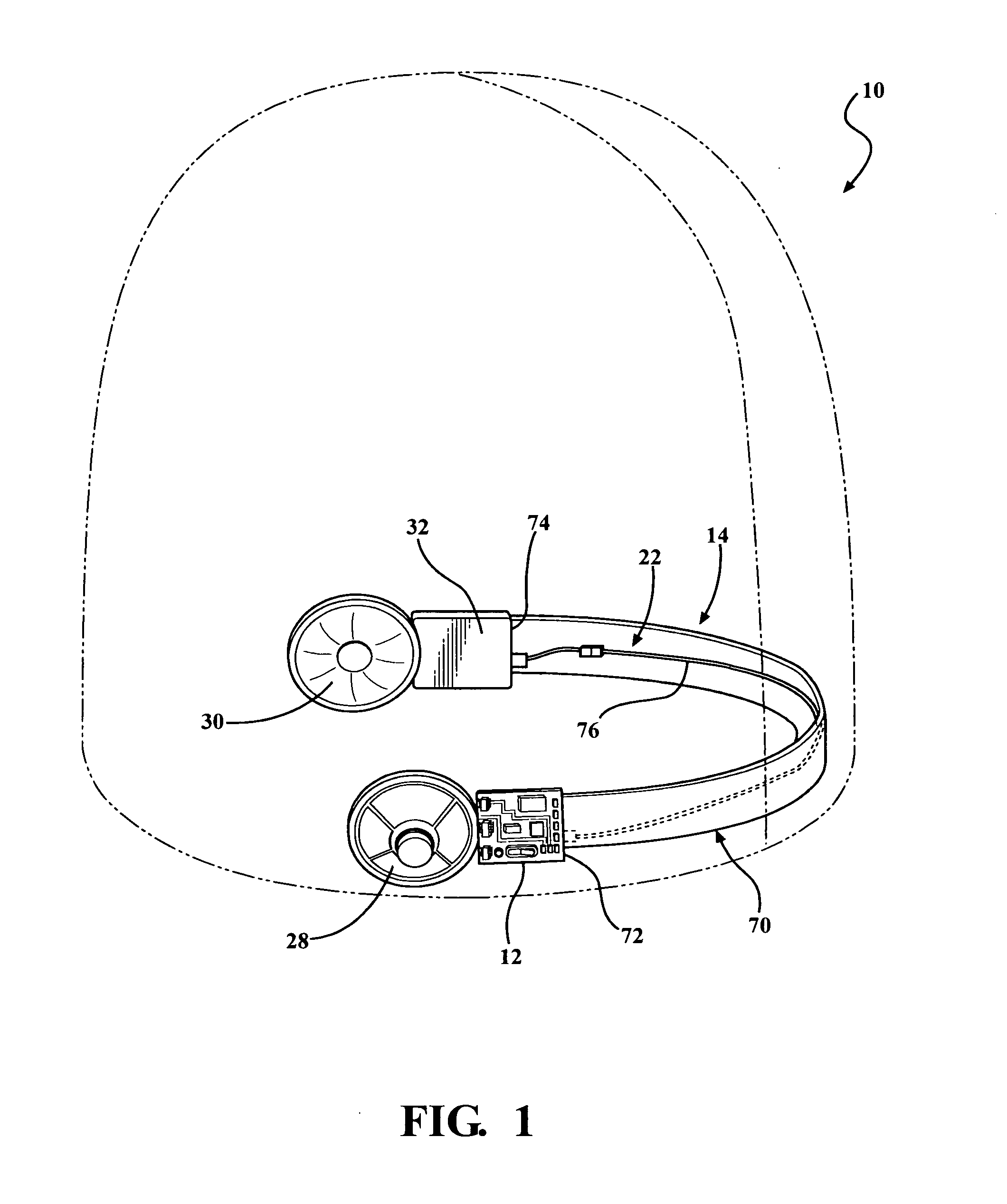

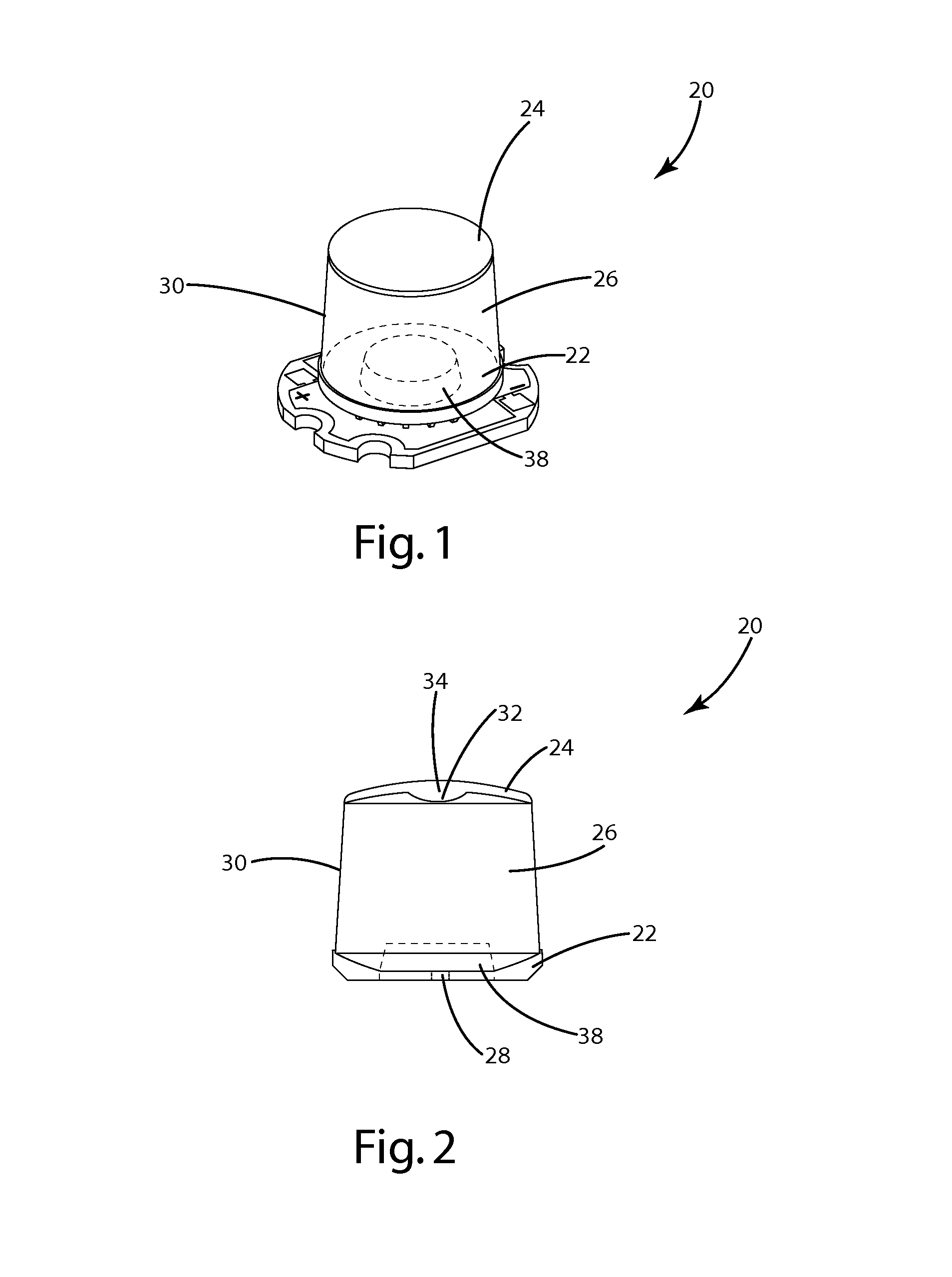

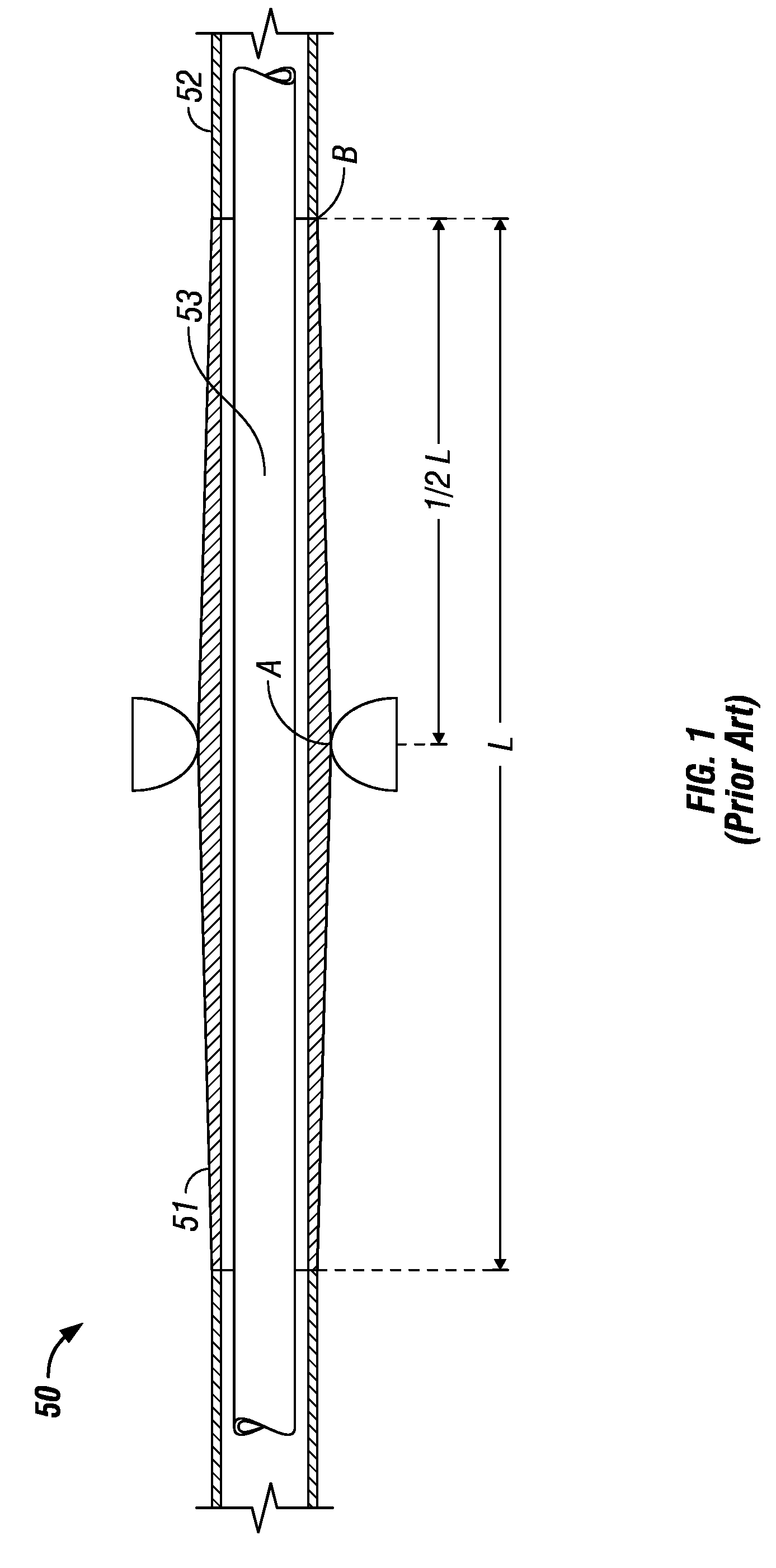

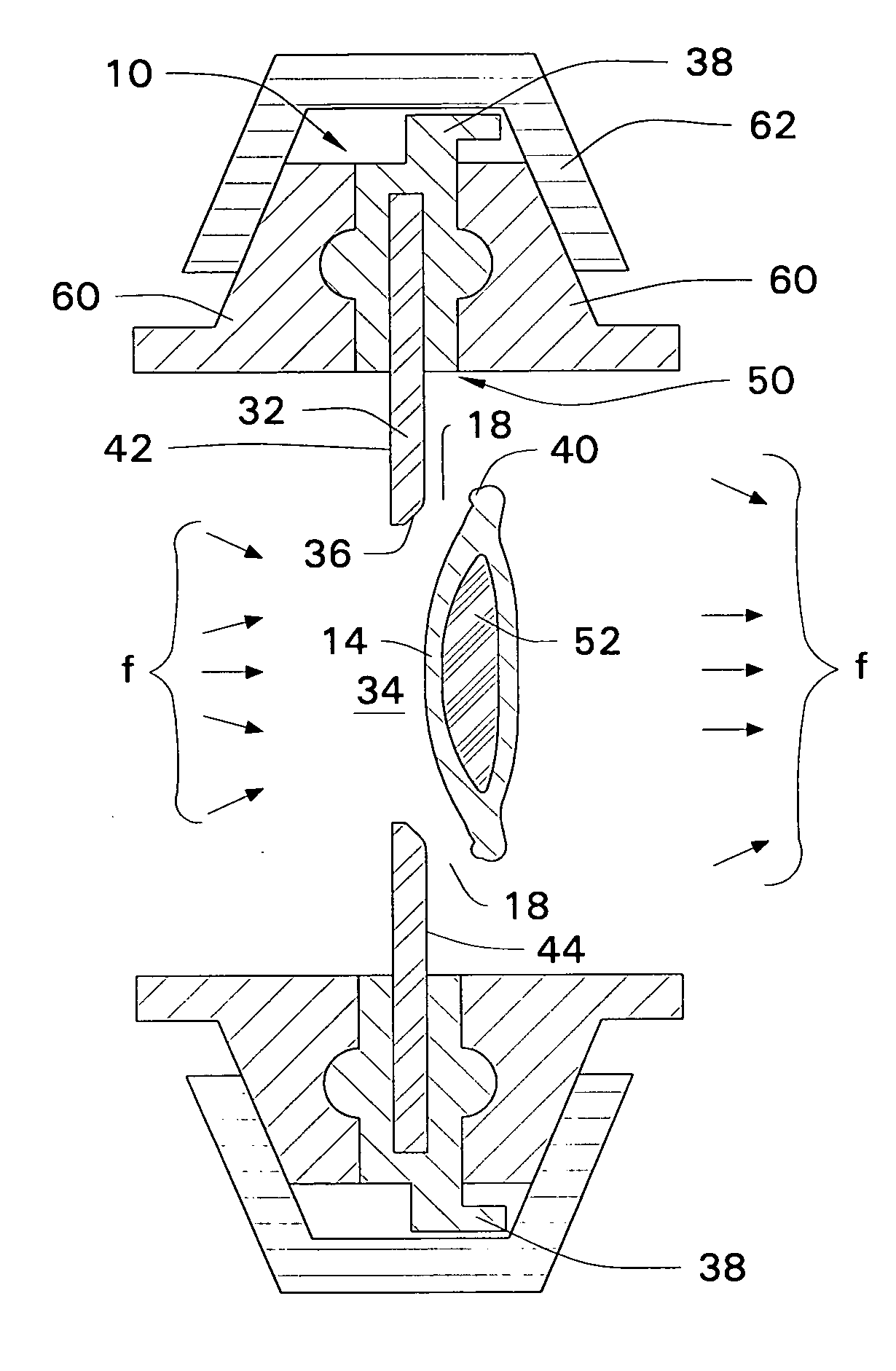

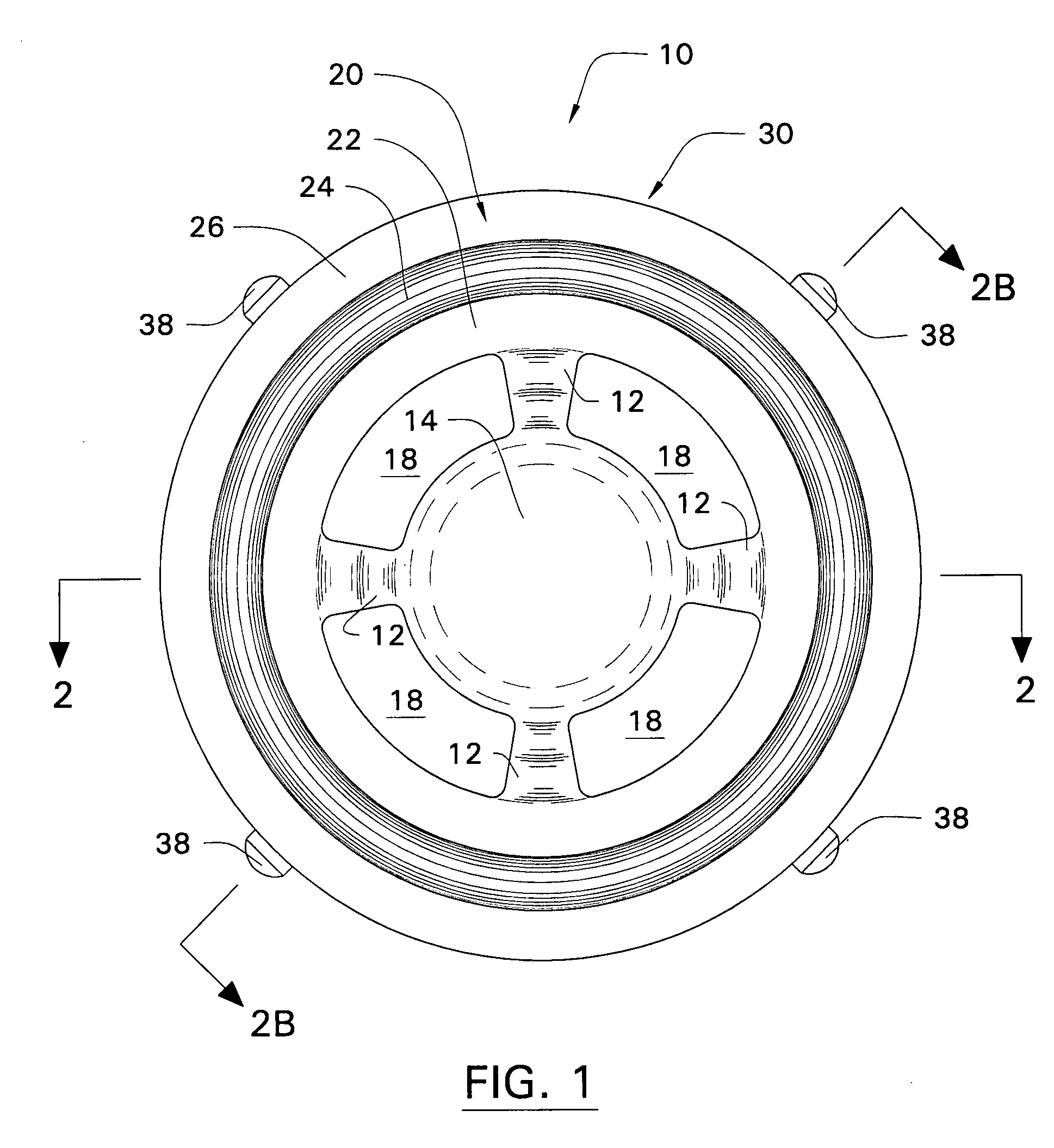

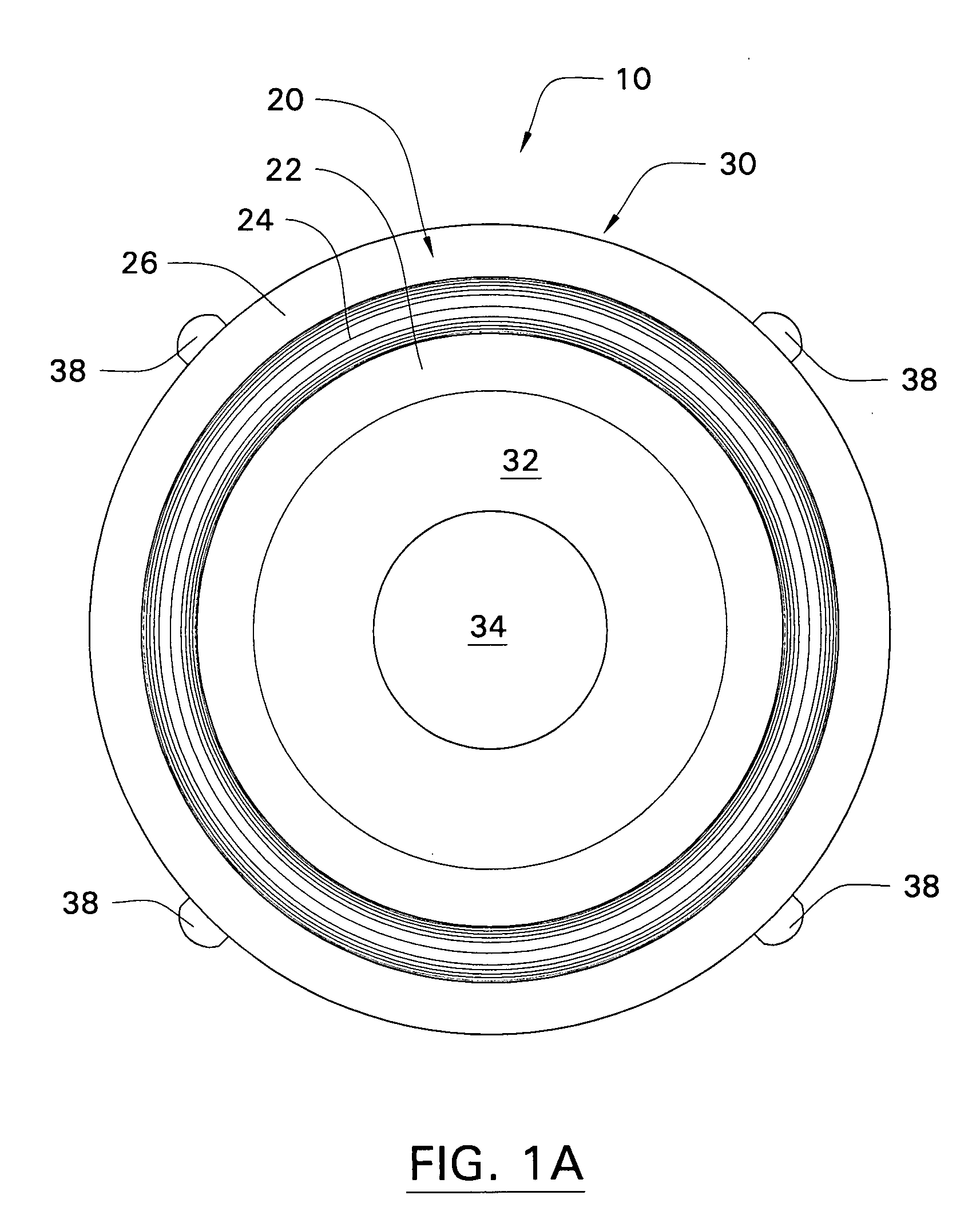

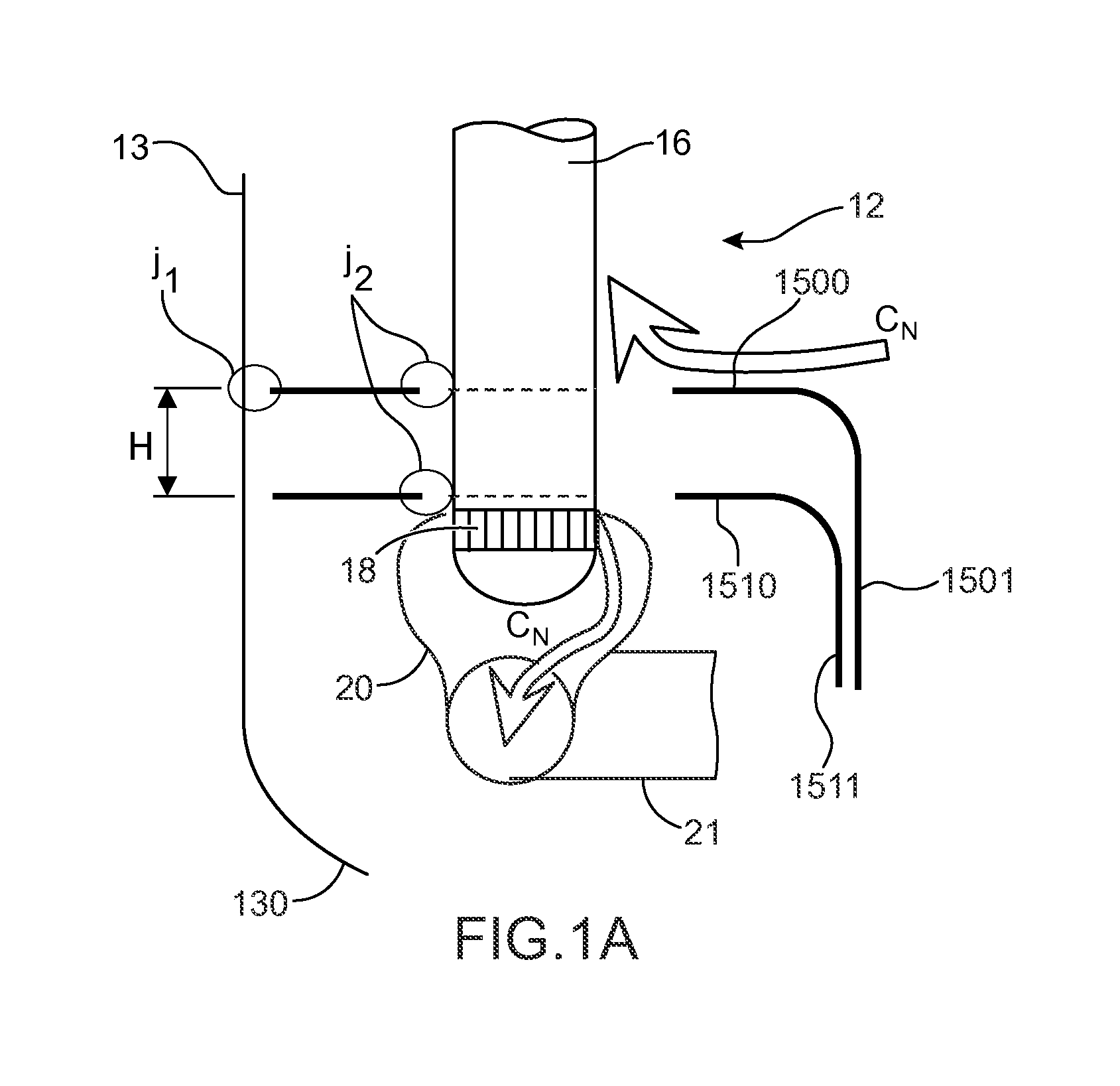

Propulsion-Release Safety Vacuum Release System

InactiveUS20030106147A1Reliably release and push awayNew designGymnasiumSwimming poolsPositive pressureFiltration

Abstract of Disclosure A propulsion-release safety vacuum release system (SVRS) for swimming pools monitors vacuum level in a suction pipe and reverses flow within the suction pipe if vacuum level exceeds a predetermined level. Thus, if a bather becomes entrapped on a suction outlet such as the pool main drain, the SVRS system not only releases the vacuum but also pushes away the suction-entrapped bather. In response to an elevated vacuum level, a vacuum-monitoring device actuates an automatic valve, which reverses fluid communications between the influent and effluent conduits of the pump and filter system. In this process, the suction pipe is converted from vacuum (negative pressure) to positive pressure. Thereafter, the automatic valve system automatically resets the SVRS to the original or normal flow configuration. The SVRS functions without interrupting operation of the swimming pool filtration system.

