Thread-measuring feeding device

A yarn feeding device and yarn technology, which is applied in the field of yarn length measuring and feeding devices, can solve problems such as yarn damage and fabric defects, and achieve the effect of eliminating the danger of entanglement formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

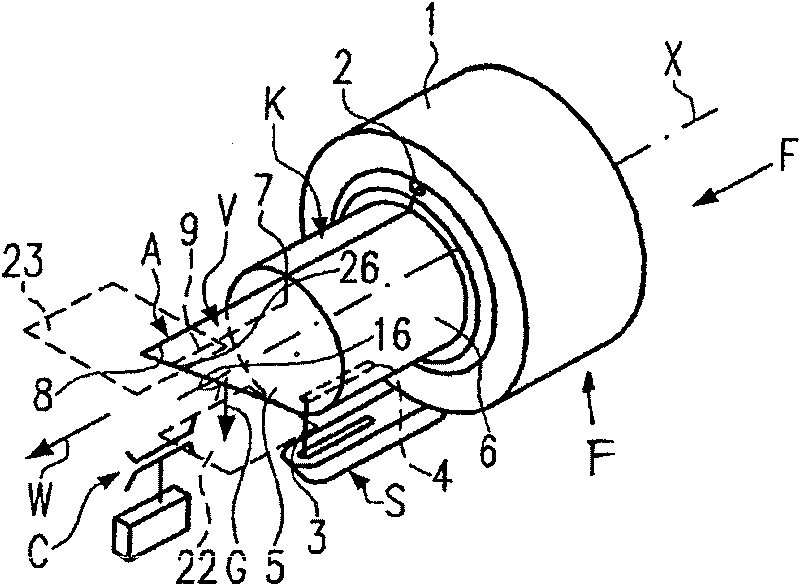

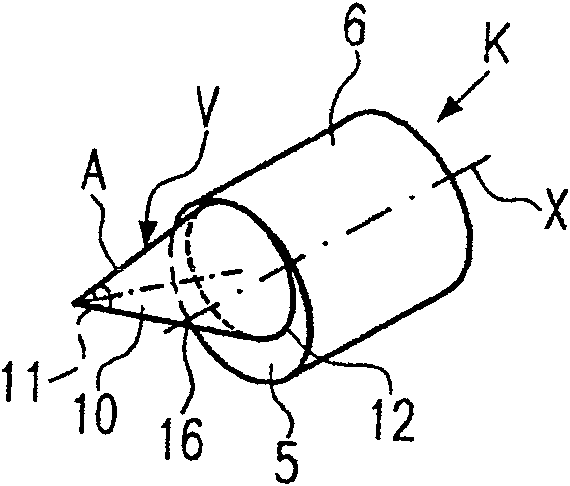

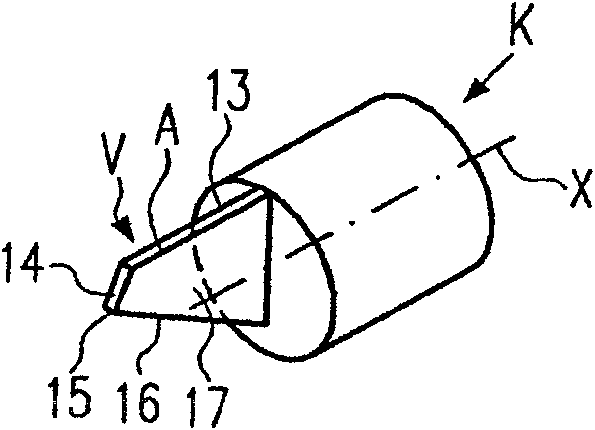

[0043] figure 1 The shown yarn length-measuring feeding device F basically corresponds to the length-measuring yarn feeding device known from the patent document WO-A-02 / 33157, and has a housing 1 containing a not shown Drive motor for winding assembly 2. A yarn storage body K is fixed on the casing 1 . Said winding element 2 is driven rotatably about a substantially cylindrical yarn storage surface 6 of the yarn storage body K. The yarn storage body K has an axis X and has a fixed or variable diameter. At least one brake device S with a brake pin 3 is arranged close to the housing 1, the function of the brake pin 3 is to cooperate with the yarn storage body K to measure the number of winding yarns, and the winding yarn is unwound in one operation will be released separately. Said winding yarns are produced with the help of the winding element 2 and are stored intermediately on the yarn storage surface 6 so as to be in direct contact with each other or separated axially fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com