Organosilicon surfactant and application thereof in preparation of slow-rebound polyurethane foam body

A surfactant and silicone technology, applied in the chemical industry, can solve the problems of poor porosity and environmental protection, and achieve the effects of porosity and stability, uniform cells, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

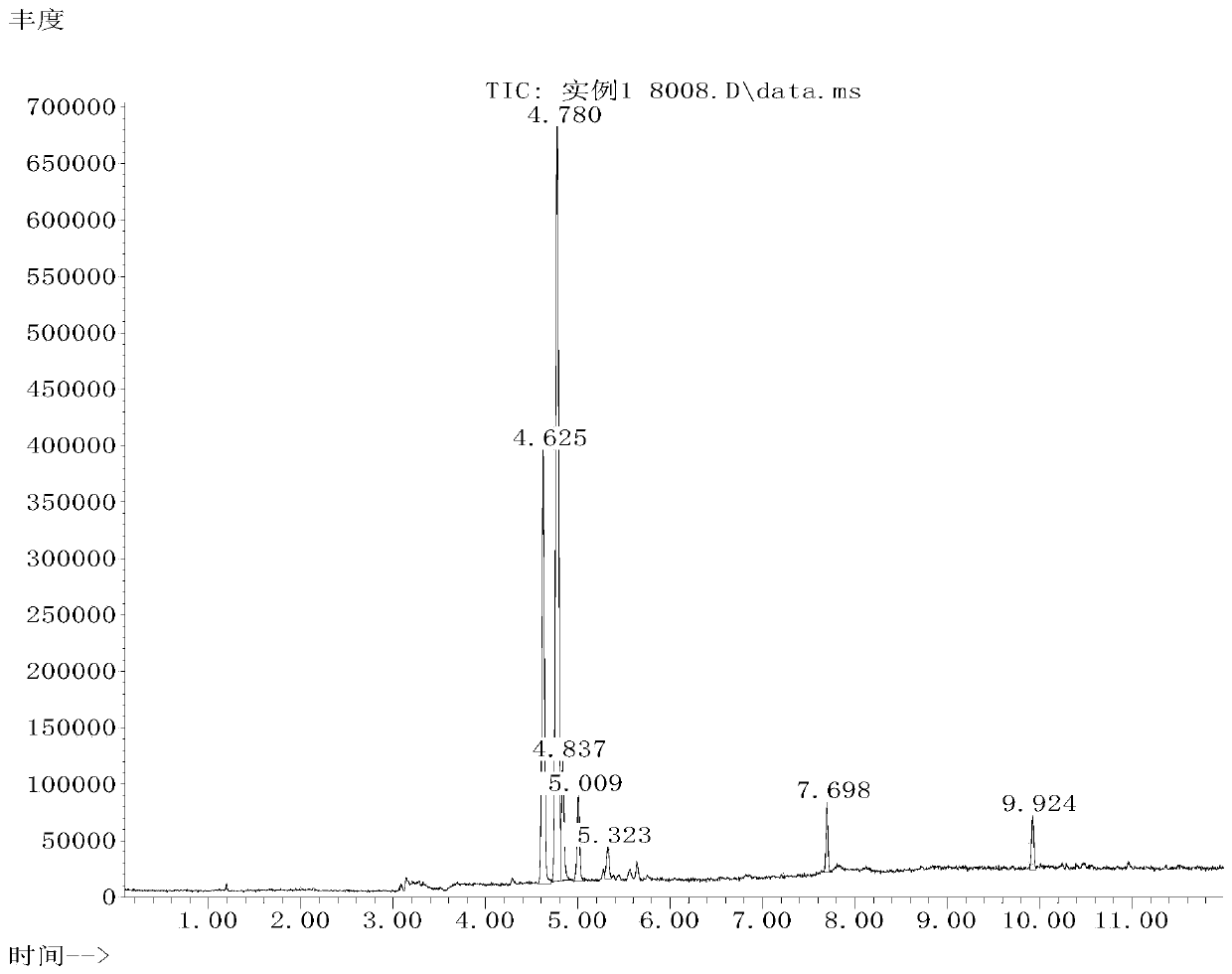

Embodiment 1

[0053] Preparation of Silicone Surfactant

[0054] In a 250L reactor with fixture, constant temperature function, mechanical stirring, thermocouple and nitrogen gas, add 82.8kg 2,5,8,11-tetramethyl-6-dodedecyne-5,8- Alkyne diol polyoxyethylene ether (referred to as polyether A) with an average molecular weight of 942 Daltons of methyl end-capped by diol. The molar ratio of oxypropylene group: ethylene oxide group is 1:2:13; adding 120kg of allyl alcohol starting methyl-terminated polyoxyethylene ether with an average molecular weight of 4000 Daltons (called polyether B), in this polyether B, the molar ratio of oxirane group and propylene oxide group is 48:52, then 55kg low hydrogen-containing polysiloxane ( MD for short 40 D' 5 M) Put it into a four-neck flask, start stirring, heat to 80°C with a heating mantle, stir for 5 minutes, add 15ppm of Pt chloroplatinic acid ethanol solution, and react for 4 hours to obtain a clear and transparent light yellow organosilicon copoly...

Embodiment 2

[0056] Preparation of Silicone Surfactant

[0057] In a 250L four-neck flask with a fixture, constant temperature function, mechanical stirring, thermocouple and nitrogen, add 48kg of 4,7-dimethyl-5-decyne-4,7-diol starting A polyoxyethylene ether with an average molecular weight of 700 Daltons terminated by a methyl group (referred to as polyether A). The molar ratio of the alkyl groups is 1:1:10; 120kg of polyoxyethylene ether (called polyether B) with an average molecular weight of 3000 Daltons (called polyether B) initiated by allyl alcohol and methyl-terminated is added. , the mol ratio of oxirane group and propylene oxide group is 50:50, then 40kg low hydrogen-containing polysiloxane ( MD for short 55 D' 13 M) Add in a four-necked flask, start stirring, heat to 80° C. with a heating mantle, stir for 5 minutes, add 15 ppm of Pt chloroplatinic acid ethanol solution, and react to obtain a clear and transparent light yellow organosilicon copolymer liquid after 4 hours. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com