Owner:COHEN JOSEPH D +1

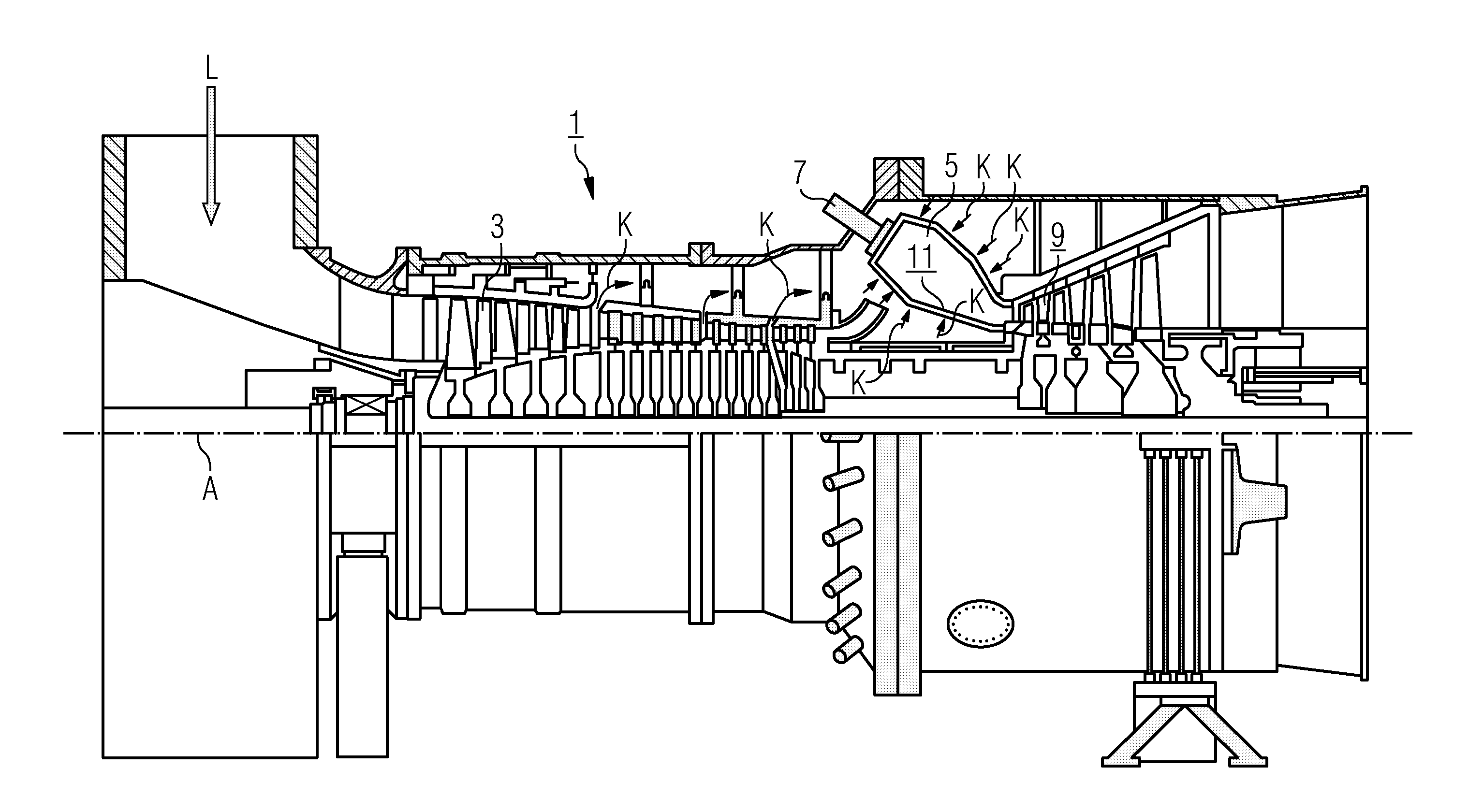

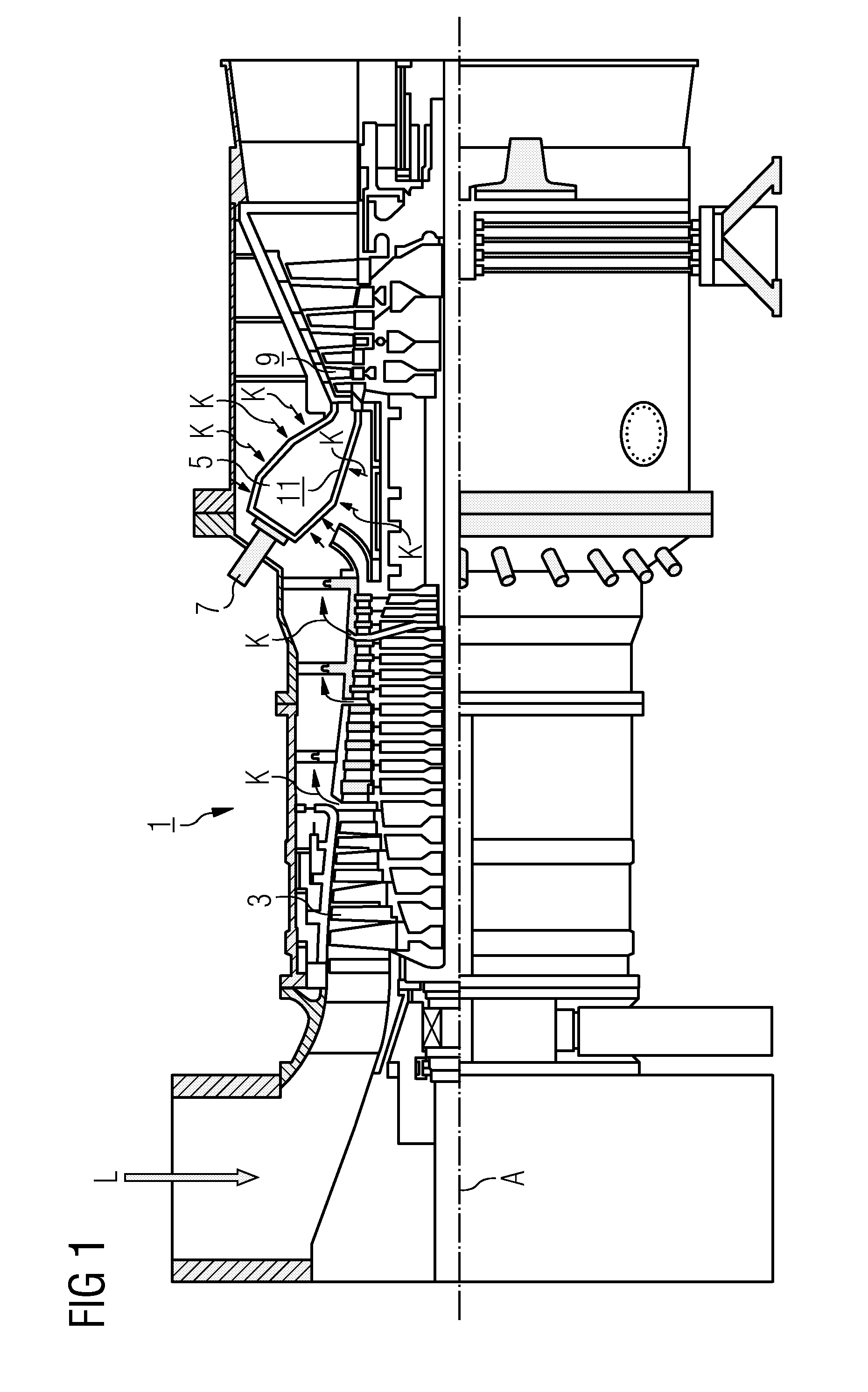

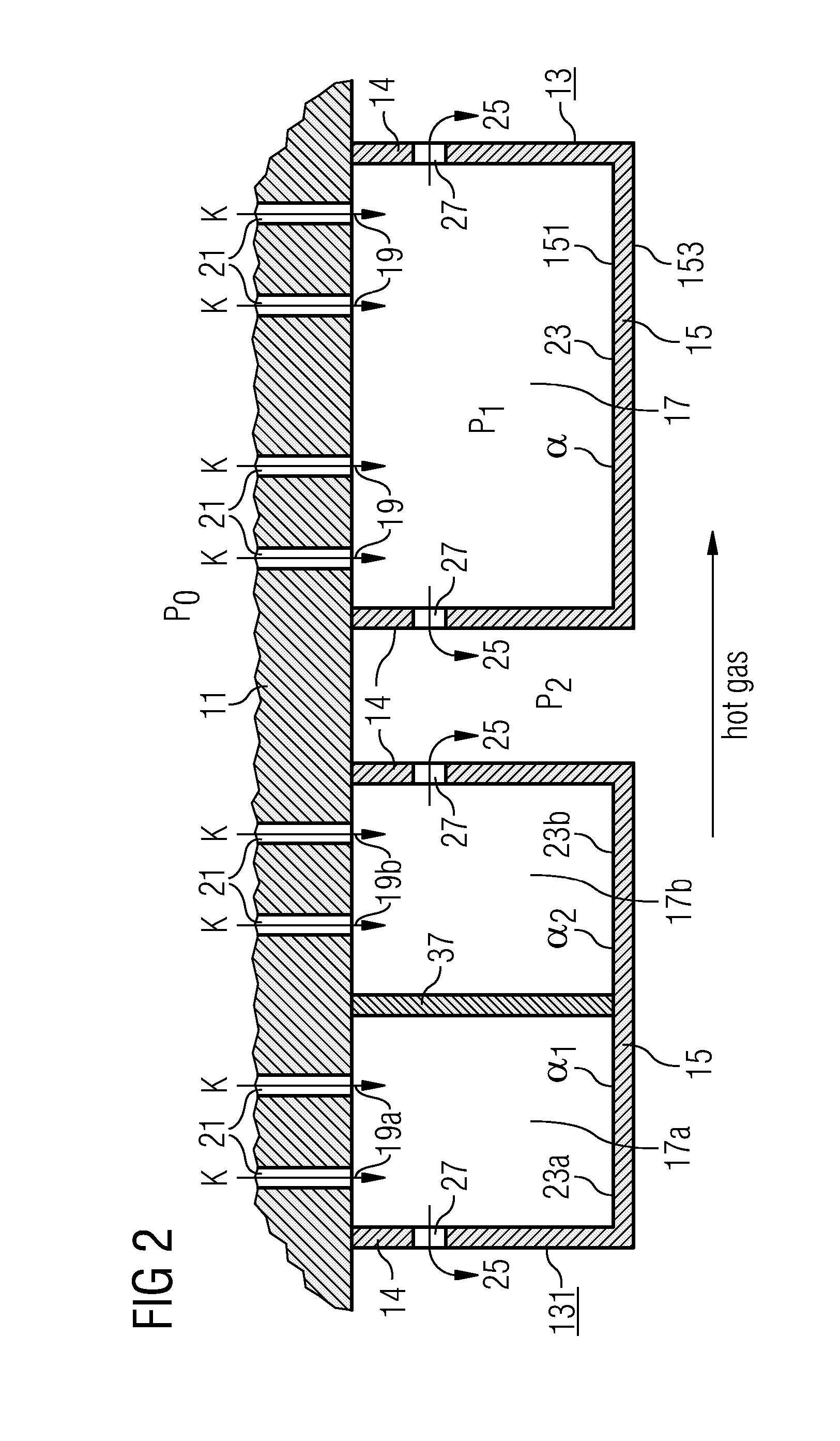

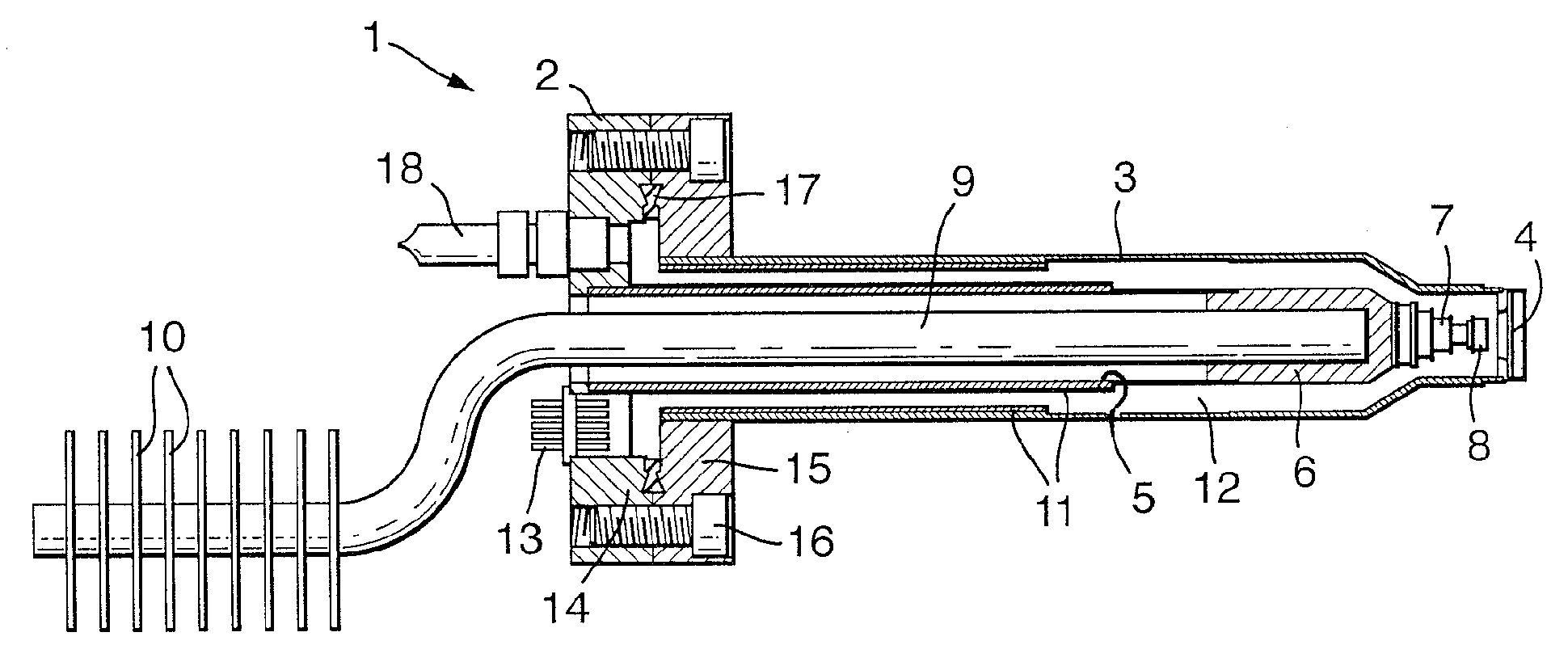

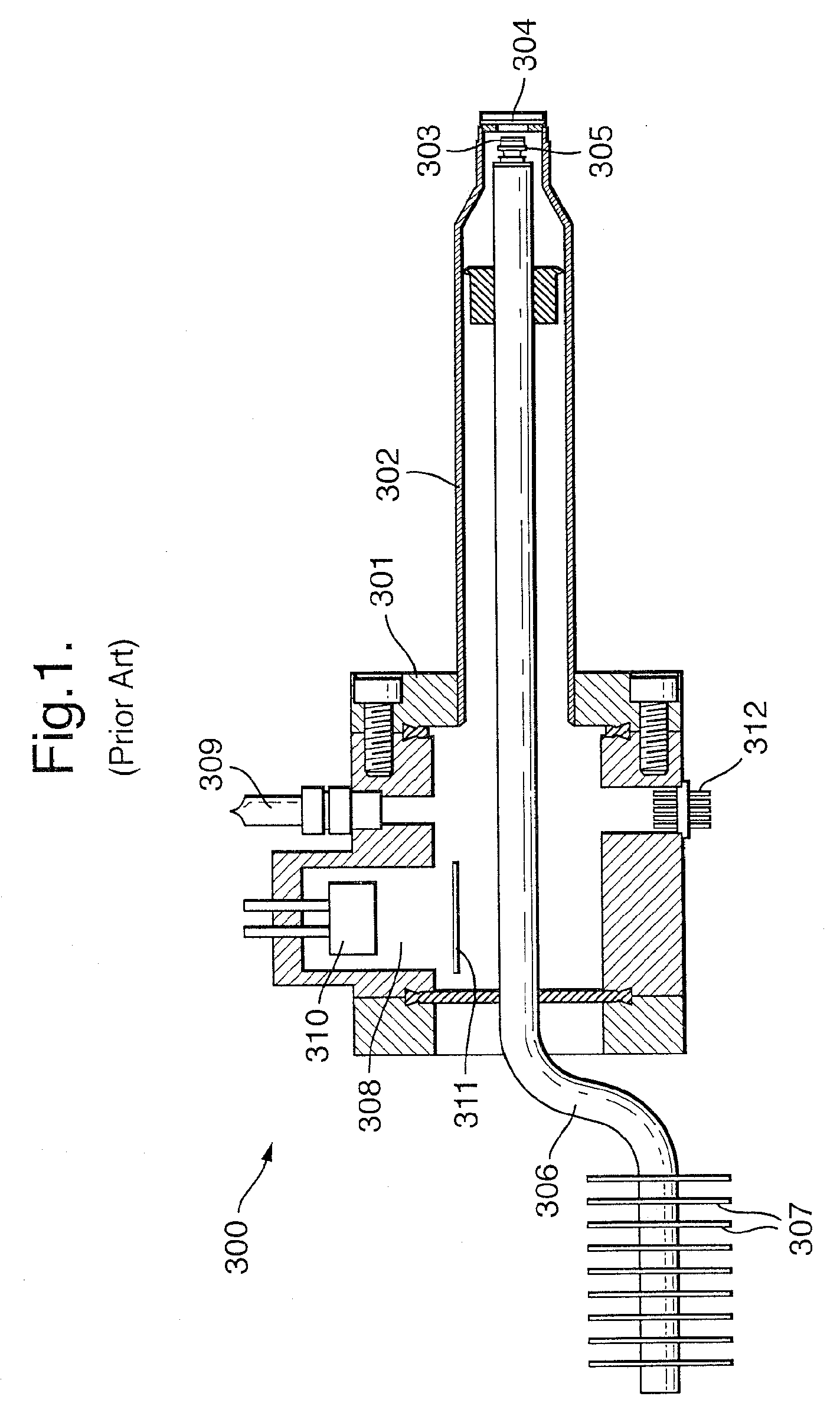

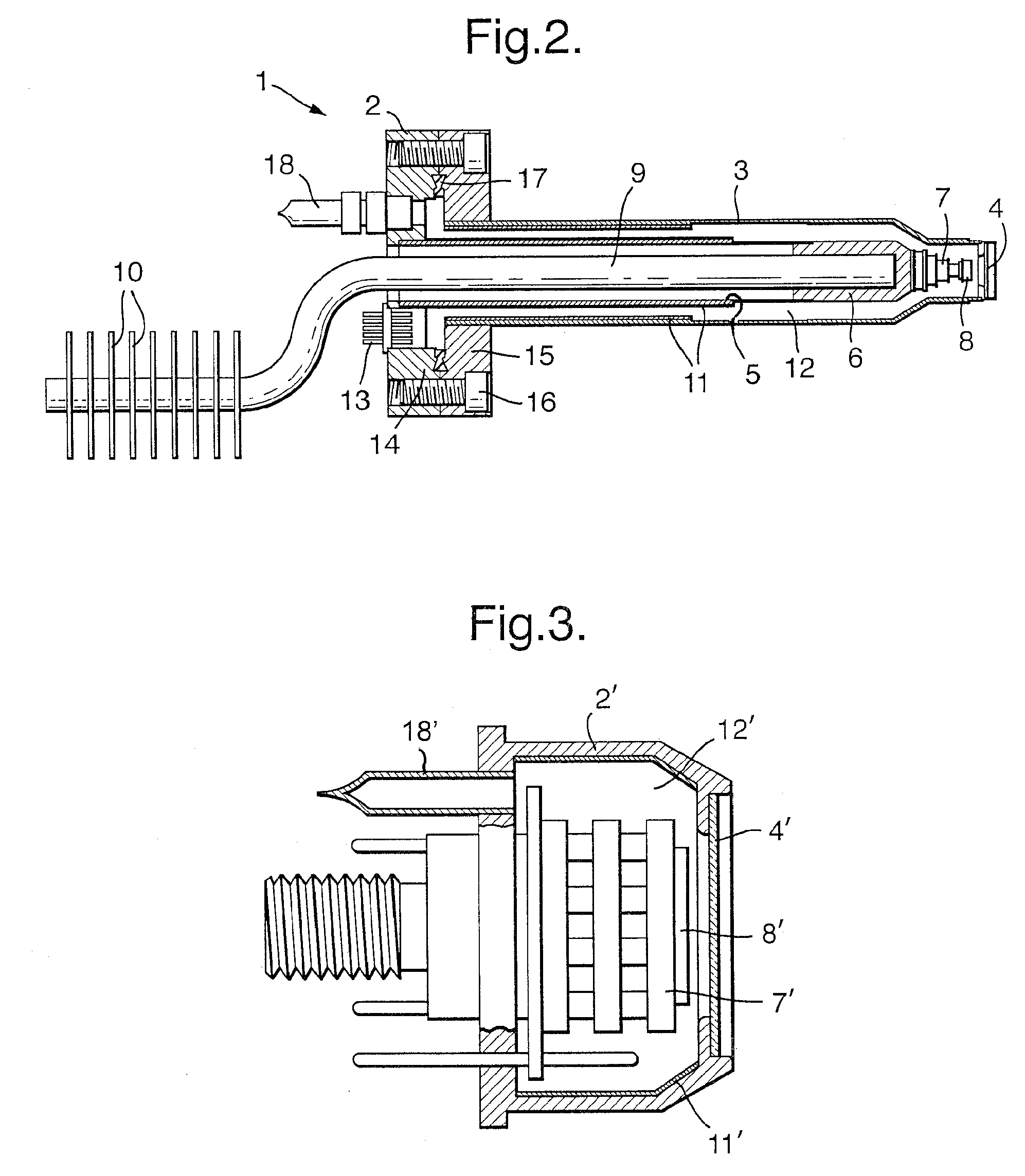

Method of Optimum Controlled Outlet, Impingement Cooling and Sealing of a Heat Shield and a Heat Shield Element

InactiveUS20070245742A1Increase powerImprove efficiencyContinuous combustion chamberEngine fuctionsCombustion chamberCoolant flow

There is described a method for cooling and sealing of a heat shield element, comprising a main wall with an inner side, which is restricted by side walls or rims, and an outer side, which can be exposed to a hot fluid, and wherein a coolant is introduced into an impingement region of that heat shield element and an impingement flow of said coolant is directed on a surface area of that inner side through a plurality of impingement holes, effecting an impingement pressure drop. In the method discharge flow is metered through a number of discharge holes through said side wall or rims from the inner side to the outer side of the main wall, generating a discharge pressure drop in series with the impingement pressure drop. The impingement pressure drop and the discharge pressure drop are matched to one another so that a required coolant flow is generated which yields a required predetermined heat-transfer coefficient of the main wall. Discharging coolant into the gaps between side opposing walls of neighbouring heat shield elements only allows for an effective sealing against hot gas pingestion. Furthermore, the invention relates to a heat shield element, preferably to a single chamber or double chamber metallic heat shield element, which can be exposed to hot gases. In particular the heat shield element is suitable for being used in a combustion chamber of a gas turbine installation.

Owner:SIEMENS AG

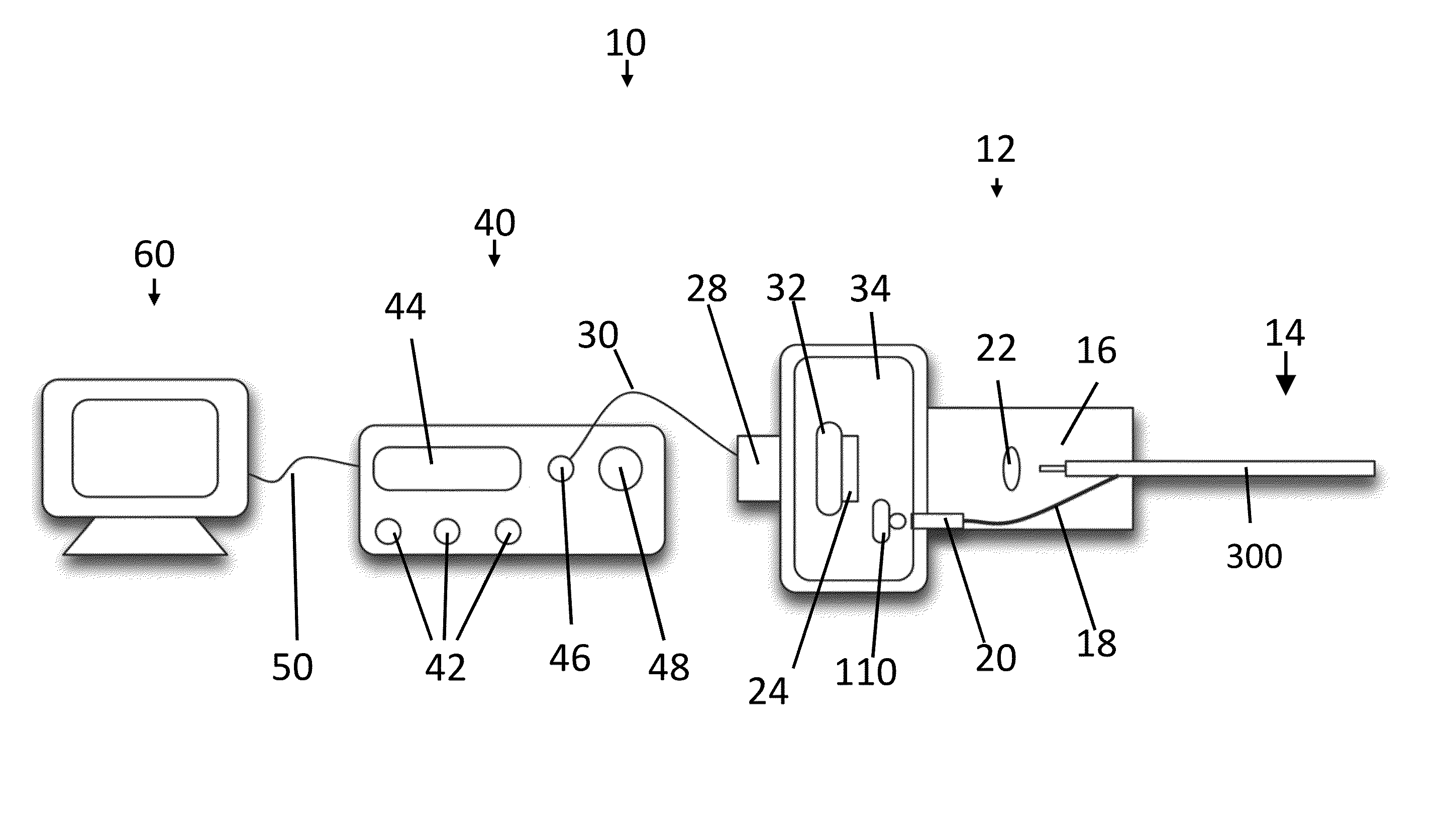

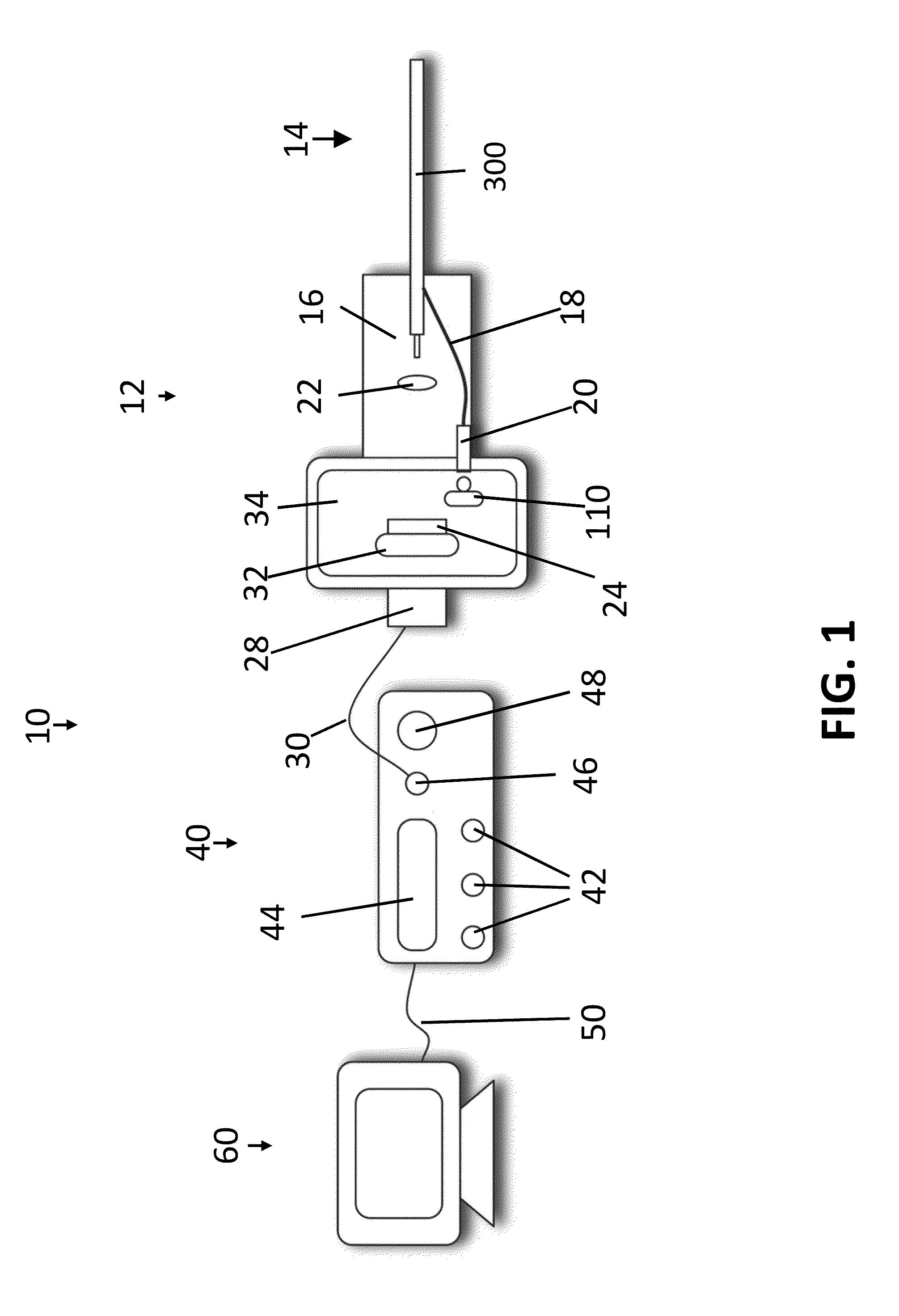

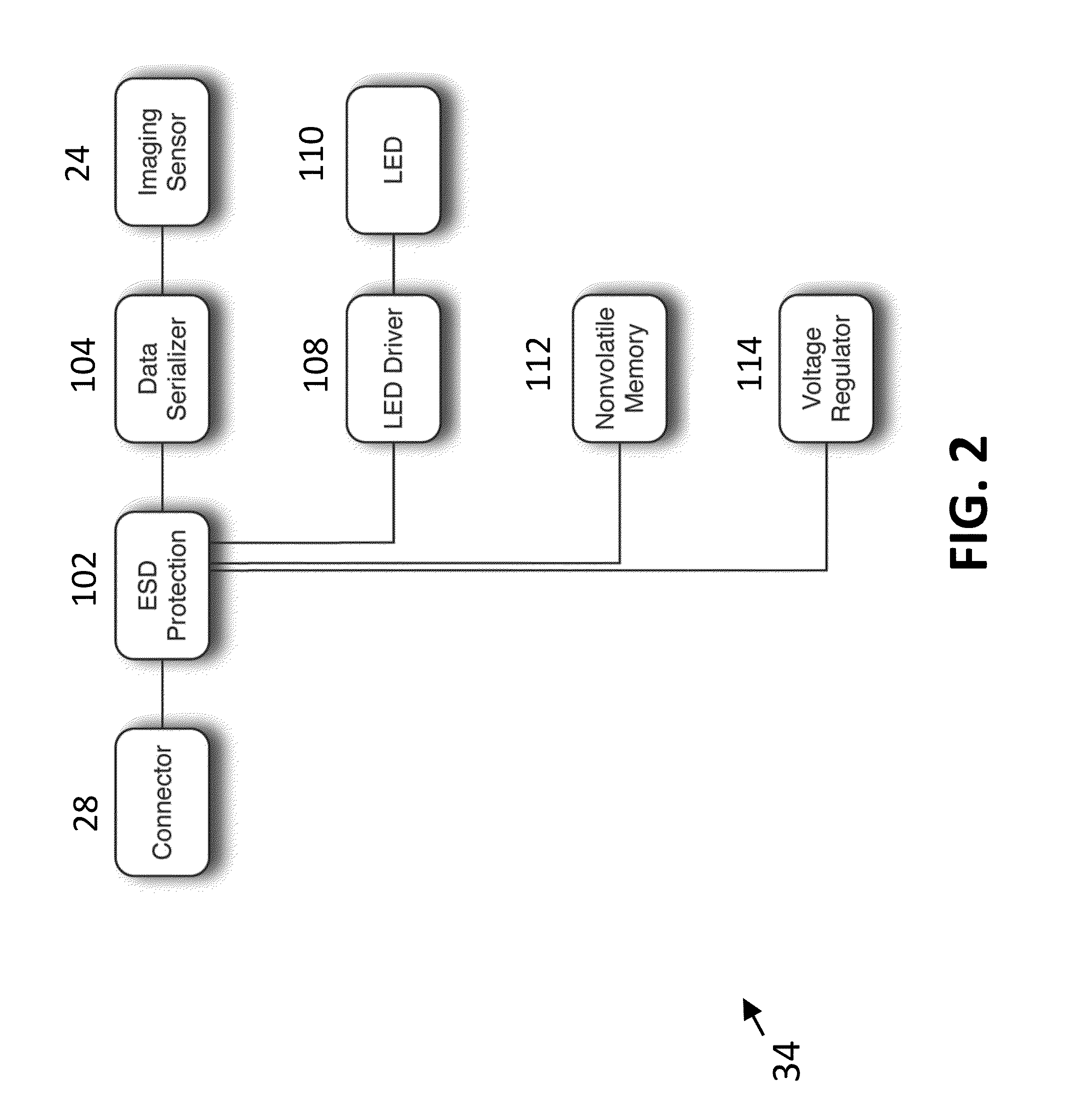

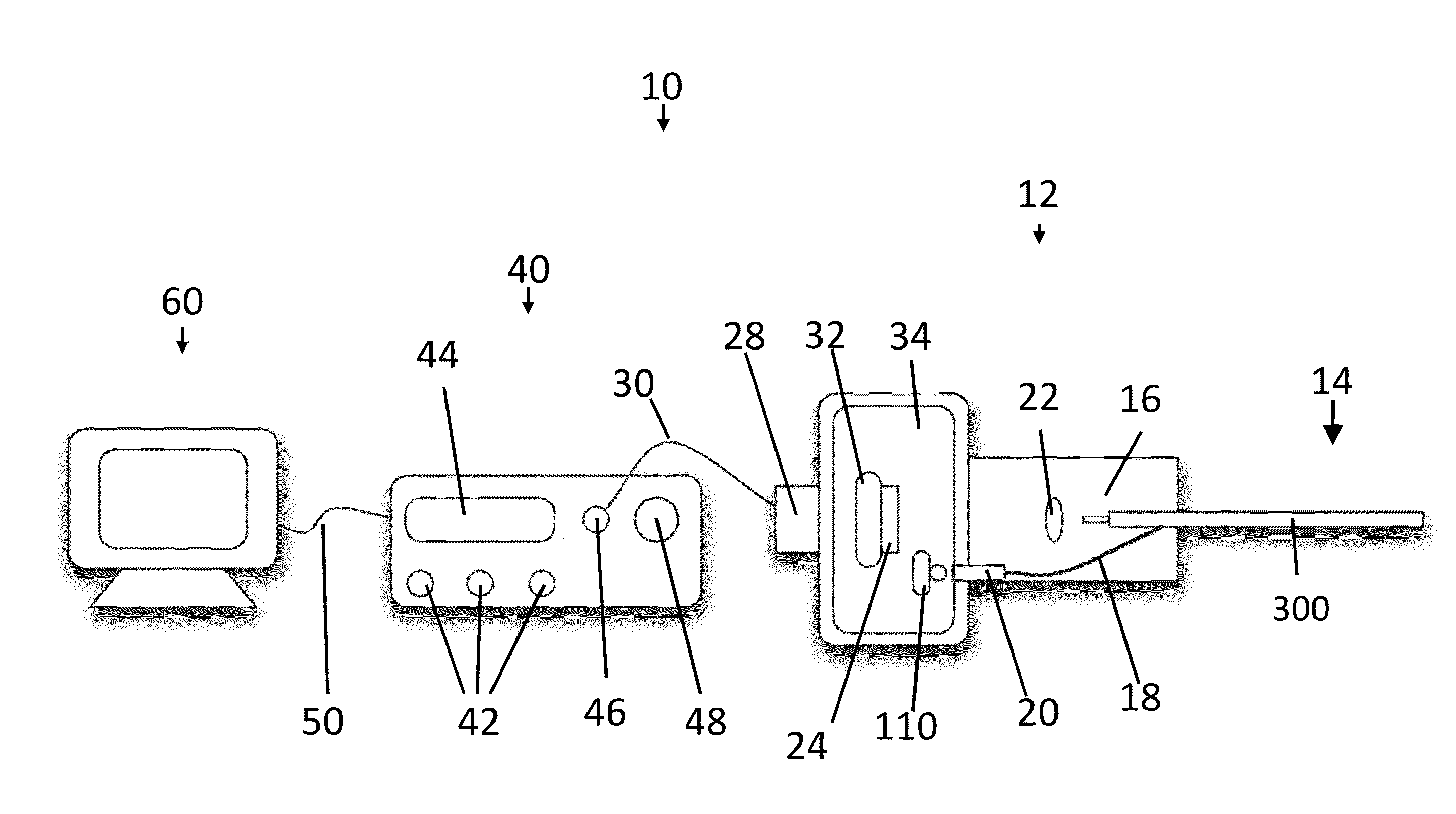

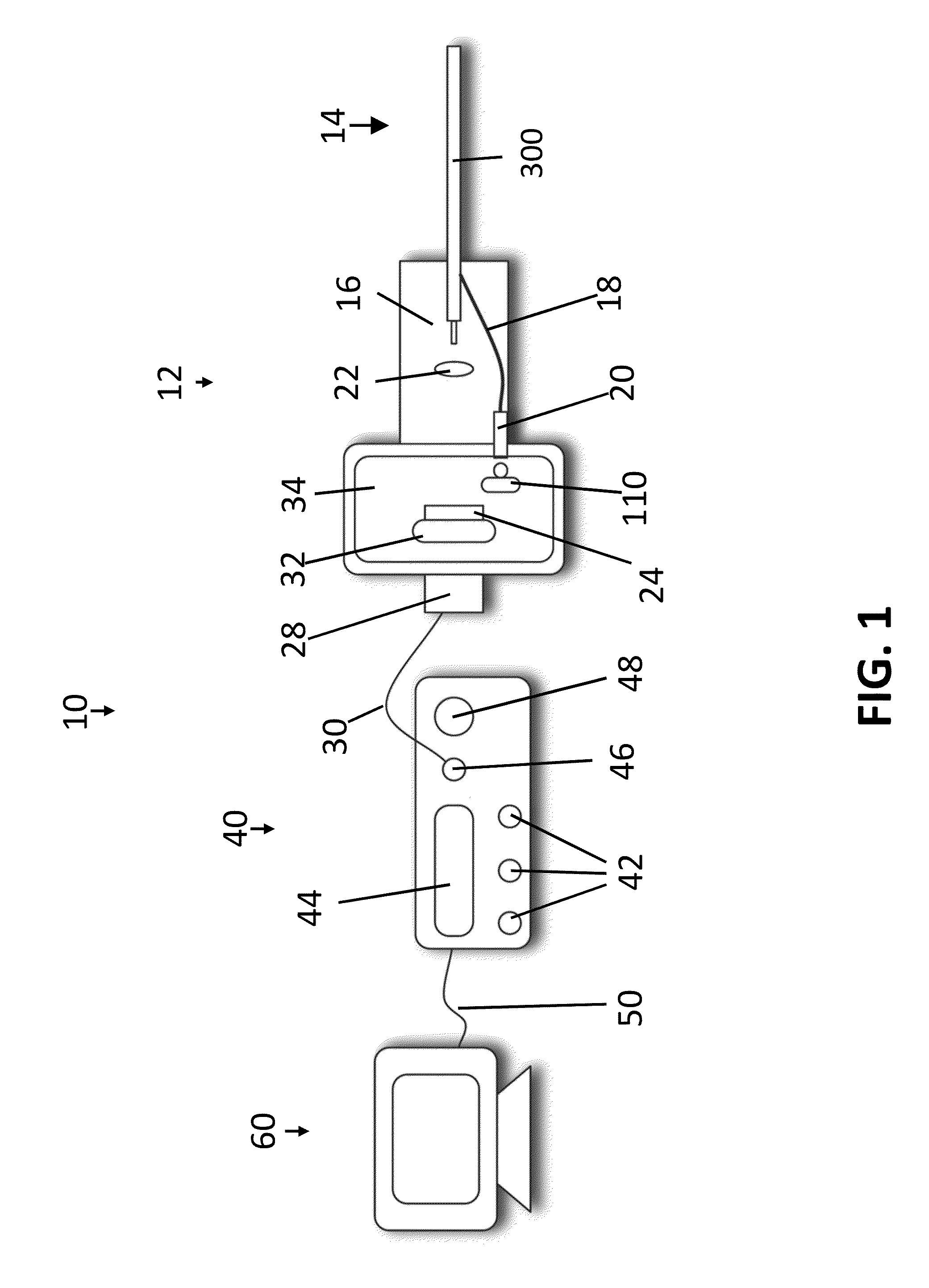

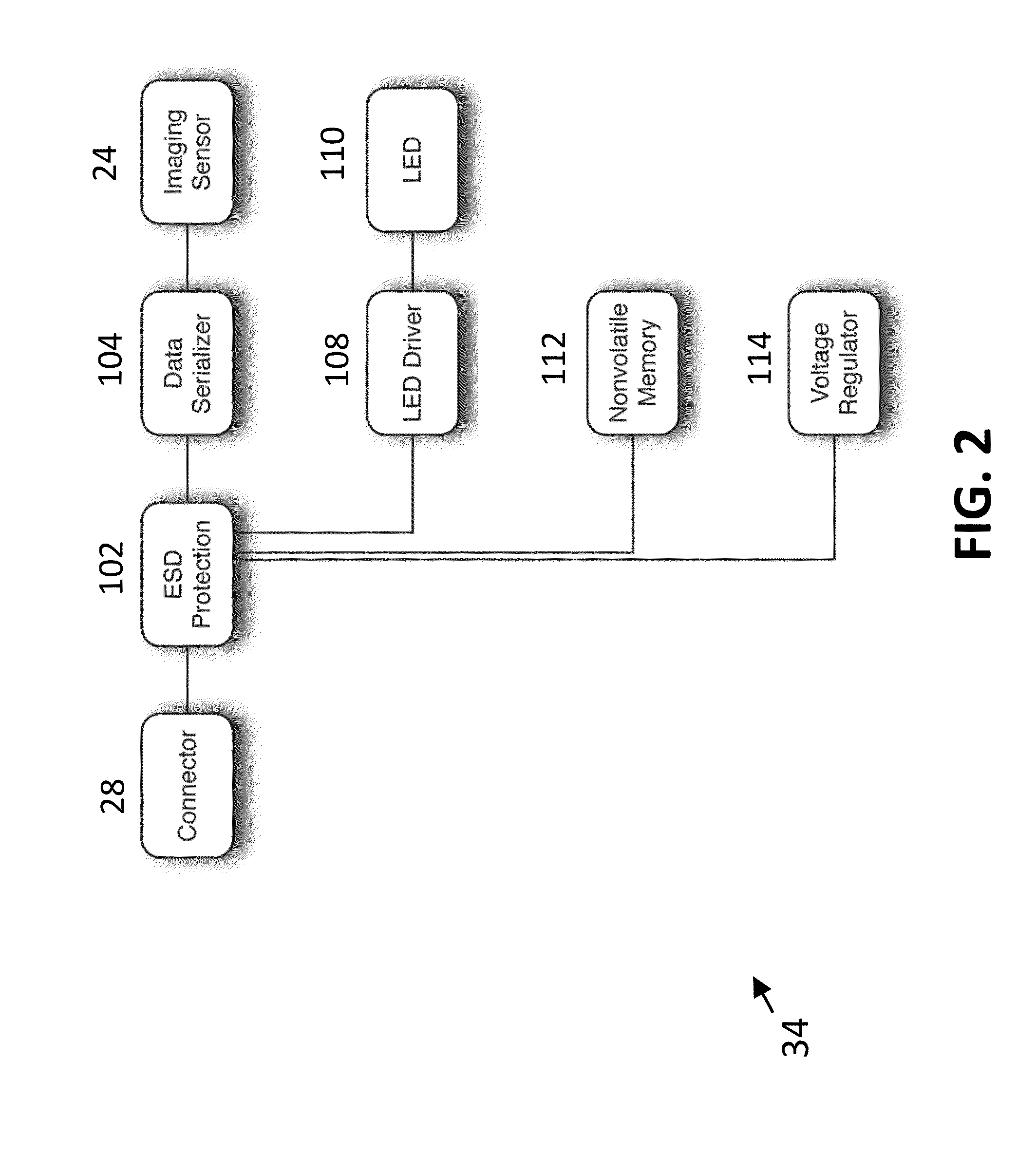

Integrated medical imaging system

A fiber optic camera system may include a fiber optic camera and a video processing console. The camera may include an elongate sheath having a proximal end and a distal end, and the sheath may contain one or more illumination optical fibers and an imaging bundle having at least one fiber optic clad and multiple fiber optic cores. The camera may further include a camera body fixedly attached to the proximal end of the elongate sheath, and the camera body may contain an imaging sensor optically coupled to a proximal end of the imaging bundle and configured to generate image data and an illumination source optically coupled to proximal ends of the illumination fibers. In some embodiments, the camera body has no connection member for connecting a secondary illumination source to the camera.

