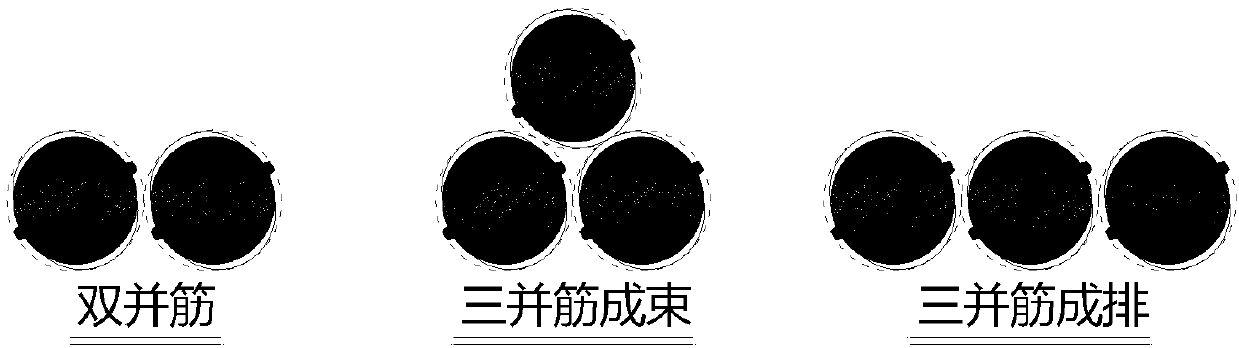

Full grouting sleeve for connecting of three-bundled-bar bundles and connecting method of three-bundled-bar bundles

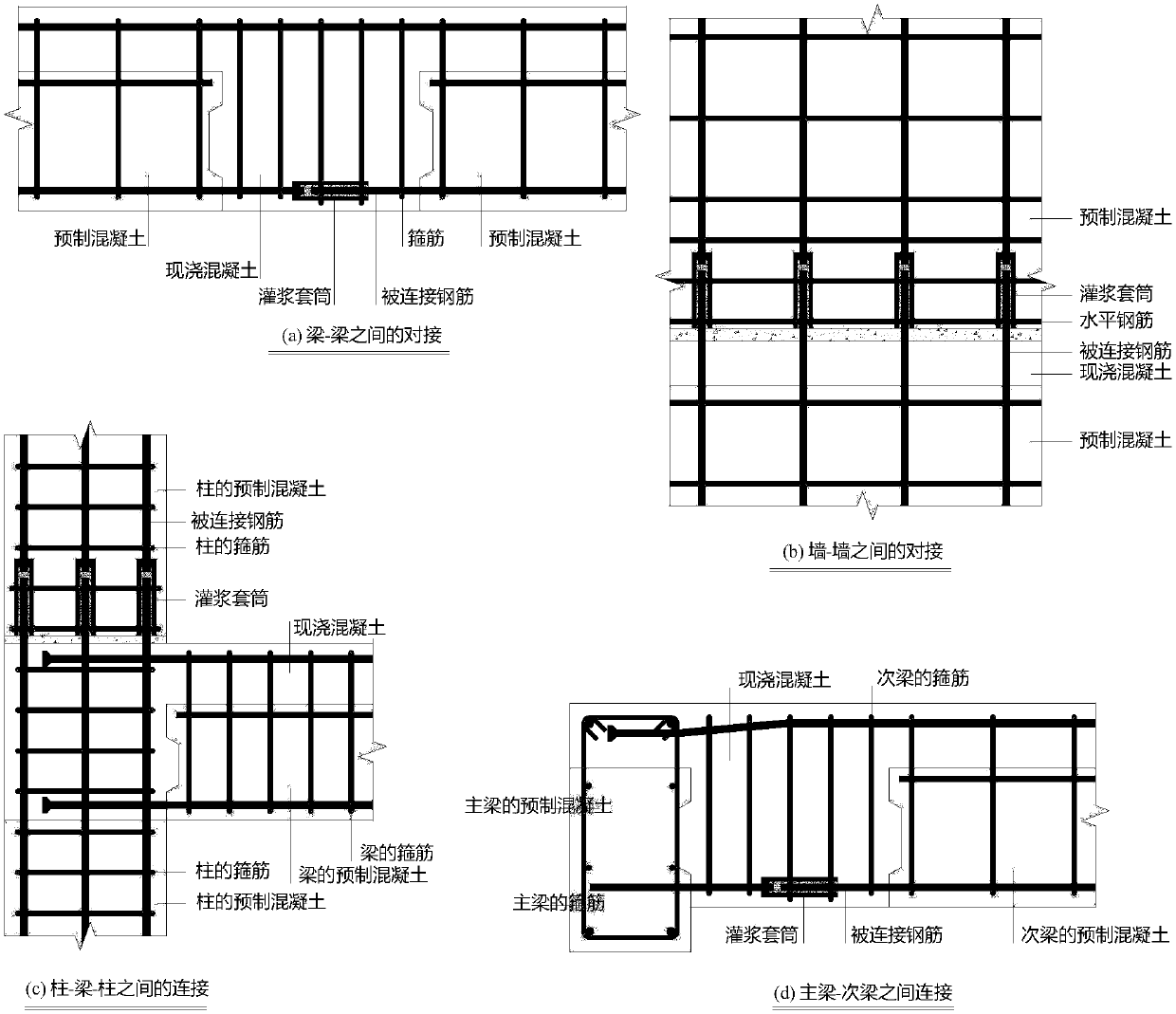

A full grouting and bundling technology, which is applied to structural elements, building components, building reinforcements, etc., can solve the problems of difficult double-bar welding quality, impossibility, inconvenient use, etc., to achieve small space occupation, safe connection interface, The effect of convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

