Electroluminescent diode panel mould set with separated casing

An electro-luminescence, panel mold technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, electrical equipment structural parts, etc., to achieve the effect of helping product yield and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

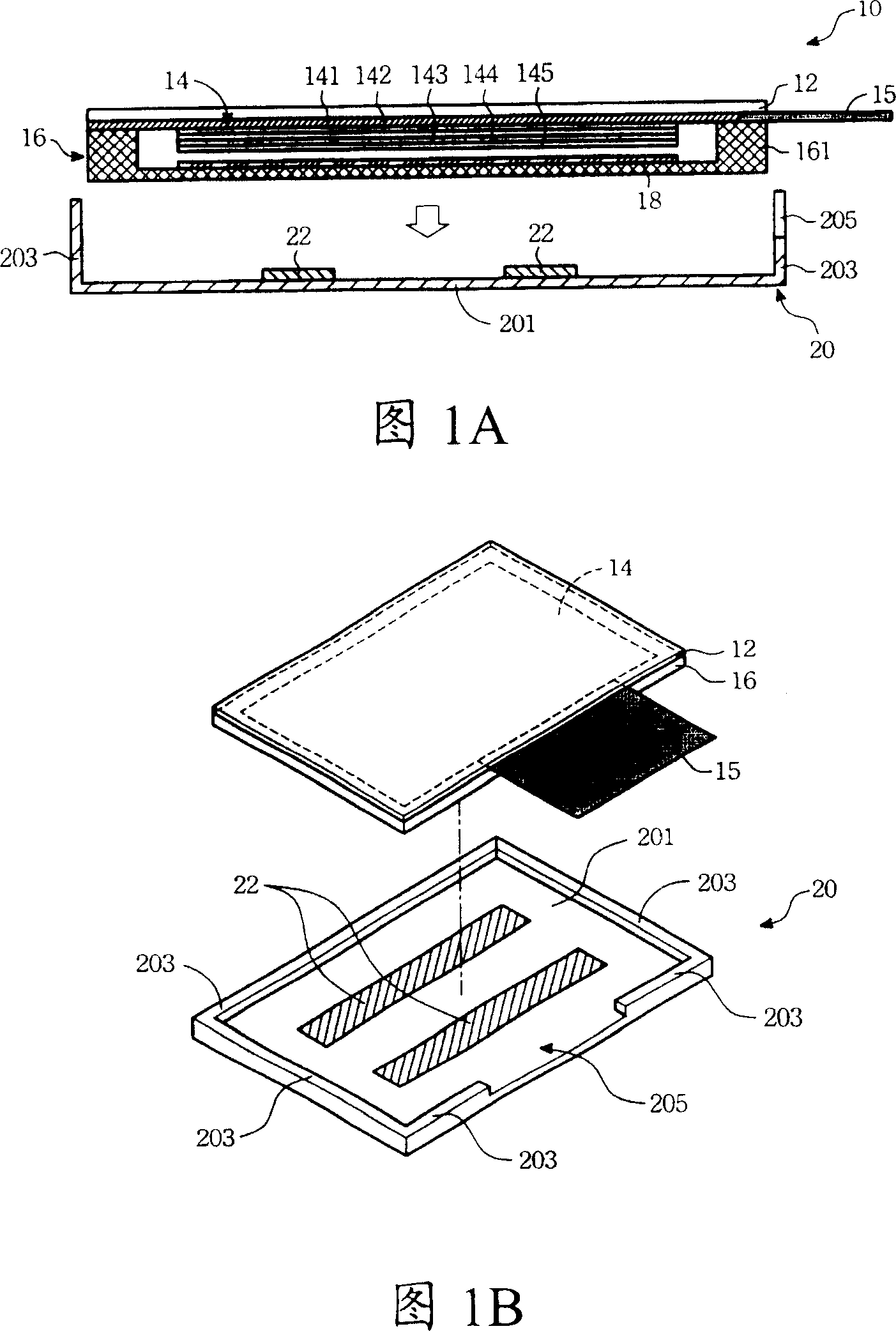

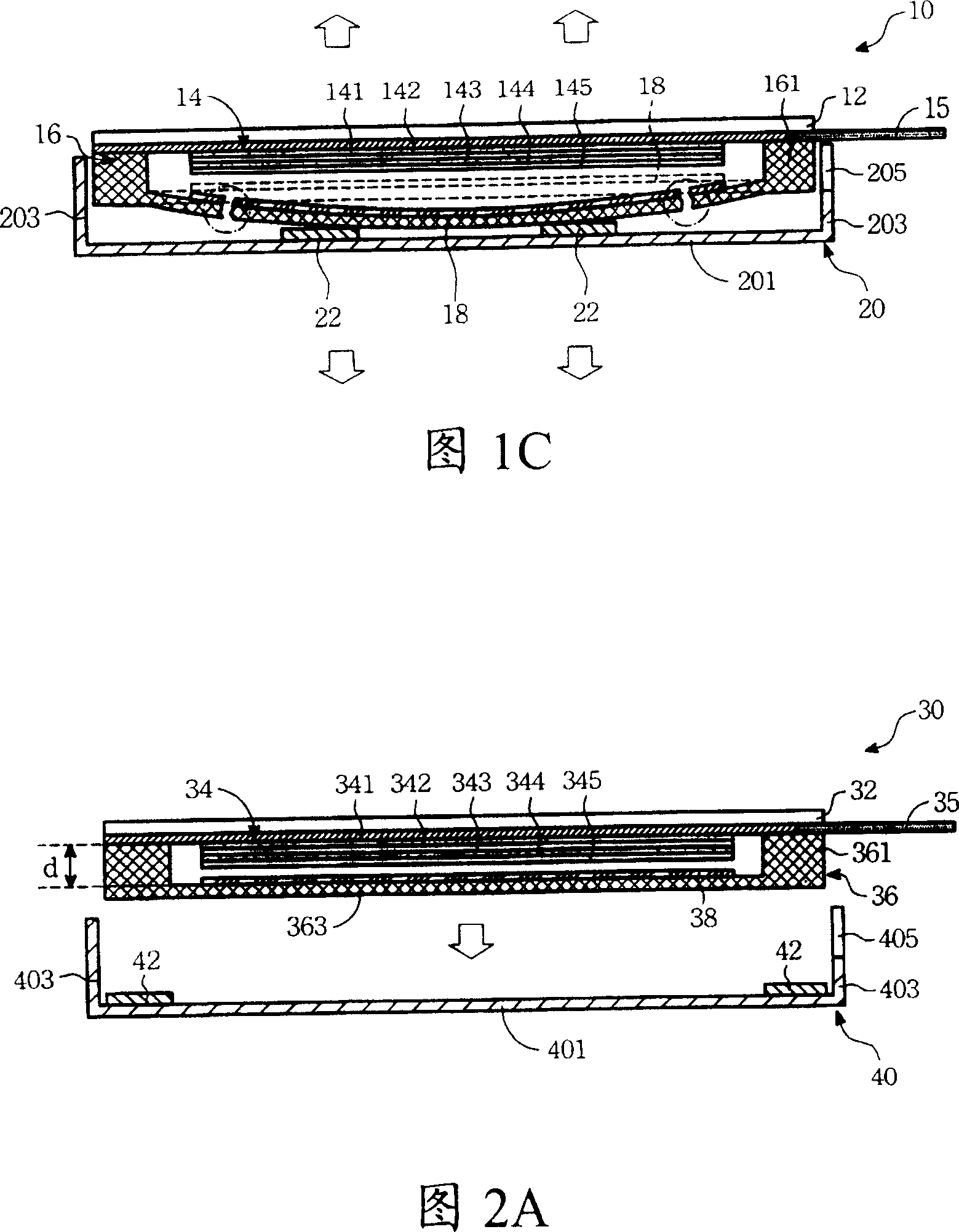

Embodiment Construction

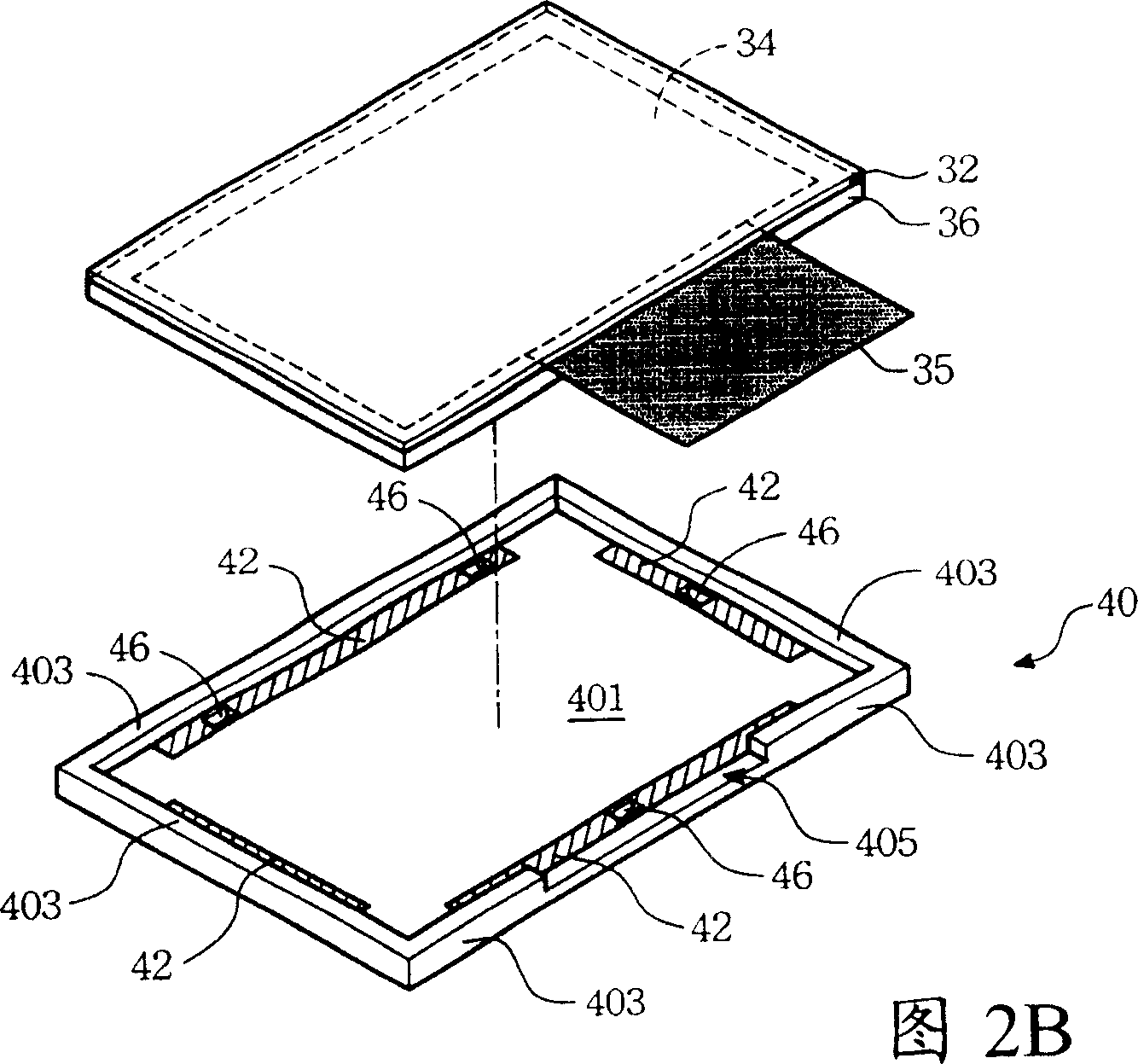

[0042] Please refer to FIG. 2A . FIG. 2A is a side sectional view of the electroluminescence panel module of the present invention. The electroluminescent body panel module 30 includes a substrate 32 , an electroluminescent body 34 , a casing 36 , and a casing 40 . The casing 36 includes a casing surface 363 and a connecting portion 361 extending from the upper surface of the casing surface 363 , and the casing 36 forms an accommodating space with the substrate 32 through the connecting portion 361 . The electroluminescent body 34 is disposed on the surface of the substrate 32 and located in the accommodating space. The shell 40 is combined with the casing 36 through an adhesive element 42 . Wherein, the adhesive element 42 is disposed on the lower surface of the shell surface 363 in a range corresponding to the connecting portion 361 .

[0043]Wherein, the height of the connecting portion 361 (height d indicated in FIG. 2A ) is between 0.1 mm˜0.5 mm. A desiccant 38 can be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com