Owner:CALCULA TECH

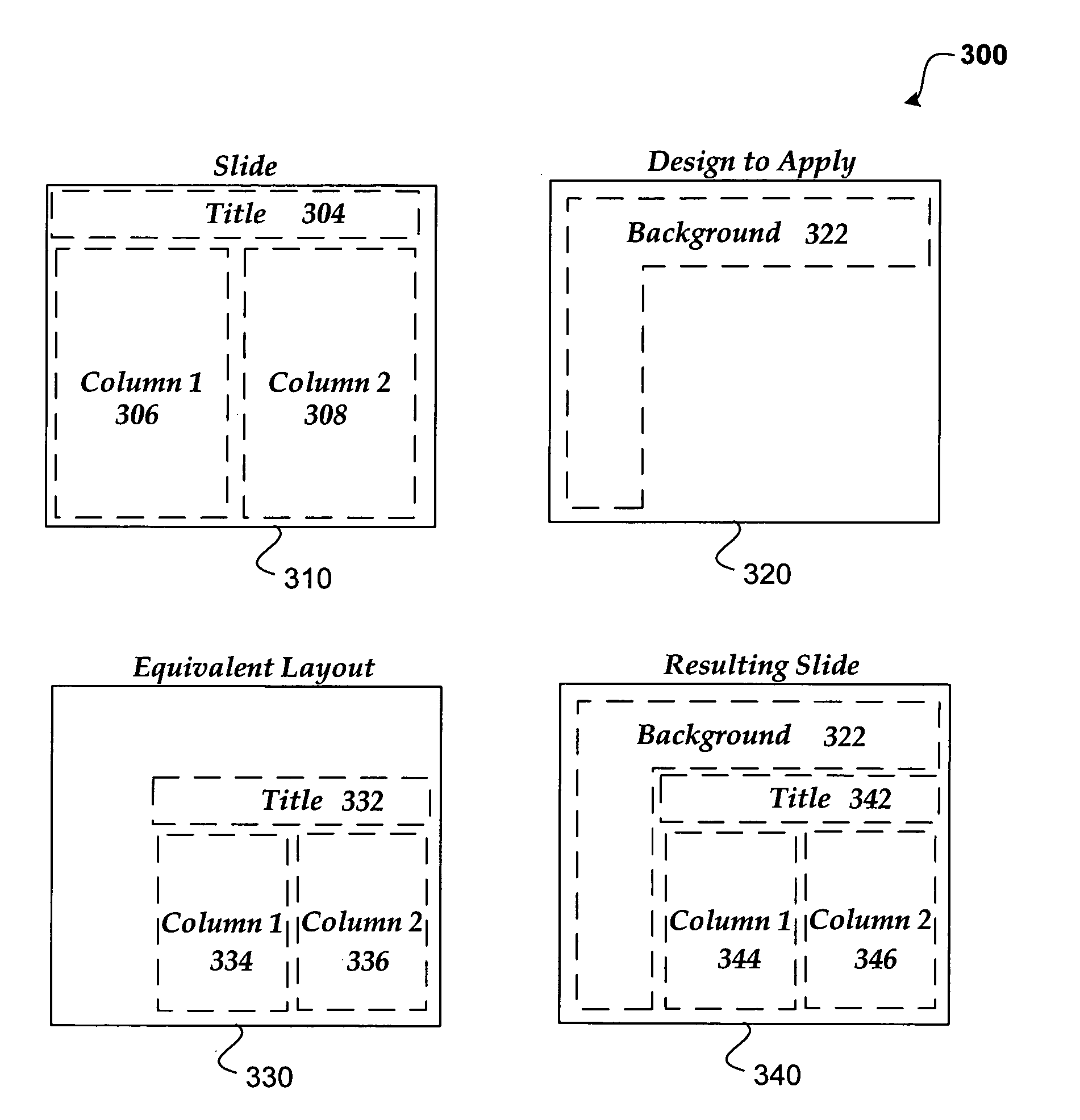

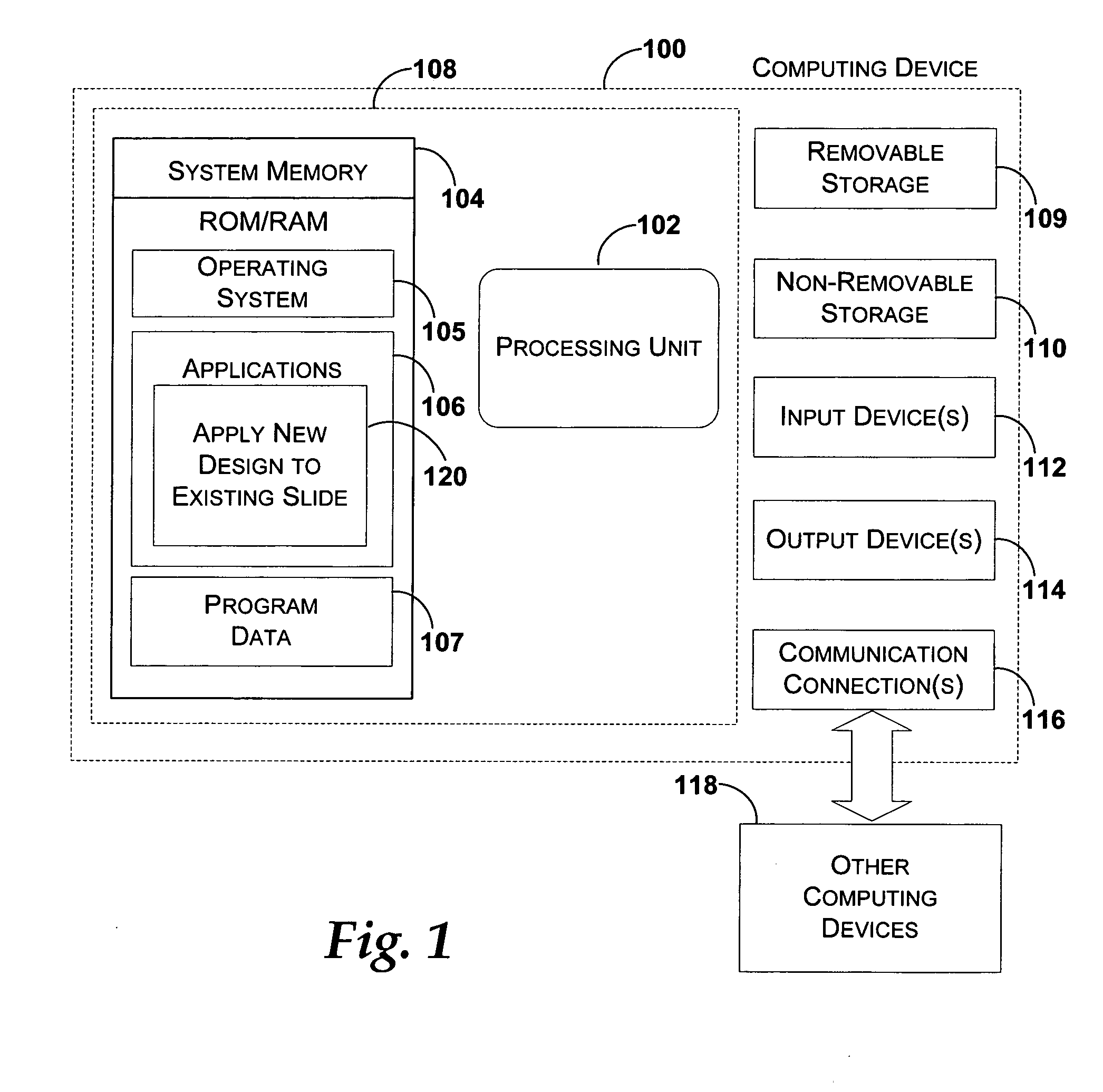

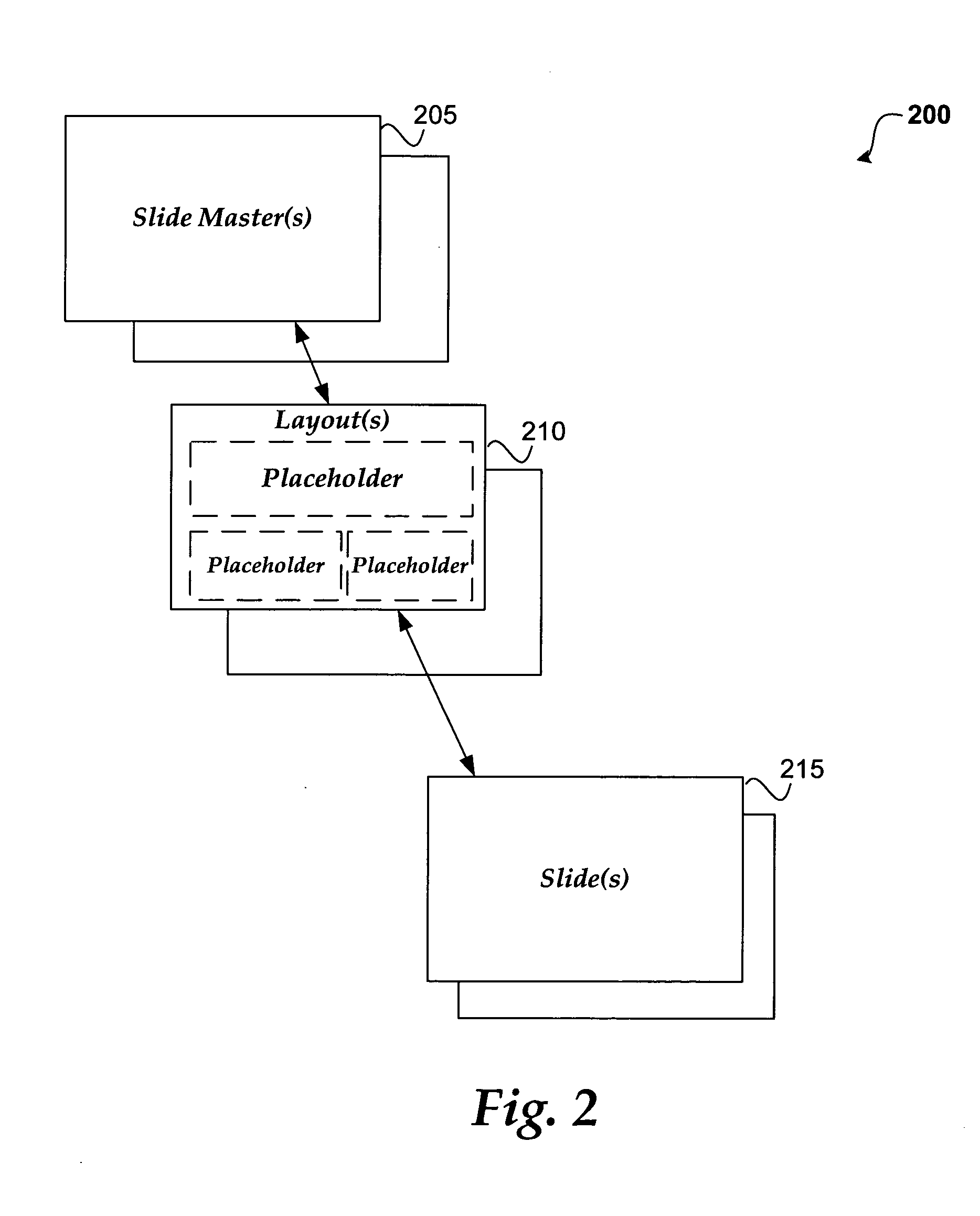

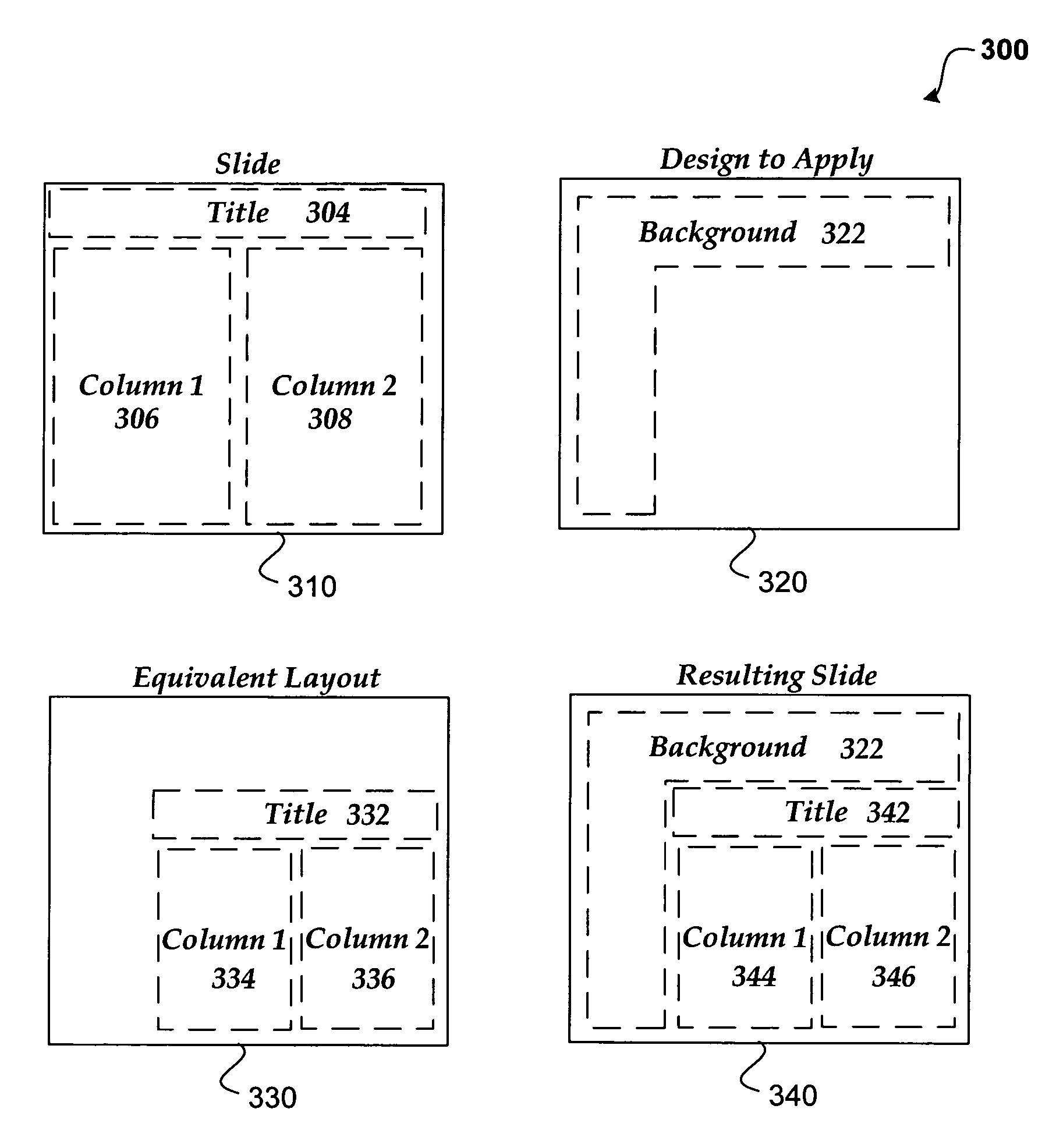

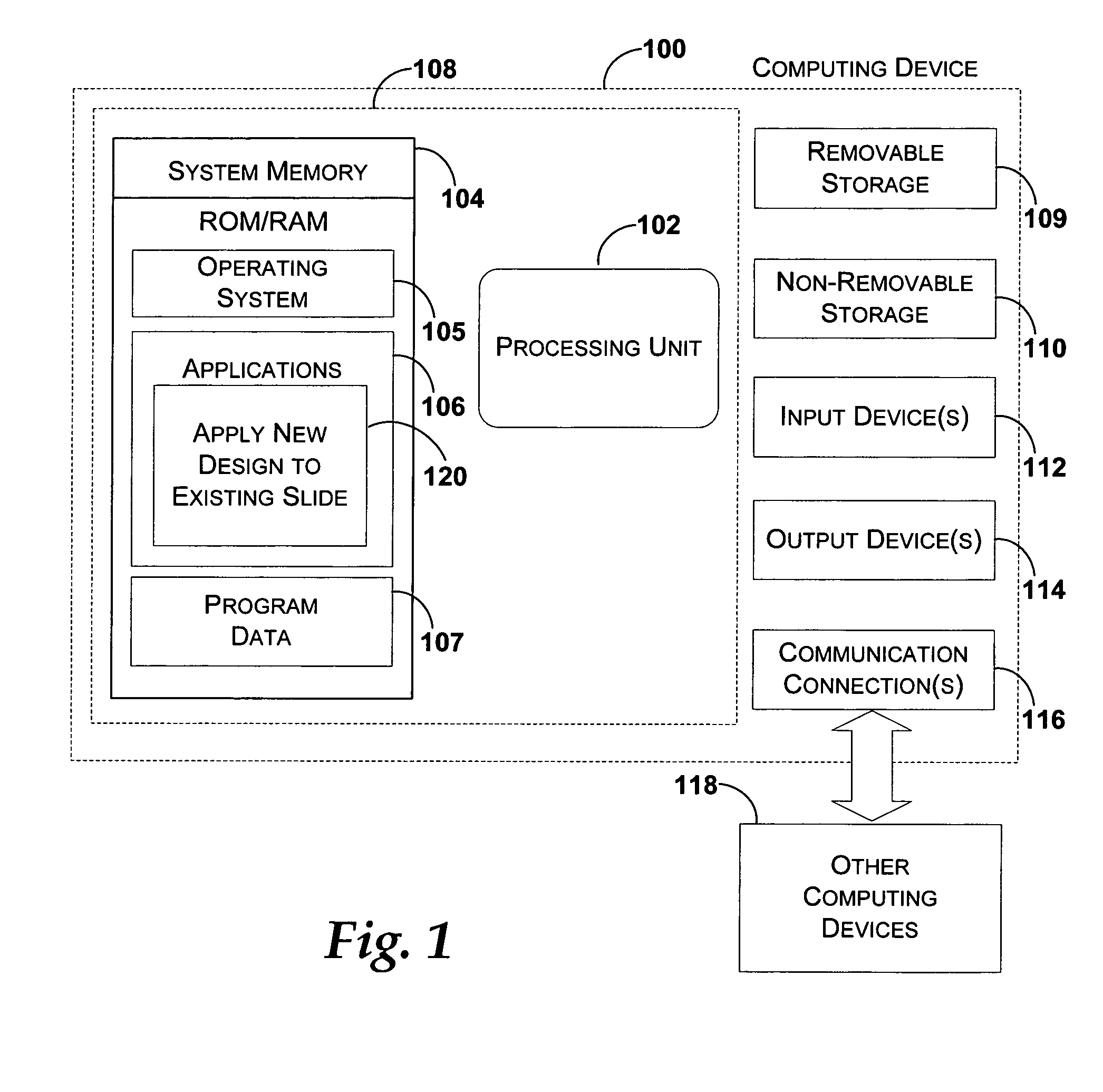

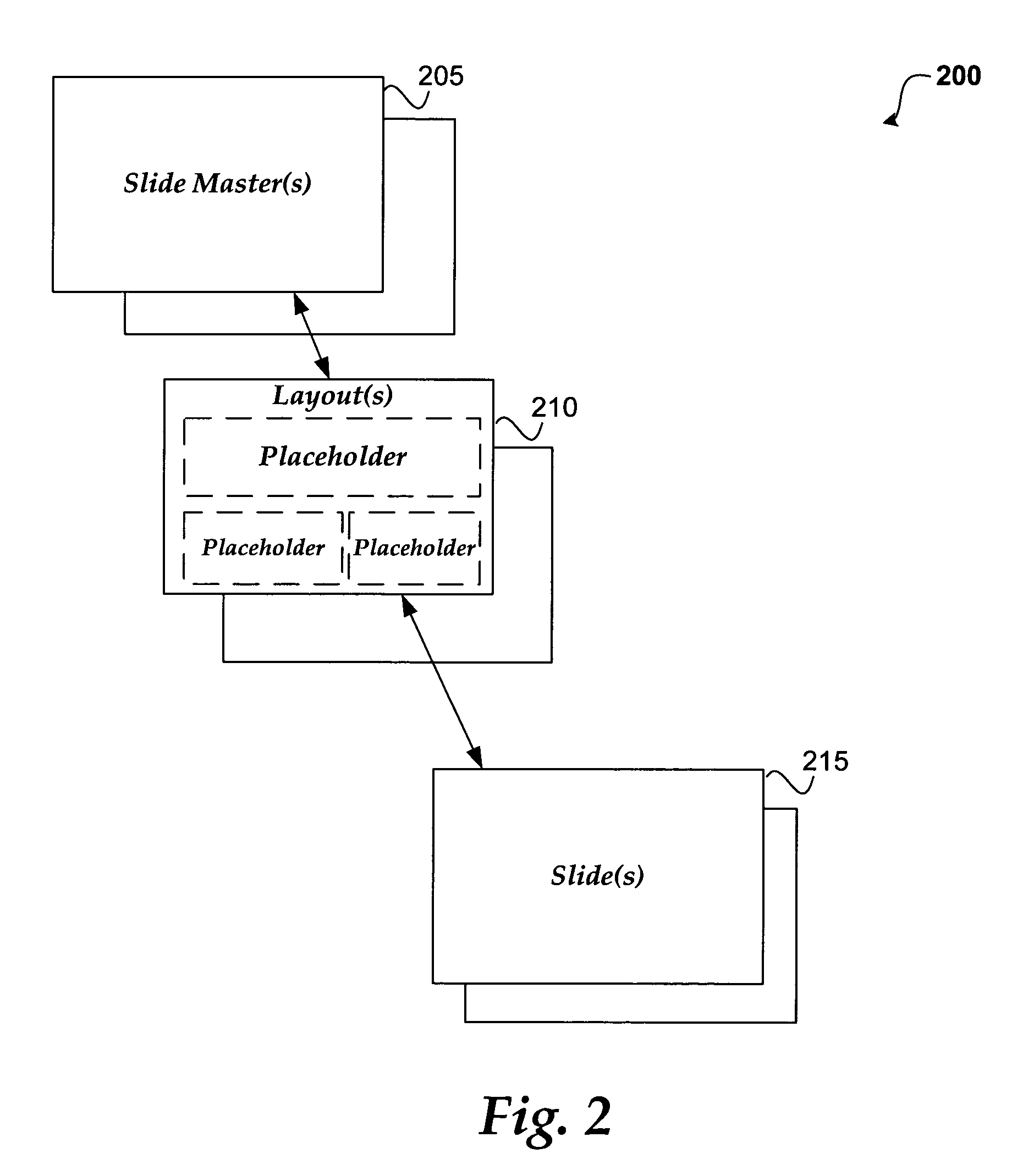

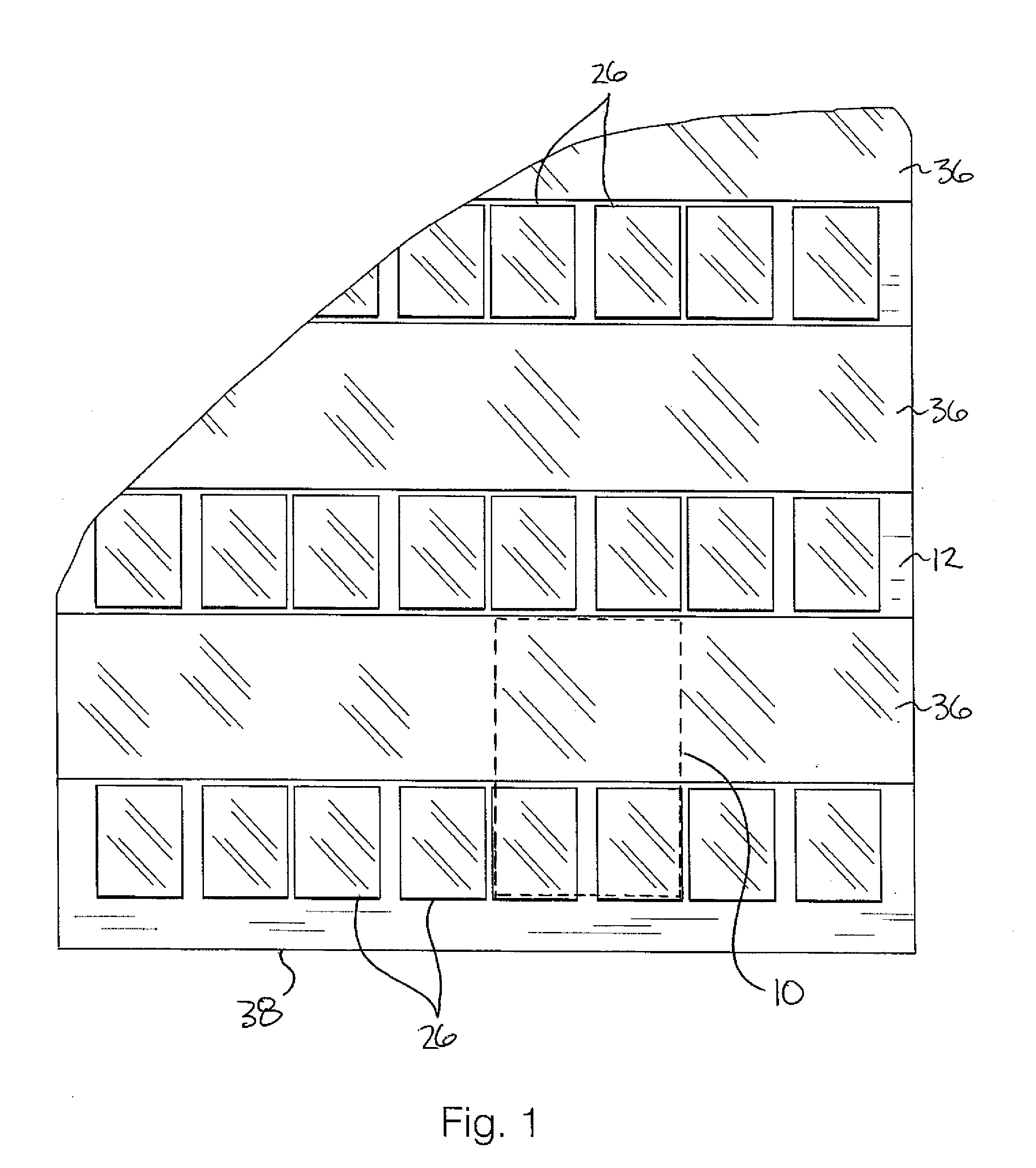

Applying a design to a slide using equivalent layouts

InactiveUS20060282779A1New designNatural language data processingWebsite content managementComputer science

A new design is applied to a slide. A search is made within layouts associated with the new design for an equivalent layout to the slide's layout. When an equivalent layout is found, the placeholders are mapped from the slide to a new slide base on the equivalent layout. An equivalent layout is determined based on a comparison between the slide's layout and the new design. The comparison is based on the name of the layouts, the number of placeholders, and whether the placeholders are of an equivalent type.

Owner:MICROSOFT TECH LICENSING LLC

Applying a design to a slide using equivalent layouts

InactiveUS7577905B2New designNatural language data processingWebsite content managementComputer science

A new design is applied to a slide. A search is made within layouts associated with the new design for an equivalent layout to the slide's layout. When an equivalent layout is found, the placeholders are mapped from the slide to a new slide base on the equivalent layout. An equivalent layout is determined based on a comparison between the slide's layout and the new design. The comparison is based on the name of the layouts, the number of placeholders, and whether the placeholders are of an equivalent type.

