Mounting structure of steering wheel central bush

A technology of installation structure and steering wheel, which is applied to steering control, handwheel and other directions installed on the car, can solve problems such as deformation, and achieve the effects of low cost, easy processing and manufacturing, and low material price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

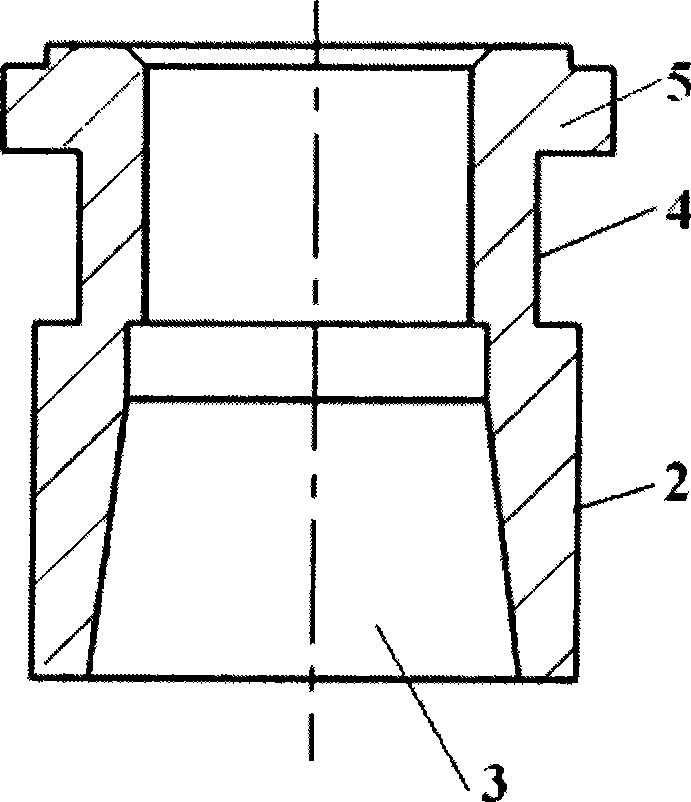

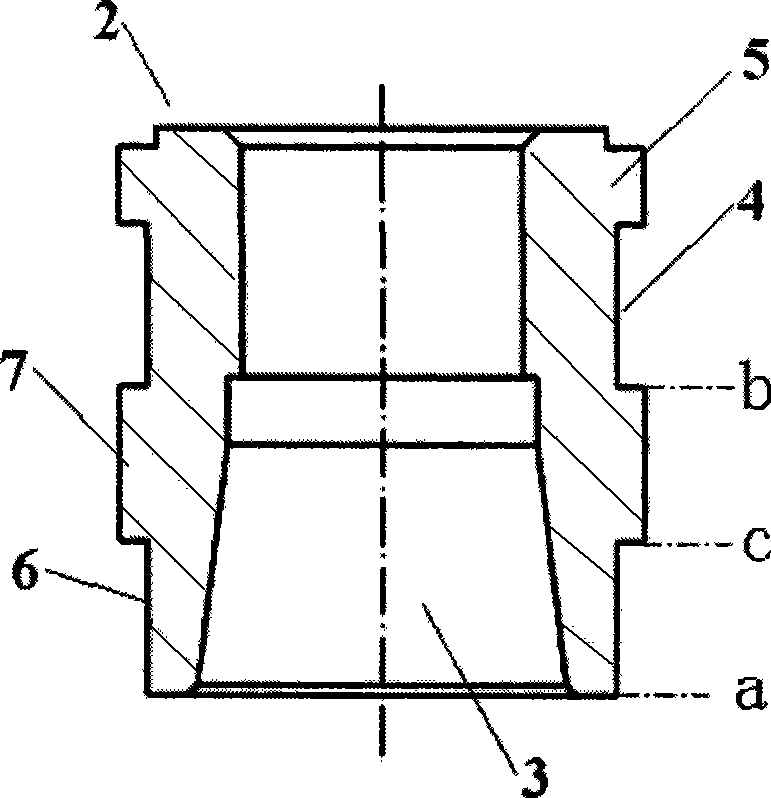

[0031] Between the end boss 5 and the middle boss 7 of the present invention is an annular groove 4; the outer circle from the middle boss 7 to the end of the tapered hole 3 is the outer circle 7 of the tapered hole; The diameter of the groove 4 is equal to the diameter of the outer circle 7 of the tapered hole.

[0032] From figure 2 It can be seen from the figure that the cross-sectional shape and size of the steering wheel center bushing 2 change: increasing the wall thickness of the groove 4 on the steering wheel center bushing 2 not only effectively increases the stiffness at the cylindrical hole of the steering wheel center bushing 2, but also improves The thermal stress distribution state at the groove 4 is shown.

Embodiment 2

[0034] Such as figure 2 As shown, the intermediate boss 7 of the present invention is located on the end face of the groove 4 direction, and the distance to the end of the tapered hole 3 is ab; the axial dimension of the intermediate boss 7 is bc ; said bc:ab=0.618:1.

[0035] Applying the "golden section" idea, the length of the thickening zone based on the boss is taken as 0.618 of the axial projection of the cone surface, and the thickness of the BUSH section at this place is increased to be equal to the diameter at position 1; figure 2 At the point b shown, taking point b as the base, take bc as the axial thickening zone of the steering wheel center bushing 2, and bc=0.618ab (that is, the golden section point). From figure 2 It can be seen from the structural diagram that increasing the section thickness of the inner bearing sleeve 2 not only effectively increases the stiffness of the section of the inner bearing sleeve 2, but also improves the thermal stress distribu...

Embodiment 3

[0037] During die-casting production, the specific implementation plan is:

[0038] 1. Cut out 45 steel materials and process the embedded bearing kit with machine tools;

[0039] 2. Put the processed inner bearing sleeve into the inlay position of the die-casting mold, and position it as an inner insert;

[0040] 3. Close the die-casting mold and pour the magnesium alloy melt;

[0041] 4. Die-casting production of steering wheel parts.

[0042] For the steering wheel produced by die-casting according to the present invention, the tapered bonding surface of the embedded steering wheel center bushing 2 can meet the testing requirements of the tapered bonding by 100% with the tapered testing tool. This technological method for solving the deformation of the tapered surface of the automobile steering wheel bearing sleeve has obvious engineering value because it is practical and simple, and can be completely solved by one-time die casting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com