Double-layer differential-pressure air-supported membrane structure

An air bearing and membrane structure technology, applied in special structures, building components, etc., can solve the problems that single-layer membrane structures cannot achieve cooling and heating, and achieve the effect of reducing air supply energy consumption and strengthening structural sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

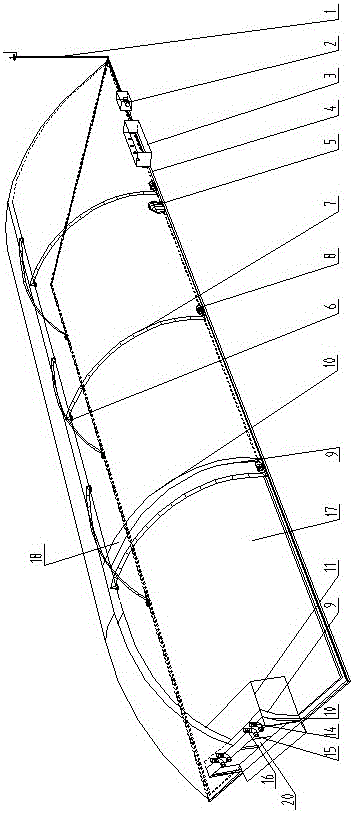

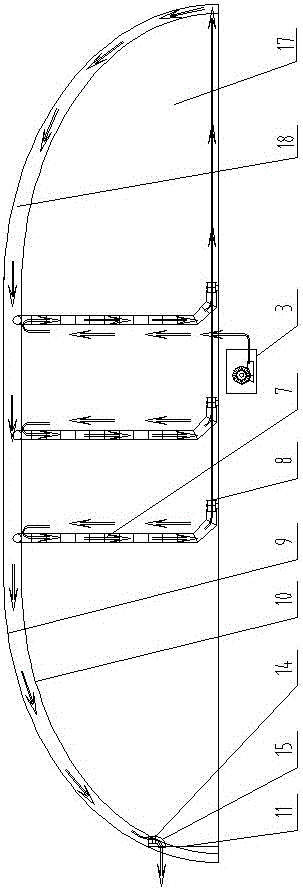

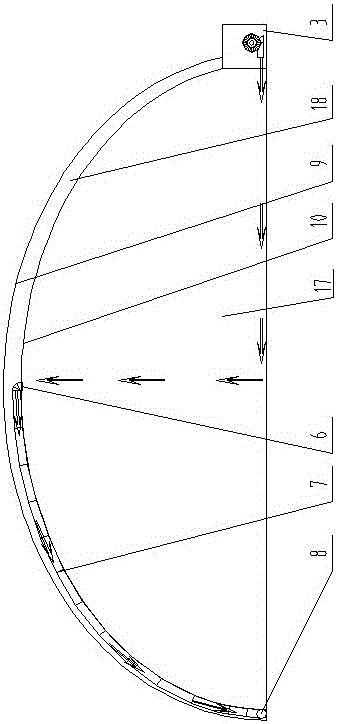

[0036] The specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing, figure 2 with image 3 The arrows in indicate the direction of the airflow.

[0037] Such as Figure 1 to Figure 7 Shown, a kind of double-layer differential pressure air-supported membrane structure of the present invention, it comprises the inner membrane 9 and the outer membrane 10 that are arranged on the bottom surface in arch shape, the outer membrane 10 is arranged on the outer layer of the inner membrane 9, and the outer There is a distance between the membrane 10 and the inner membrane 9, and the bottom sides of the outer membrane 10 and the inner membrane 9 are sealed and connected to the bottom surface through the anchoring infrastructure 4 arranged on the bottom surface, and the inner membrane 9 and the outer membrane 10 form a double Layer film structure. An airtight inner membrane cavity 17 is formed between the inner membrane 9 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com