Owner:MICROSOFT TECH LICENSING LLC

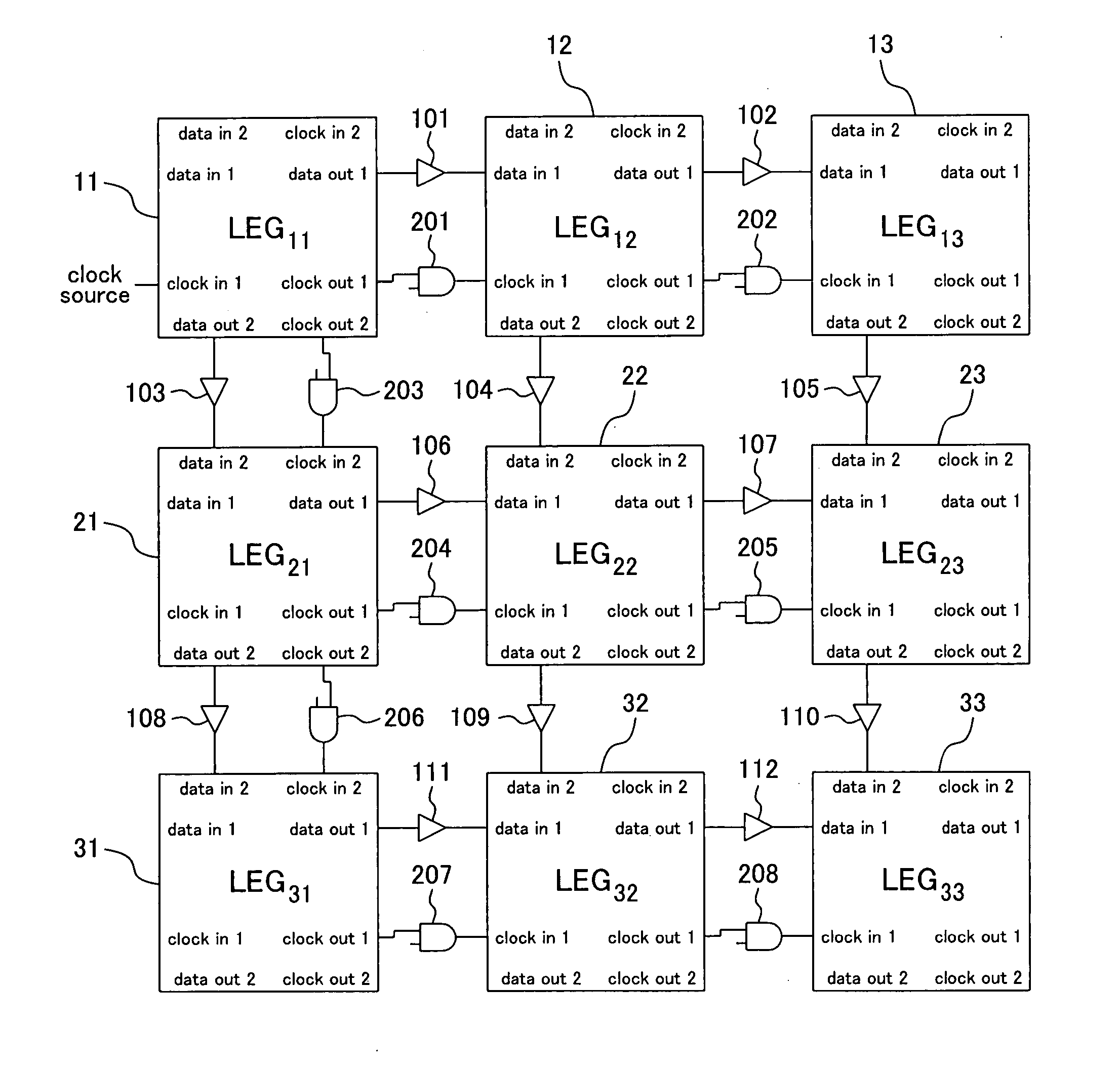

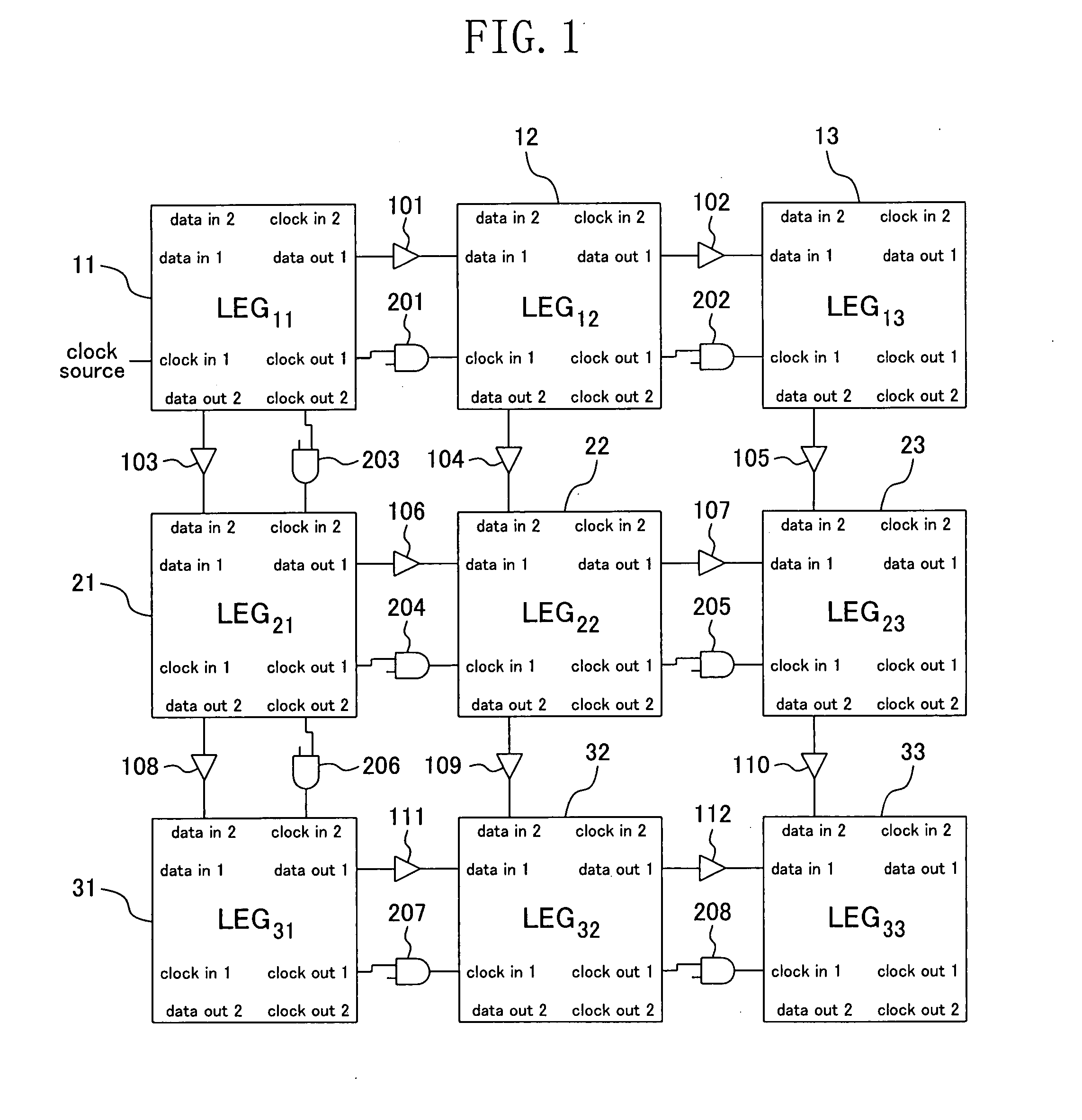

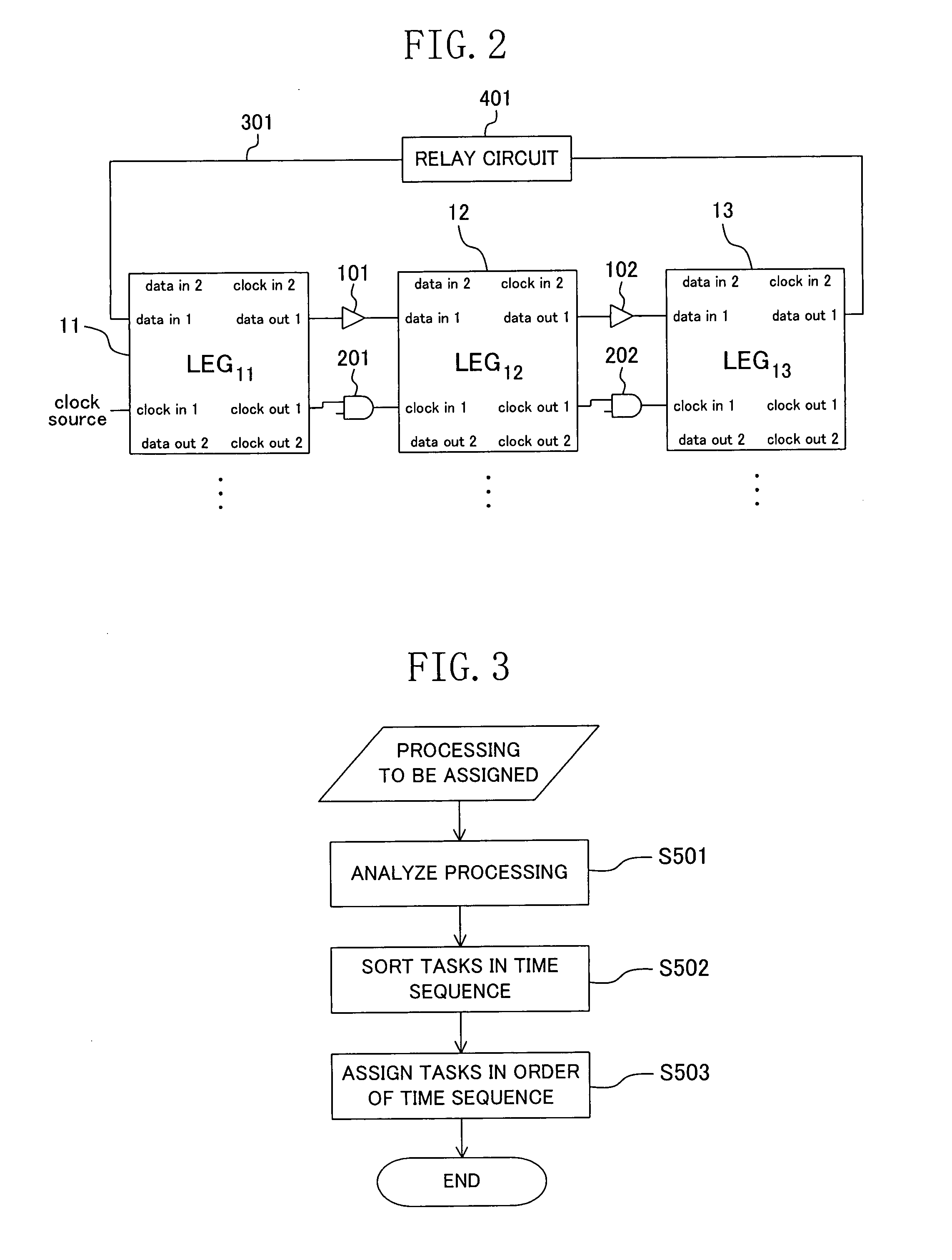

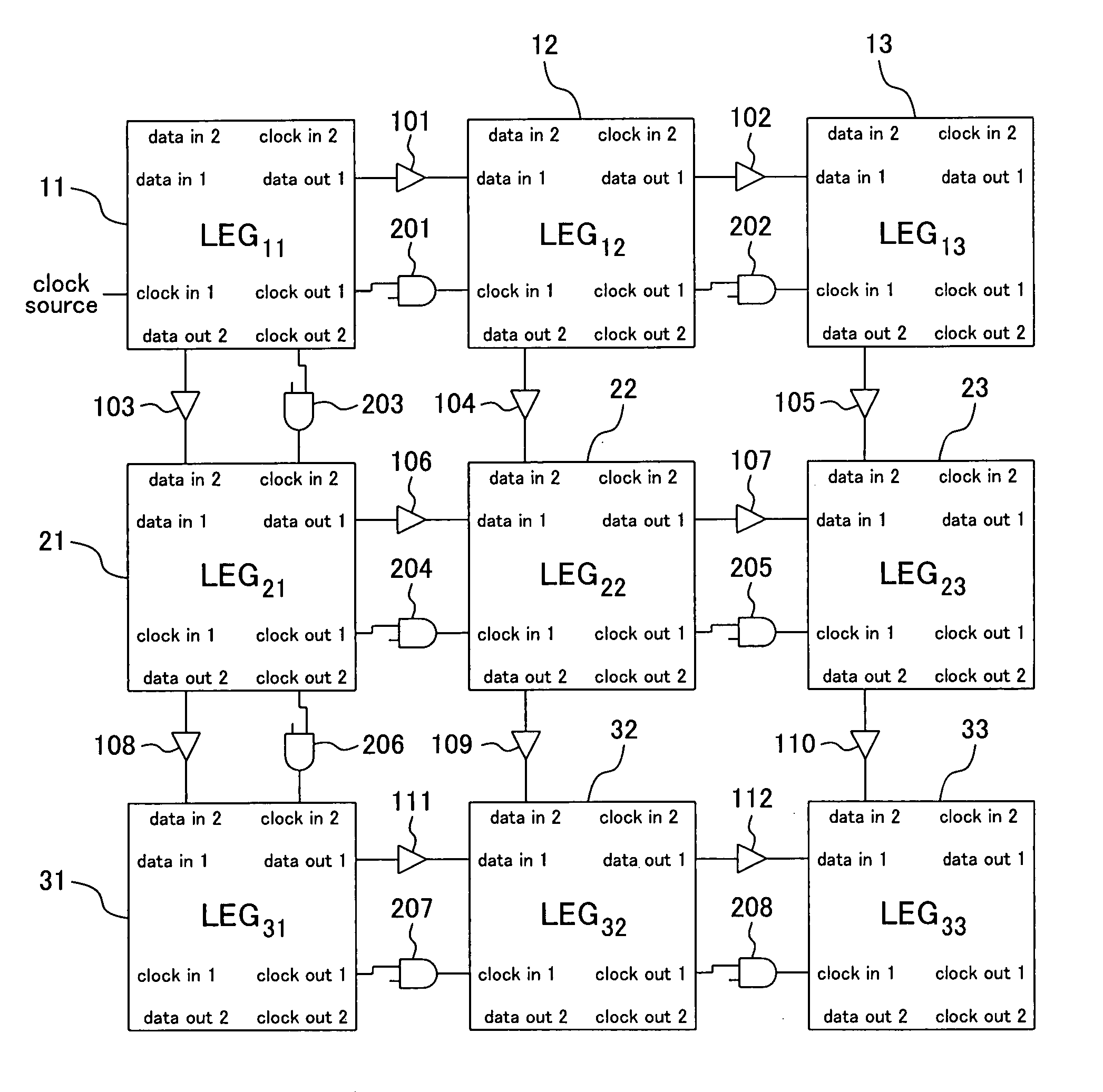

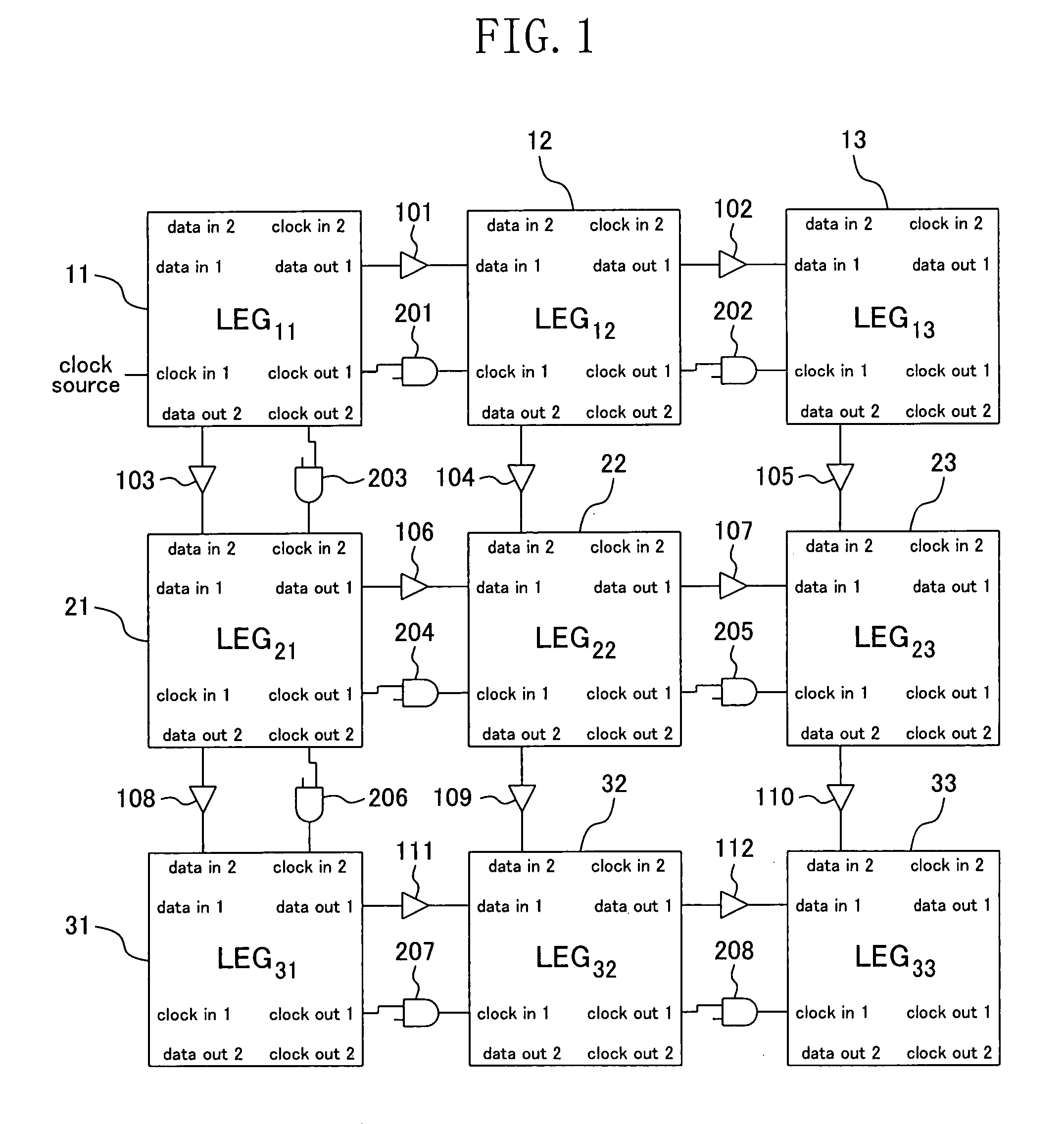

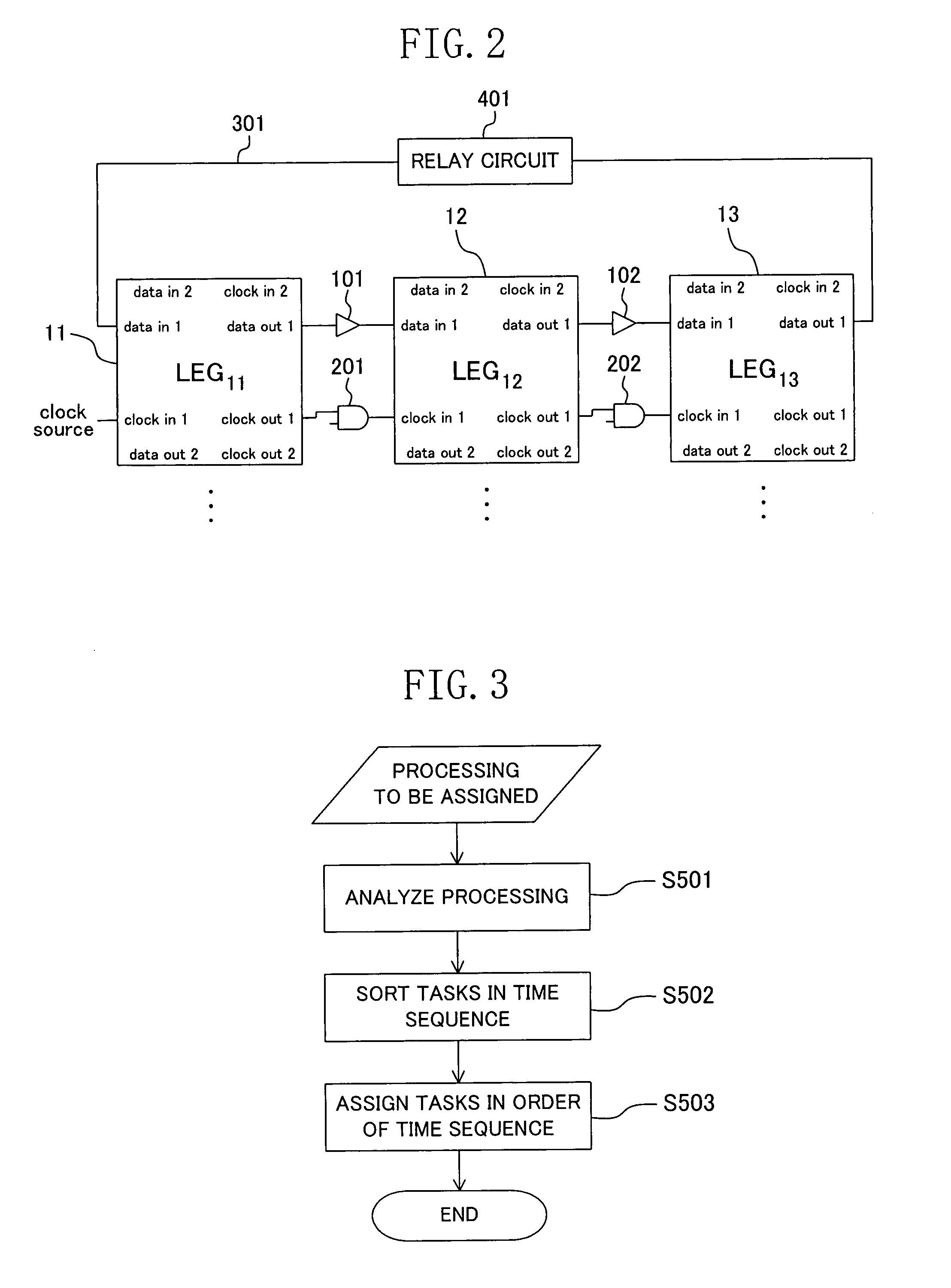

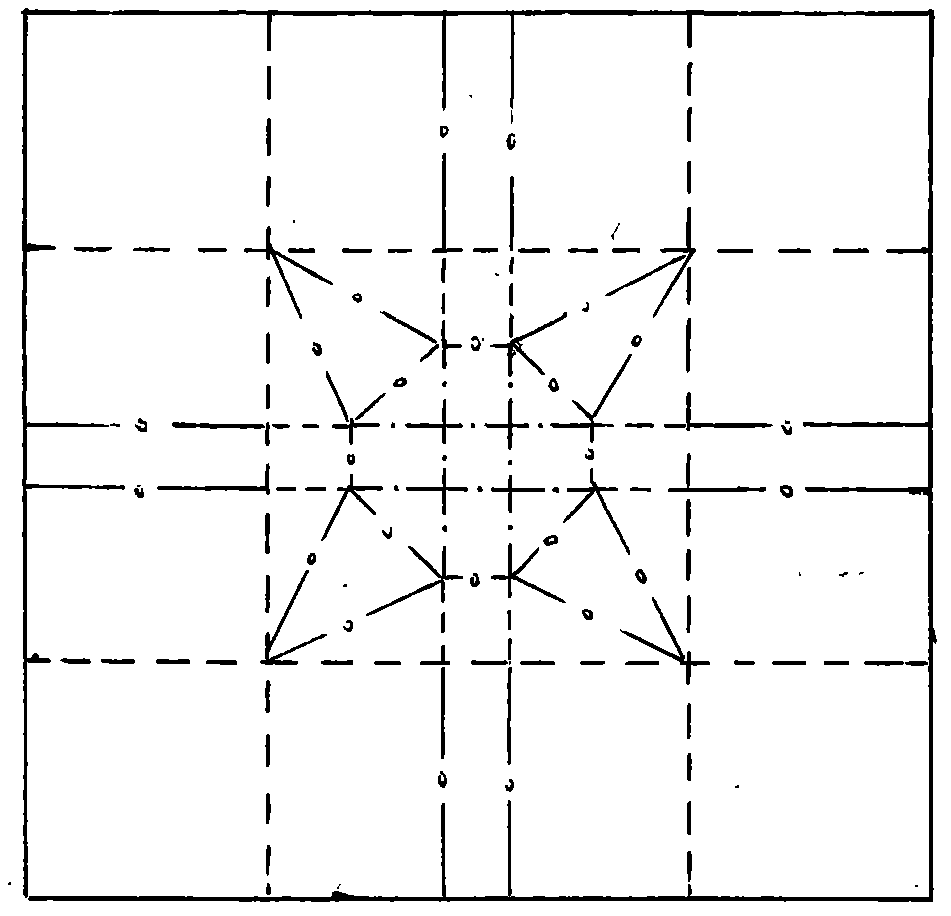

Reconfigurable semiconductor intergrated circuit and processing assignment method for the same

InactiveUS20080061834A1Shorten design timeNew designSolid-state devicesCAD circuit designLogical elementData transmission

A plurality of logic element groups LEG11 to LEG33 respectively include at least one logic element as a component of a reconfigurable semiconductor integrated circuit. Between any logic element groups engaging in data transmission / reception, e.g., LEG11 and LEG12, clock out terminal and clock in terminal are connected via a line while data out terminal and data in terminal are connected via a delay element 101. The logic element groups LEG11 to LEG33 are therefore independent of one another in terms of timing design. Thus, if redesign is necessary for a semiconductor integrated circuit completed with a plurality of logic element groups, only a new circuit may be designed and connected to an existing circuit, or an unnecessary logic element group may just be removed, to complete a new semiconductor integrated circuit.

Owner:SOCIONEXT INC

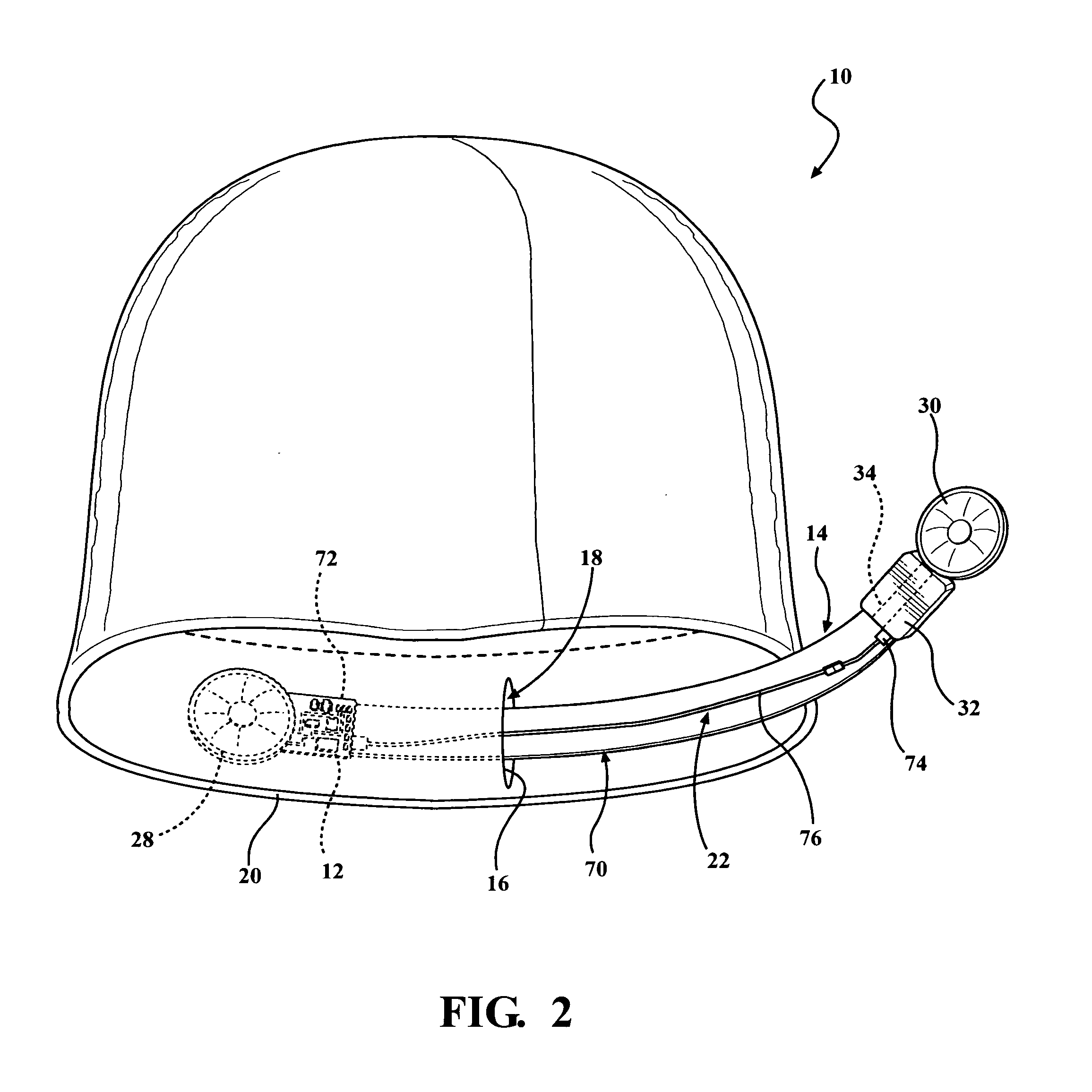

Hat with sound playing device

A hat of the present invention includes at least opening to define a pocket extending along the peripheral edge of the hat. A speaker device includes a plurality of components removably connected with one another to form a uniformed piece thereby allowing the user to insert the speaker device into the pocket to allow the user to wear the hat and listed to sounds. The speaker device includes a pair of speakers, a controller unite connected to one of the speakers and a battery unit including a battery for supplying power to the speakers and the controller unit. The battery unit is connected to another speaker.

Owner:JACKS EMILY ANN +1

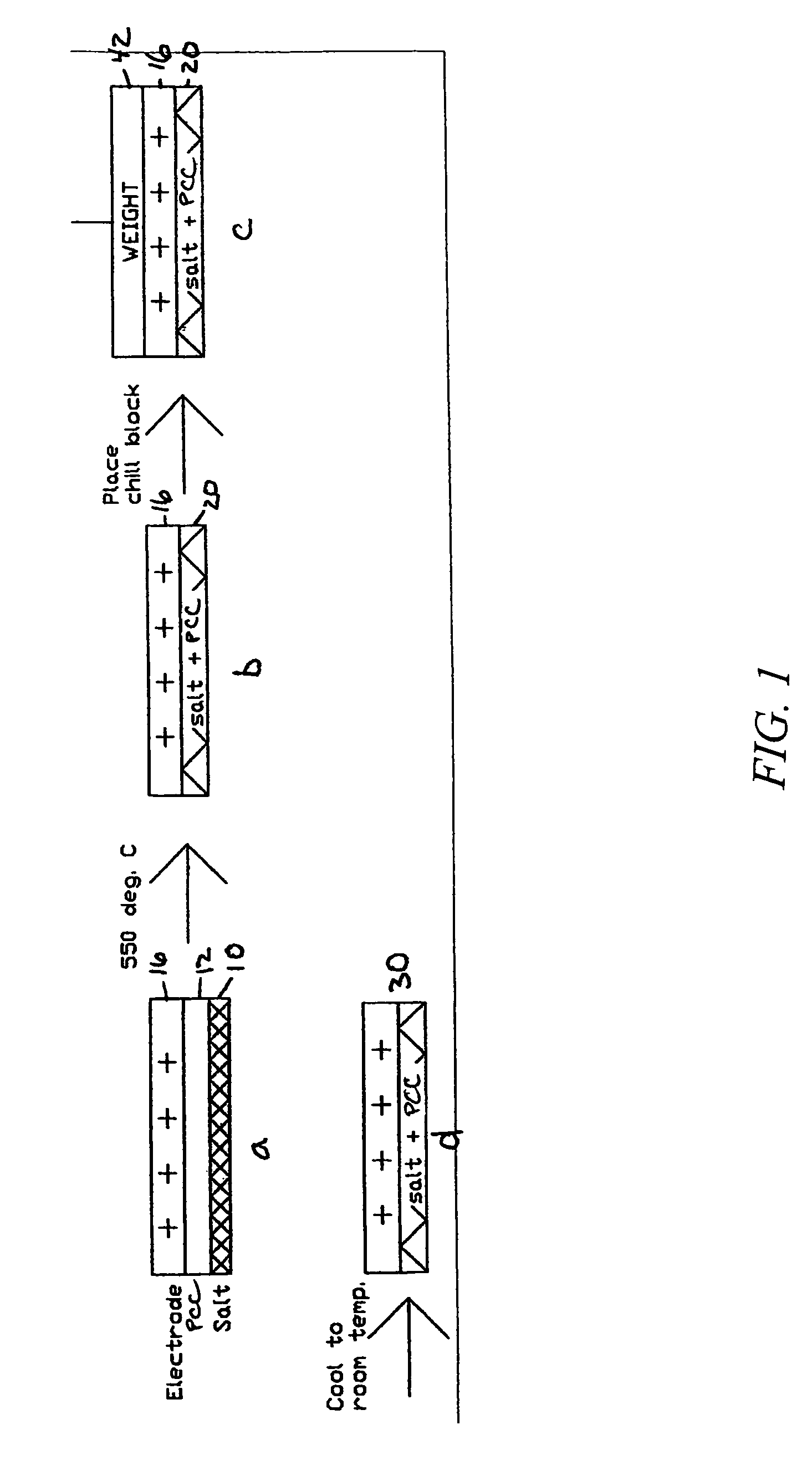

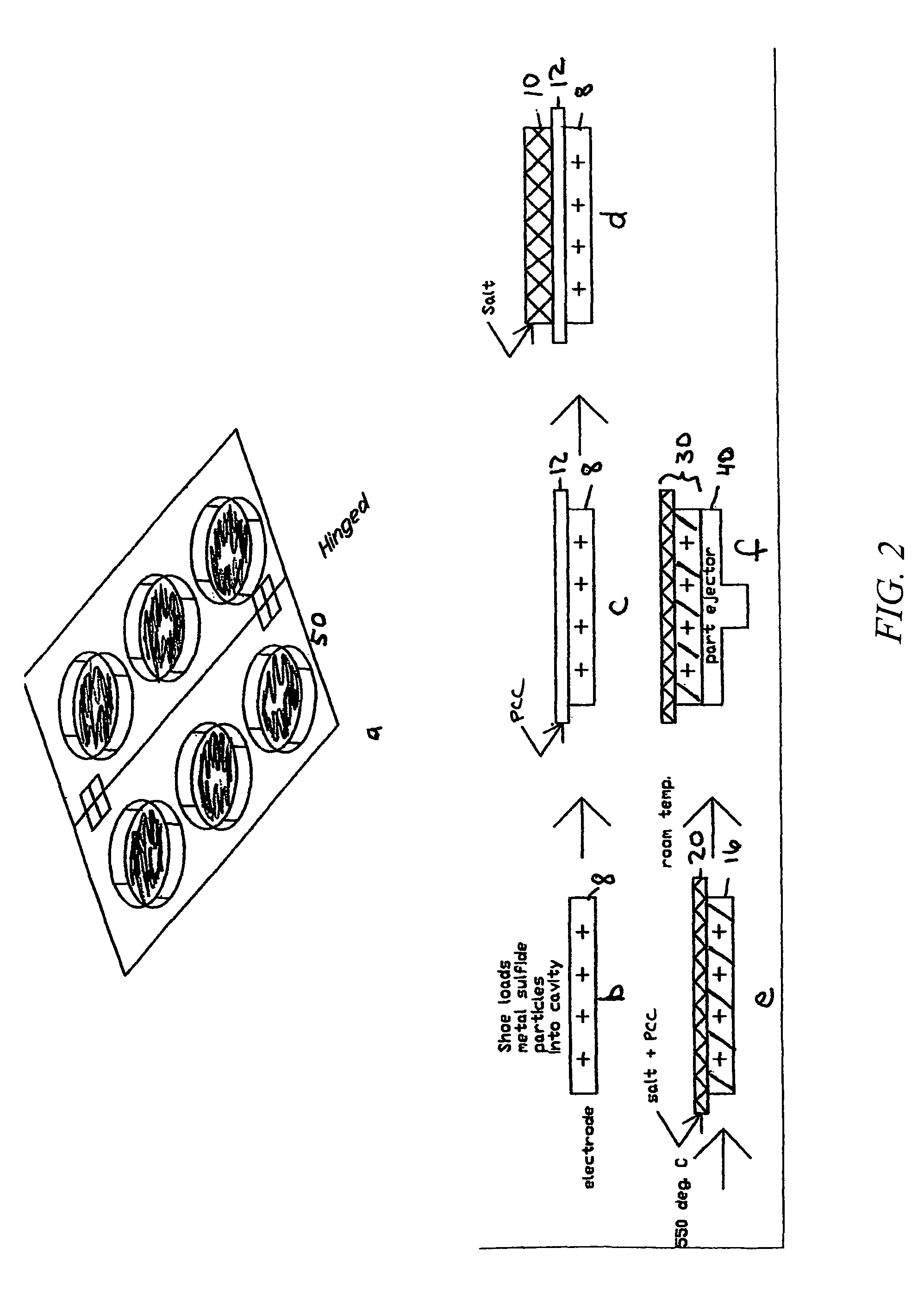

X-ray detector and method

InactiveUS20070114429A1Avoid deflationIncrease surface areaElectric discharge tubesSolid-state devicesX-rayEngineering

We provide an x-ray detector having a housing with one or more internal surfaces defining an internal volume. The housing is adapted in use to contain a vacuum within the internal volume. An x-ray sensor is located within the internal volume of the housing. A window, located within the housing, is adapted to permit the passage through the window of x-rays to be detected from the external environment to the sensor. A getter material is applied as a coating to the one or more internal surfaces, for absorbing gaseous species present within the vacuum and for substantially preventing outgassing from the parts of the walls coated by the getter material.

Owner:OXFORD INSTUMENTS ANALYTICAL LIMITED

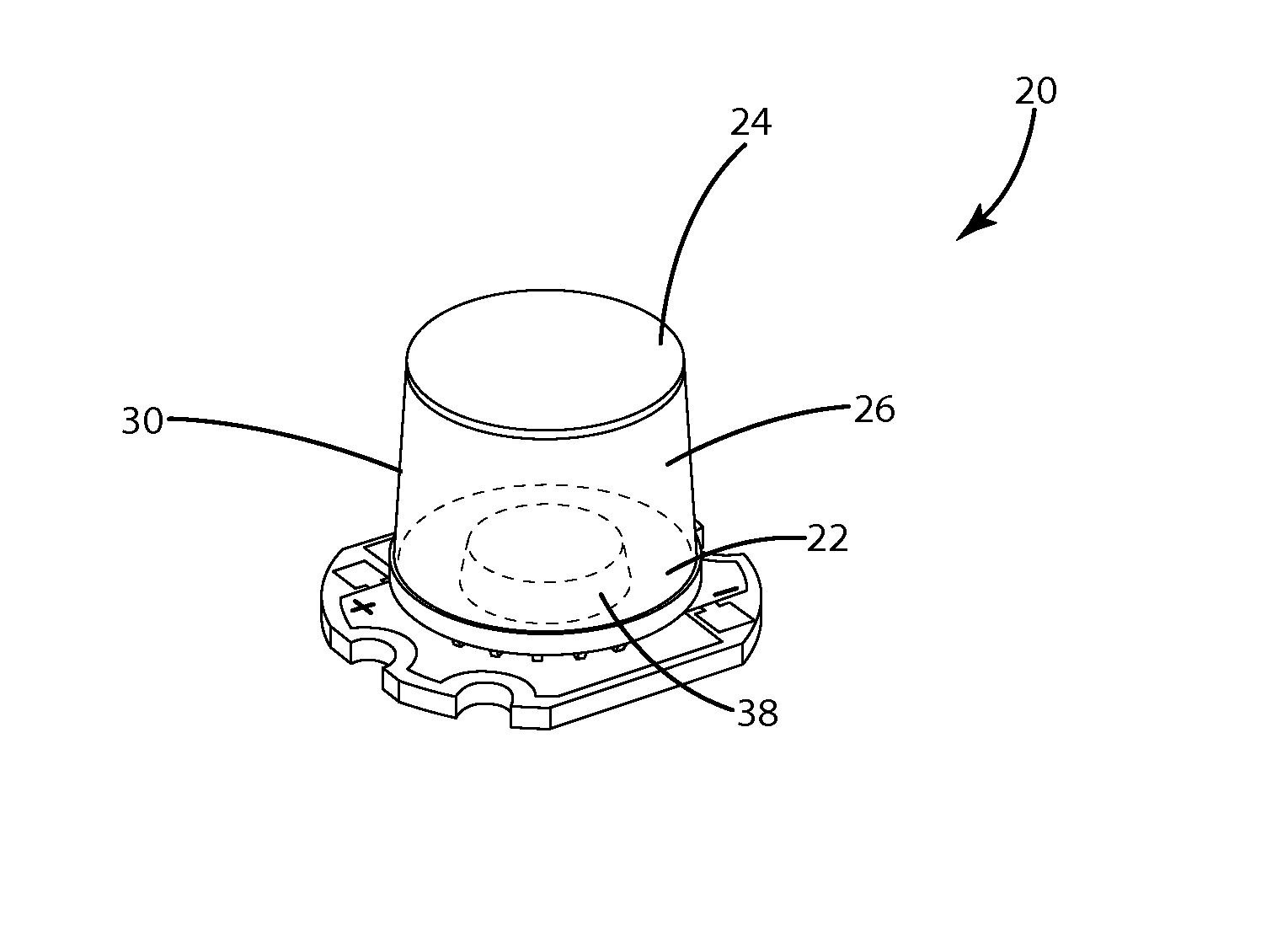

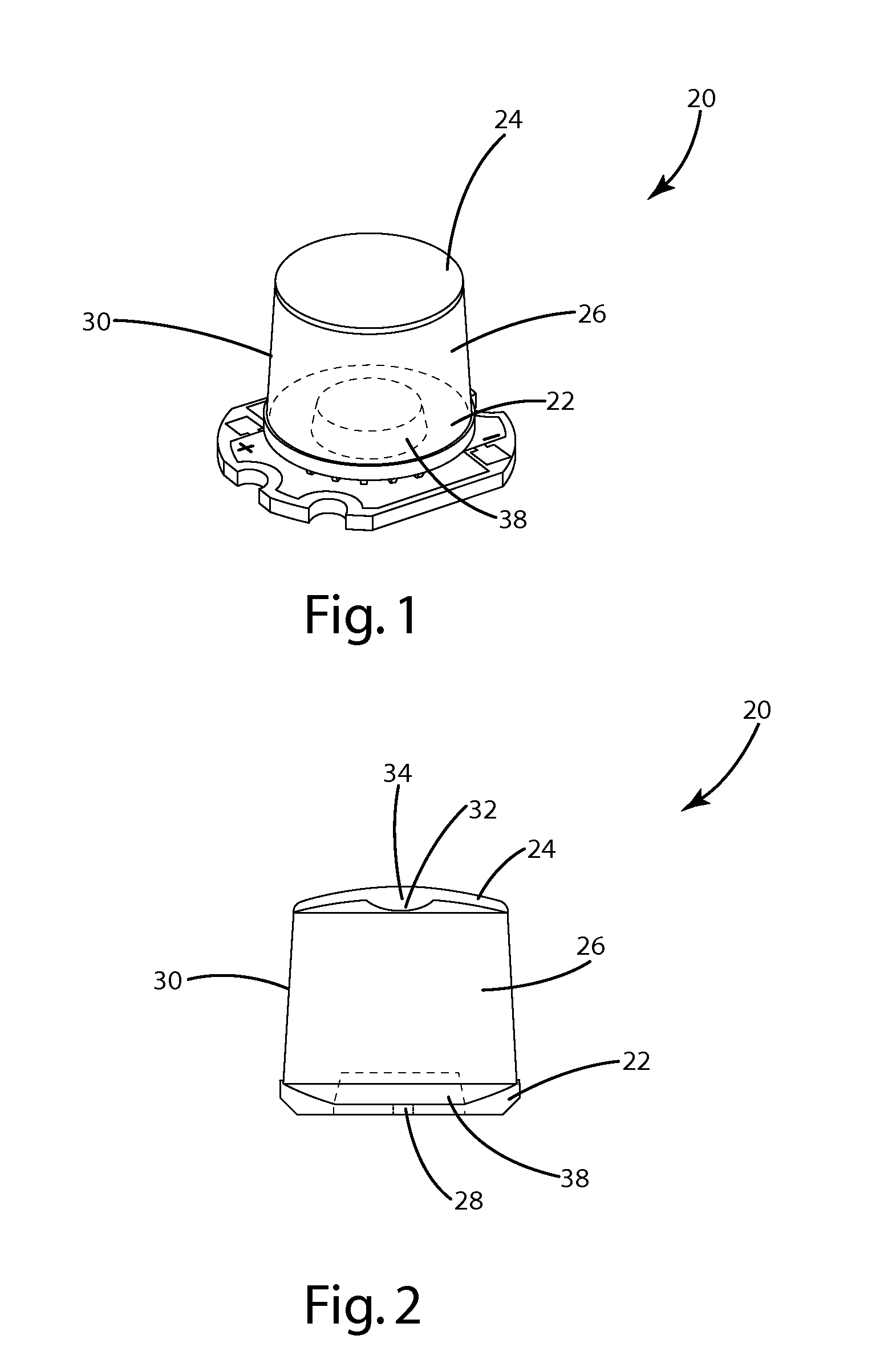

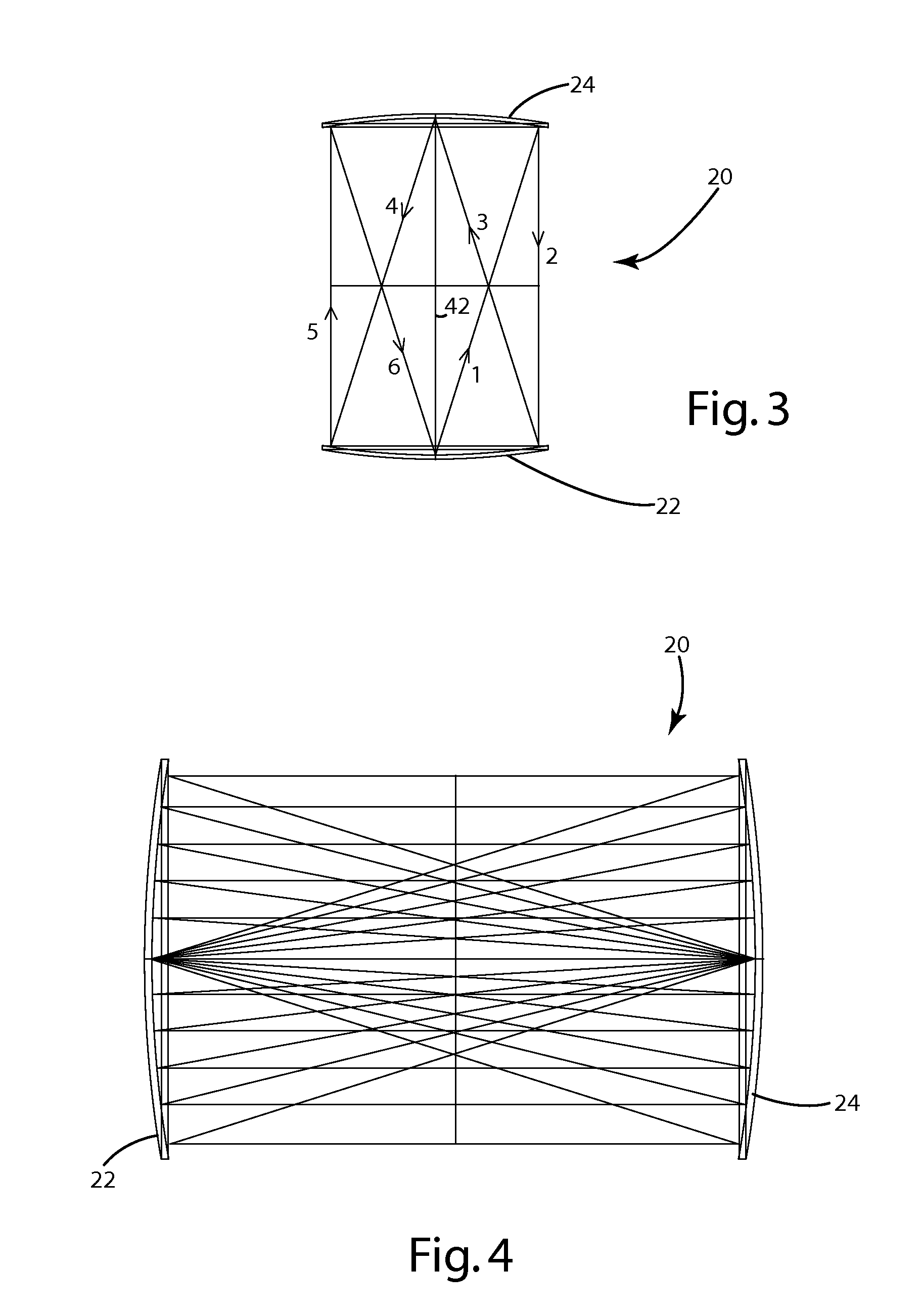

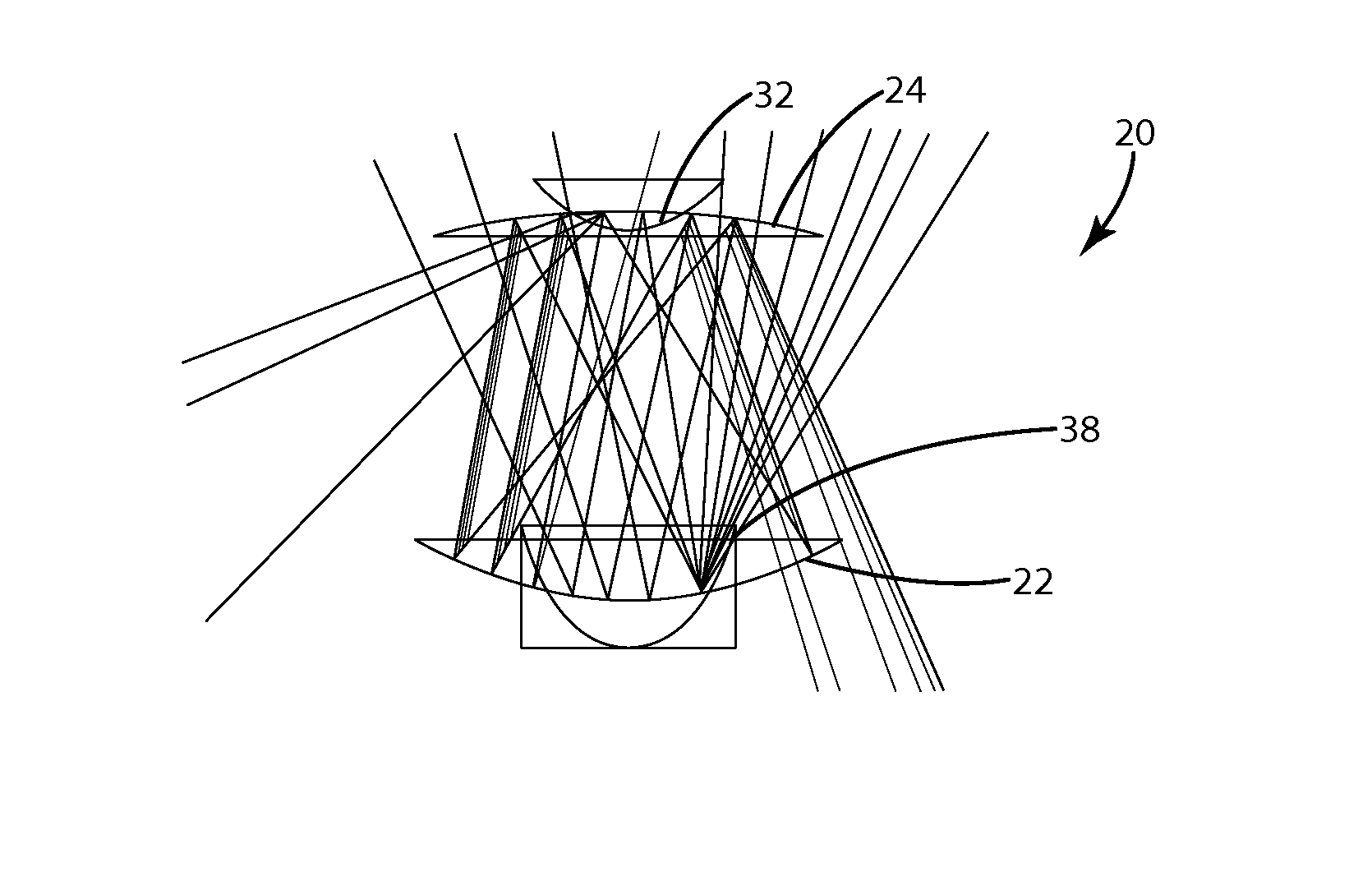

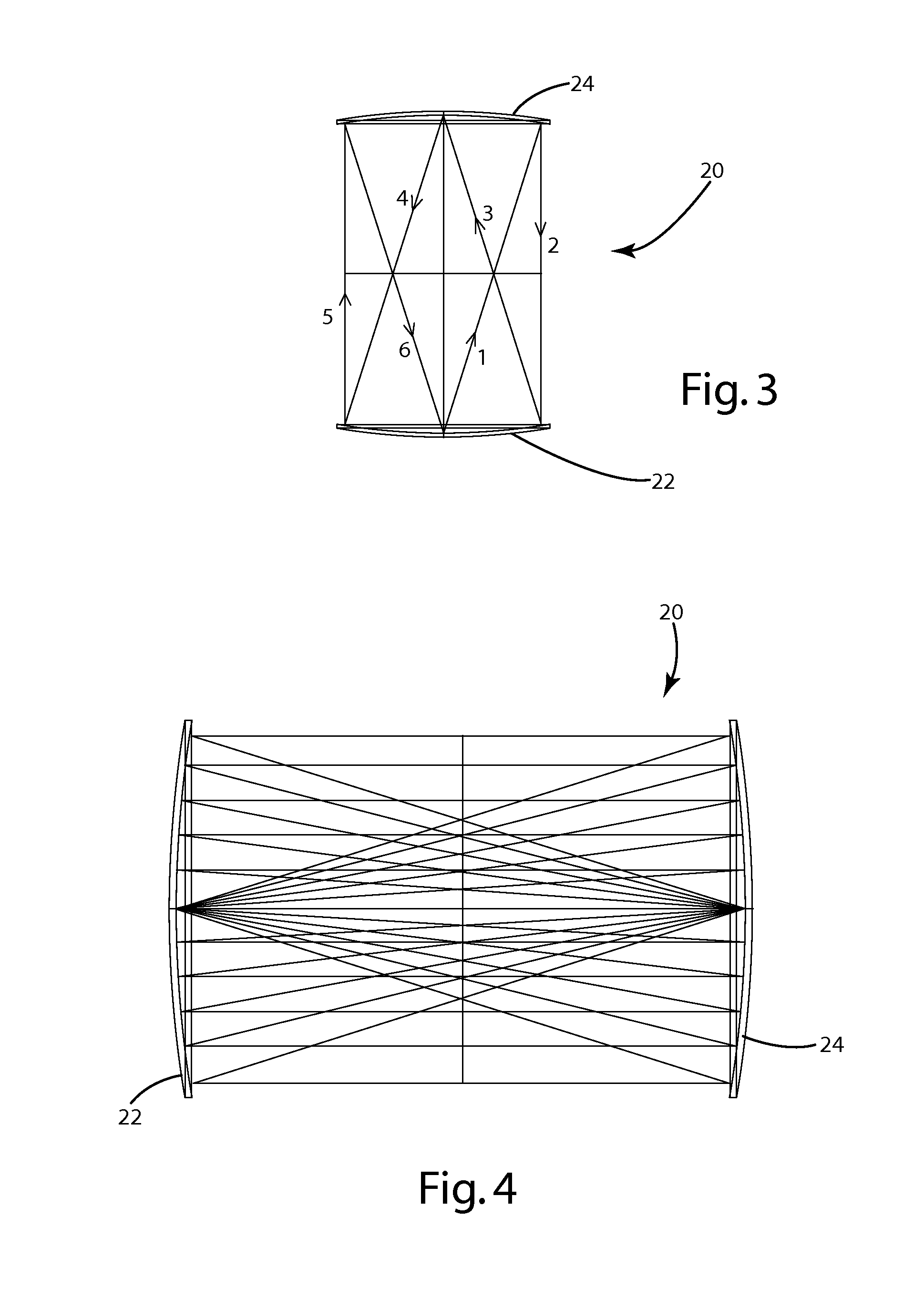

Constrained folded path resonant white light scintillator

ActiveUS8646949B2Improving utilization and containmentConversion of lightIncadescent screens/filtersDischarge tube luminescnet screensPhosphorLength wave

An optical emitter enabling conversion of light from a light source. The optical emitter includes a first conic reflector defining an aperture for receiving the light source, a second conic reflector opposite the first conic reflector for collimating light emitted by the light source, and a volumetric light conversion element between at least a portion of the first reflector and at least a portion of the second reflector. The optical emitter can also include a convex mirror adjacent the vertex of the second conic reflector, and an elliptical element adjacent the first conic reflector. The light conversion element can include phosphor dispersed in a resin to convert light from a first wavelength to light of a second, longer, wavelength, wherein converted light is emitted from the light conversion element.

