Method for making hollow solid figure

A production method and three-dimensional technology, which are applied to cardboard articles and other directions, can solve the problems of insufficient solidity of hollowed-out three-dimensional shapes, complicated production of hollowed-out three-dimensional shapes, etc., and achieve a three-dimensional shape with uncomplicated insertion, novel design, and simple production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

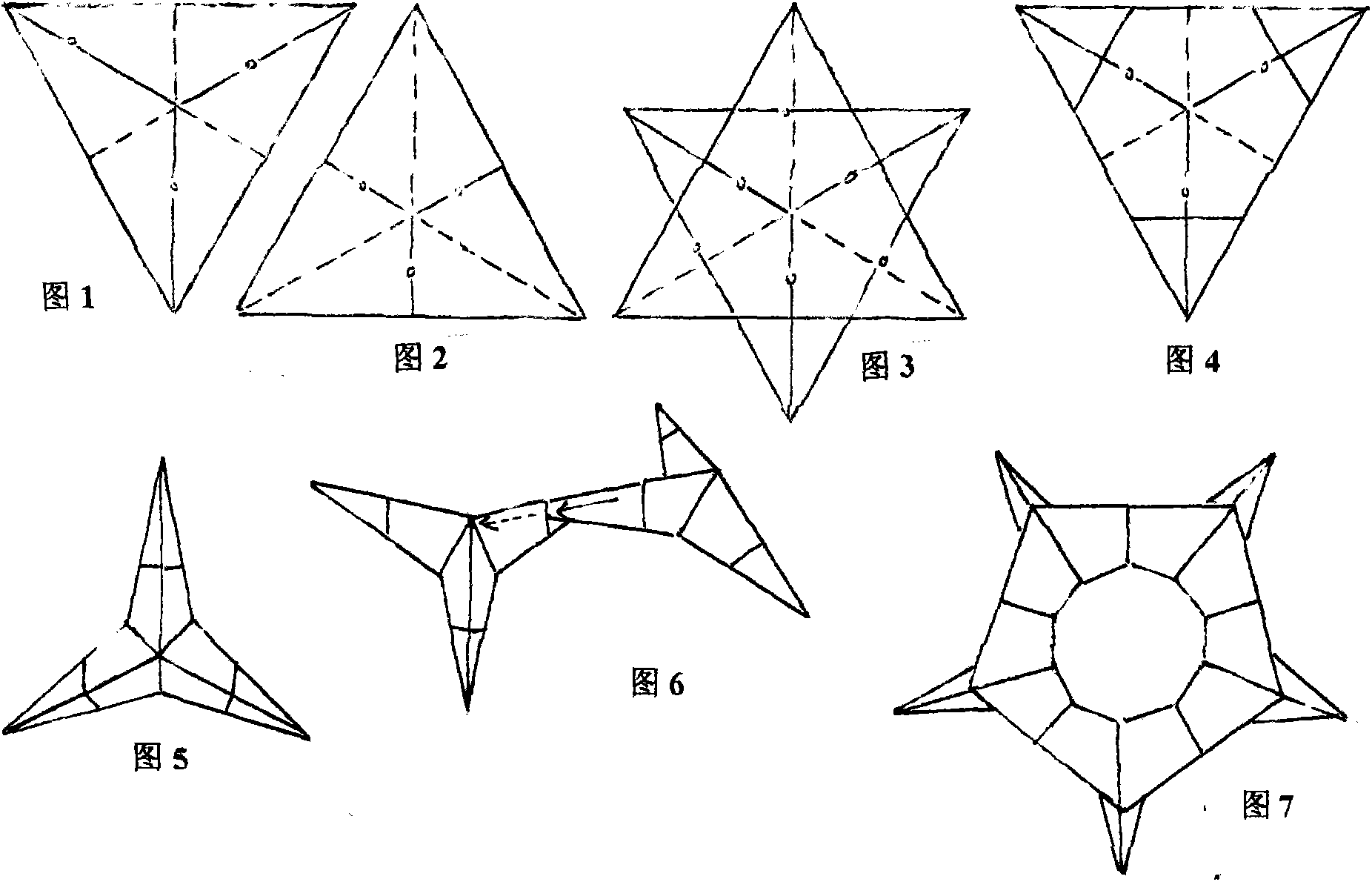

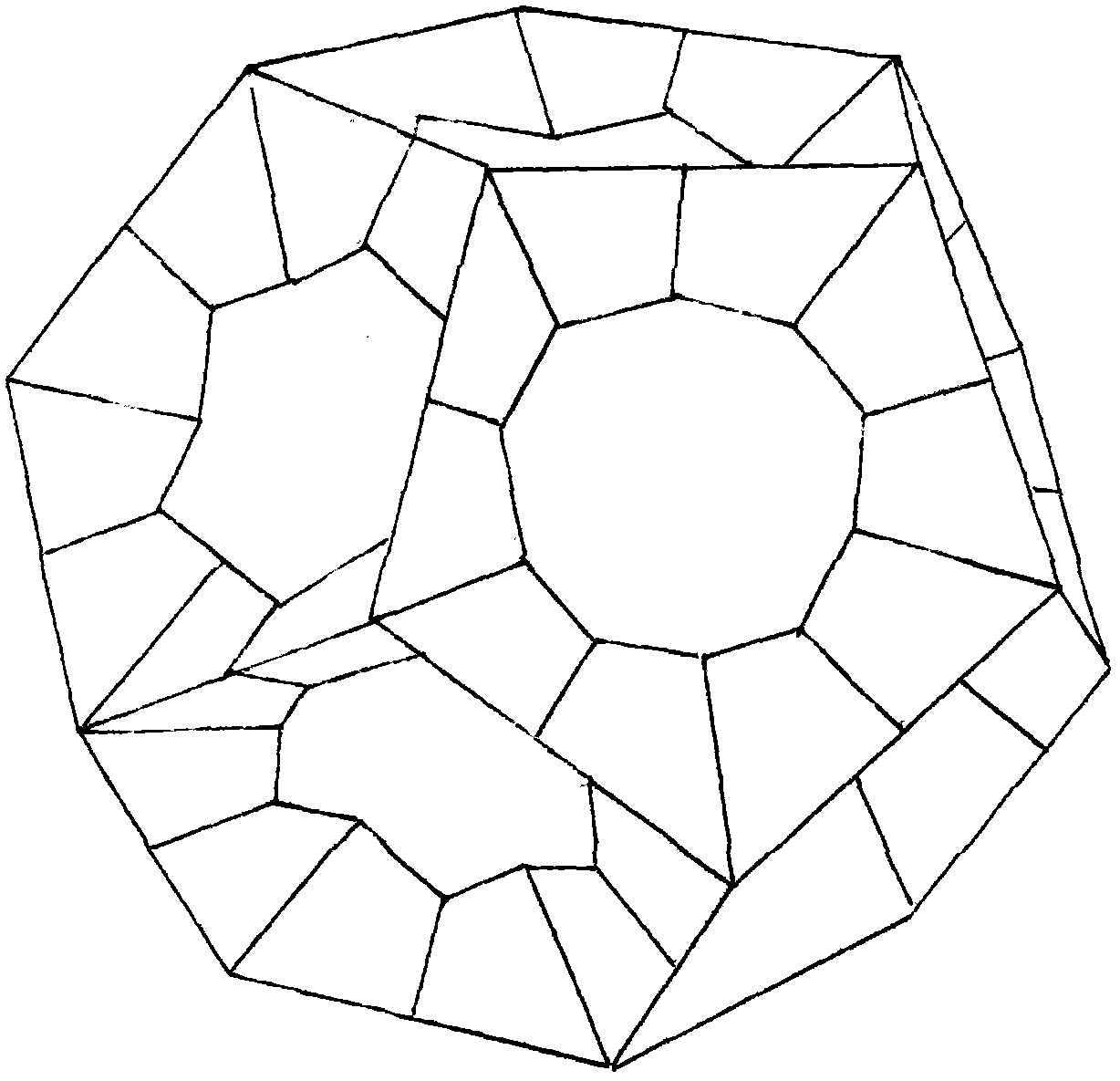

[0023] The hollow three-dimensional shape is formed by plugging 20 identical components such as component A, component B, component C, component D, and component E. Each component is composed of two congruent equilateral triangular parts, that is, an inner part and an outer part. The dotted line is used to indicate the positive fold line of the front half fold, and the solid line plus a circle is used to represent the reverse fold line of the reverse face fold;

[0024] The method of making the inner part: take equilateral triangle paper, draw a connection line between each corner and the midpoint of its opposite side, and the three connection lines intersect at the midpoint of the equilateral triangle paper, that is, the first intersection point; the first intersection point to The part of the line connecting the corner of the paper is the inverse fold line of the paper corner; the part of the line connecting the first intersection point to the edge of the paper is the positiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com