High-efficiency and high-quality plate drilling method

A drilling method and board technology, which are applied in wood treatment, humidity-conditioning wood, wood heating, etc., can solve problems such as board damage, low efficiency, and increase labor intensity, so as to improve production efficiency, improve processing efficiency, and reduce labor. the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

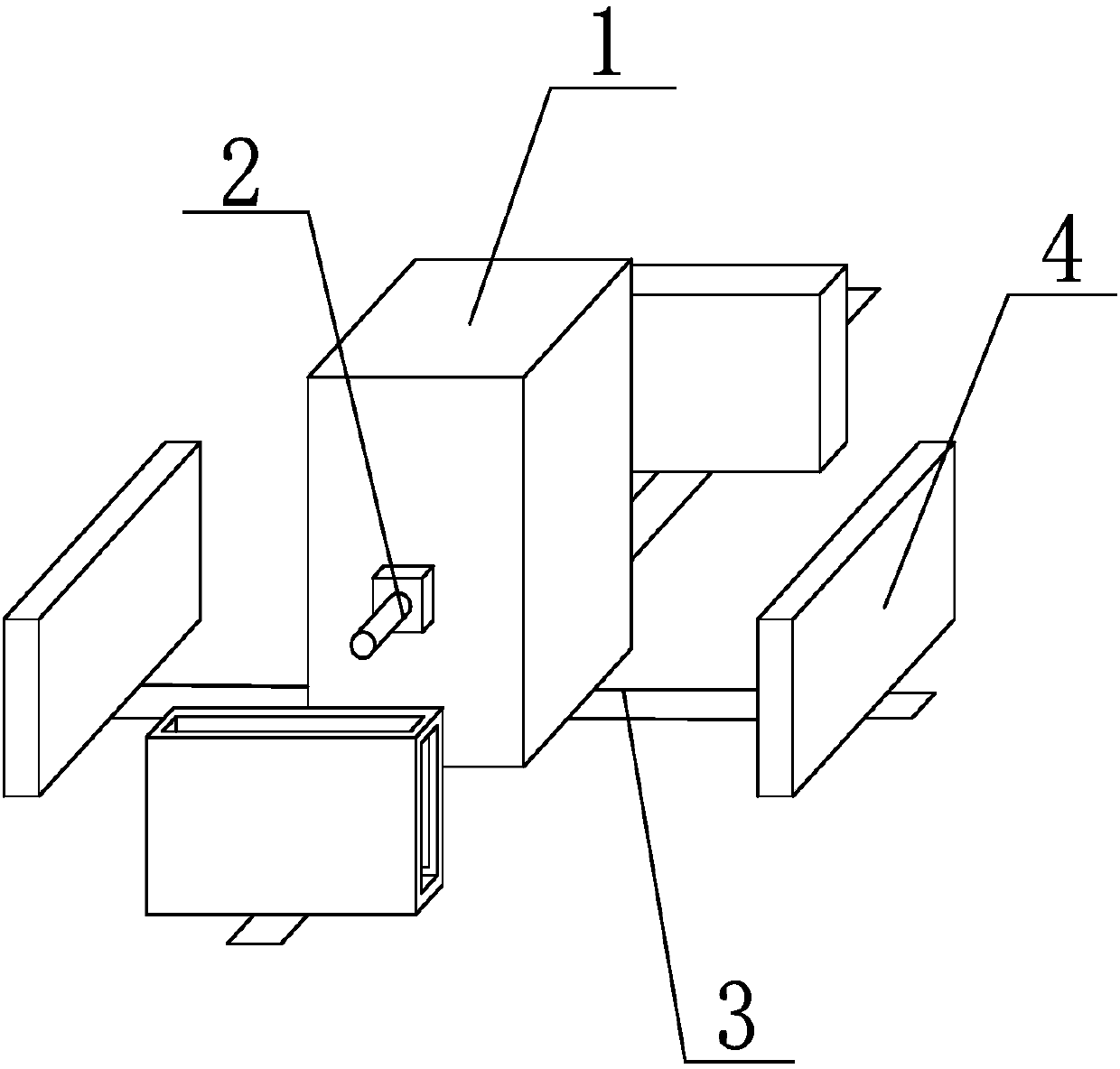

[0021] A high-efficiency and high-quality plank drilling method of the present invention comprises the following steps: 1) firstly, the surface of the plank is polished; 2) the plank is put into a heating box, and steam is passed into it at a temperature of 30-35° C. After 5-10 minutes, dry the obvious water droplets on the surface; 3) place the plate on the drilling equipment, and determine the drilling position. The drilling equipment includes a drilling mechanism 1, and the surrounding area of the drilling mechanism 1 is All are provided with drilling tool 2, and described drilling tool 2 is arranged horizontally, and drilling tool 2 is driven by motor, and four guide rails 3 are arranged around the bottom of drilling mechanism 1, and two adjacent guide rails 3 are perpendicular to each other, and the guide rails 3 is vertically provided with a feed plate 4, the feed plate 4 is a hollow structure, the side of the feed plate 4 facing the drilling tool 2 is the front, the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com