Owner:VENTURA MFG1 LLC

Constrained folded path resonant white light scintillator

InactiveUS20140126224A1Improving utilization and containmentConversion of lightSemiconductor devices for light sourcesSemiconductor devicesPhosphorLength wave

An optical emitter enabling conversion of light from a light source. The optical emitter includes a first conic reflector defining an aperture for receiving the light source, a second conic reflector opposite the first conic reflector for collimating light emitted by the light source, and a volumetric light conversion element between at least a portion of the first reflector and at least a portion of the second reflector. The optical emitter can also include a convex mirror adjacent the vertex of the second conic reflector, and an elliptical element adjacent the first conic reflector. The light conversion element can include phosphor dispersed in a resin to convert light from a first wavelength to light of a second, longer, wavelength, wherein converted light is emitted from the light conversion element.

Owner:LUMENFLOW CORP

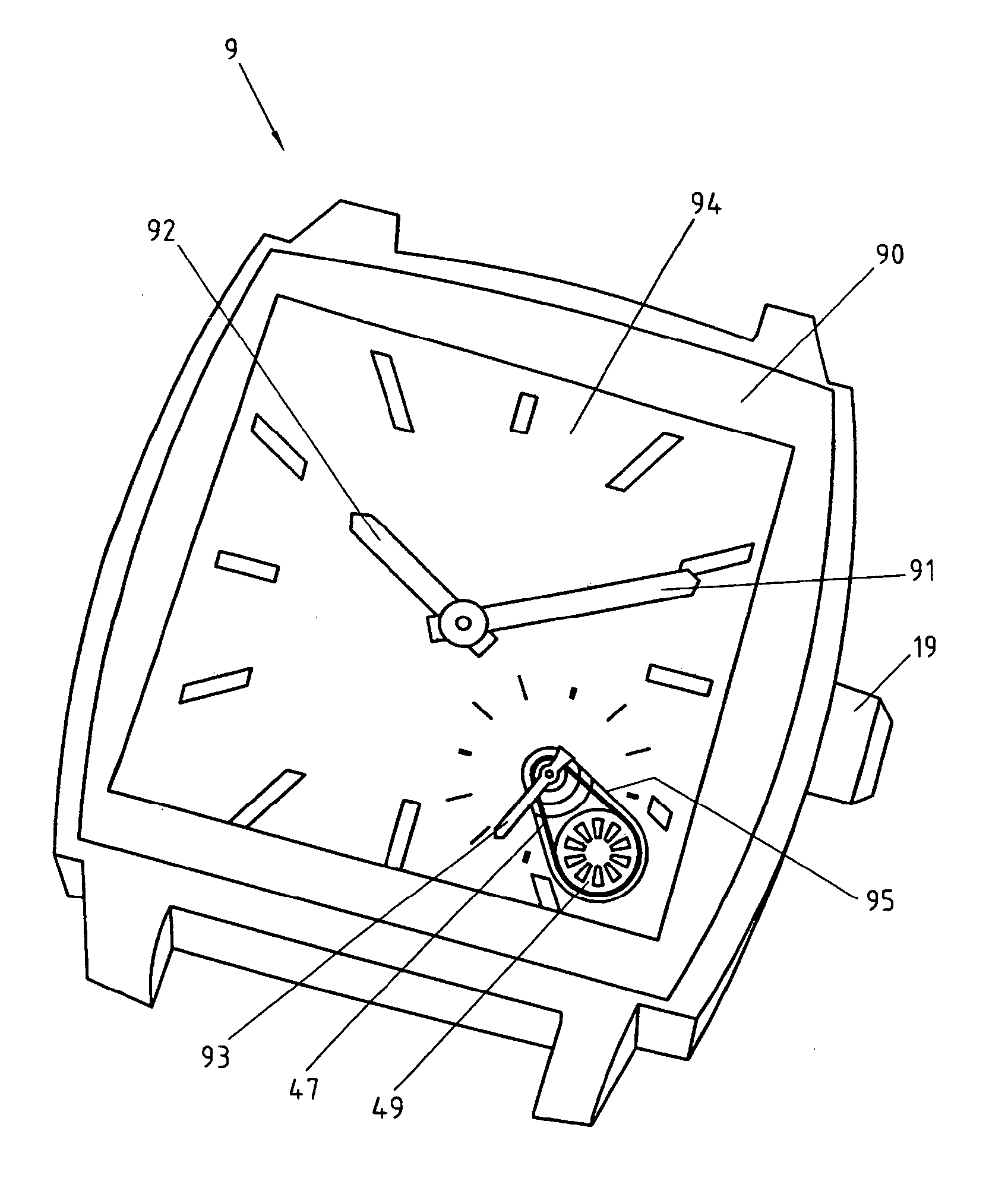

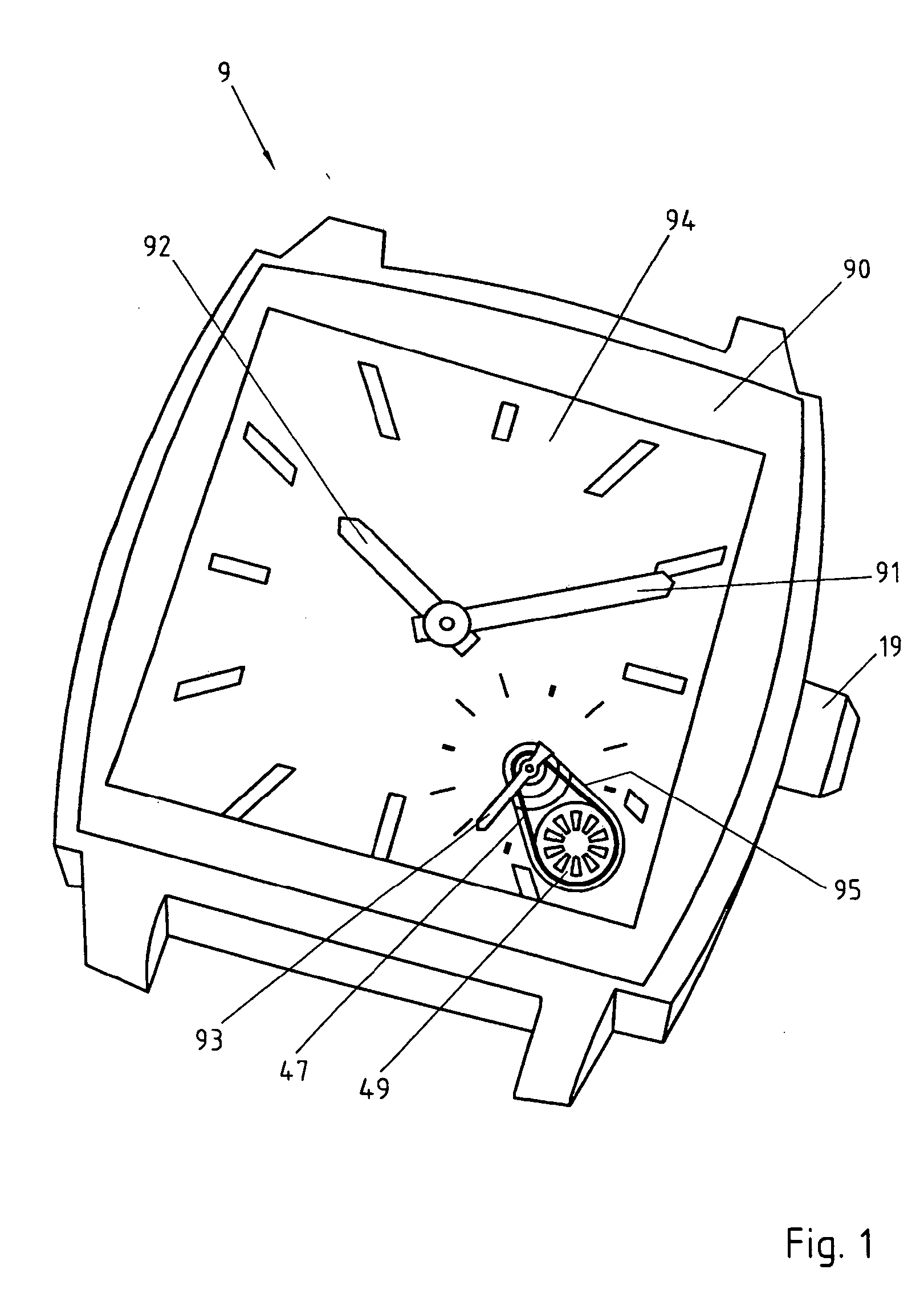

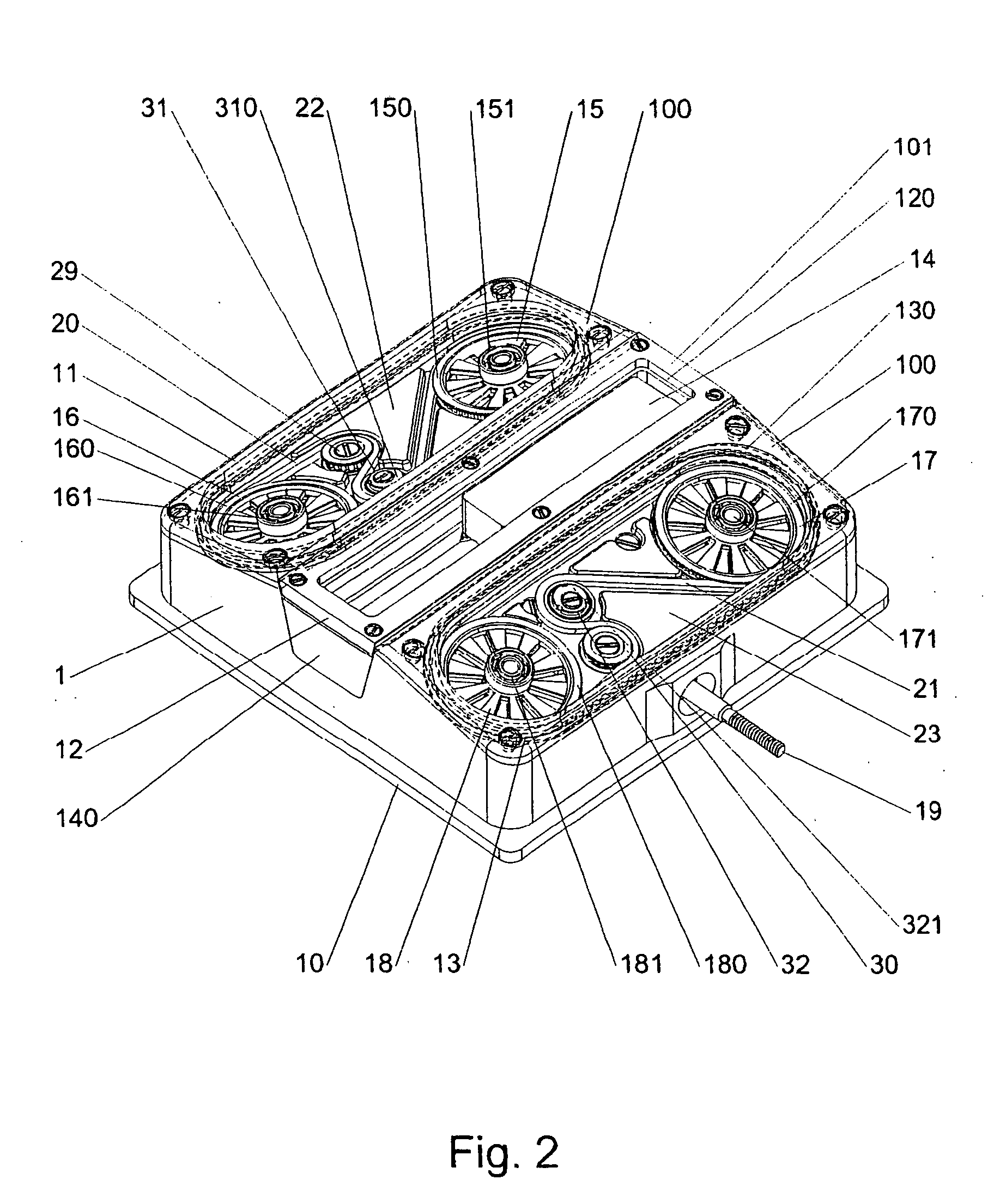

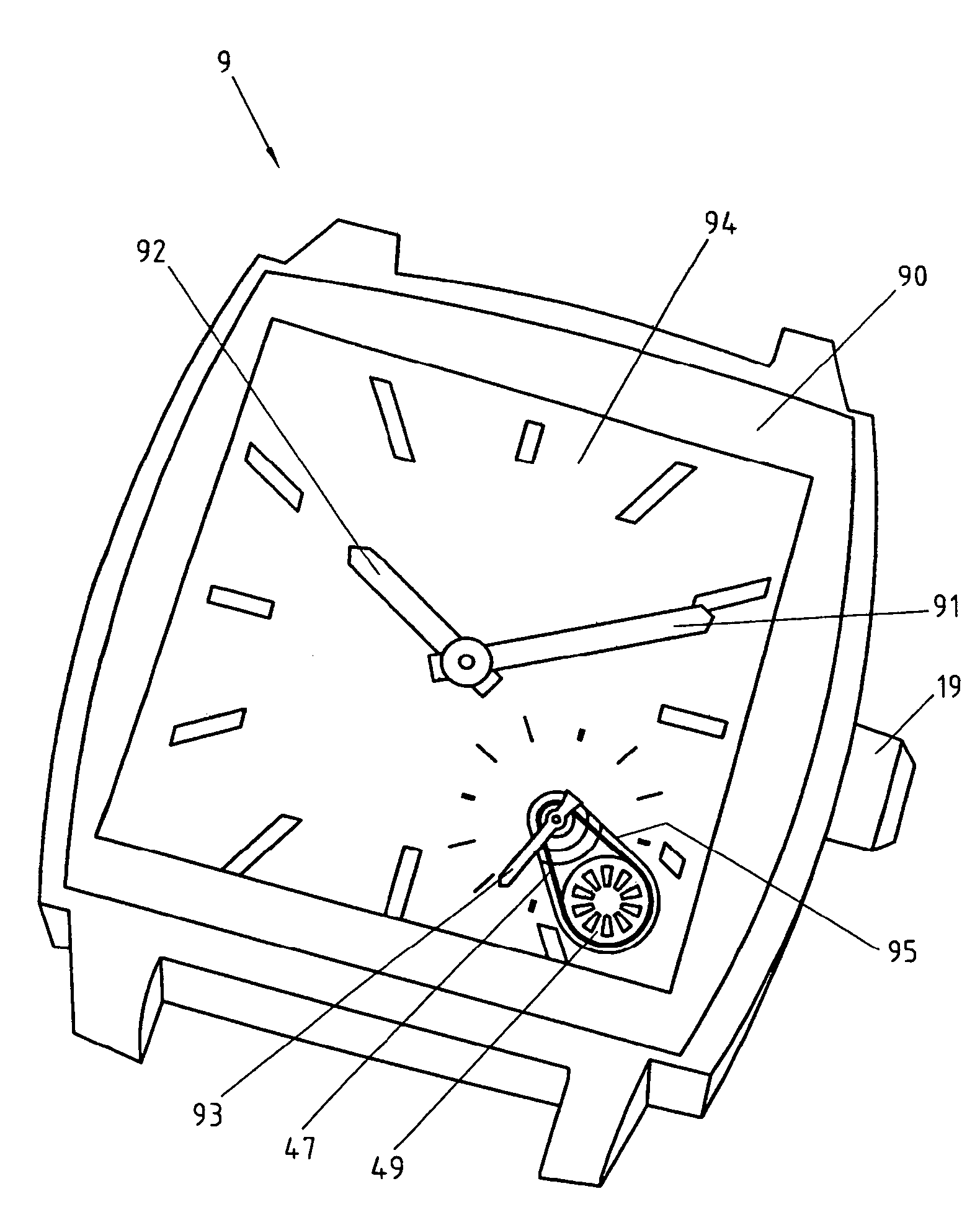

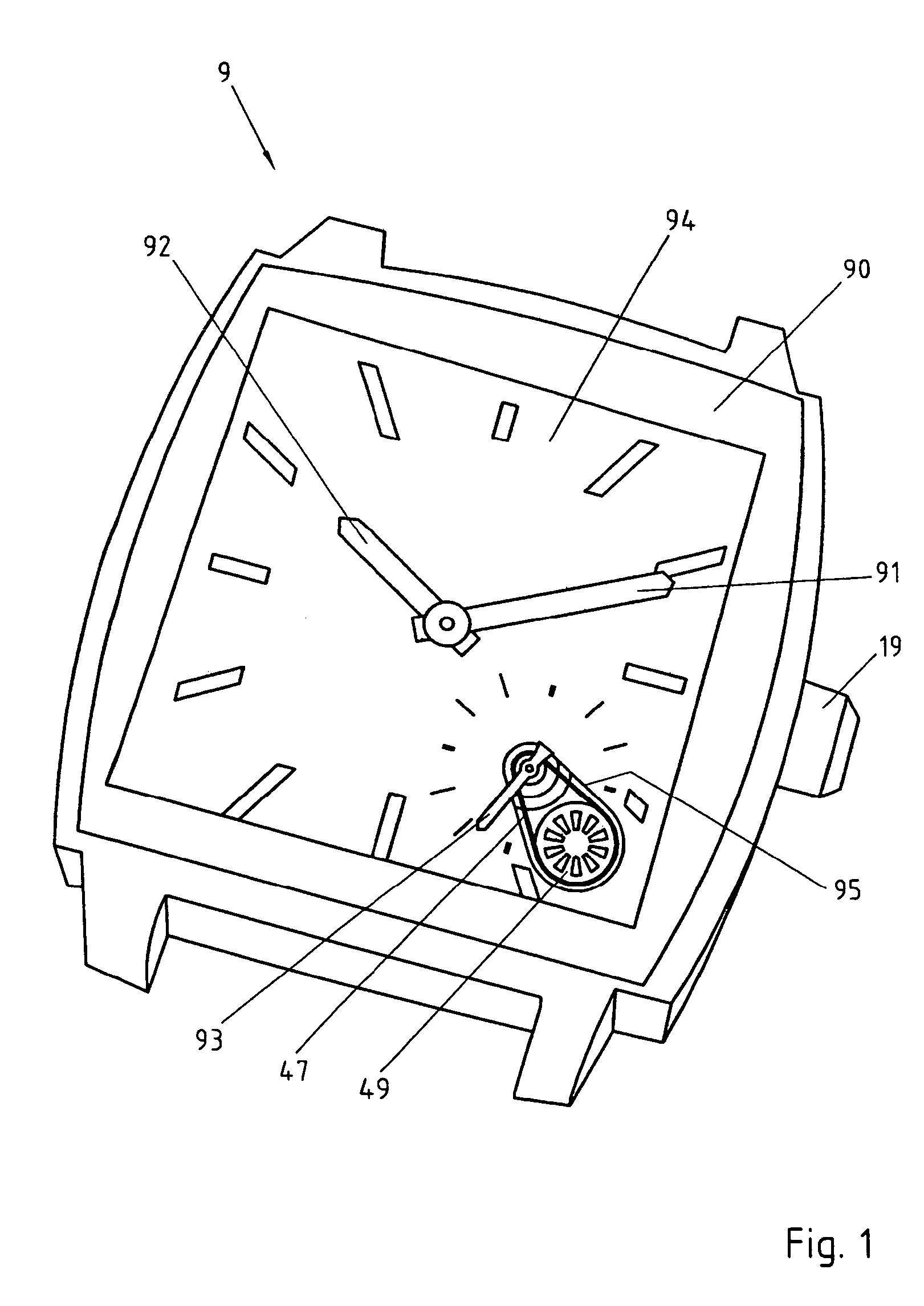

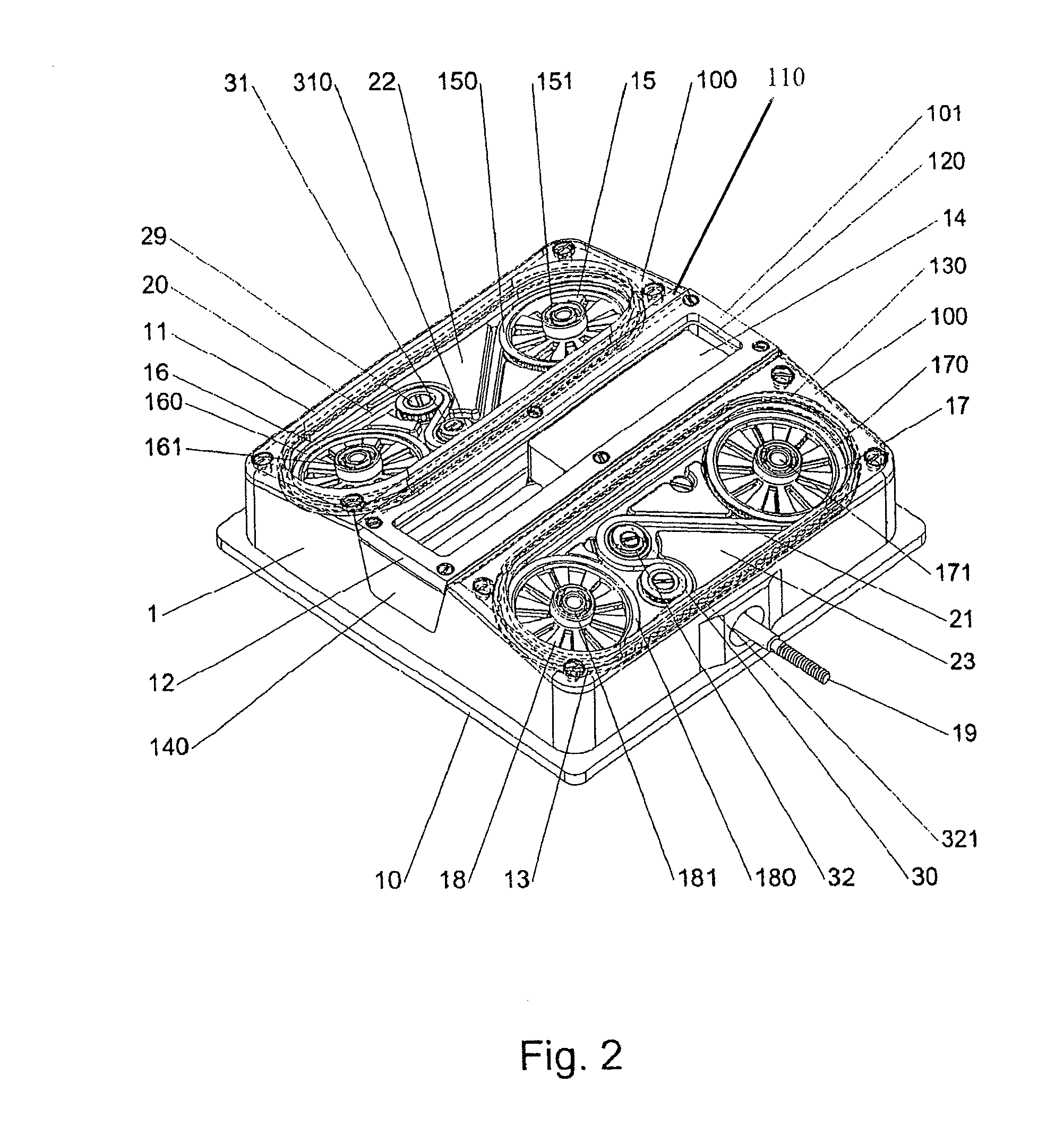

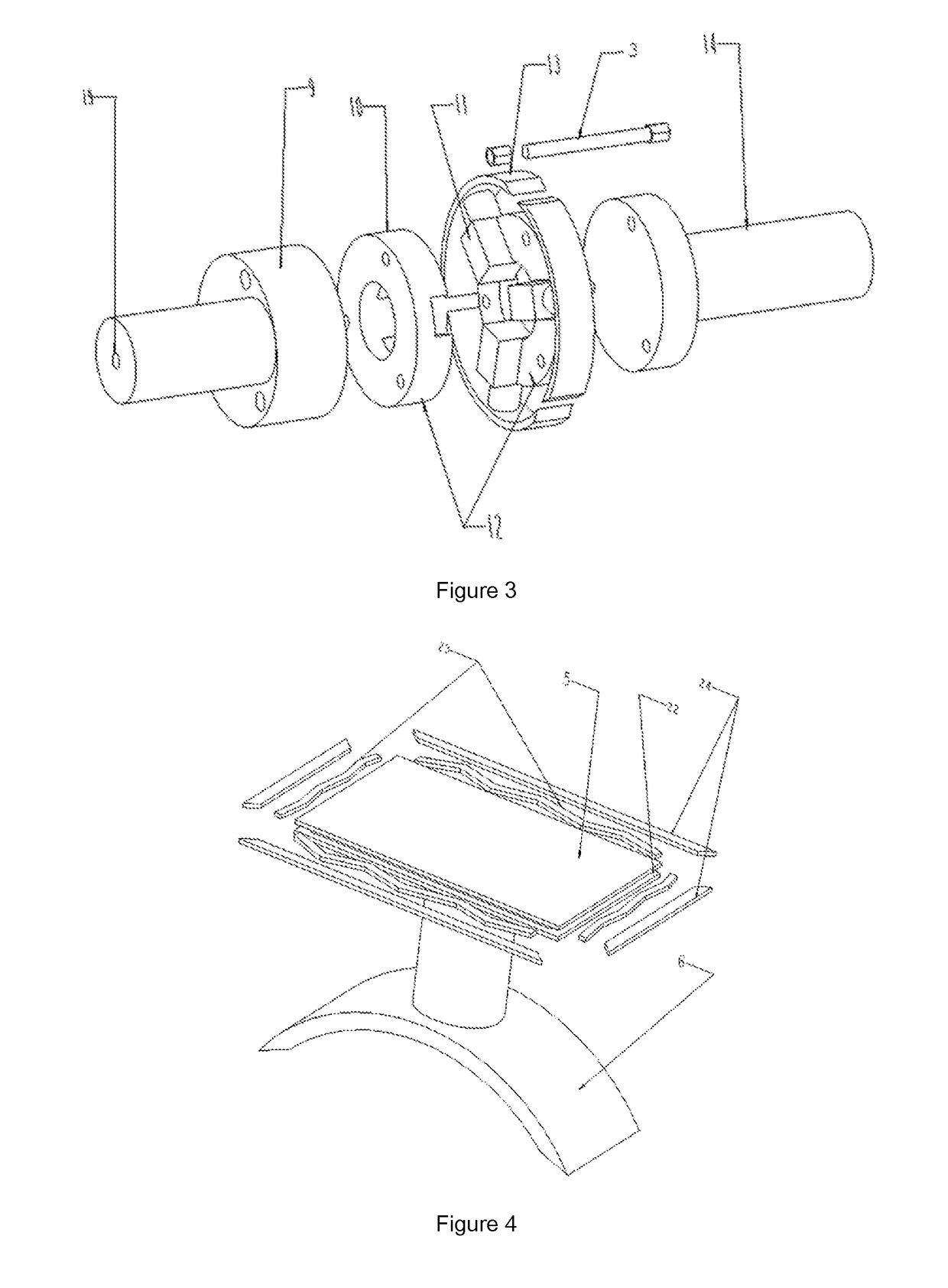

Clockwork movement for a wristwatch

Clockwork movement for a wristwatch, comprising a kinematic chain including at least one belt (20, 21) for transmitting the movements and / or couples between at least two pulleys. The pulleys are held on the bottom plate or the bridges by ball bearings (151, 161, 171, 181). The movement is rewound by means of linear oscillating mass (14) charging four barrels (15, 16, 17, 18) through a couple distributor (40). The barrels are non-parallel to one another. The back cover is covered by inclined glasses (110, 120, 130) allowing the barrels, the linear oscillating mass and at least certain pulleys to be seen. The regulating organ (51) is removable.

Owner:LVMH SWISS MFG SA

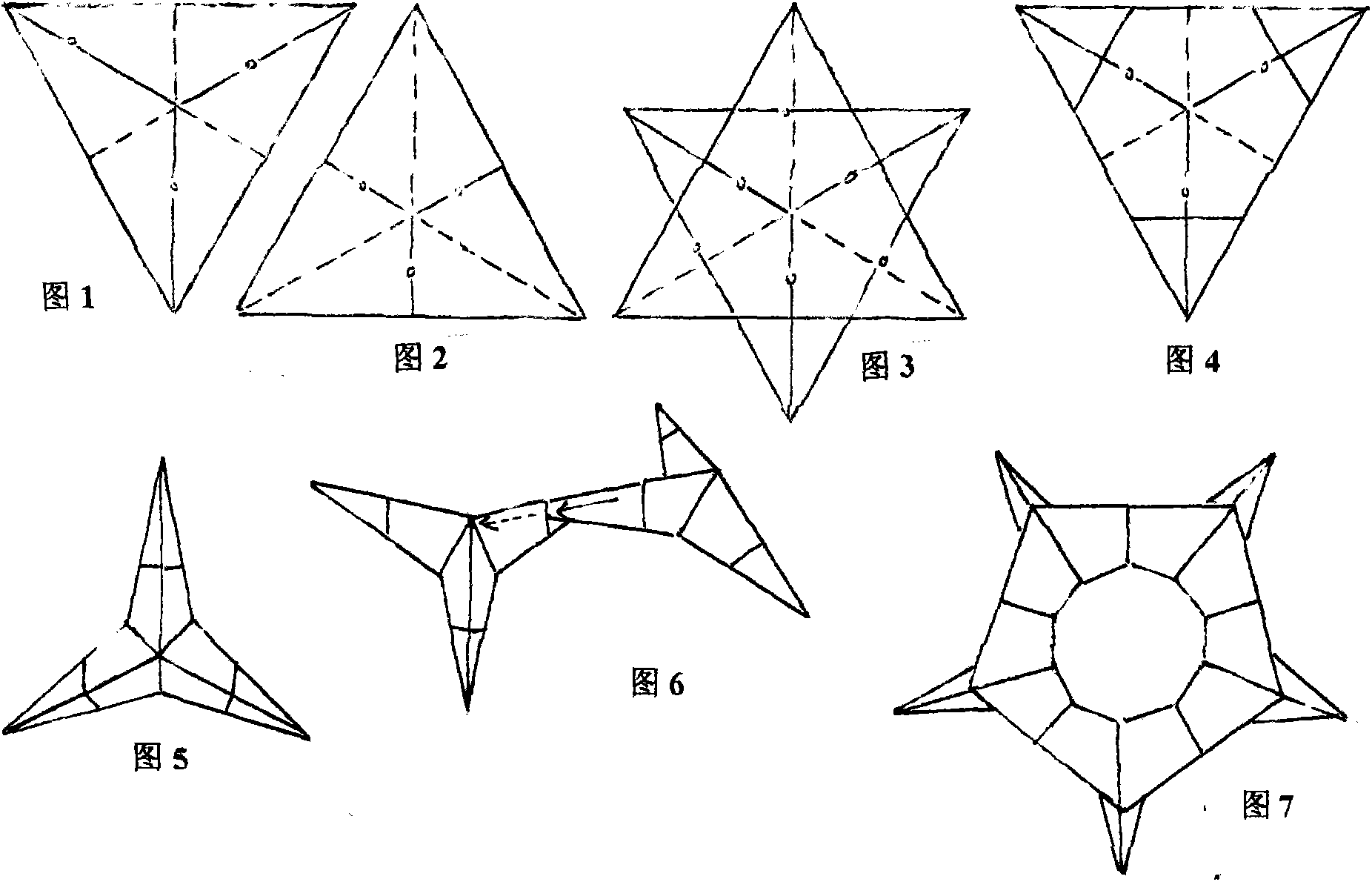

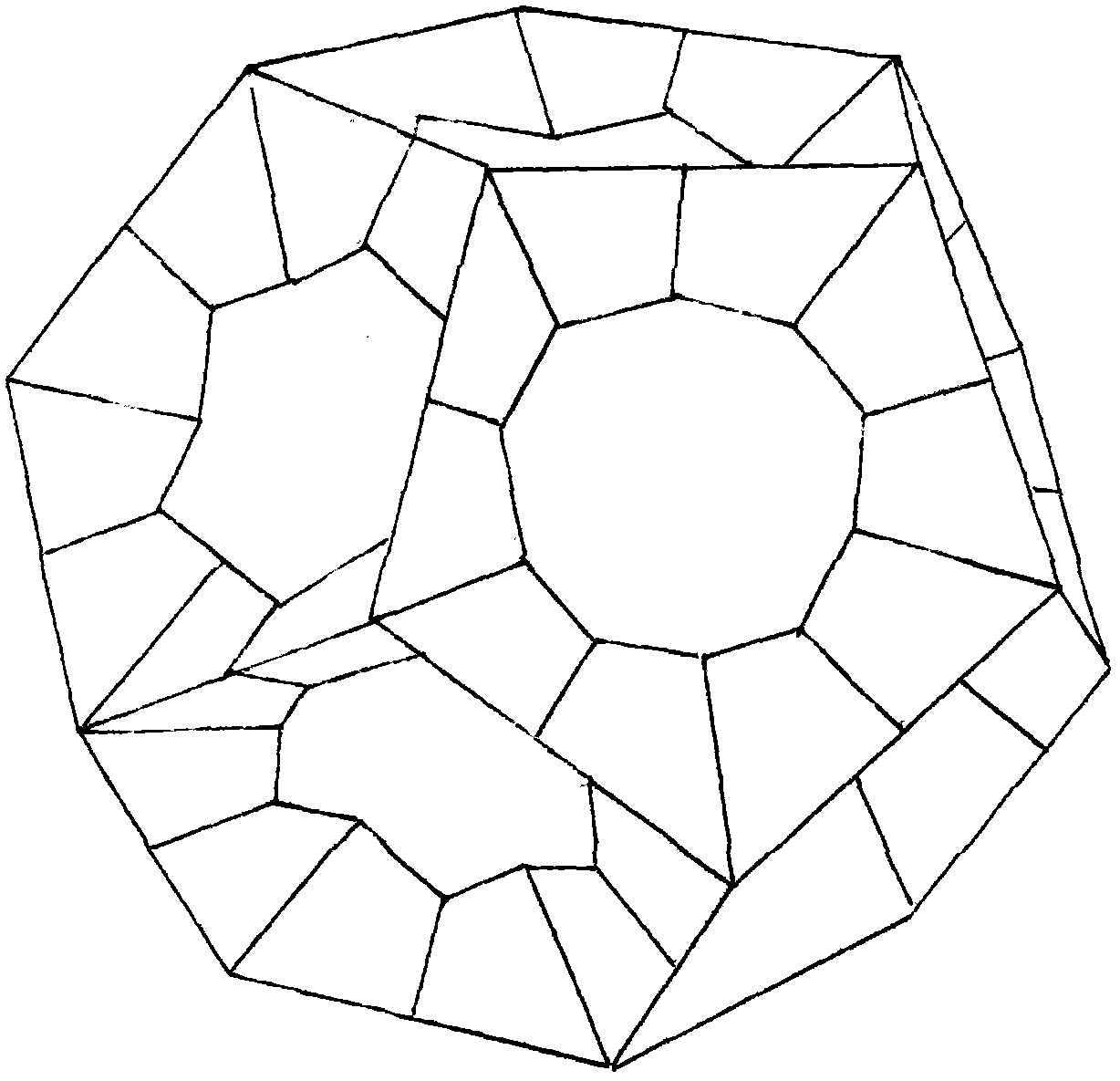

Method for making hollow solid figure

The invention provides a method for making a hollow solid figure, and relates to a method for making paper utensils. The hollow solid figure is formed by connecting 20 identical components inn an inserted mode, and each component is formed by combining an inner part and an outer part; each outer part and the corresponding inner part are combined to form the corresponding component which is provided with an interlayer, and each component is in a new equilateral triangle shape; each component comprises three inserted portions and three inserting portions; the components A, B, C, D and E are inserted circularly to form a regular-pentagon-shaped body; other components are inserted in the same method, five inserted portions and five inserting portions are combined to form one regular-pentagon-shaped body, and a round cube with 12 regular-pentagon-shaped bodies is formed and is the hollow solid figure. By means of the method, design is novel and ingenious, the hollow solid figure is easy to make, the components are easy to combine, the hollow solid figure is formed in an inserted mode uncomplicatedly, and the appearance is peculiar and beautiful.

