Propulsion-Release Safety Vacuum Release System

a vacuum release and safety technology, applied in the field of fluid handling, can solve the problems of air within the circulation system of the swimming pool, the victim cannot be removed from the suction outlet, and the prime is lost, and achieves the effect of eliminating the built-in suction hazards, easy retrofitting, and convenient design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

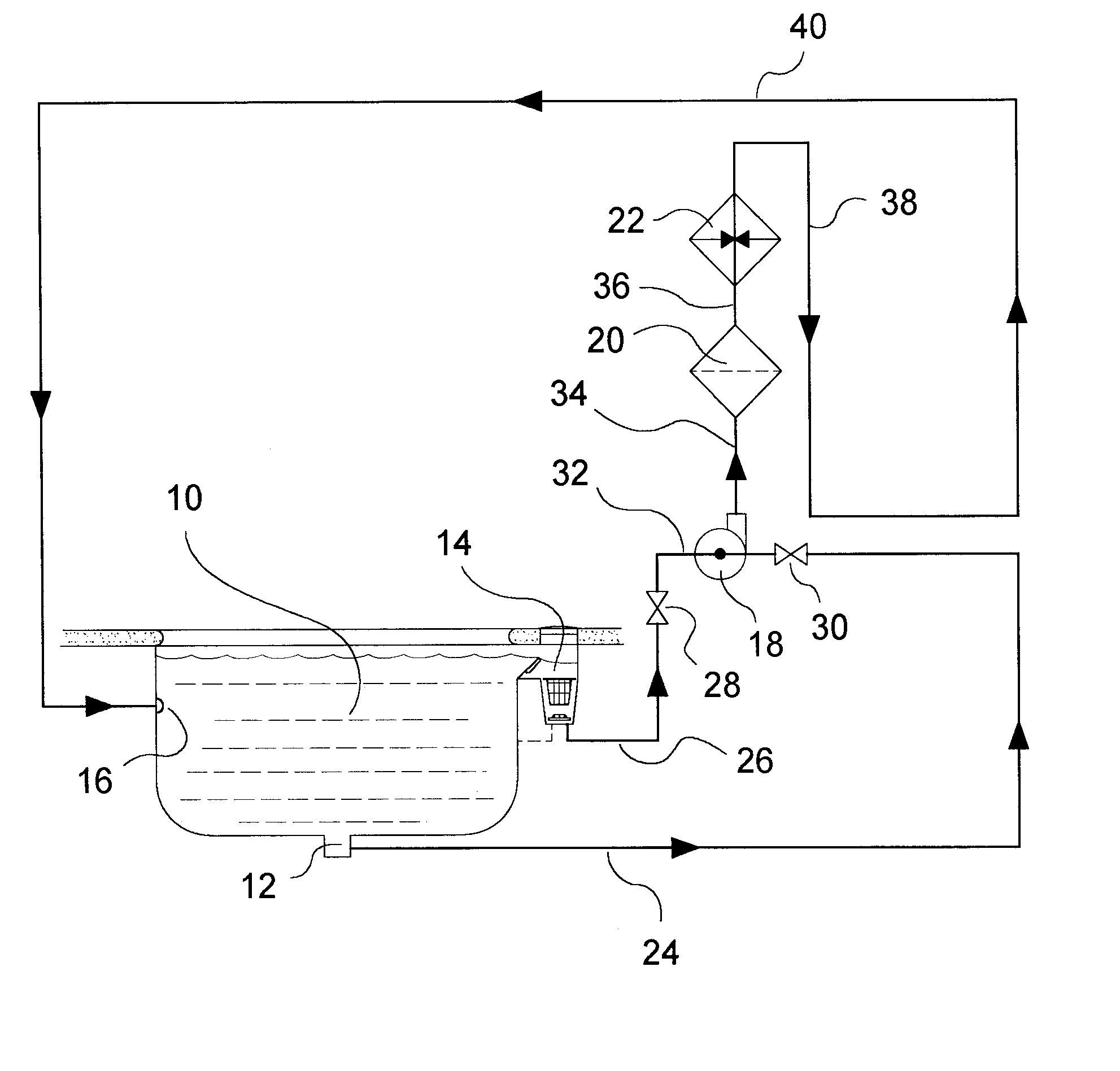

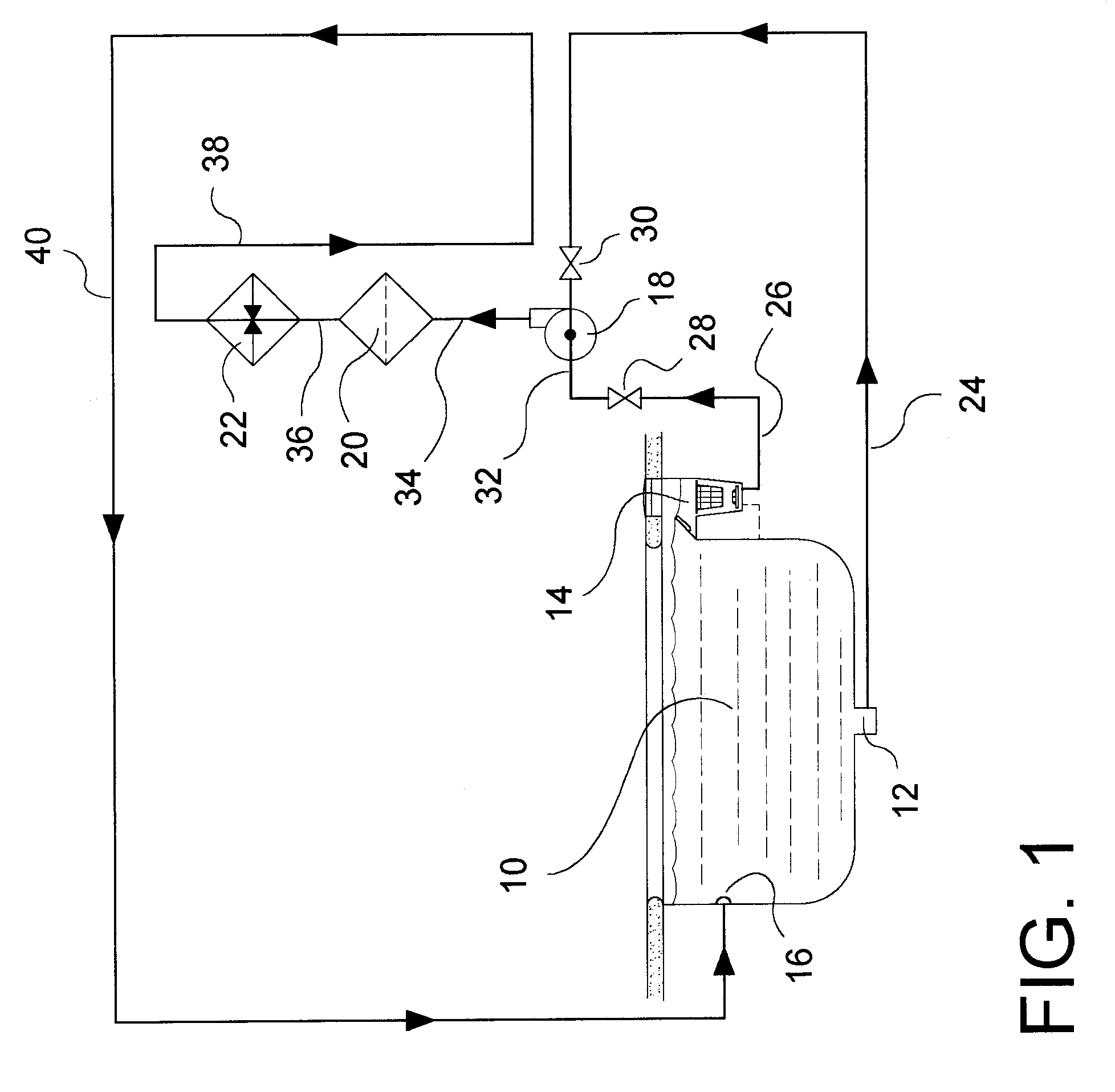

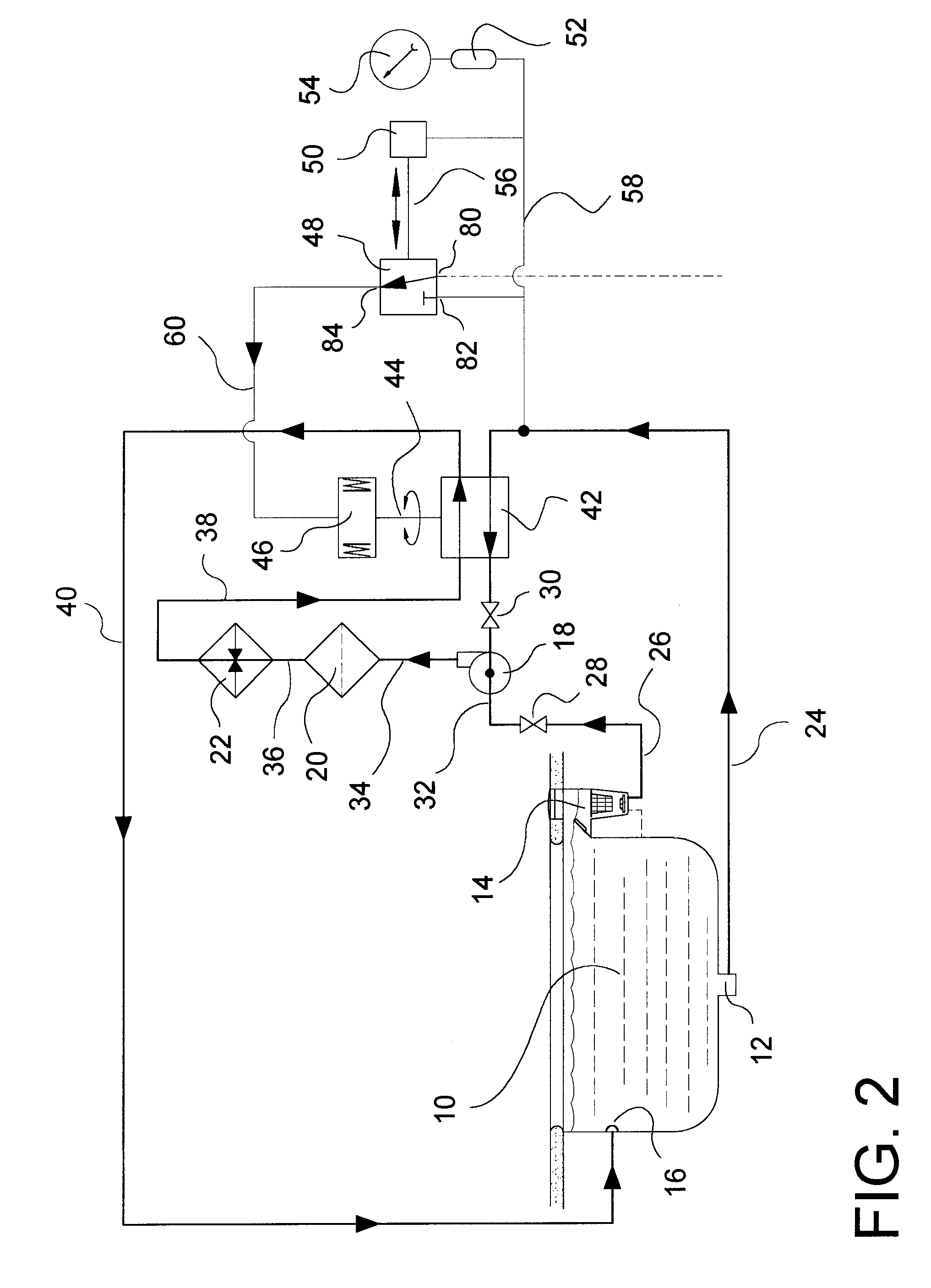

[0035] The following item numbers are used in the drawings to identify the elements of the invention and are used throughout the following description:

[0036] Swimming pool components:

[0037] 10 Pool

[0038] 12 Pool Main Drain

[0039] 14 Pool Surface Skimmer

[0040] 16 Pool Surface Return

[0041] 18 Pump

[0042] 20 Filter

[0043] 22 Heater

[0044] Circulation system components:

[0045] 24 Pool Drain Line

[0046] 26 Pool Skimmer Line

[0047] 28 Skimmer Control Valve

[0048] 30 Drain Control Valve

[0049] 32 Main Pump Suction Line

[0050] 34 Pump Discharge Line

[0051] 36 Filter Effluent Line

[0052] 38 Support System Effluent Line

[0053] 40 Pool Return Line

[0054] Propulsion-release safety vacuum release system (SVRS) components:

[0055] 42 Four-Port Multi-port Flow Reversing Valve

[0056] 44 Reversing Valve Actuator Shaft

[0057] 46 Hydraulic Valve Actuator

[0058] 48 Directional Control Valve

[0059] 50 Flow Blockage Suction Interrupter Valve (FBSI)

[0060] 52 Suction Spike Arrester

[0061] 54 Vacuum / Pressure Gauge

[0062] 56 FB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com