Reverse circulation drilling device and process for soft projecting coal seam

A technology of protruding coal seams and reverse circulation, applied in drilling equipment, drilling equipment and methods, earthwork drilling and mining, etc., can solve the problem that it is difficult to deal with collapsed and shrinking strata, cannot effectively improve the on-site operating environment, and the injection hole phenomenon is impossible Avoid other problems to achieve the effect of avoiding spray hole phenomenon, improving drilling efficiency and reducing drilling rig investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

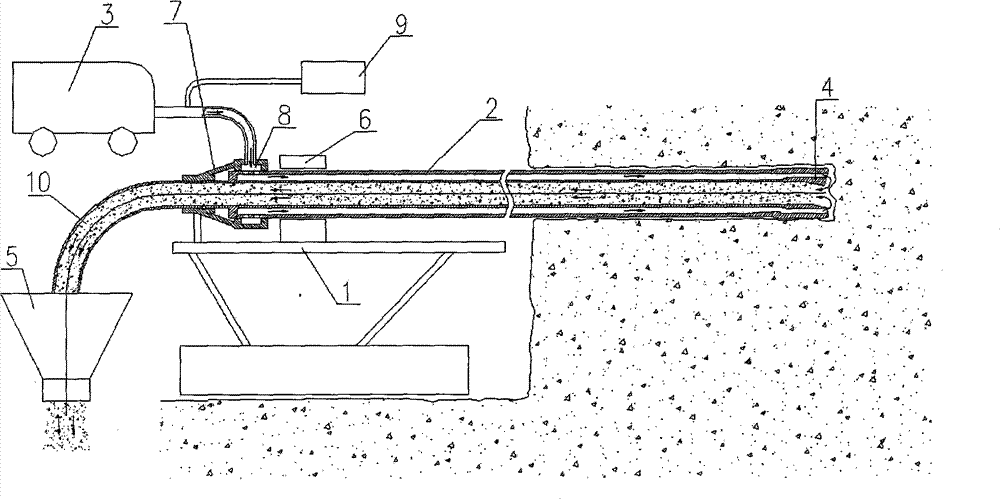

[0032] Such as figure 1 As shown, the reverse circulation drilling equipment for soft and outburst coal seams includes a drilling rig 1, a double-walled drill pipe 2, a double-channel gas tap 7, a drill bit 4 and an air compressor 3. The drilling rig 1 is provided with a power head 6, and the double-walled The wall drill pipe 2 is installed through the power head 6, and the inner pipe at one end of the double-wall drill pipe 2 communicates with the rubber hose 10 through the double-channel air tap 7. The end of the rubber pipe 10 is connected with a pulverized coal receiving device 5. 7 is provided with an air box 8 communicating with the annular channel of the inner and outer tubes of the double-walled drill pipe 2. The air box 8 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com