Owner:YANCHENG SILU INFORMATION TECH SERVICE CO LTD

Integrated medical imaging system

A fiber optic camera system may include a fiber optic camera and a video processing console. The camera may include an elongate sheath having a proximal end and a distal end, and the sheath may contain one or more illumination optical fibers and an imaging bundle having at least one fiber optic clad and multiple fiber optic cores. The camera may further include a camera body fixedly attached to the proximal end of the elongate sheath, and the camera body may contain an imaging sensor optically coupled to a proximal end of the imaging bundle and configured to generate image data and an illumination source optically coupled to proximal ends of the illumination fibers. In some embodiments, the camera body has no connection member for connecting a secondary illumination source to the camera.

Owner:CALCULA TECH

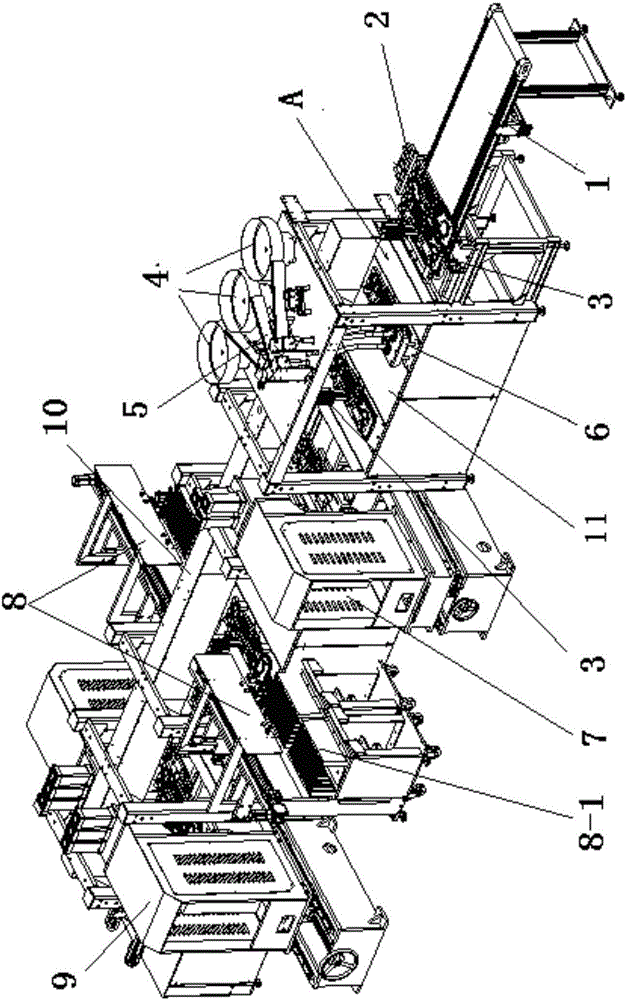

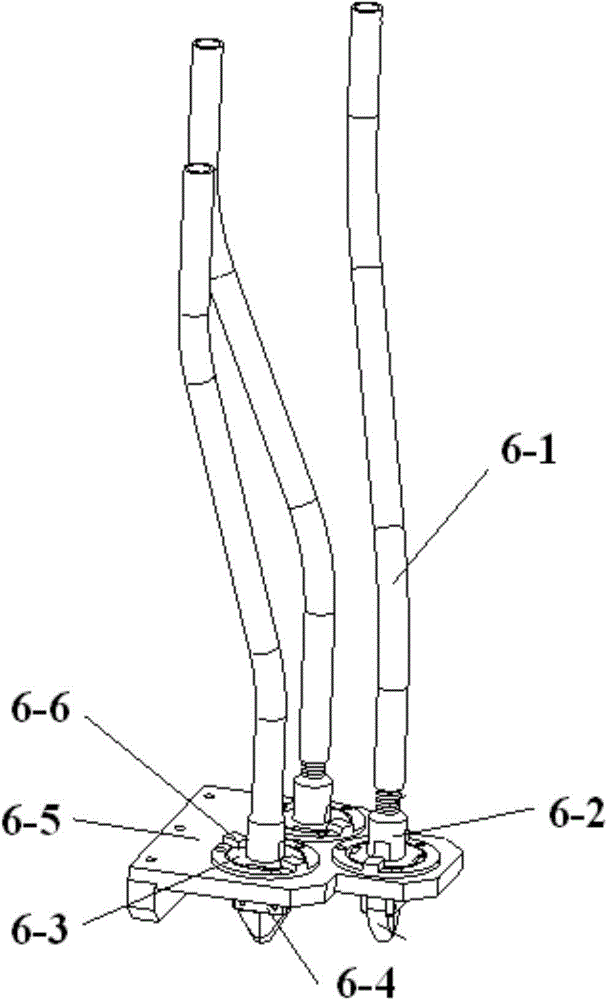

Automatic air conditioner base bolt and base foot welding production system

InactiveCN104858579ARealize automatic weldingSave human effortWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMaterial resources

The invention discloses an automatic air conditioner base bolt and base foot welding production system which comprises a conveying belt and a rack matched with the conveying belt. An air conditioner base plate feeding station, a screw feeding station, a screw welding station, a base foot feeding station and a base foot welding station are sequentially arranged on the rack in the air conditioner base plate machining direction, positioning templates are arranged on the stations, and station manipulators are installed on the rack. The automatic air conditioner base bolt and base foot welding production system is characterized in that the air conditioner base plate feeding station comprises a conveying belt and a correction device; the screw feeding station comprises a vibratory selecting machine, a screw distributor and an automatic bolt feeding device; the screw welding station comprises a screw welding machine; the base foot feeding station comprises an automatic base foot feeding device and a moving feeding trolley; the base foot welding station comprises a base foot double-end welding machine. The automatic air conditioner base bolt and base foot welding production system completely achieves automatic air conditioner base bolt and base foot welding, and the whole system enables labors to be saved, overcomes the shortcoming that the quality of an existing air conditioner base plate cannot be ensured and has the advantages of being capable of saving manpower and material resources, high in production process and free of insufficient solder.

Owner:武汉市博达自动焊接设备有限公司

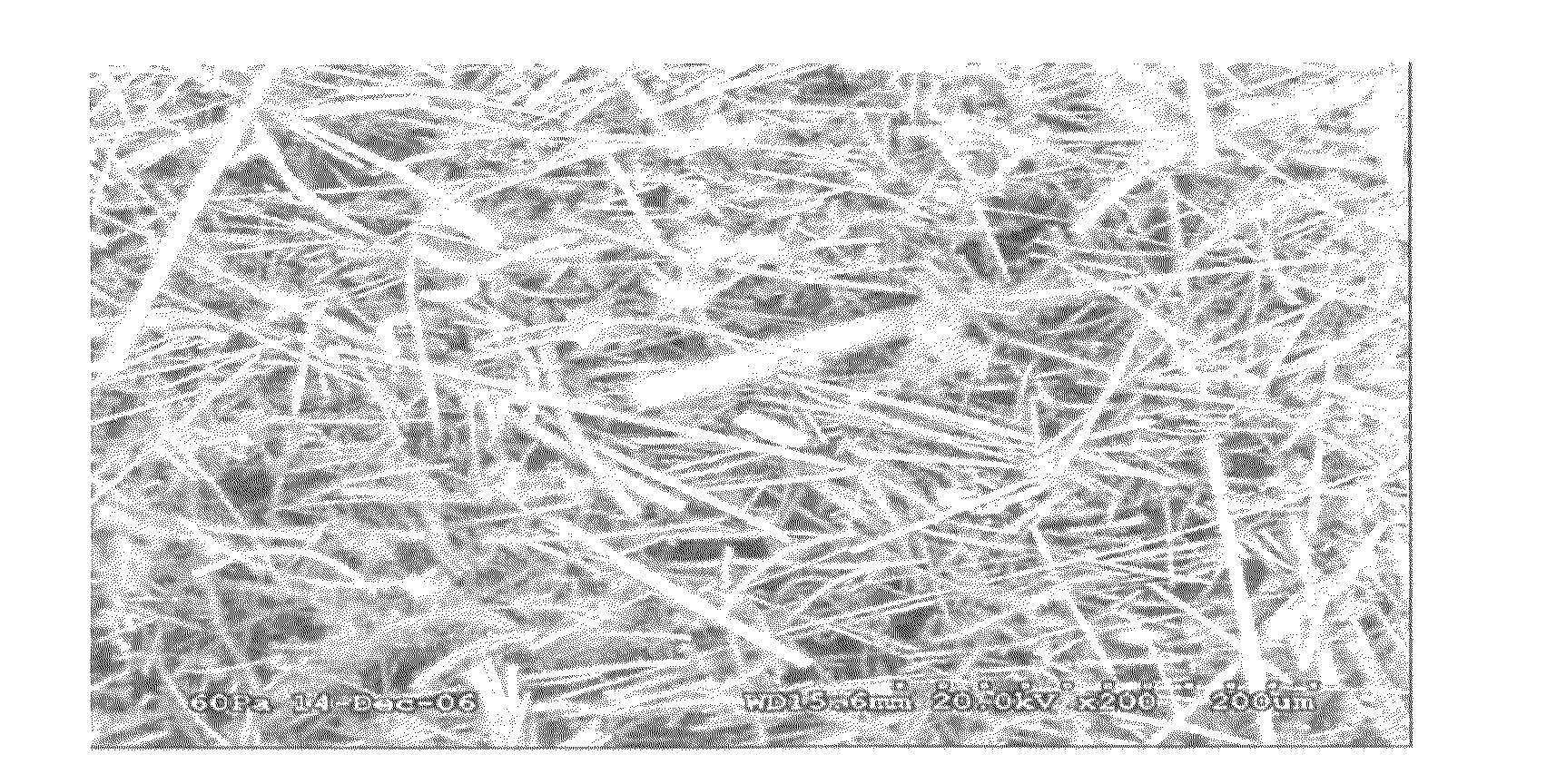

Flexible, porous ceramic composite film

ActiveUS8313853B2Surprising flexibility and handling strengthEasy to cutPrimary cell to battery groupingDeferred-action cellsFiberComposite film

Owner:TDK EDISON LLC

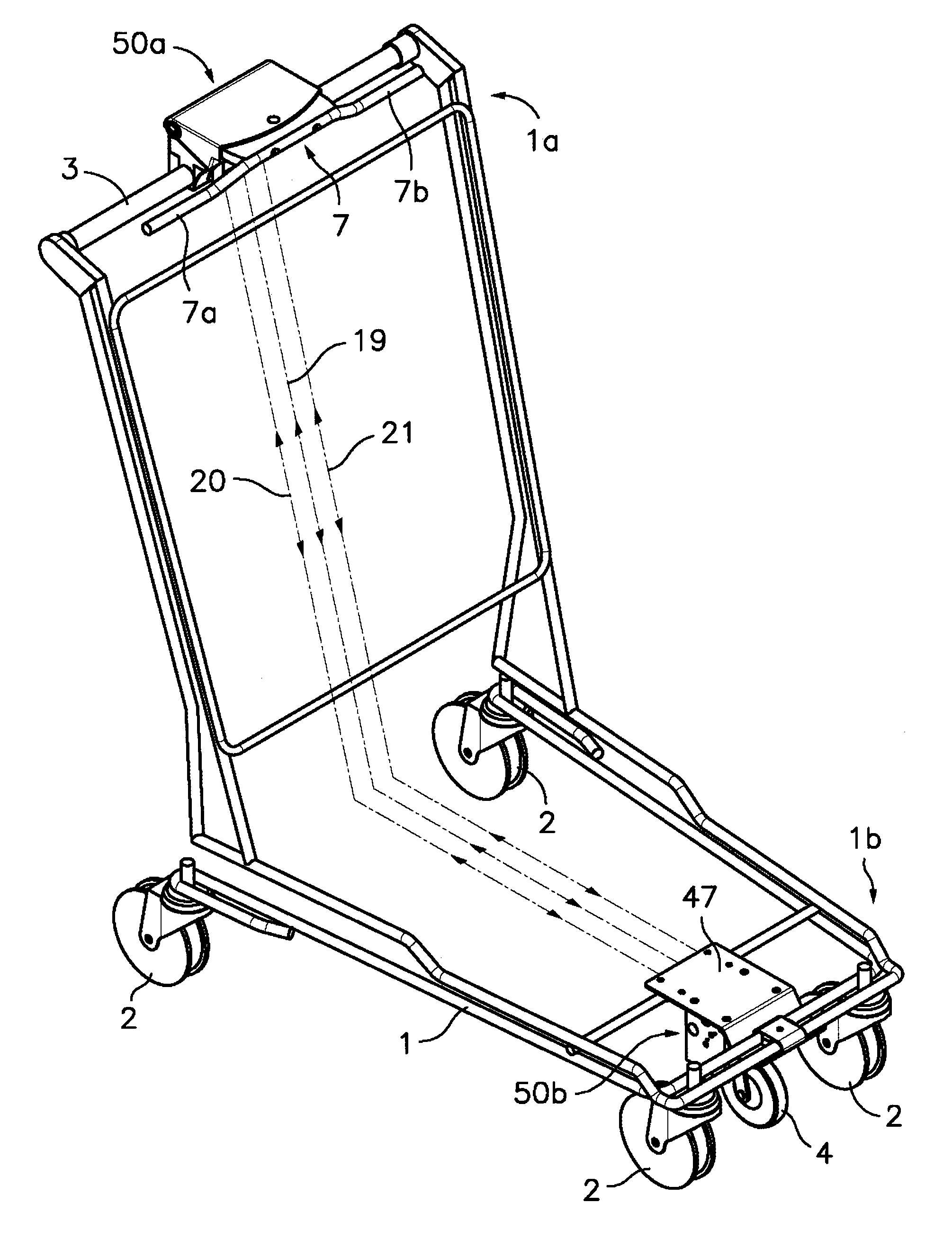

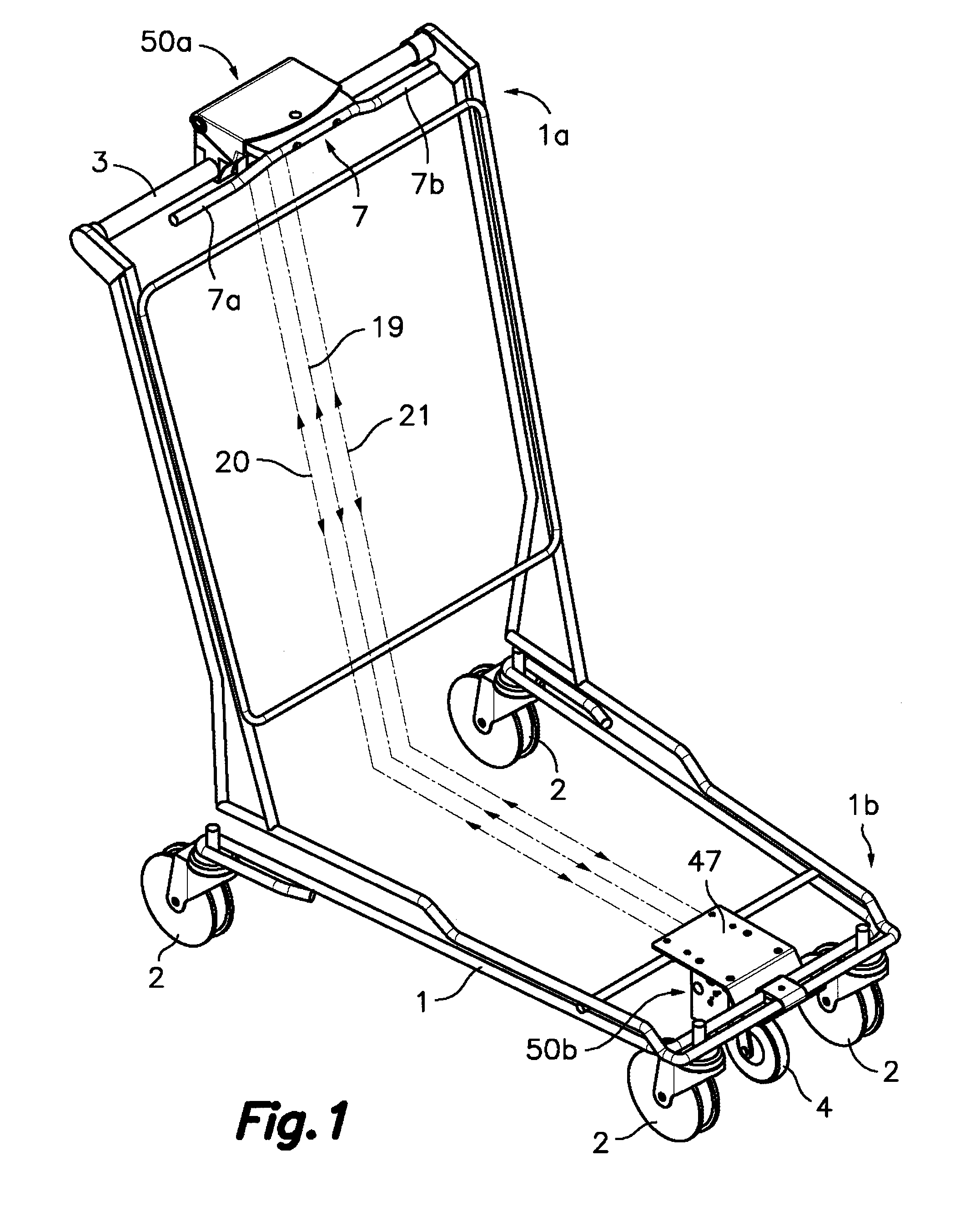

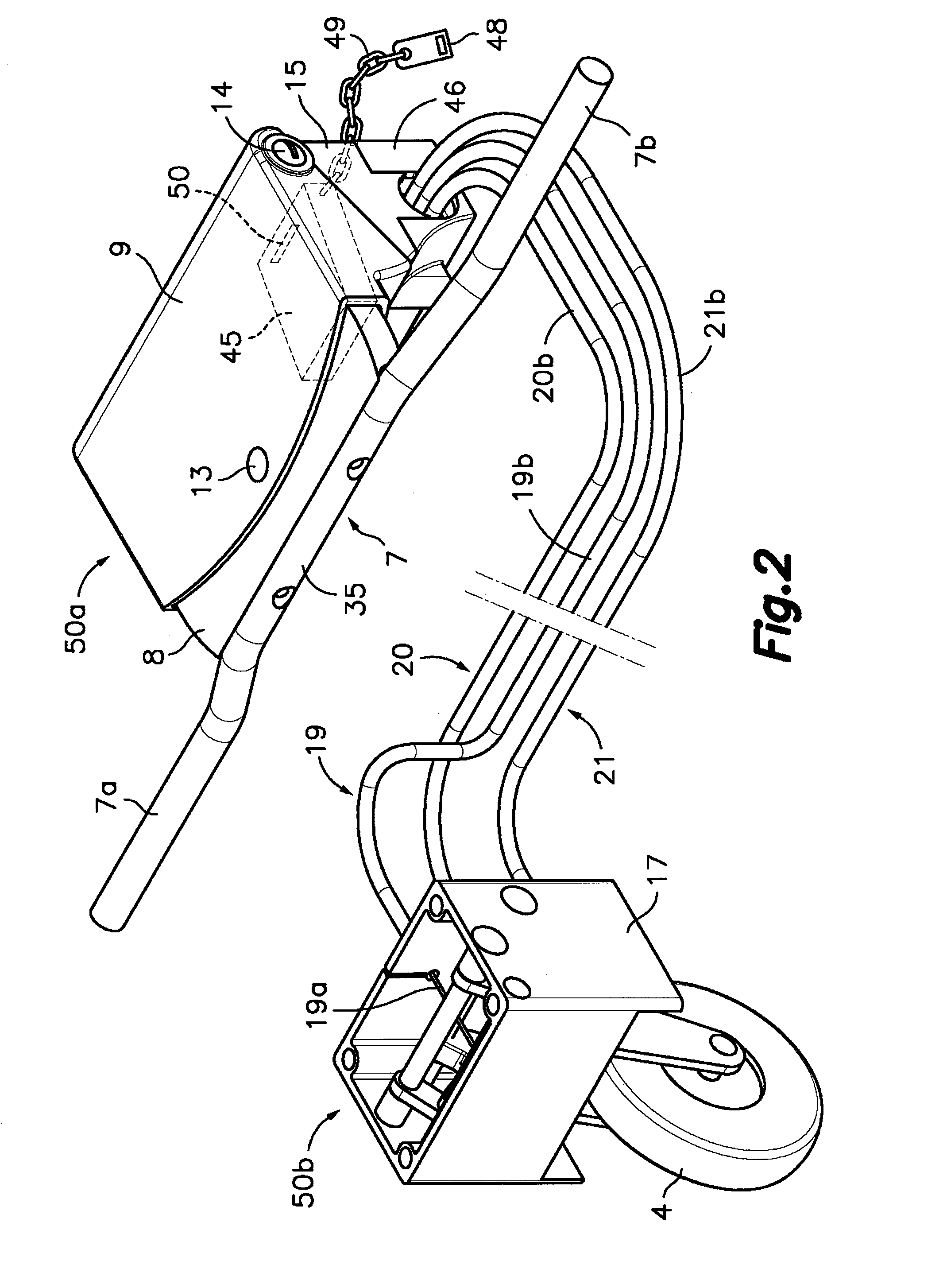

Steering assembly for a human-driven vehicle, and human-driven vehicle

InactiveUS8944441B2Reduce spacingNew designCarriage/perambulator with multiple axesUnderstructuresSteering wheelControl theory

Owner:VAN DIJCK BART

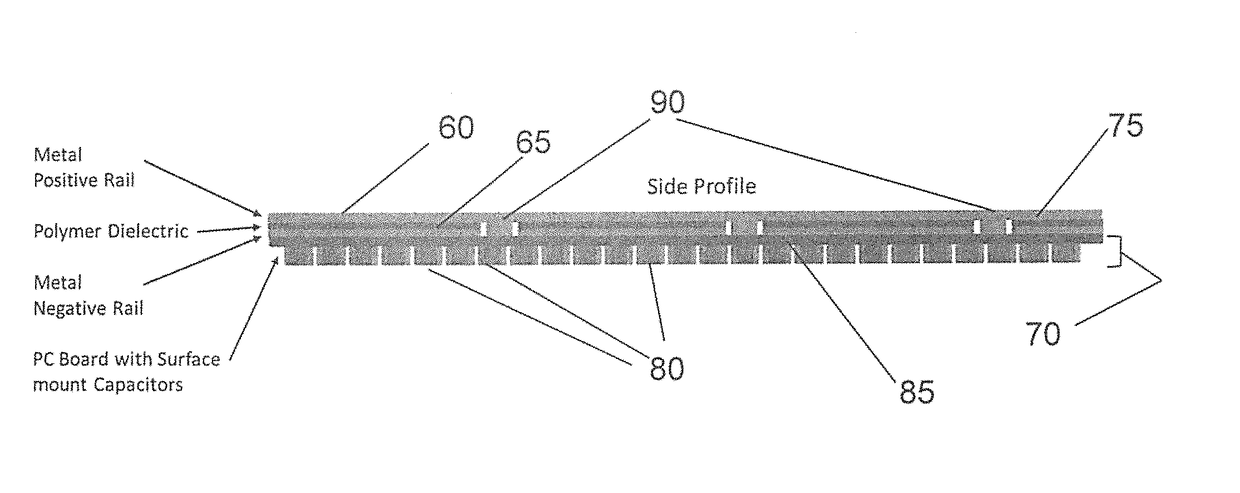

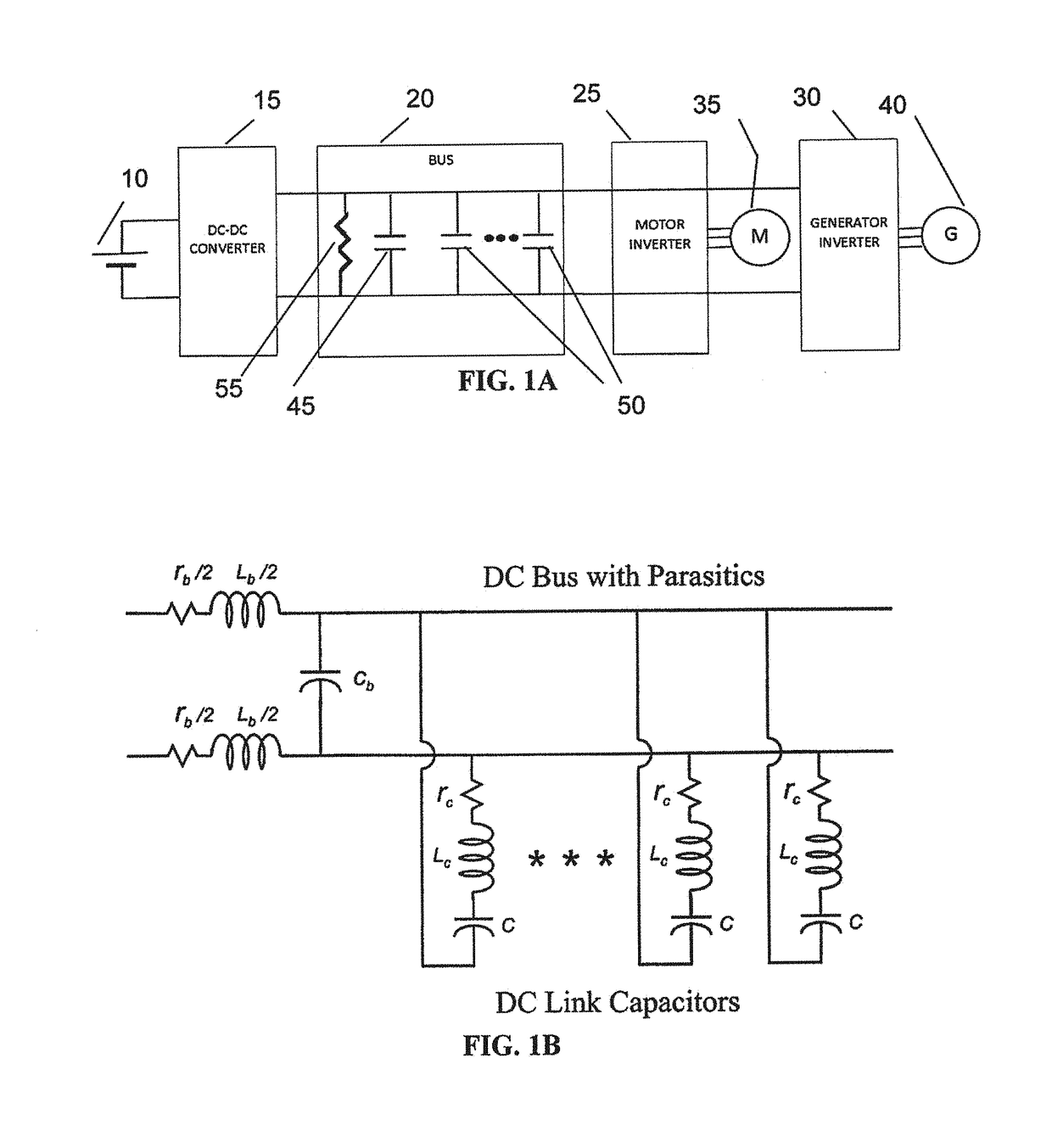

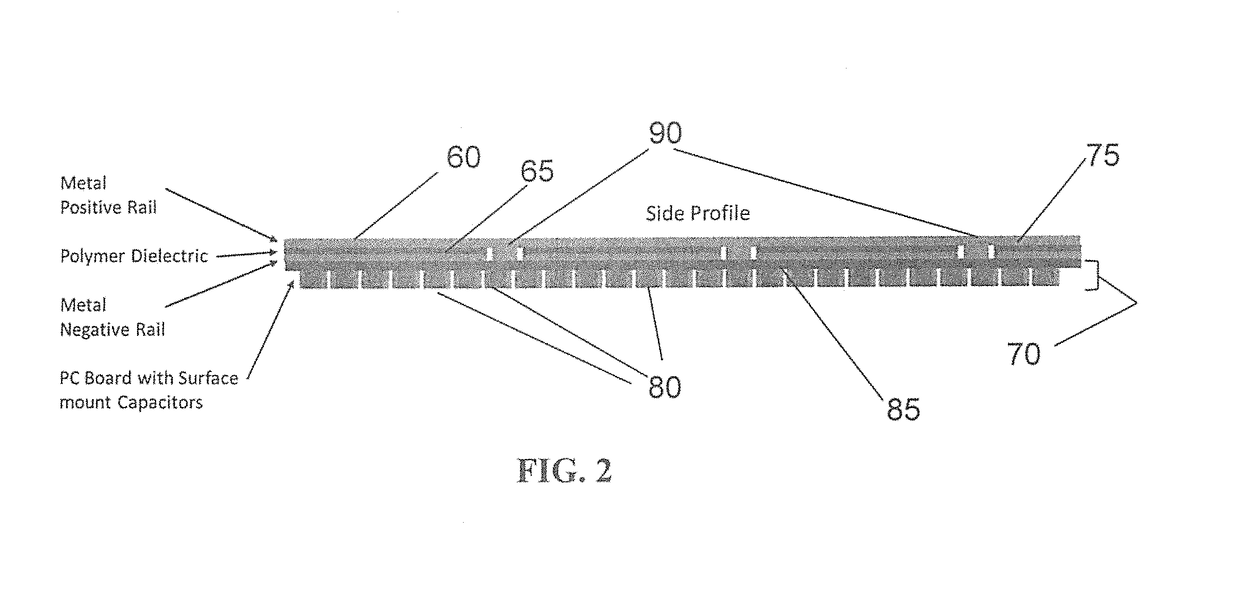

Low-inductance direct current power bus

ActiveUS10084310B1Reduce inductanceIncrease the number ofHybrid vehiclesConversion constructional detailsEngineeringLow inductance

A DC power bus having reduced parasitic inductance and higher tolerable operating temperature is disclosed. In example embodiments, a bus structure overlies a printed circuit board, and an array of capacitors is arranged on a surface of the printed circuit board distal the bus structure. The bus structure comprises an upper metal plate, a lower metal plate, and a dielectric film interposed between the upper and lower metal plates. The capacitors are connected in parallel between conductive planes of the printed circuit board. The upper and lower metal plates of the bus structure are connected to respective conductive planes of the printed circuit board.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

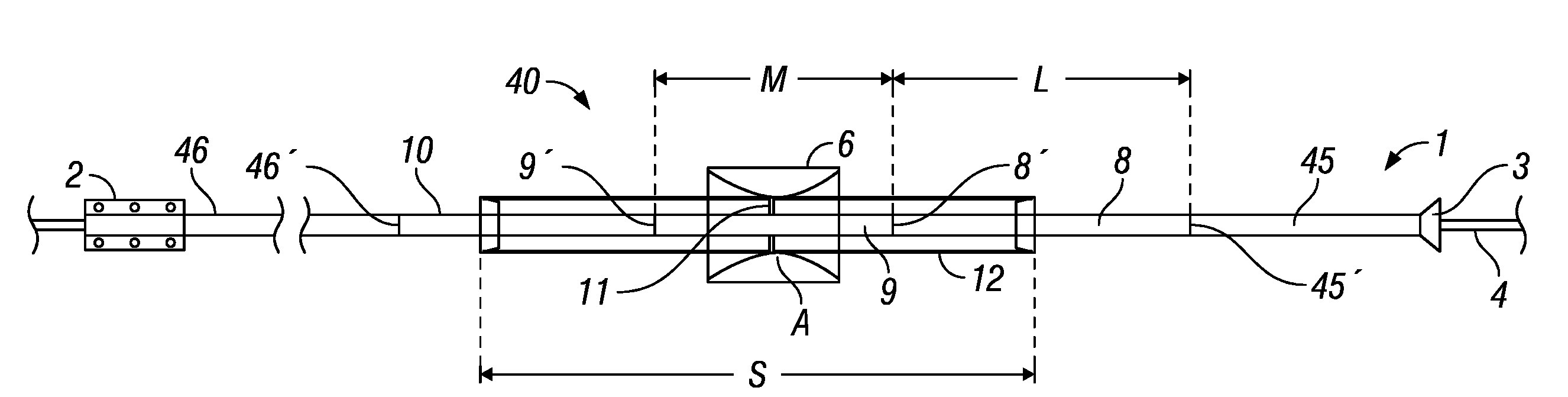

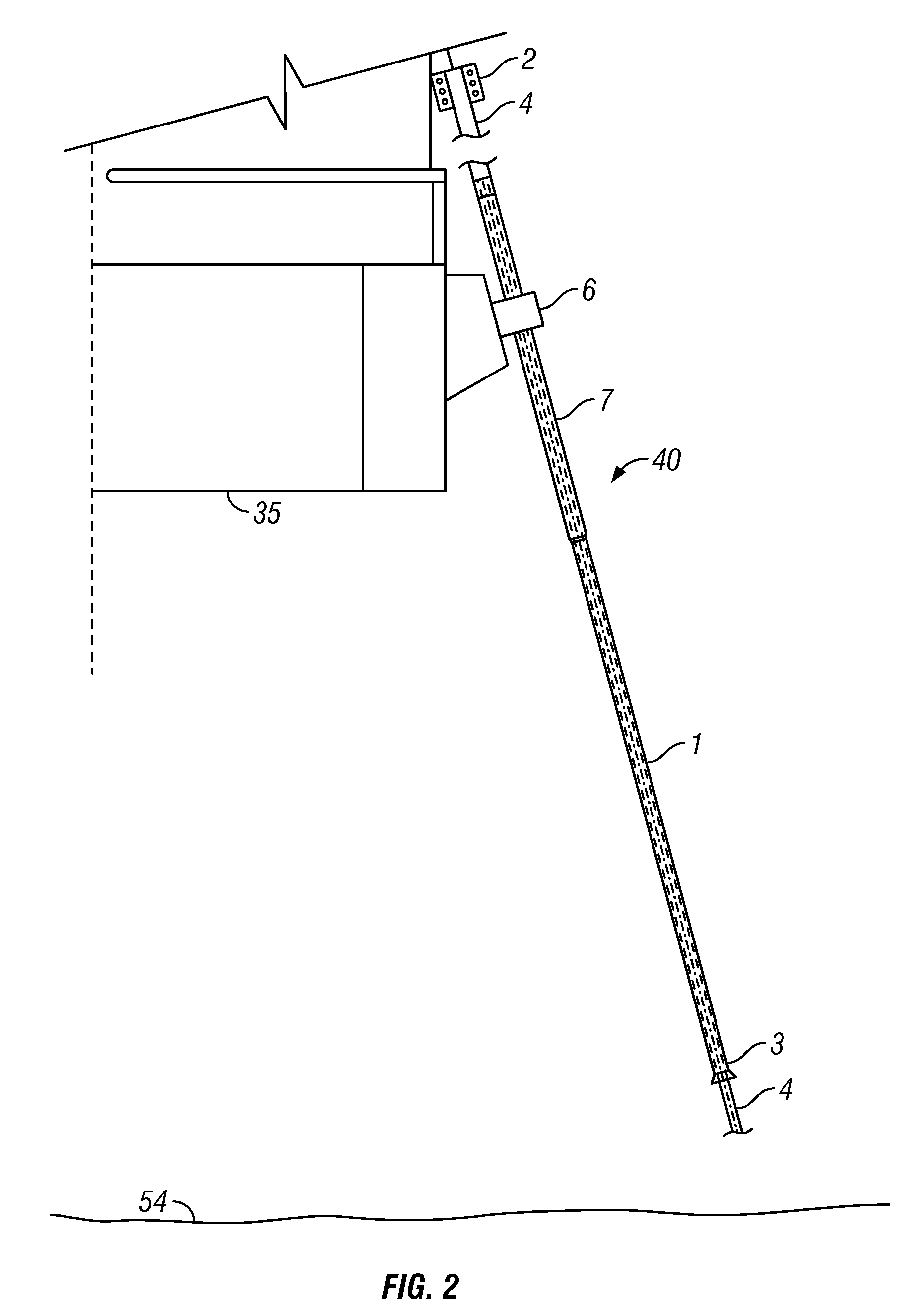

Pull tube sleeve stress joint for floating offshore structure

ActiveUS20110048729A1Minimize welded connectionHigh modulusDrilling rodsFluid removalEngineeringMechanical engineering

The present disclosure provides an improved design for a pull tube sleeved stress joint and associated pull tube for managing stresses on a catenary riser for a floating offshore structure. The pull tube sleeve stress joint includes at least one sleeve surrounding a length of the pull tube with an annular gap between the sleeve and pull tube and a link ring therebetween. For embodiments having a plurality of sleeves, a first sleeve can be spaced by an annular first gap from the pull tube and coupled thereto with a first ring between the pull tube and the first sleeve, and a second sleeve can be spaced by an annular second gap from the first sleeve and coupled thereto with a second ring between the first sleeve and the second sleeve. Both pull tube and sleeves can be made with regular pipe segments welded together with regular girth welds.

