Escapement gear, escapement wheel employing the escapement gear, anchor-shaped escapement, movement, mechanical timepiece and method of torque transmission

A torque transmission and escape wheel technology, applied in the field of escapement teeth, can solve the problem of torque transmission loss LP2 not being improved, and achieve the effect of efficient torque transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

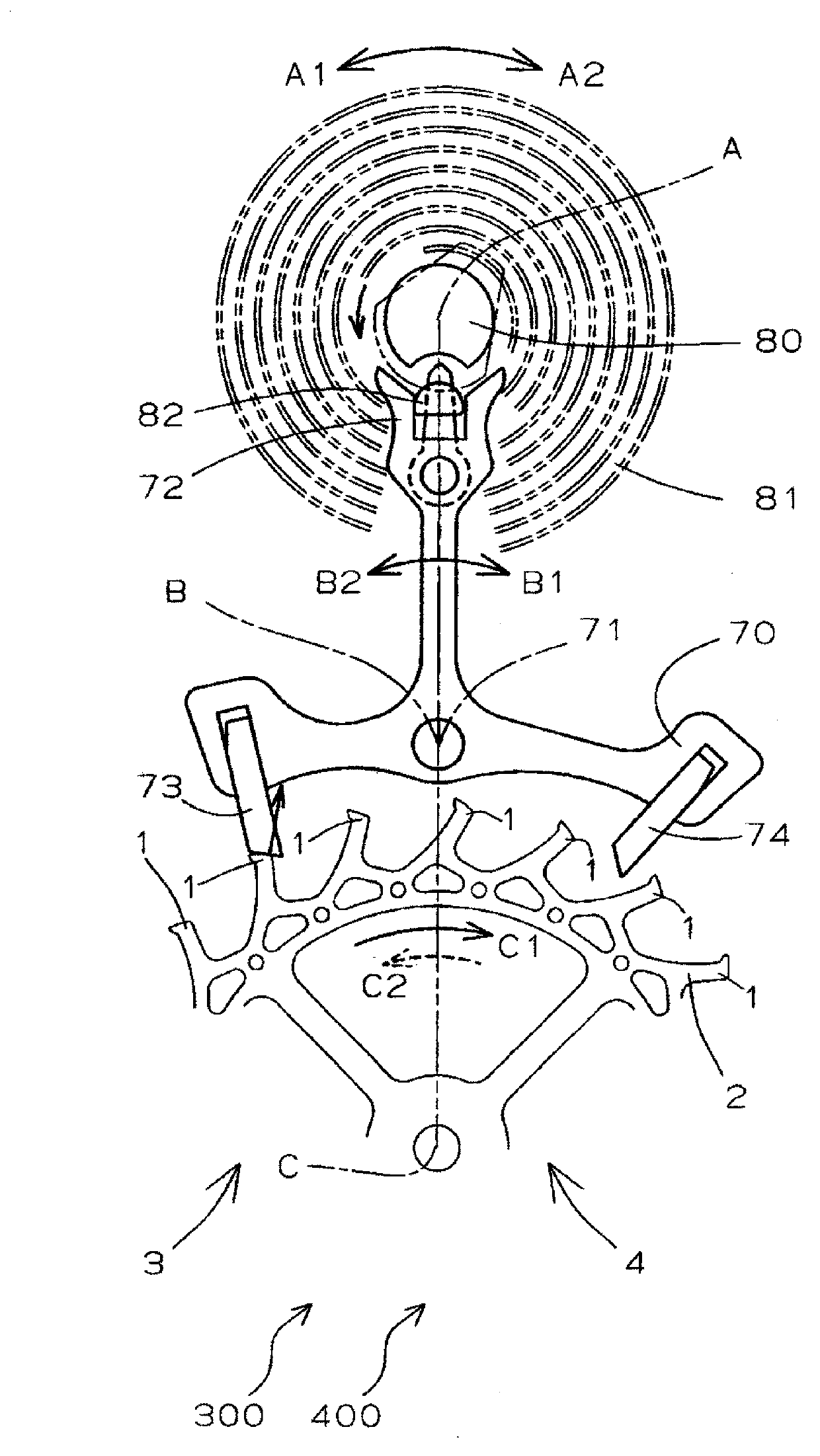

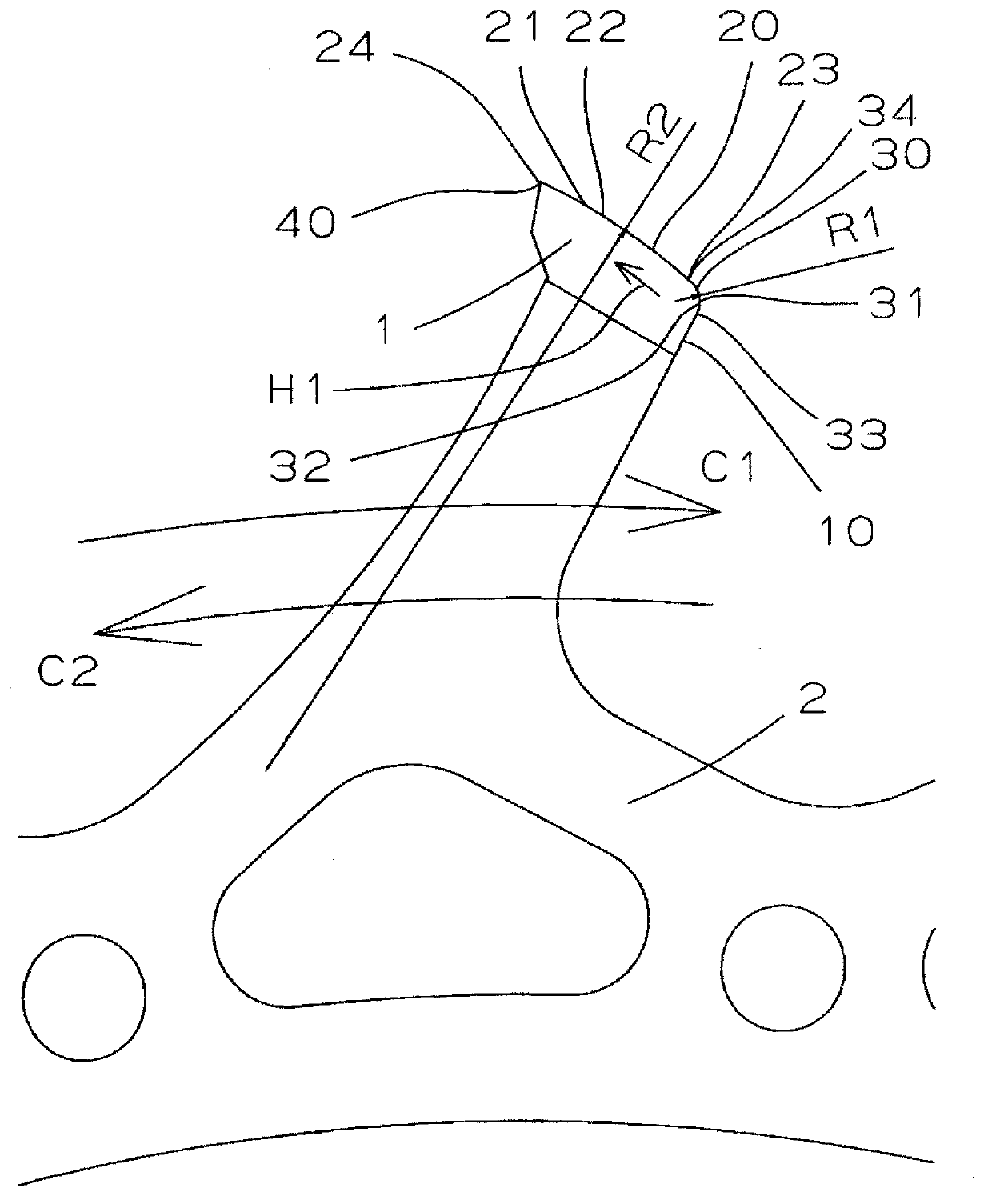

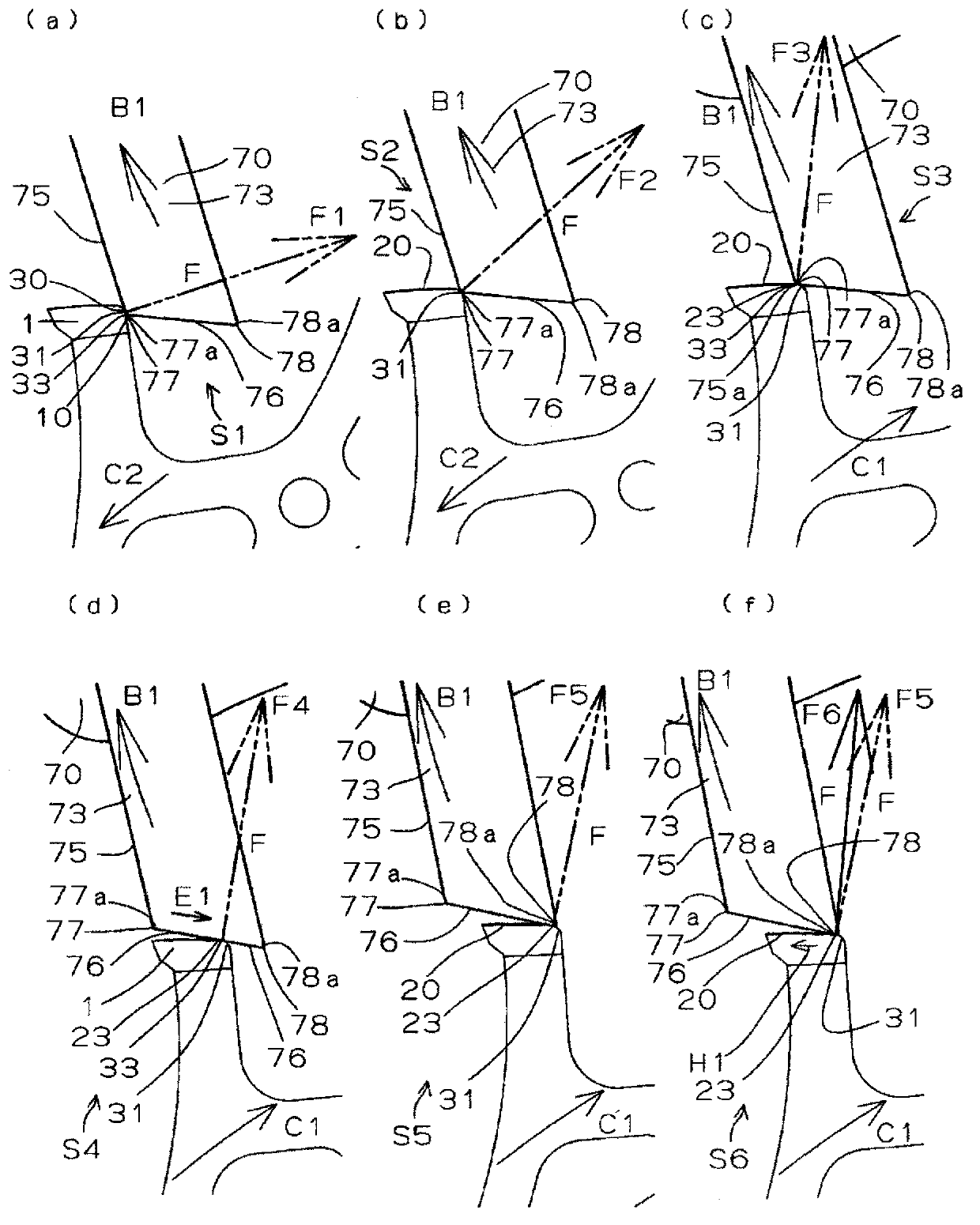

[0103] exist figure 1 A movement 300 of a preferred embodiment of the present invention is shown in , and is a movement assembled in a mechanical timepiece 4. The movement 300 has an anchor escapement 3 of a preferred embodiment of the present invention, The anchor escapement 3 has an escape wheel 2 according to a preferred embodiment of the present invention, which escape wheel is provided with an escape tooth 1 according to a preferred embodiment of the present invention. The escape wheel 2 can rotate around the central axis C in directions C1 and C2 to transmit the torque of a mainspring (not shown). In the anchor escapement 3, reference numeral 70 is a pallet fork, and reference numeral 80 is a balance wheel. The balance wheel 80 can reciprocate around the central axis A in directions A1 and A2 under the action of the hairspring 81 , and the balance wheel 80 receives torque from the pallet fork 70 at the balance pin 82 and acts on the pallet fork 70 . The pallet fork 70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com