Hydrocarbon conversion processes using ionic liquids

a technology of ionic liquid and hydrocarbon conversion process, which is applied in the field of hydrocarbon conversion process using ionic liquid, can solve the problems of high sulfur or nitrogen content of feed stream, affecting product quality specifications, catalyst deactivation, and/or product yield, etc., and achieves the desired product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

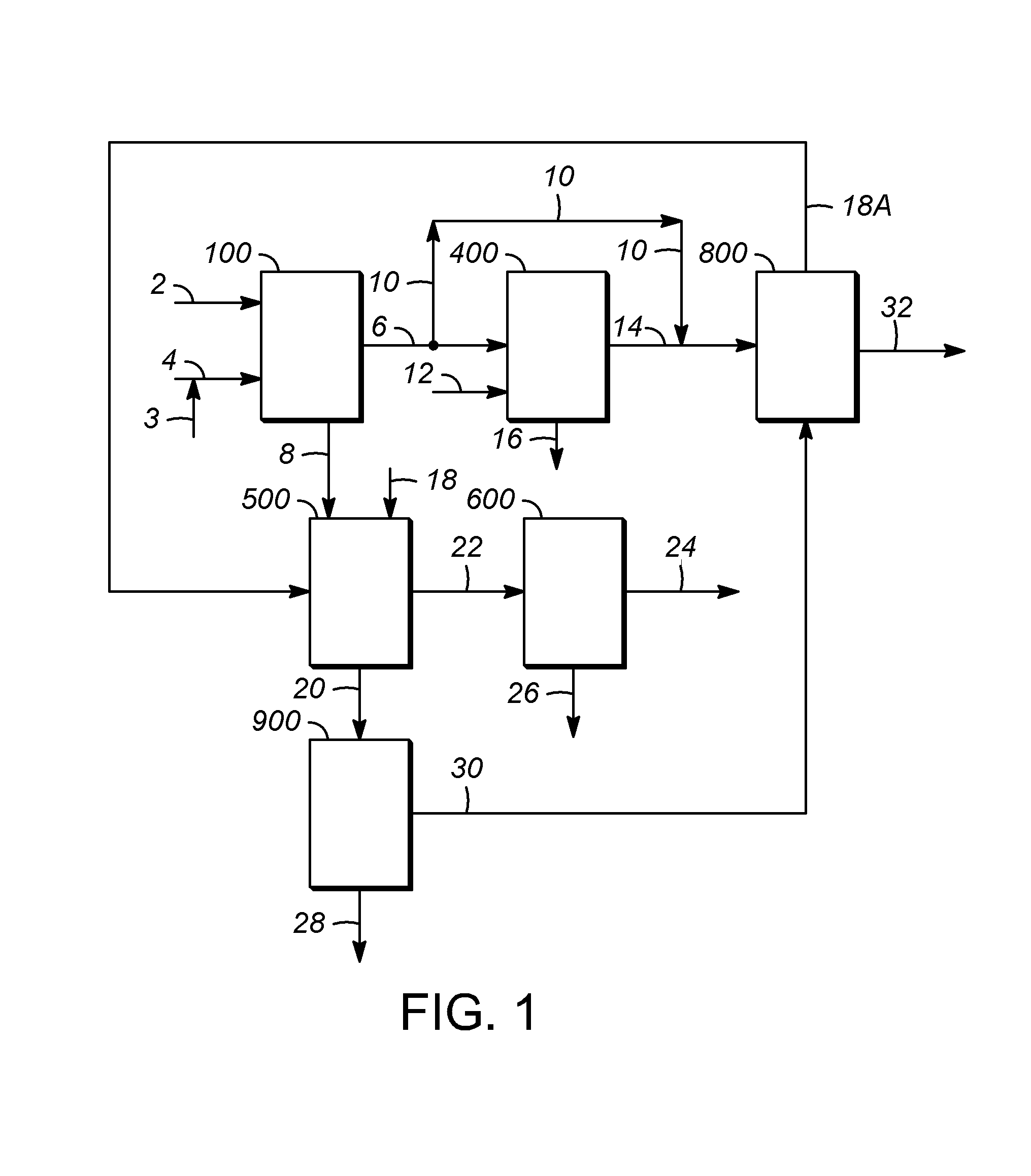

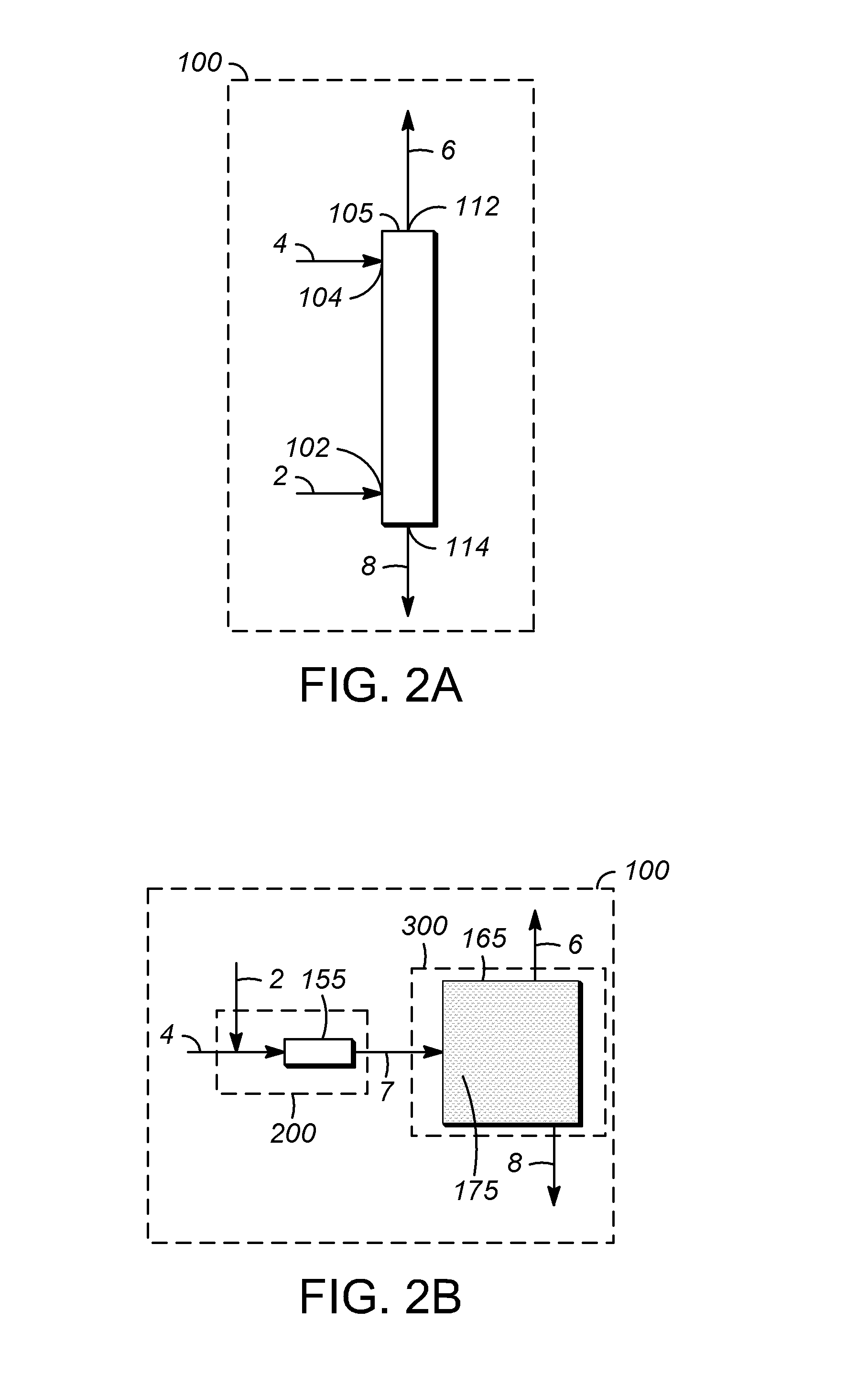

Image

Examples

example 1

[0082]A sample of triisobutylmethylphosphonium tosylate ionic liquid and vacuum gas oil (VGO) containing 1400 ppm of nitrogen were combined in a beaker at a weight ratio of 10:1 hydrocarbon feed: ionic liquid. The beaker was placed onto a heated stir plate and stirred at 80° C. for 30 minutes. After 30 minutes, the stirring was stopped, and the ionic liquid mixture was allowed to settle for 30 minutes. A pipette was used to draw off the extracted hydrocarbon feed from the ionic liquid. The catalyst / oil ratio was adjusted for the ionic liquid treated case to account for the same coke combustion in the regenerator. Analysis showed that 42.3% of the nitrogen was removed from the extracted hydrocarbon feed. This extracted hydrocarbon feed was tested in an FCC pilot plant. The conversion of ionic liquid treated VGO to hydrocarbons boiling below 193° C. (380° F.) increased by 5.0 volume % over that of the untreated hydrocarbon feed. The gasoline yield from ionic liquid treated VGO increas...

example 2

[0083]For comparison purposes a sample made up of 80% untreated VGO was blended with 20% untreated coker gas oil (CGO), the total nitrogen in this blend was 2816 ppm. This blend was tested in an FCC pilot plant. A sample of triisobutylmethylphosphonium tosylate ionic liquid and CGO