Process for manufacturing single-wall carbon nanotubes

a carbon nanotube and single-wall technology, applied in the direction of carbonsing rags, chemistry apparatus and processes, fibre chemical treatment, etc., can solve the problems of limiting the application high production costs of single-wall carbon nanotubes by using this technique, and relatively large quantities of low-purity materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

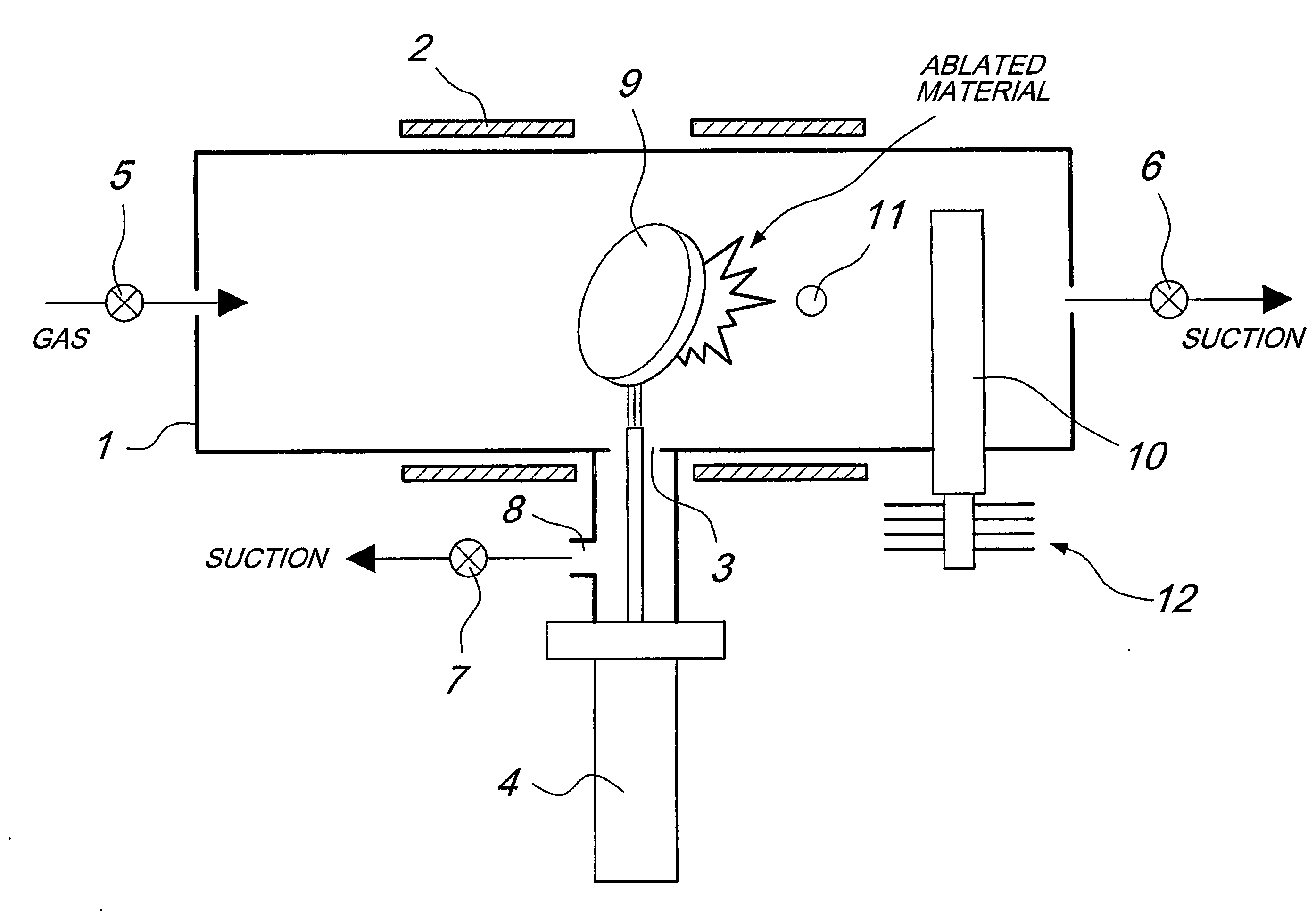

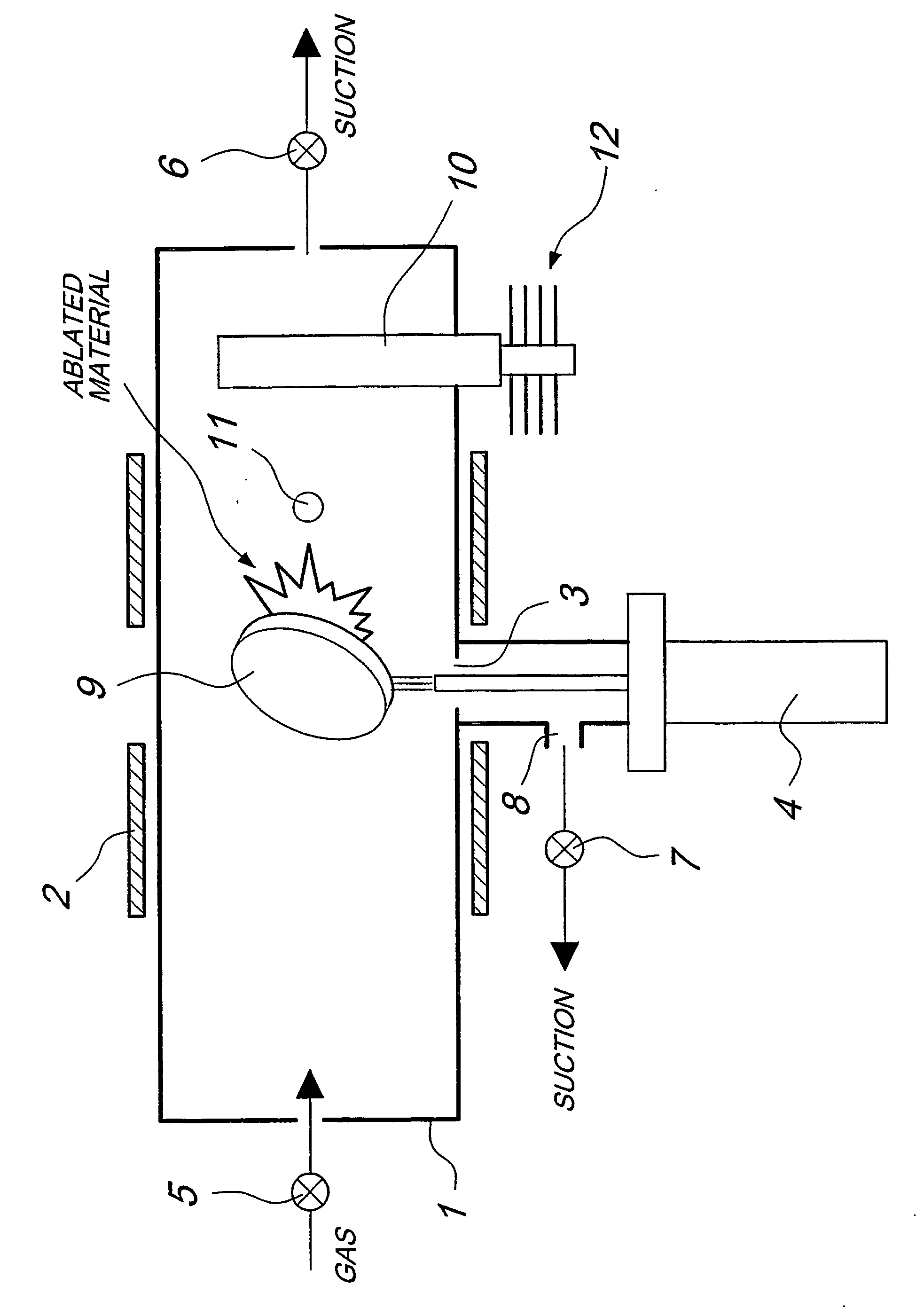

[0045]FIG. 1 illustrates the experimental layout used: the central part of a quartz tubular reactor 1 is heated by two electric high-temperature heaters 2, which maintain the temperature in the reactor at 1050° C. As an alternative to the second heater, it is possible to use a microwave antenna 11. At the center of the reactor, in a downward region, an opening 3 allows the entry of the pulsed electron beams that arrive from a channel-spark source 4 (shown schematically), which is provided as disclosed in U.S. Pat. No. 5,576,793. A needle valve 5 arranged at the left inlet of the reactor and two adjustable valves 6, 7, arranged respectively at the opposite end of the reactor and on the quartz neck 8 of the section that connects the reactor 1 to the spark to the channel-spark system 4, allow to maintain a flow of 5 normal cc / minute of argon in the reactor at a pressure of 1 mbar and a pressure of 2 10−2 mbar in the CSA system. A target 9, constituted by a graphite disk containing 0.5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com