PDC (polycrystalline diamond compact) bit vibration reduction and torque increase device

A drill bit and core tube technology, applied in the field of vibration reduction and torque increase devices, can solve the problems of strong stratum heterogeneity, slow drilling speed, and short service life of the drill bit, so as to improve the ability of cutting teeth to break rock and avoid cutting teeth damage, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

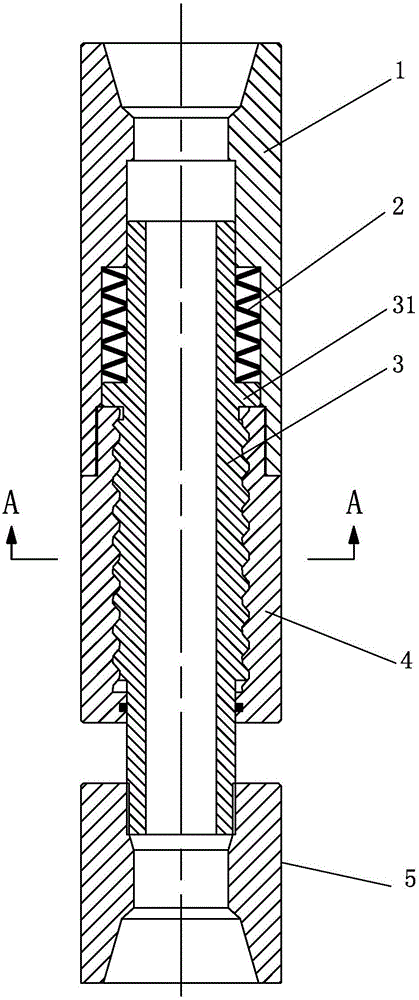

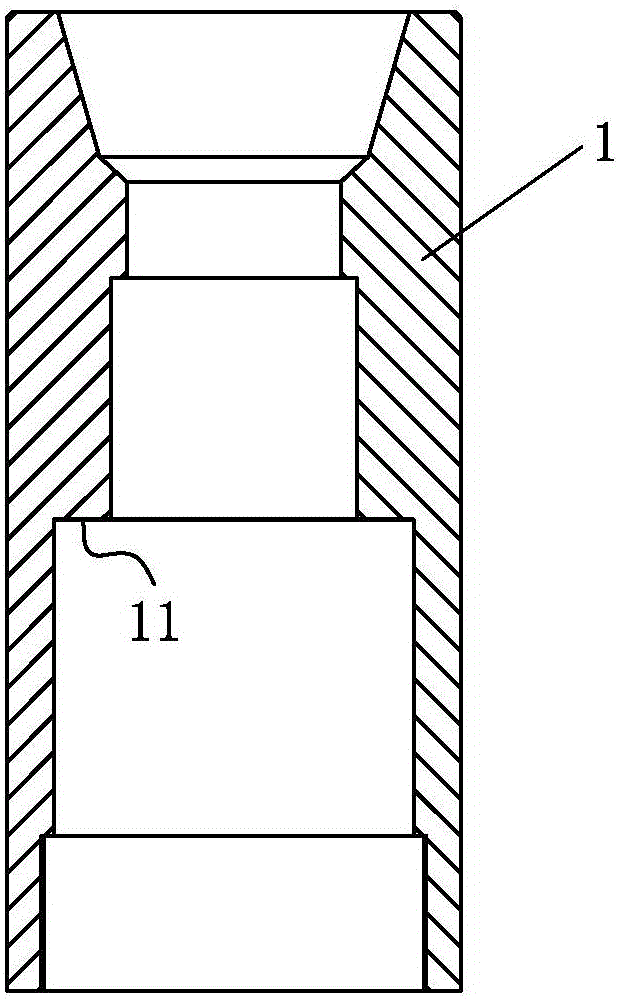

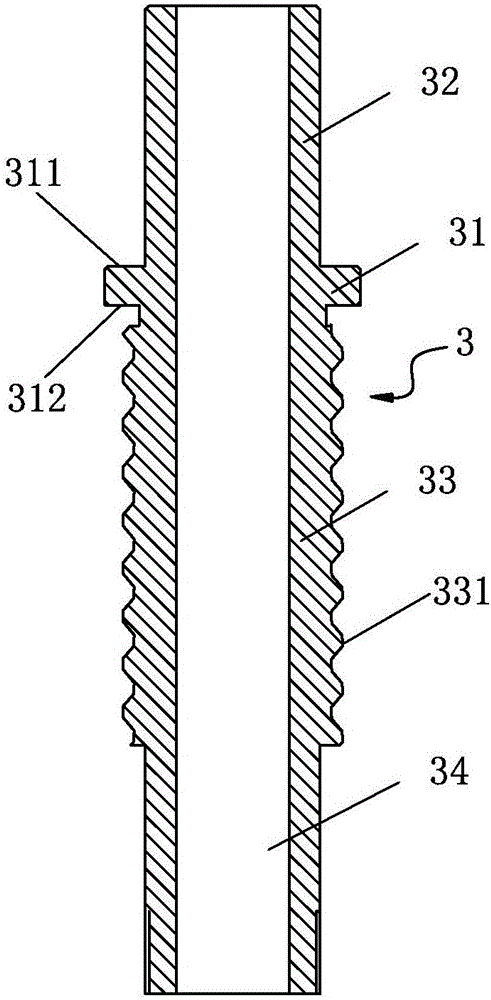

[0024] The specific implementation of the PDC drill bit vibration reduction and torsion increasing device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0025] Such as figure 1 , figure 2 , image 3 and Figure 4 Commonly shown, the PDC drill bit vibration reduction and torsion increasing device of the embodiment of the present invention includes: a cylinder body having a cylinder inner cavity penetrating along its axial direction, and the cylinder body is formed by screwing the outer cylinder 4 and the upper joint 1 , the upper end of the upper joint 1 is provided with an upper joint thread for connecting with the drill string, the upper joint thread is a female thread, and a stepped surface 11 perpendicular to the axial direction is provided on the inner side of the lower part of the upper joint 1 . A core tube 3 is arranged in the inner cavity of the cylinder, and the core tube 3 has a core tube inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com