Owner:TECH FRANCE SA

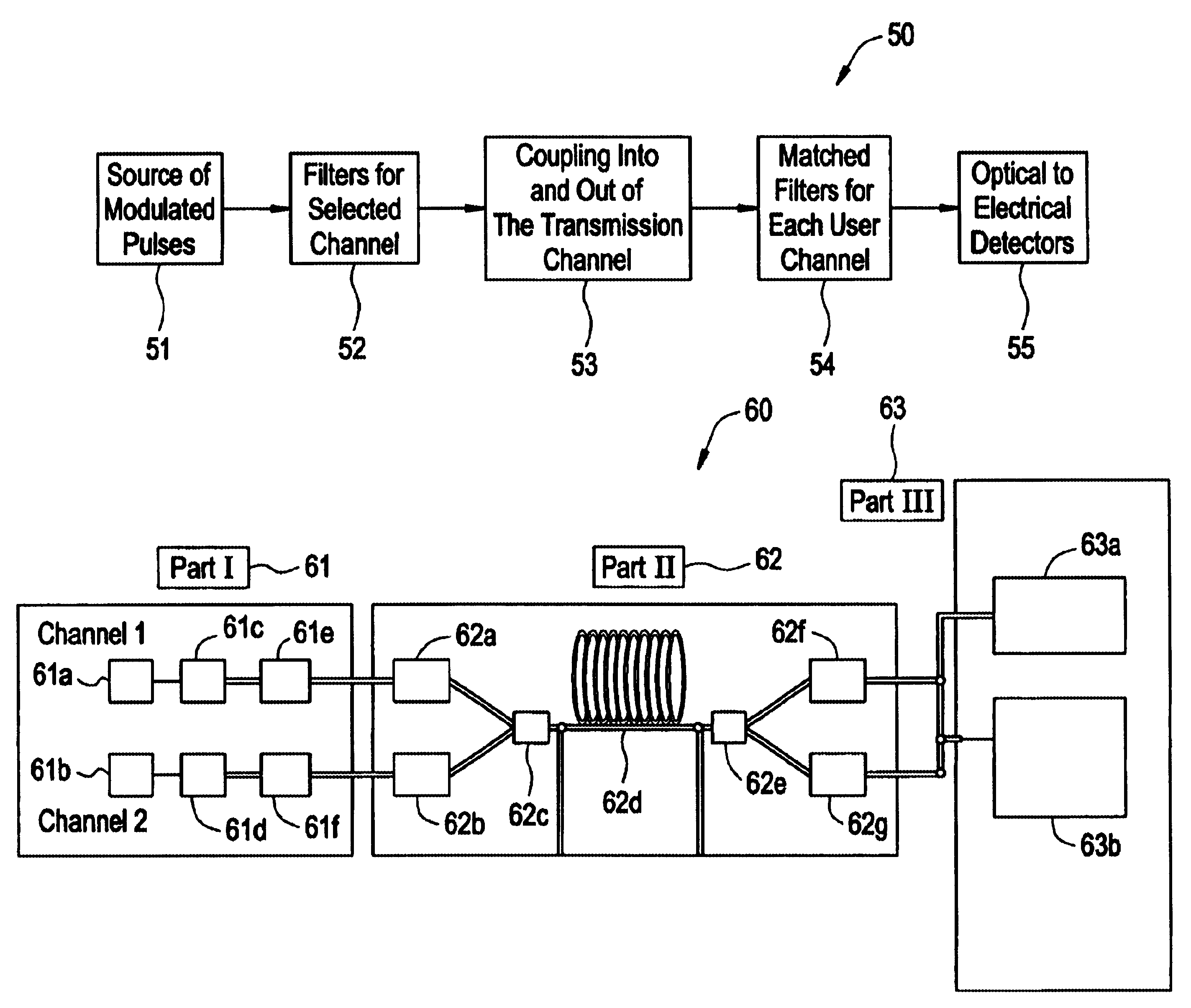

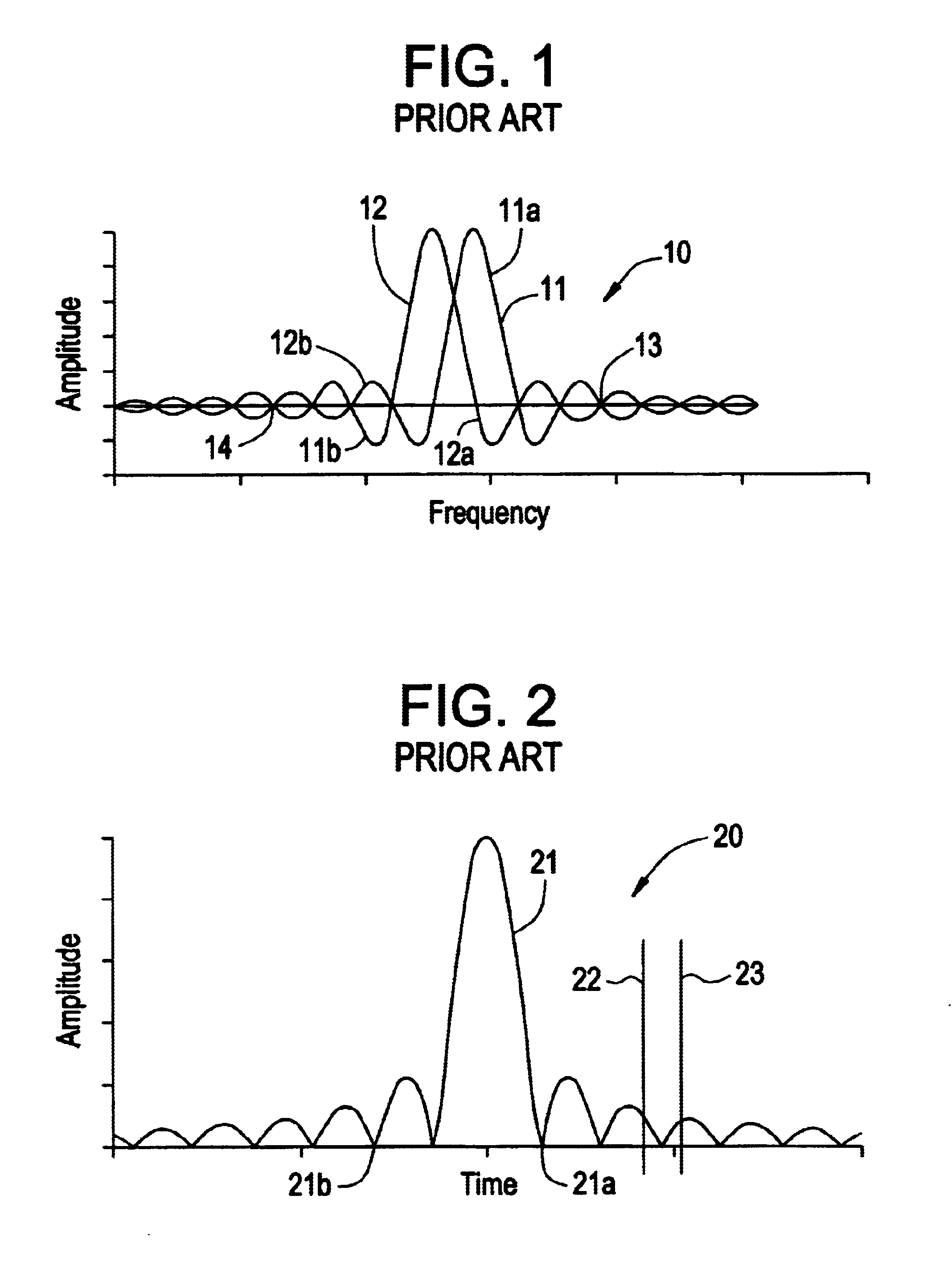

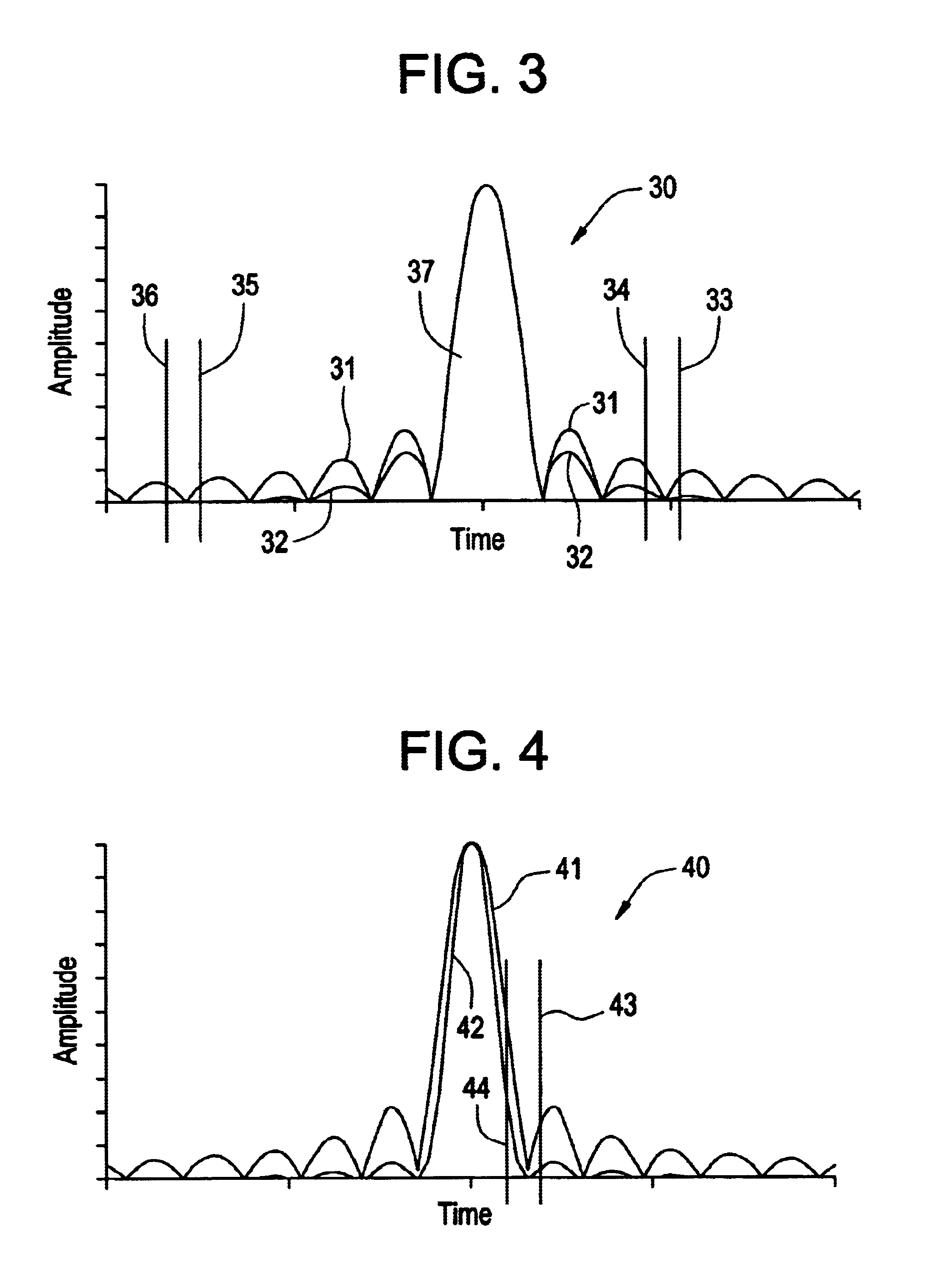

Electromagnetic matched filter based multiple access communications systems

InactiveUS6885713B2Great flexibility and robustness and densityMore bandwidthModulated-carrier systemsWavelength-division multiplex systemsDigital dataMultiplexing

Owner:COMLINK 3000

Sanitary check valve

InactiveUS20080011373A1Rigid enoughNew designCheck valvesEqualizing valvesElastomerClassical mechanics

A check valve adapted for mounting between any flanges and specifically between sanitary flanges in a piping system, the check valve comprising a stationary portion and a flexible portion; the single-piece rigid stationary portion including and supporting a valve seat; the single-piece molded elastomeric flexible portion including a flange gasket, a valve plug, flexible retaining arms for guiding and securing the valve plug movement with respect to the valve seat, and a visual means to indicate that the check valve is installed, permits flow in the desired direction, and is drainable; the check valve being fully cleanable and sterilizable in situ by flow-through methods and having at least one embodiment that is fully drainable when mounted in any orientation.

Owner:ZELSON LARRY SAUL

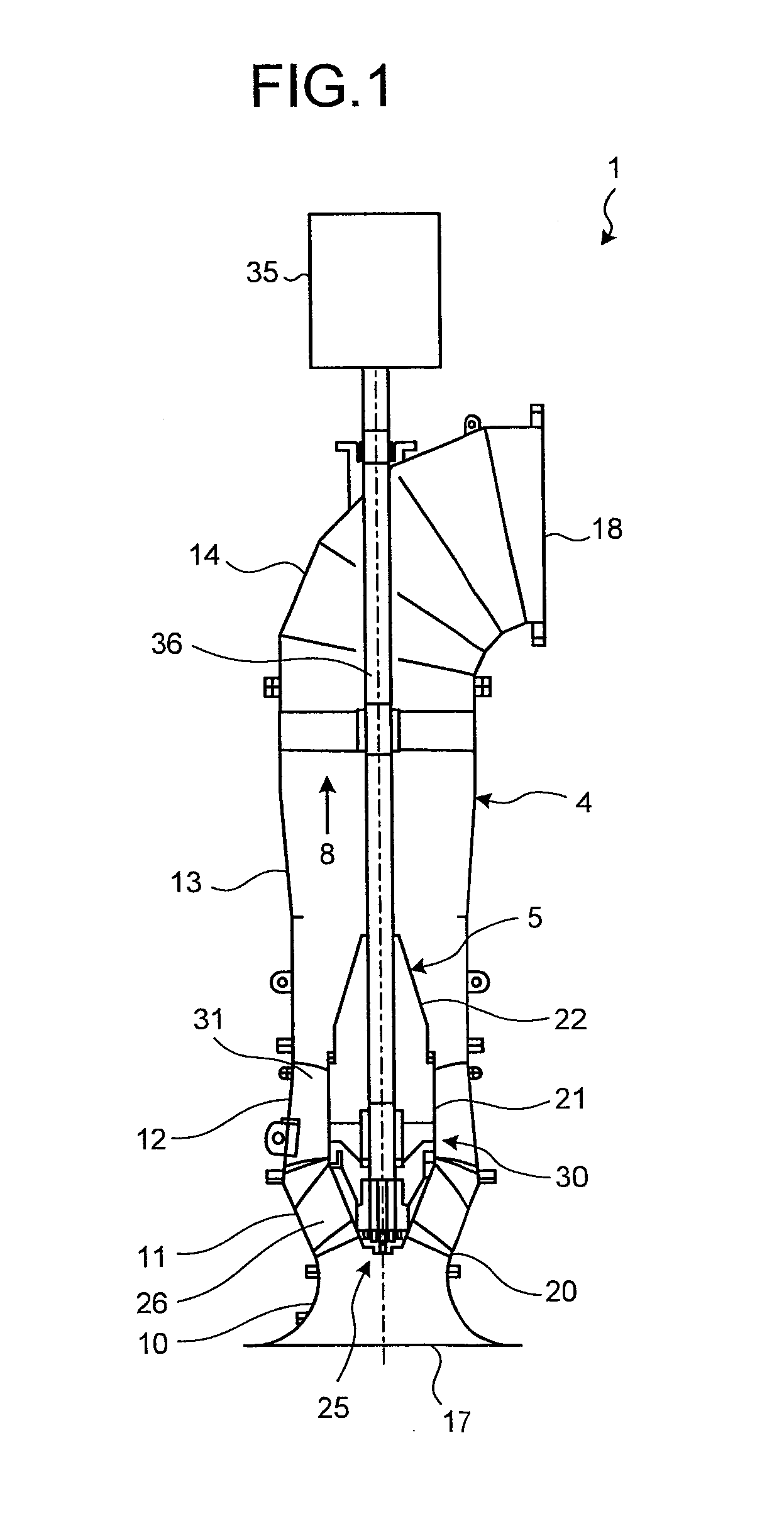

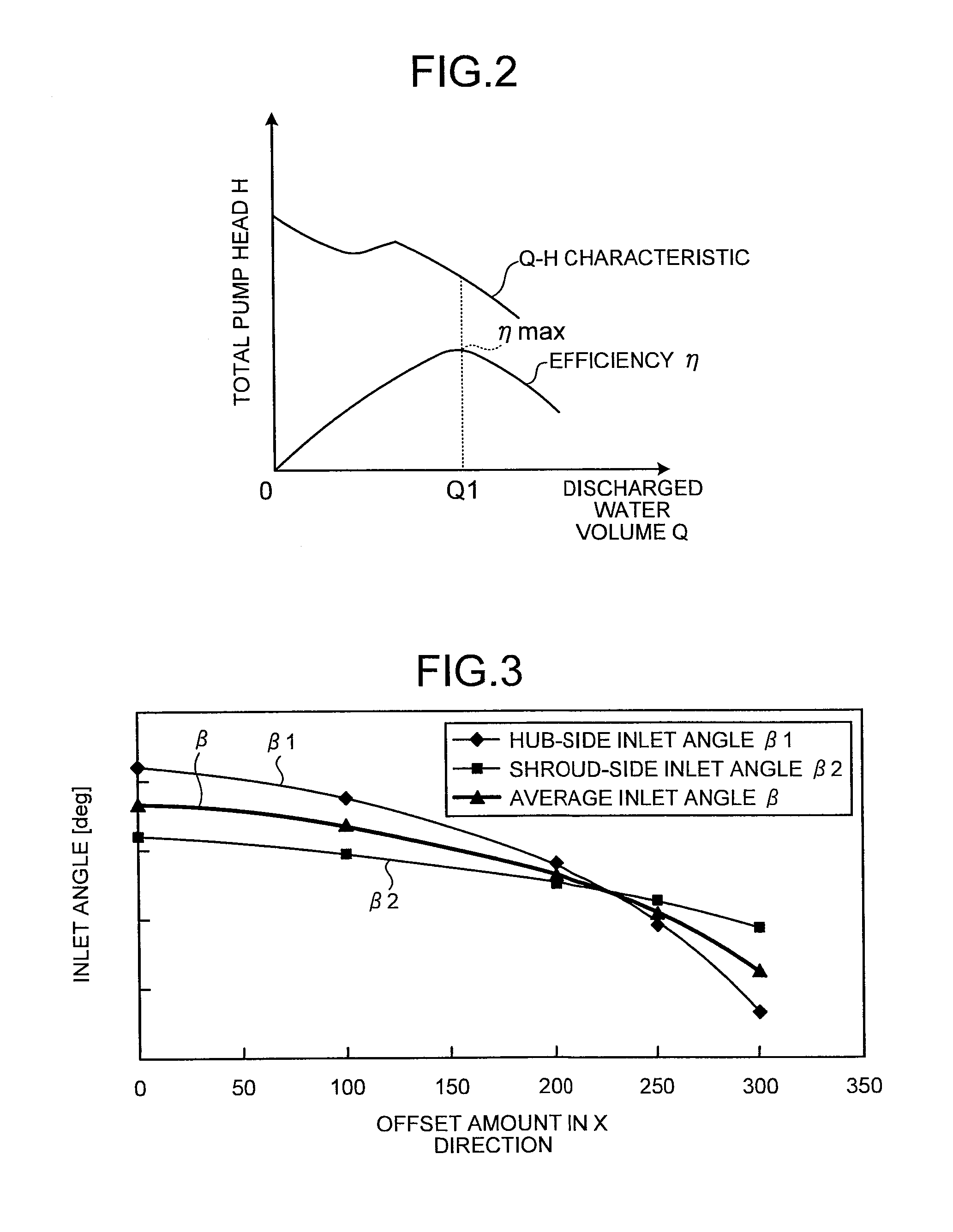

Method of setting performance characteristic of pump and method of manufacturing diffuser vane

To provide a method of setting a performance characteristic of a pump for setting a performance characteristic of a pump, the pump including an impeller that takes in fluid from a suction port and that sends out the fluid toward a discharge port, and a diffuser provided in a flow passage between the impeller and the discharge port, where the diffuser includes a hub arranged in a central portion of the flow passage, a shroud arranged around a periphery of the hub, and a plurality of diffuser vanes radially arranged from an outer peripheral surface of the hub toward an inner peripheral surface of the shroud, and the method includes a mounting-position setting step of setting a mounting position of each of the diffuser vanes to be mounted on the hub according to the performance characteristic of the pump in a direction perpendicular to a radial direction extending from the hub toward the shroud.

Owner:MITSUBISHI HEAVY IND LTD

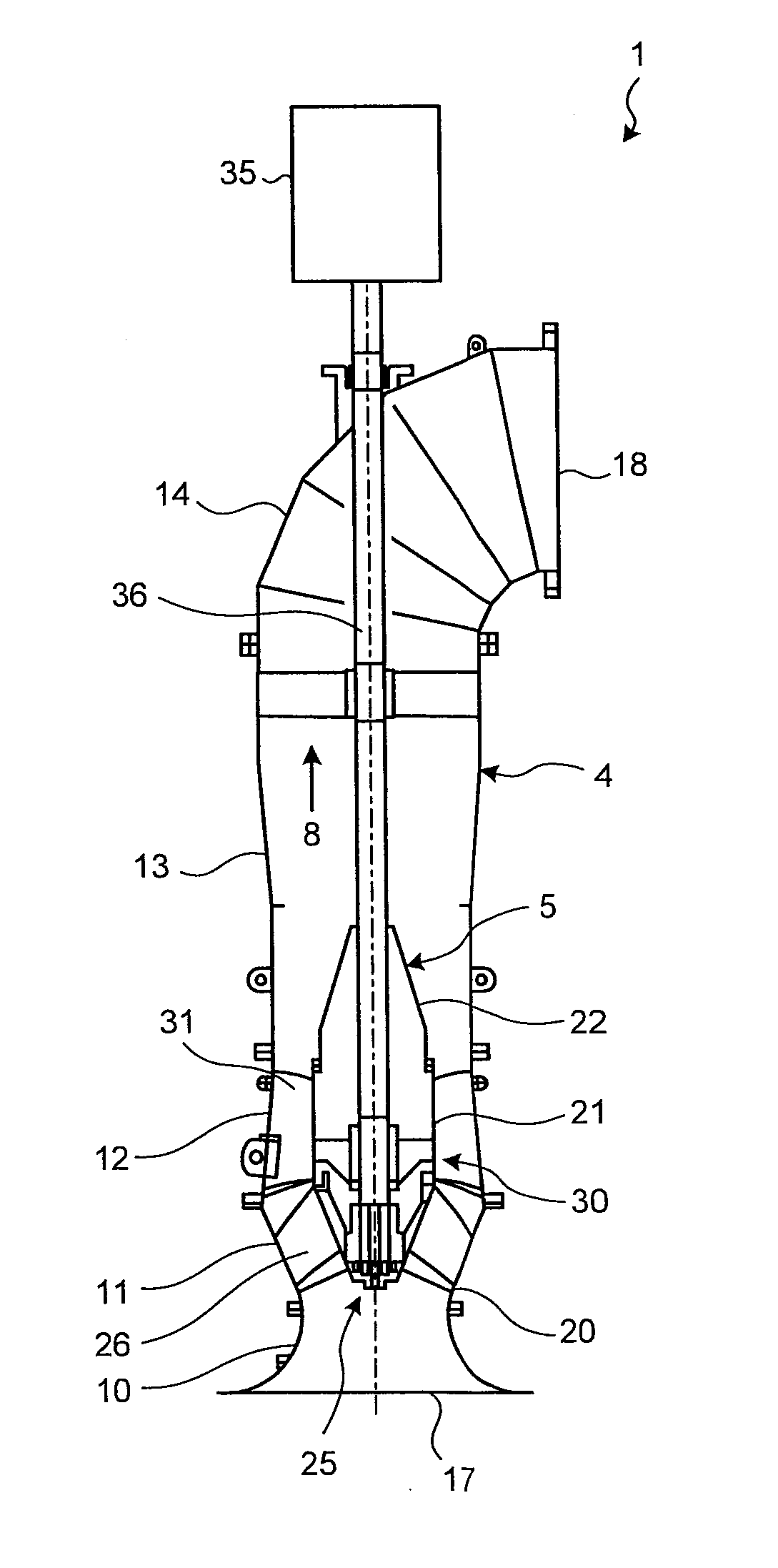

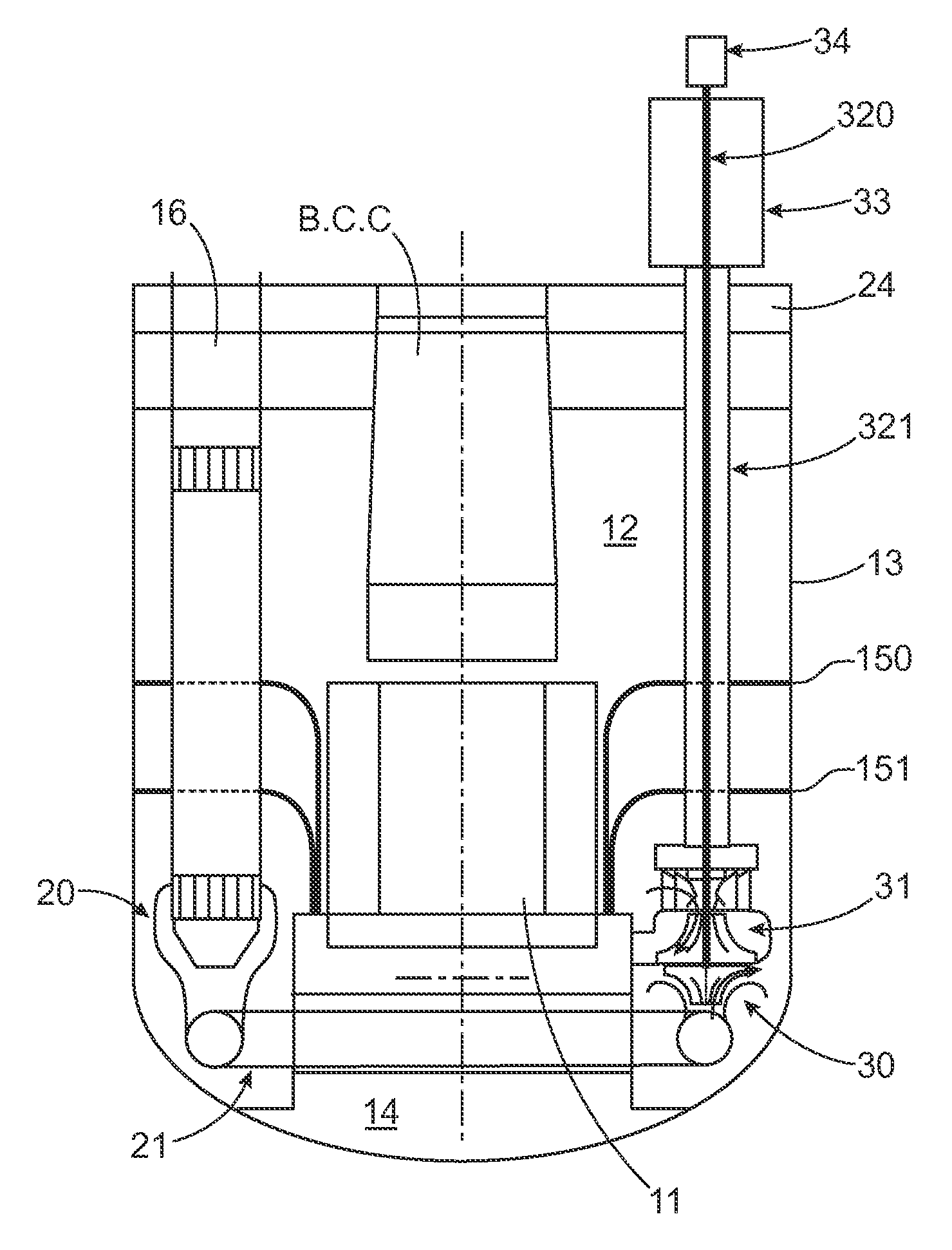

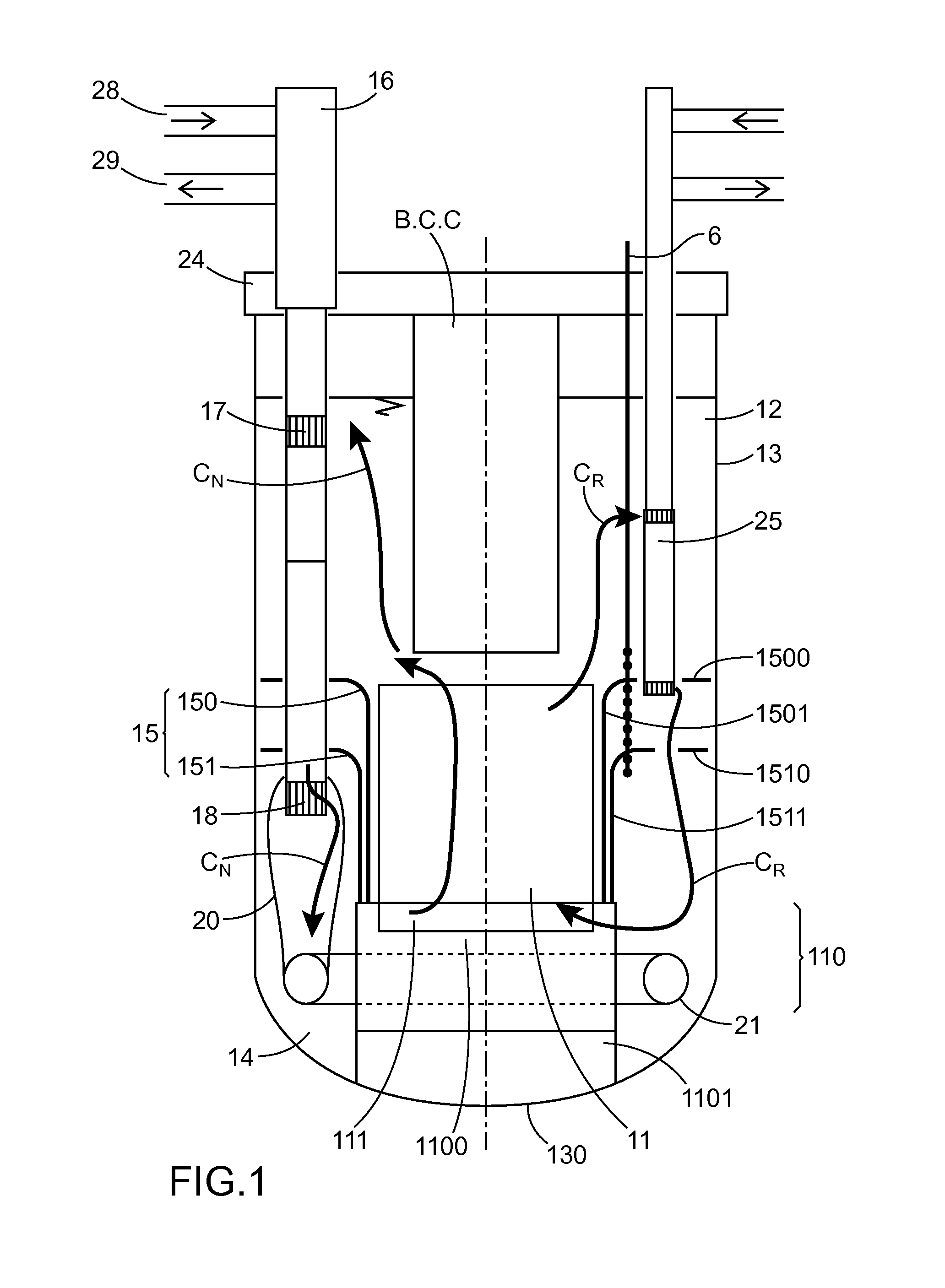

Integrated sodium-cooled fast nuclear reactor

InactiveUS20130216015A1Improve mechanical propertiesHomogenised more easilyIntegral reactorsNuclear energy generationNuclear reactorCold area

An improvement to an SFR reactor of the integrated type wherein each of the outlet windows of the intermediate exchangers is surrounded in an enclosure in fluid communication with a pipe shaped into a toroid; and each of the inlets of the pump group which pumps the sodium from the hot area to the cold area through the intermediate exchangers is also in fluid communication with the toroid, such that the primary sodium originating from the hot area and exiting from the intermediate exchangers flows through the toroid and is then directed to the cold area by the said pump group.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Clockwork movement for a wristwatch

Clockwork movement for a wristwatch, comprising a kinematic chain including at least one belt (20, 21) for transmitting the movements and / or couples between at least two pulleys. The pulleys are held on the bottom plate or the bridges by ball bearings (151, 161, 171, 181). The movement is rewound by means of linear oscillating mass (14) charging four barrels (15, 16, 17, 18) through a couple distributor (40). The barrels are non-parallel to one another. The back cover is covered by inclined glasses (110, 120, 130) allowing the barrels, the linear oscillating mass and at least certain pulleys to be seen. The regulating organ (51) is removable.

Owner:LVMH SWISS MFG SA

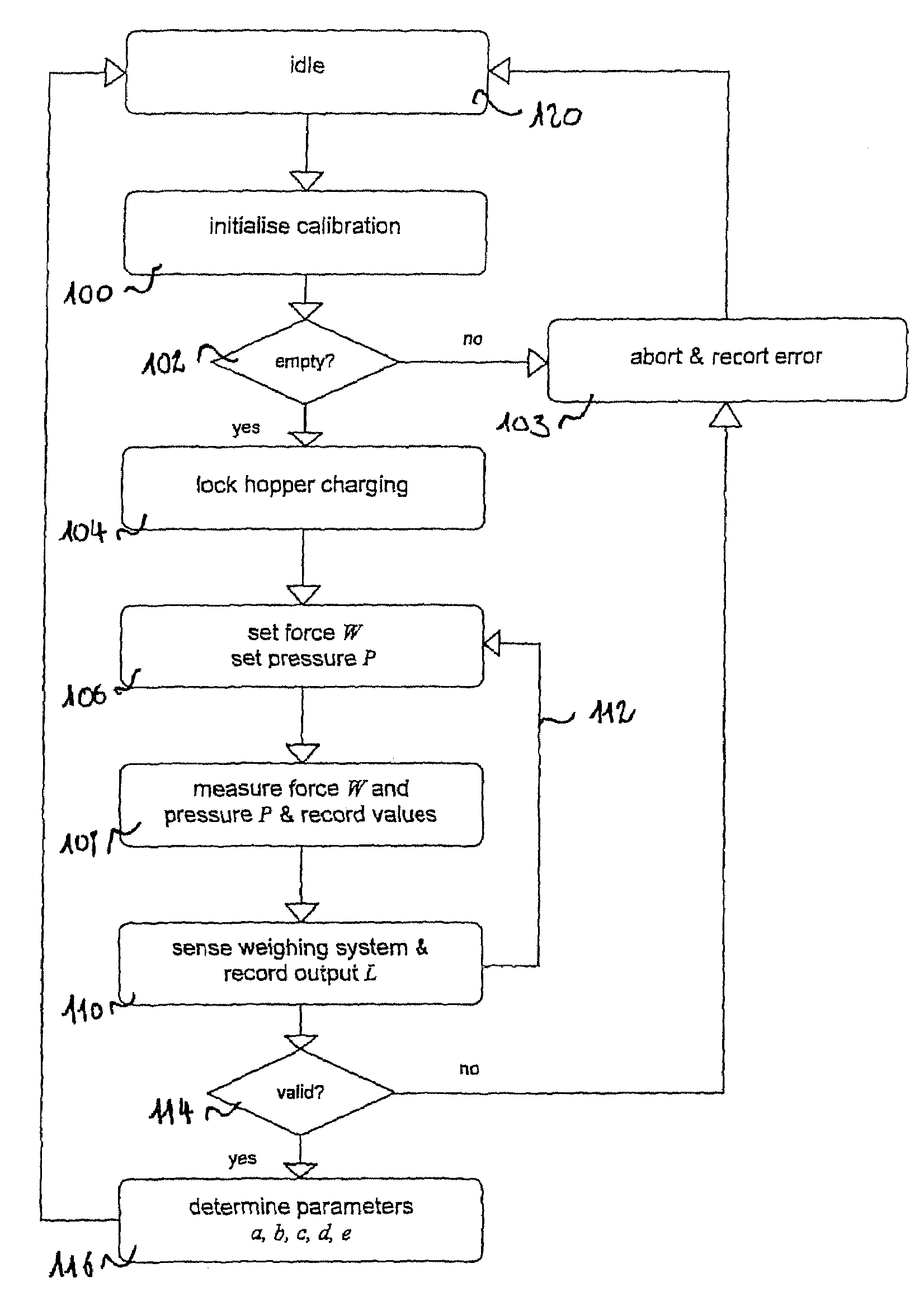

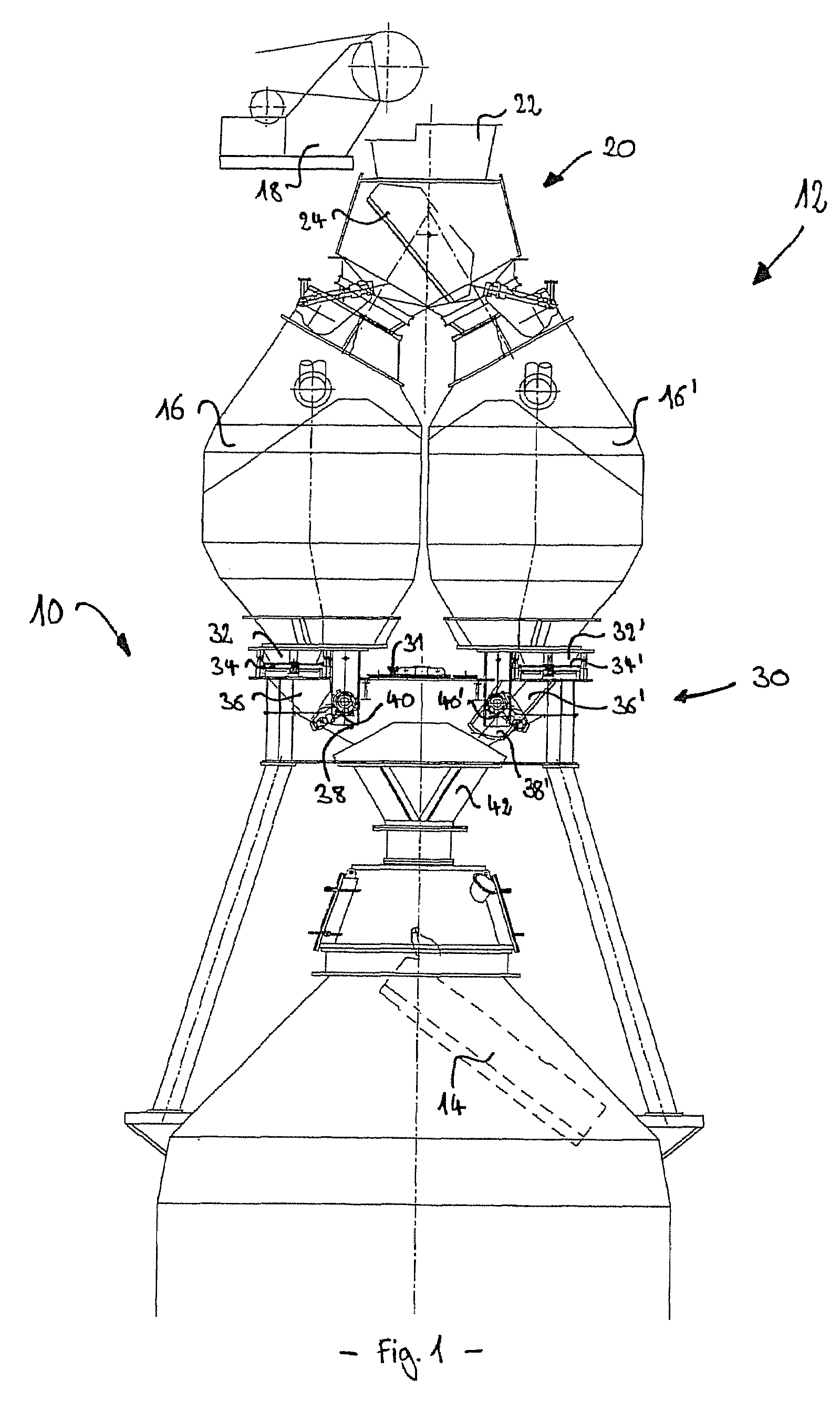

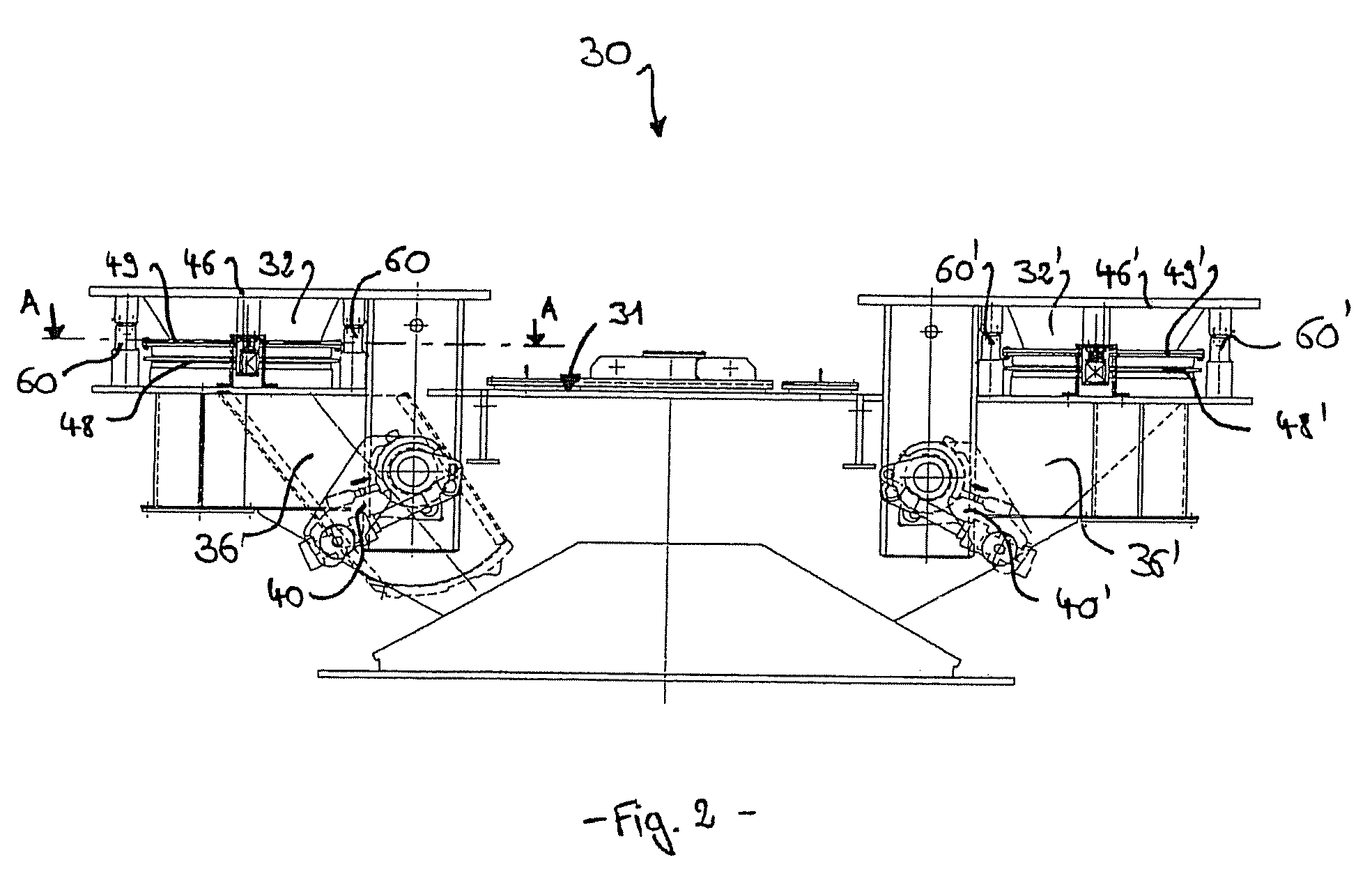

Method and device for calibrating a weighing system of a blast furnace top hopper