were combined in a beaker at a weight ratio of 10:1 CGO: ionic liquid. The beaker was placed onto a heated stir plate and stirred at 80° C. for 30 minutes. After 30 minutes, the stirring was stopped, and the ionic liquid mixture was allowed to settle for 30 minutes. A pipette was used to draw off the extracted CGO from the ionic liquid. The catalyst / oil ratio was adjusted for the ionic liquid treated case to account for the same coke combustion in the regenerator. Analysis showed that the extraction removed 34.6% of the nitrogen from the CGO. This extracted CGO was blended with 80% untreated VGO, the total nitrogen in this blend was 2186 ppm. This blend was also tested in an FCC pilot plant. The conversio...

example 3

[0084]A sample of triisobutylmethylphosphonium tosylate ionic liquid and vacuum gas oil (VGO) containing 1386 ppm of nitrogen were combined in two beakers at a weight ratio of 20:1 and 2.5:1 hydrocarbon feed: ionic liquid respectively. The beakers were placed onto a heated stir plate and stirred at 80° C. for 30 minutes. After 30 minutes, the stirring was stopped, and the ionic liquid mixture was allowed to settle for 30 minutes. A pipette was used to draw off the extracted hydrocarbon feed from the ionic liquid. Analysis showed that 33% of the nitrogen was removed from the extracted hydrocarbon feed for 20:1 case and 60% of nitrogen was extracted for 2.5:1 case. This extracted hydrocarbon feed was tested in an FCC pilot plant. The conversion of 20:1 ionic liquid treated VGO to hydrocarbons boiling below 193° C. (380° F.) increased by 4.5 vol % over that of the untreated hydrocarbon feed and the conversion of 2.5:1 ionic liquid treated VGO to hydrocarbons boiling below 193° C. (380°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| atmospheric equivalent boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com