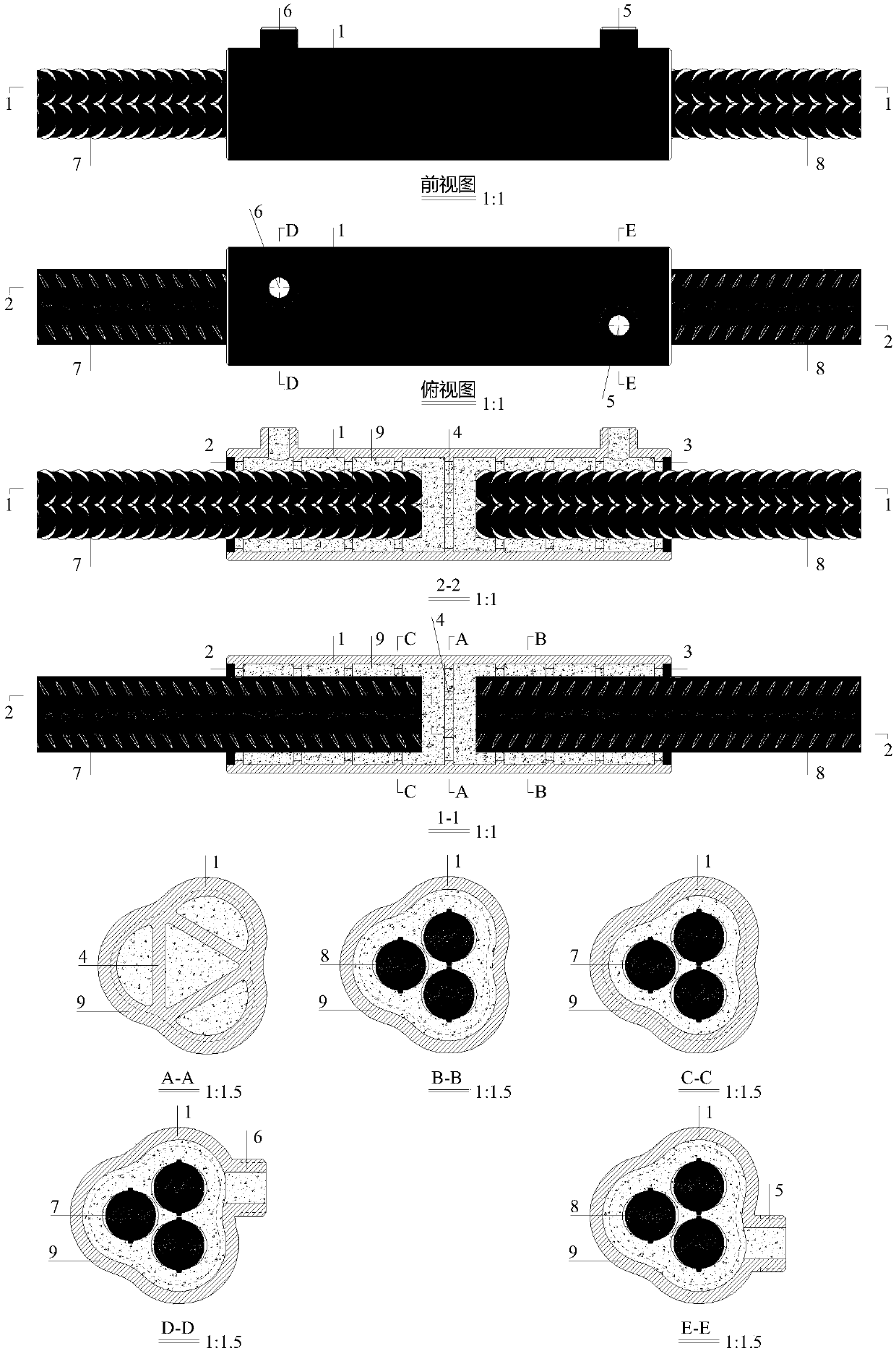

[0048] like image 3 A full-grouting sleeve for three-bundle connection is shown, including a metal sleeve (1) for connecting two sections of three-bundle bundles, and two seals respectively arranged at both ends of the metal sleeve (1) The rings (2, 3), the stoppers that are arranged in the middle of the cavity of the metal sleeve (1) and are integrated with the metal sleeve (1) and that limit the bundling of the three parallel ribs in the two sections, and are poured into the The grouting structure (9) formed by the metal sleeve (1) and the grouting material in the cavity between the two sections of the three-jointed tendon bundles, the metal sleeve (1) is a linear or fish-belly connecting sleeve, The three parallel tendons in the two sections are anchored and connected with the metal sleeve (1) through the grouting structure (9); the three parallel tendons in the two sections are respectively inserted into the metal sleeve (1) from left to right The first section of the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com