Direction-changing forging process for large cake forgings

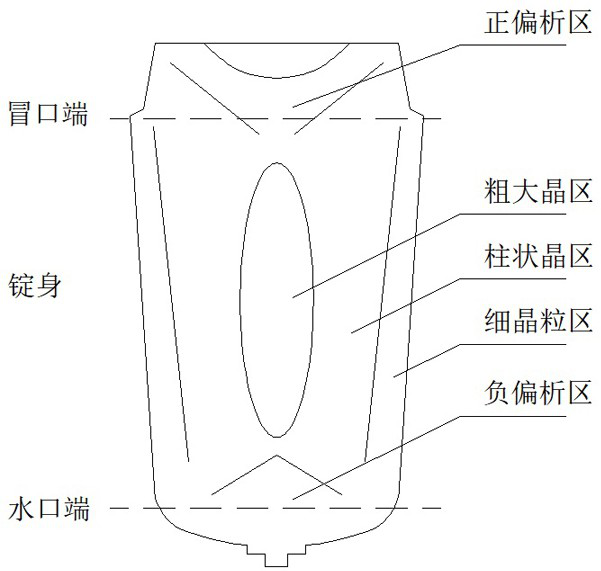

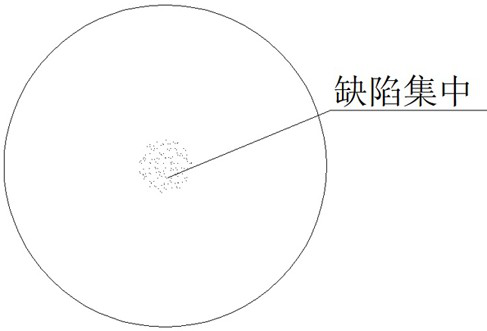

A forging, large-scale technology, applied in the forging field of cake forgings, can solve the problems of slow cooling of molten steel, shrinking volume, small area, etc., to achieve the effect of improving looseness, improving product quality, and dispersing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] See Figure 4 and Figure 5 , Figure 4 A process diagram of a changeable forging process of a large piecera forging is drawn. As shown, a large-scale cake forging process according to the present invention is a forged forging process for the production of pieces for cookies, and a 11.5-ton steel ingot is equipped with a diameter of 2675 mm, and the thickness is 168mm.

[0031] Its process flow includes the following:

[0032] First fire

[0033] At 1180 ° C, the ingot is rolled down, and the ingot is pulled out over, and the end of the end of 850 ° C is risoted, and the ingot is back and the riser is high.

[0034] Second fire

[0035] The noast is heated to the starting temperature of 1180 ° C, and the water port end of the steel ingot is upset to the forgings, upset to about 900 mm;

[0036] The steel ingots are flattened by the steel ingots above the end of 850 ° C, and then pressed, chamfer;

[0037] Third fire

[0038] The forging is heated to the starting temperature of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com