InactiveUS7788964B2Simple and reliable solutionEfficient use ofWeighing apparatus testing/calibrationBell-and-hopper arrangementNet forceEngineering

Owner:PAUL WURTH SA

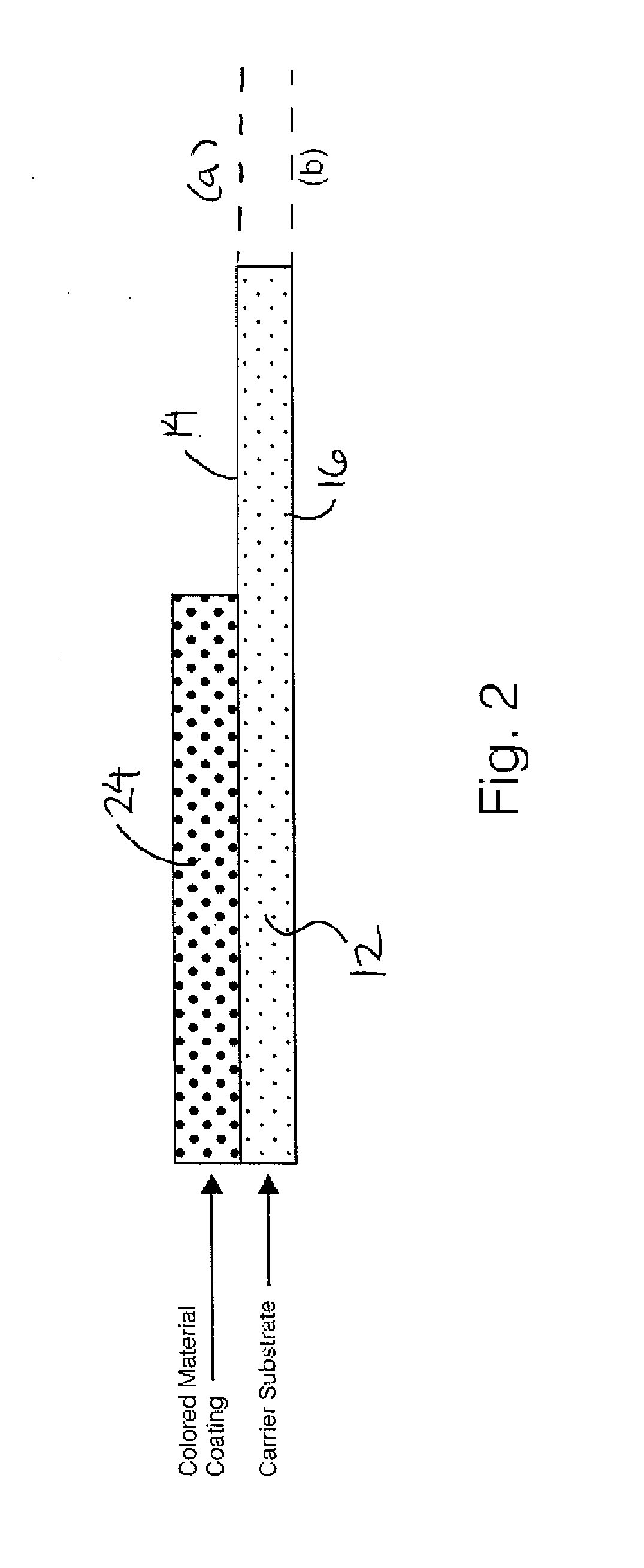

Color Sample Device and Method of Manufacture

InactiveUS20160078775A1Reduce the amount requiredSmall sizePretreated surfacesPattern printingEngineeringSecondary color

A color sample device has a substrate having a front surface, a back surface opposite from the front surface, a top edge, a bottom edge opposite from the top edge, and two side edges which are laterally opposed from one another. A primary color sample coating is applied to an upper portion of the front surface of the substrate adjacent to the top edge so as to fully span between the two side edges. A plurality of secondary color sample coatings are applied to a lower portion of the front surface of the substrate between the primary color sample and the bottom edge. The primary color sample coating is a stripe coating applied directly to the substrate. The secondary color sample coating is deposit coating applied directly to the substrate.

Owner:DUHA COLOR SERVICES

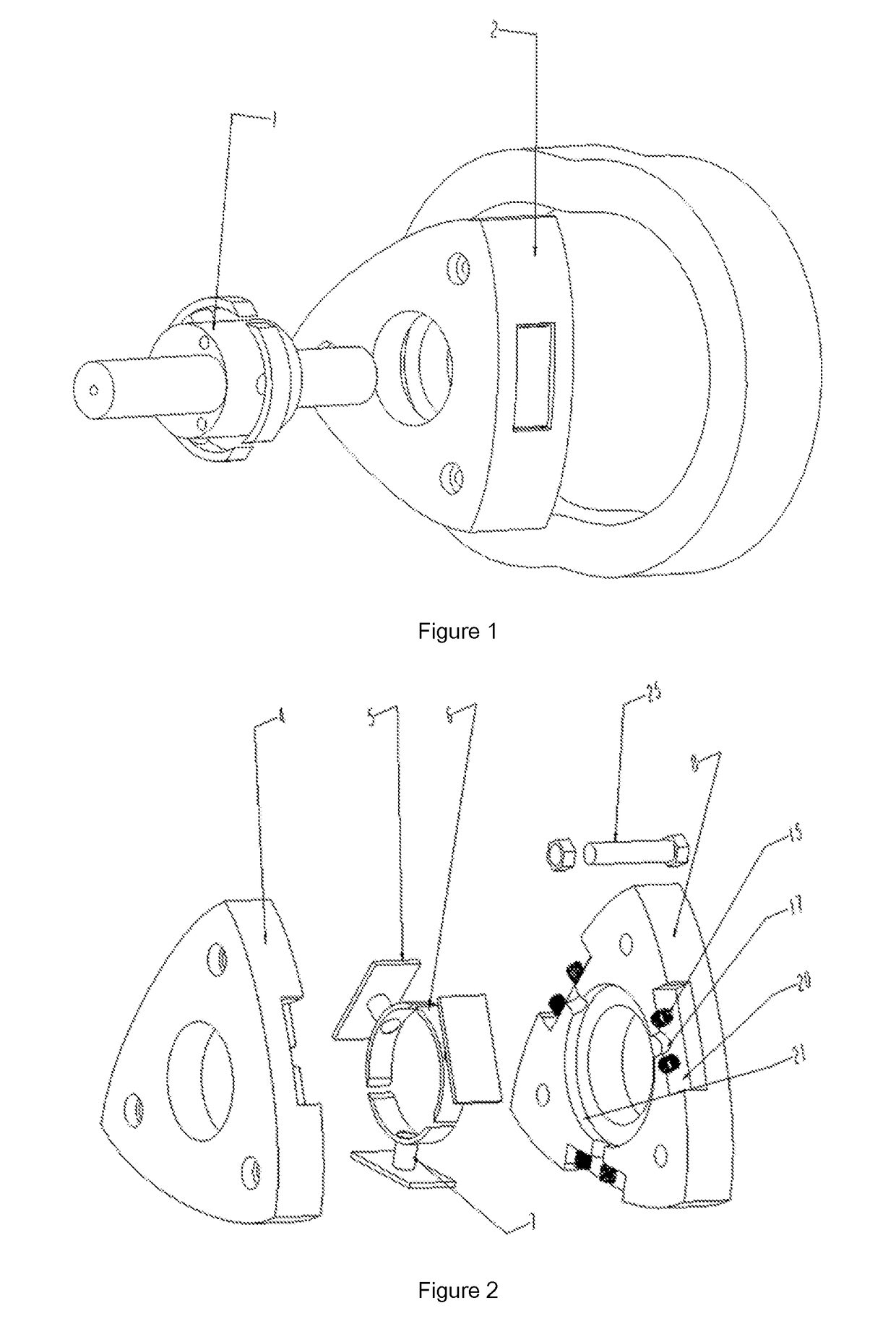

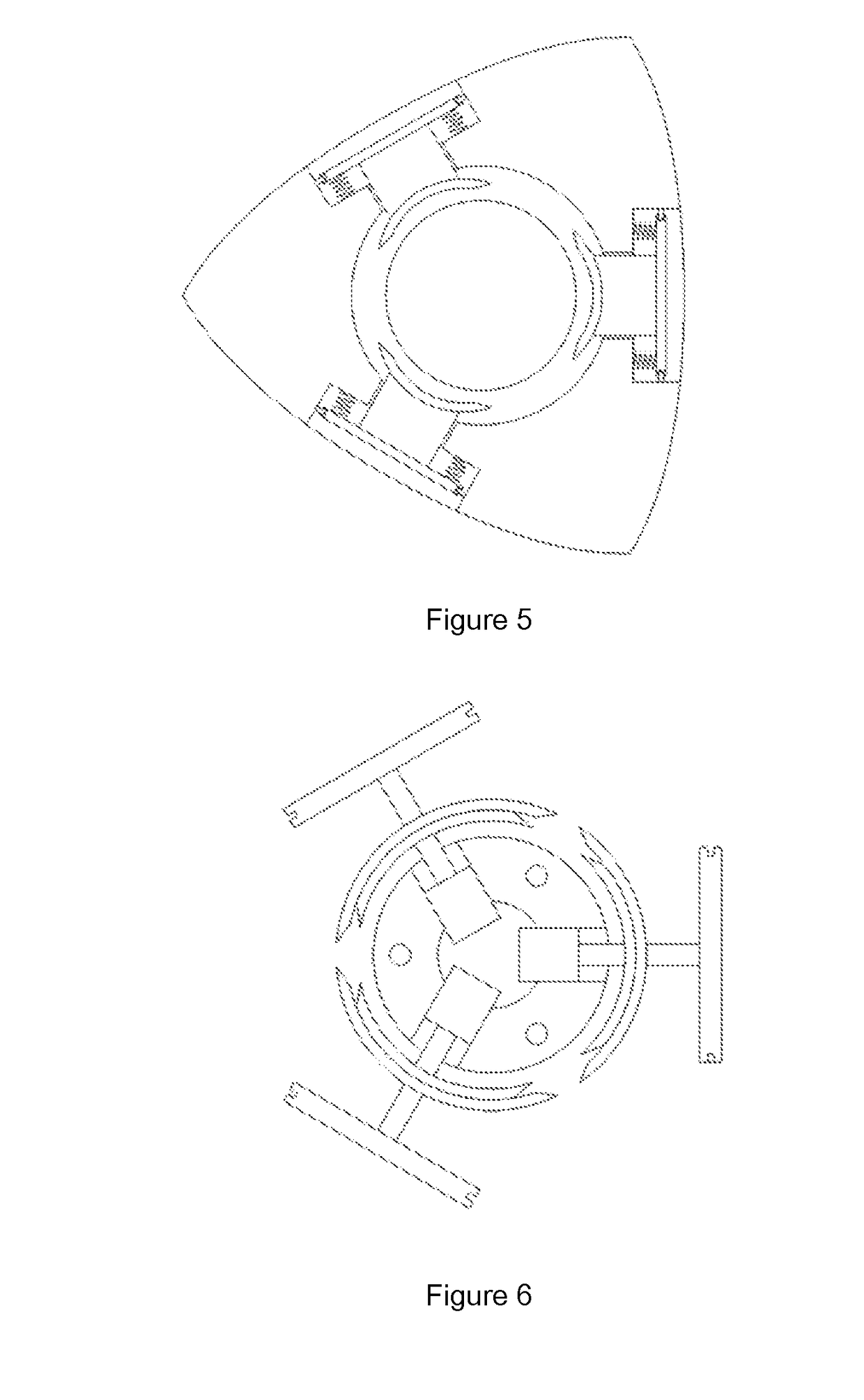

Control device to achieve variable compression ratio for triangle rotary engine

ActiveUS20190010806A1Increase the compression ratioImprove performanceInternal combustion piston enginesSealing arrangements for enginesControl systemReciprocating motion

The present invention provides an actuator that can realize the different compression ratios of the rotary engine. The invention actuator described above, includes three parts: the eccentric shaft part, the triangle rotor part and the control system. The eccentric shaft part which is described above, includes the front part of the eccentric shaft, the combination of electric three jaw and the rear part of the eccentric shaft. The triangle rotor part which is described above, includes the variable volume actuator, the front part of the rotor and the rear part of the rotor. The control system which is described above, includes the control system of electric three jaw and the rotating joint. The expansion and contraction of the electric three jaw described above, are controlled by the control system of electric three jaw described above. The eccentric shaft part described above passes through the triangle rotor part described above, to make the combination of electric three jaw to arrange in the annular groove described above. The reciprocating motion of the variable volume actuator described above, is controlled by the expansion and contraction of the claw top of the electric three-jaw. The invention can adjust the engine compression ratio through the whole compression ratio adjustment system, to make the rotary engine always work in the best compression ratio under different working conditions. Therefore, the invention can improve the performance of rotary engine significantly.

Owner:JIANGSU UNIV

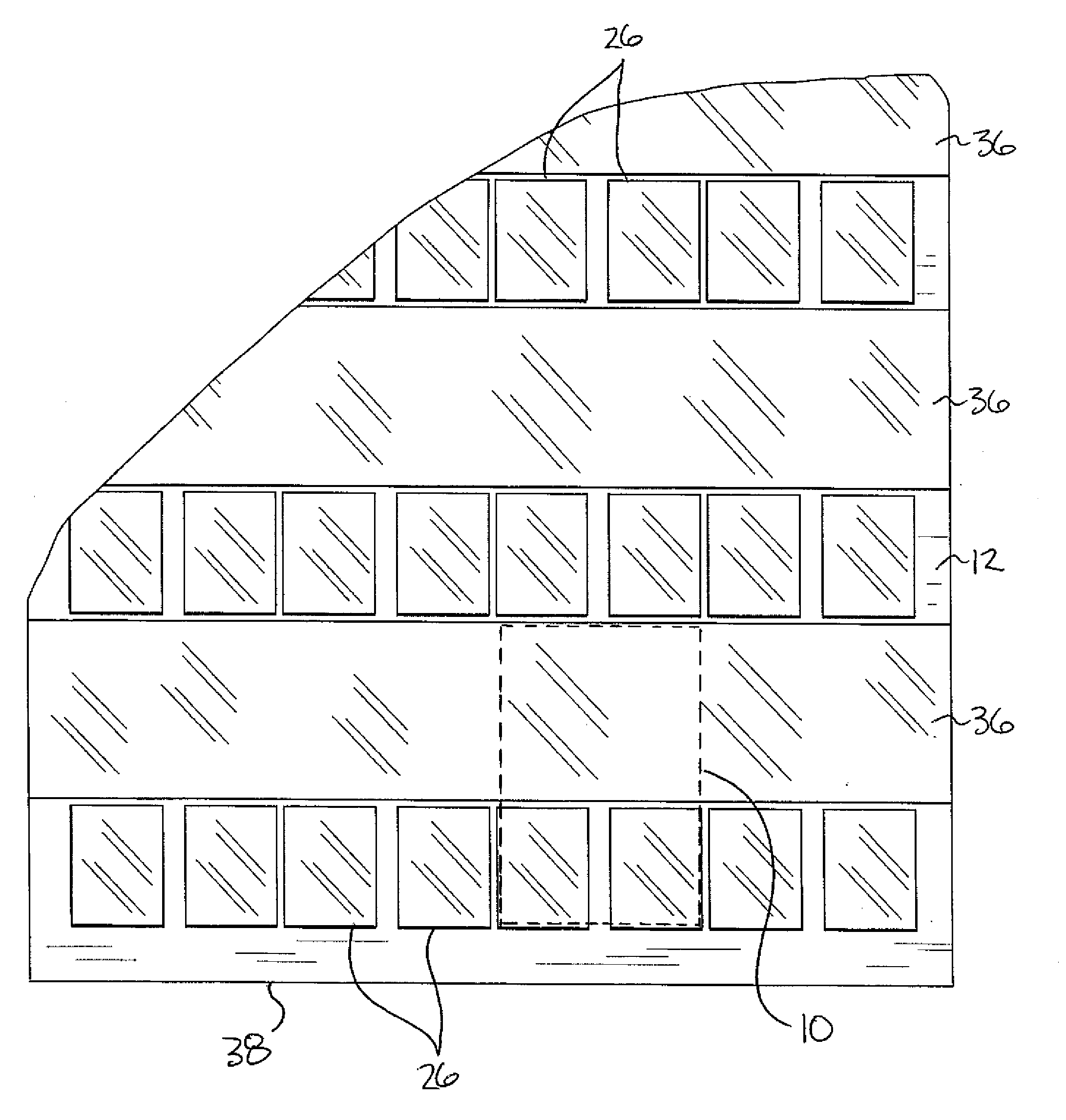

Reconfigurable semiconductor integrated circuit and processing assignment method for the same

InactiveUS7551001B2New designShorten design timeSolid-state devicesCAD circuit designData transmissionComputer science

A plurality of logic element groups LEG11 to LEG33 respectively include at least one logic element as a component of a reconfigurable semiconductor integrated circuit. Between any logic element groups engaging in data transmission / reception, e.g., LEG11 and LEG12, clock out terminal and clock in terminal are connected via a line while data out terminal and data in terminal are connected via a delay element 101. The logic element groups LEG11 to LEG33 are therefore independent of one another in terms of timing design. Thus, if redesign is necessary for a semiconductor integrated circuit completed with a plurality of logic element groups, only a new circuit may be designed and connected to an existing circuit, or an unnecessary logic element group may just be removed, to complete a new semiconductor integrated circuit.

Owner:SOCIONEXT INC

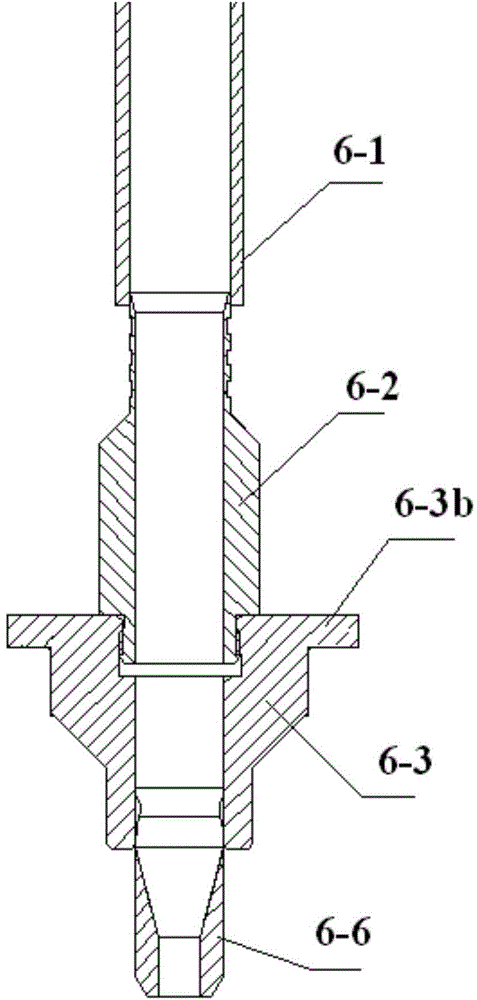

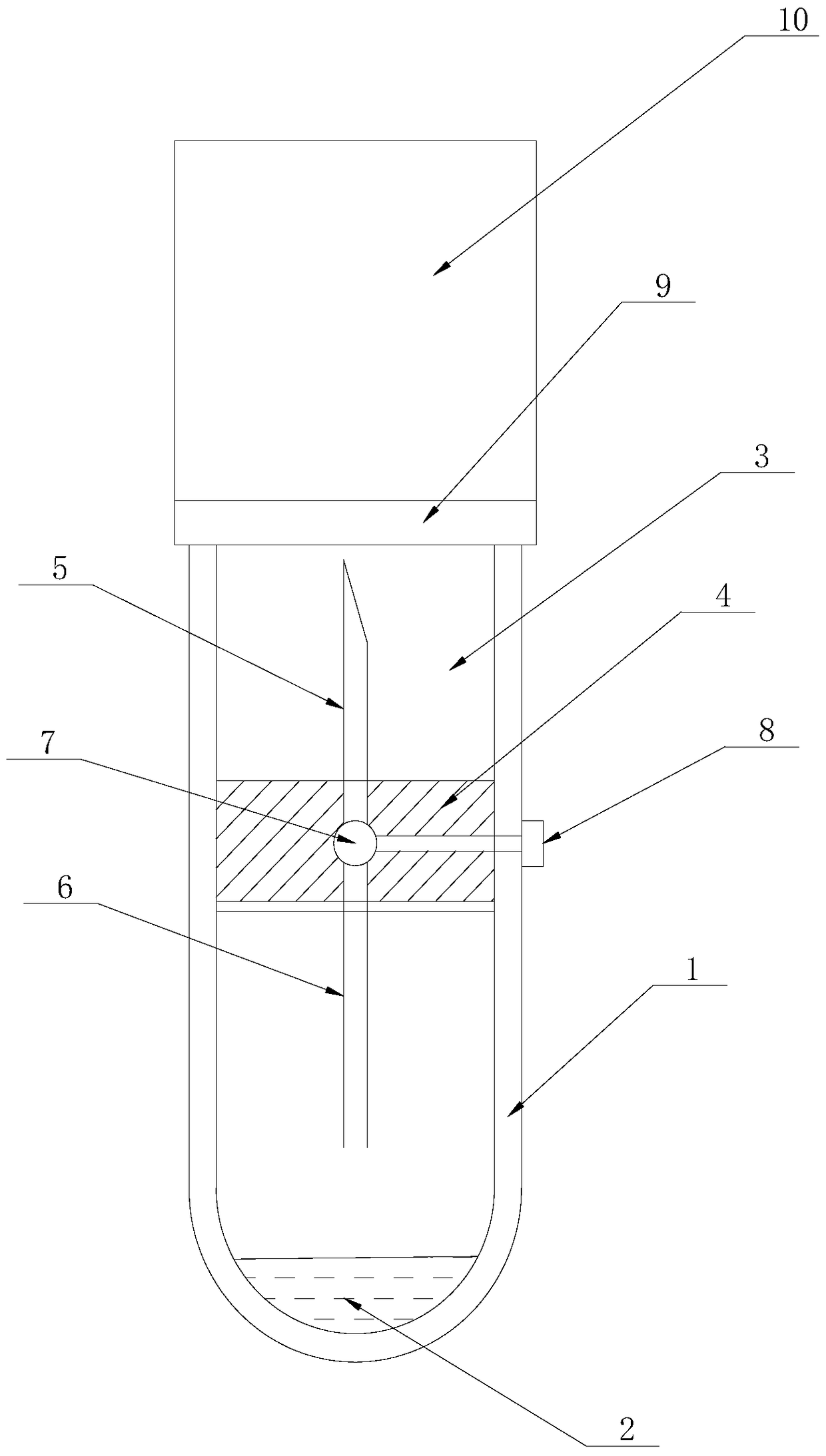

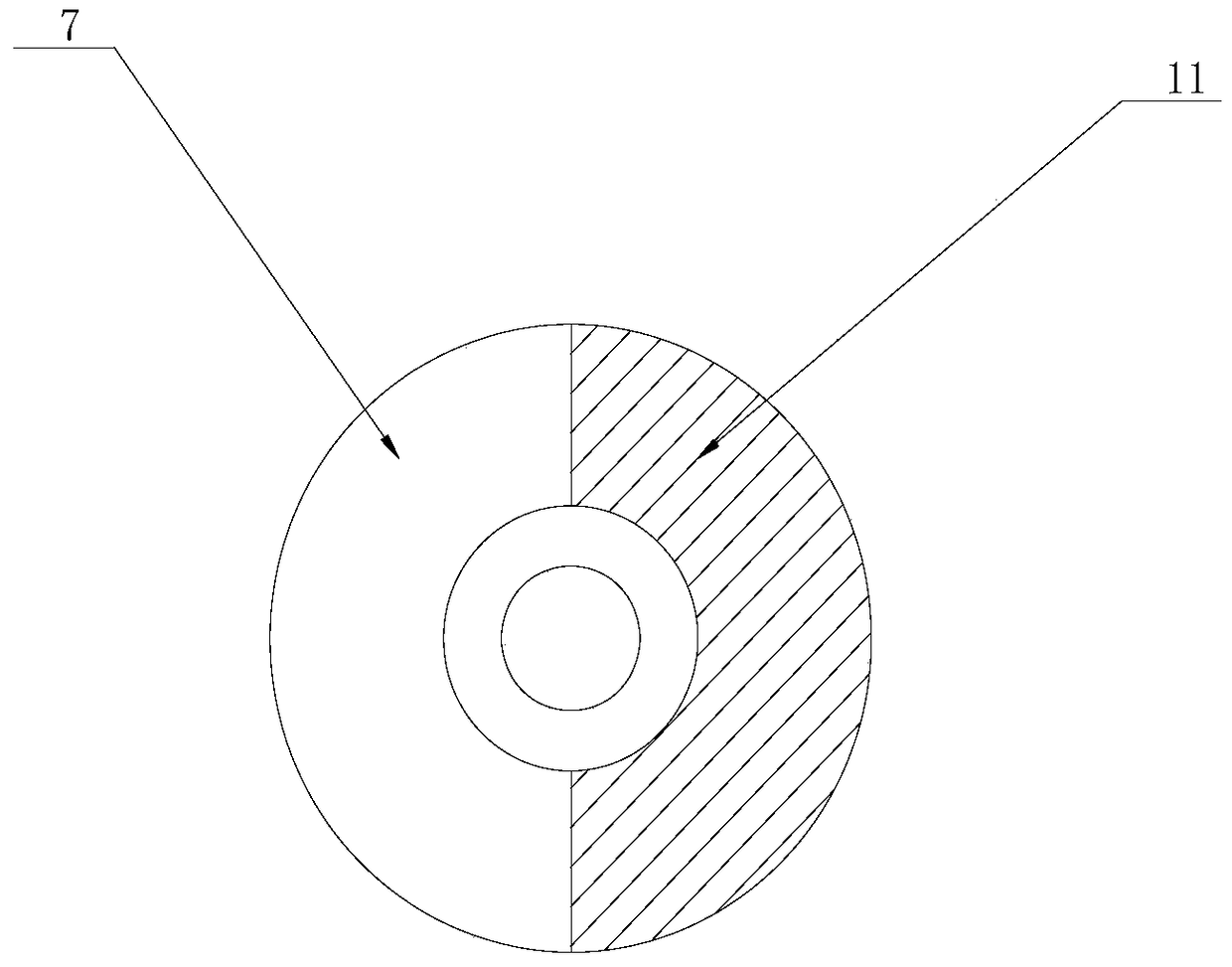

A New Type of Safety Blood Collector

ActiveCN104983433BSimple structureNew designDiagnostic recording/measuringSensorsBlood Collection TubeCatheter

The invention relates to the technical field of blood collection medical instruments, in particular to a novel safe blood collector. An anticoagulation medicament is arranged in a blood collection glass tube. A puncture needle groove is formed in the upper end of the blood collection glass tube. A rubber sealing sliding block is arranged in the puncture needle groove. A switching valve is arranged in the rubber sealing sliding block. The upper end of the switching valve is connected with a puncture needle. The lower end of the switching valve is connected with a guide tube. One side of the switching valve is connected with a switching connecting rod. A rubber sealing plug is arranged at the upper end of the puncture needle groove. A protective cover is arranged at the upper end of the rubber sealing plug. The novel safe blood collector is simple in structure and novel in design. The hidden puncture needle is adopted and hidden in the blood collector, operation is quick and convenient, and the novel safe blood collector is suitable for small-dosage blood collection.

Owner:山东鲁健生物医药科技有限公司

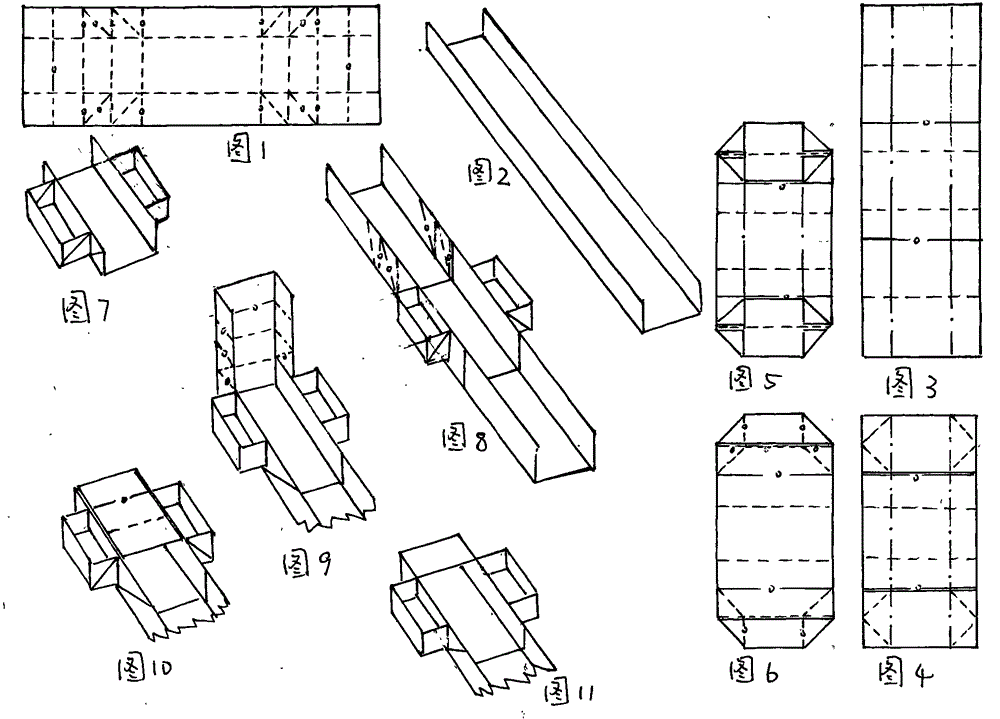

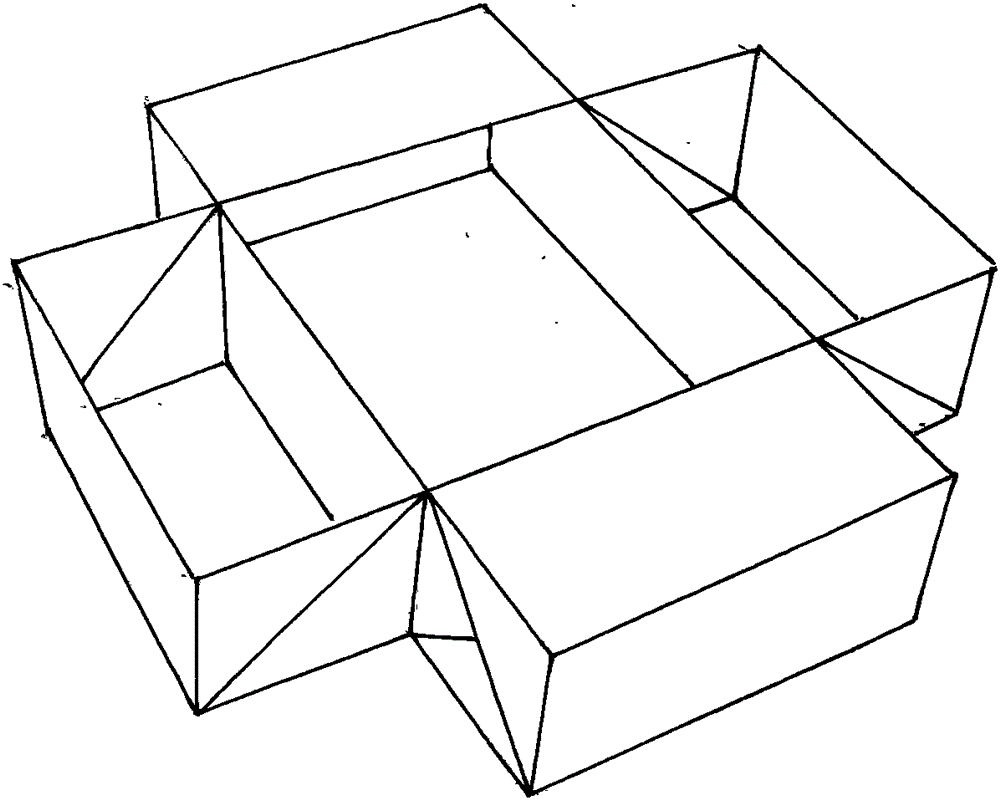

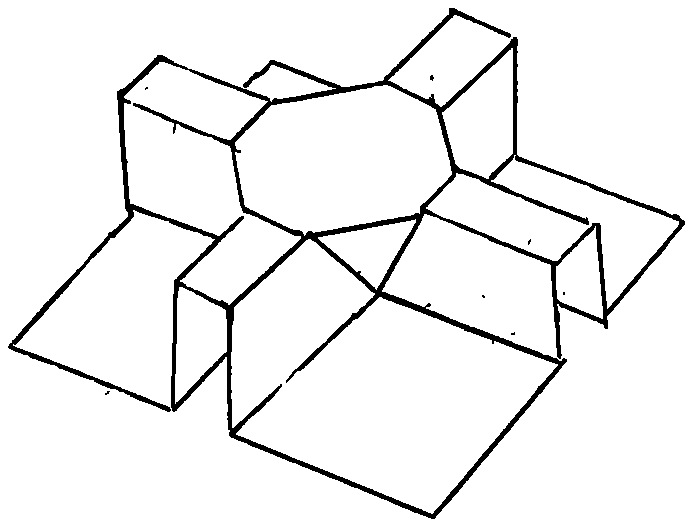

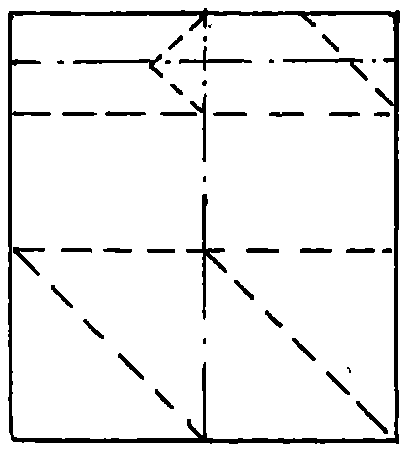

Cross-shaped semi-closed carton

The invention relates to a method for making paper containers and discloses a crossed semi-closed carton which is formed by combining a part 1 with a part 2. A piece of rectangular paper which is transversely long and longitudinally wide is used to make the U-shaped part 1, a piece of rectangular paper which is longitudinally long and transversely wide is used to make the U-shaped part 2 between two rectangular boxes, two erect portions of the U shape in the middle of the part 1 are inserted into an interlayer of the part 2 from bottom to top respectively to form an L shape, the L shape is folded to form a semi-box initial shape, and the crossed semi-closed carton can be formed by folding the right half of the rectangular paper which is transversely long and longitudinally wide in that way. The crossed semi-closed carton is unique in concept and novel in design, the parts are simple to make, easy to combine and firm in combining fit, and the crossed semi-closed carton is novel and attractive in appearance.

Owner:南通双渡包装制品有限公司

Wide cross interlayer square box

Owner:李平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com