Drilling equipment used for machine parts

A technology for processing equipment and mechanical accessories, applied in metal processing equipment, drilling/drilling equipment, metal processing mechanical parts, etc., can solve the problems of single drilling method, insufficient time and labor saving, etc., and achieves convenient use and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

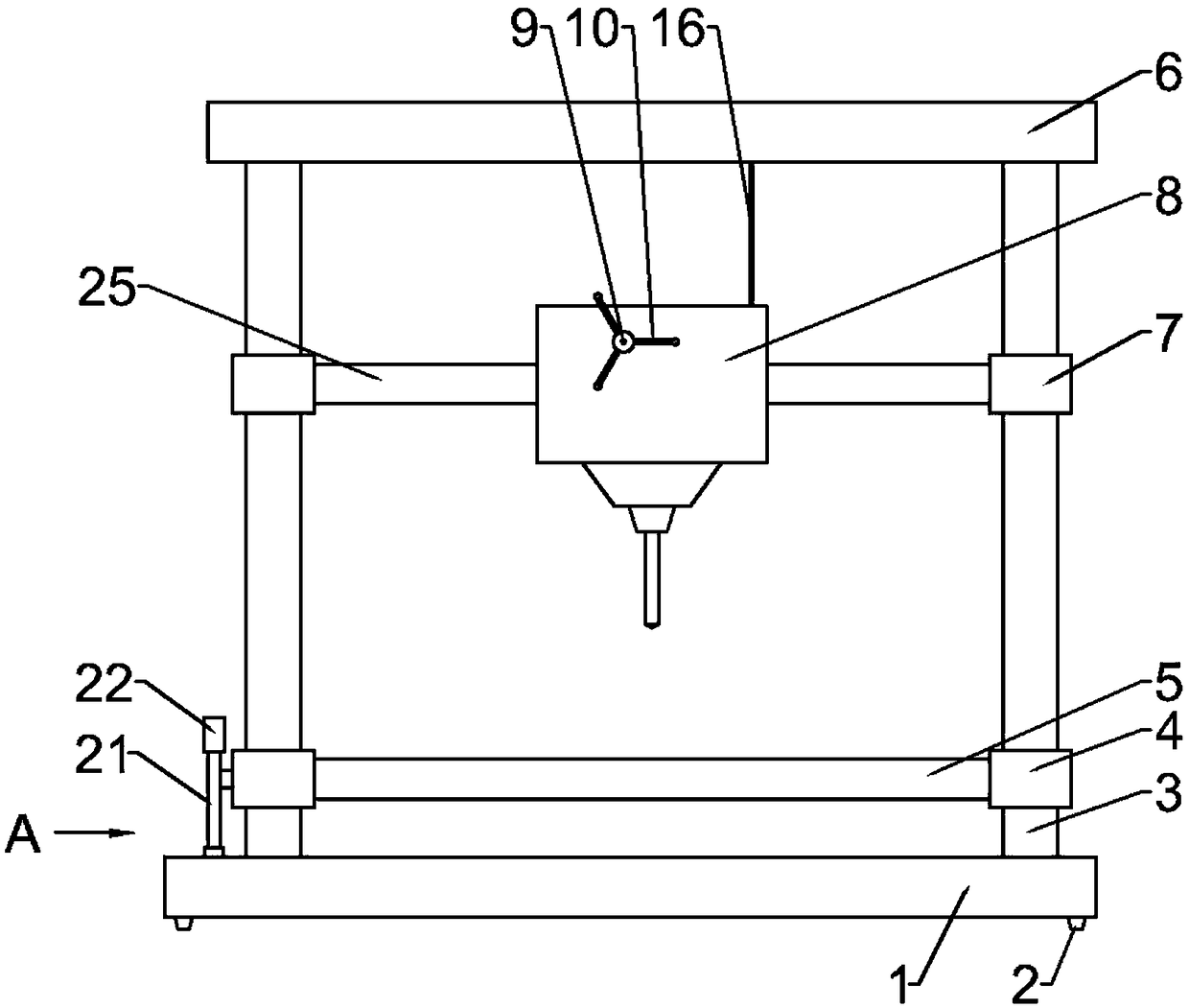

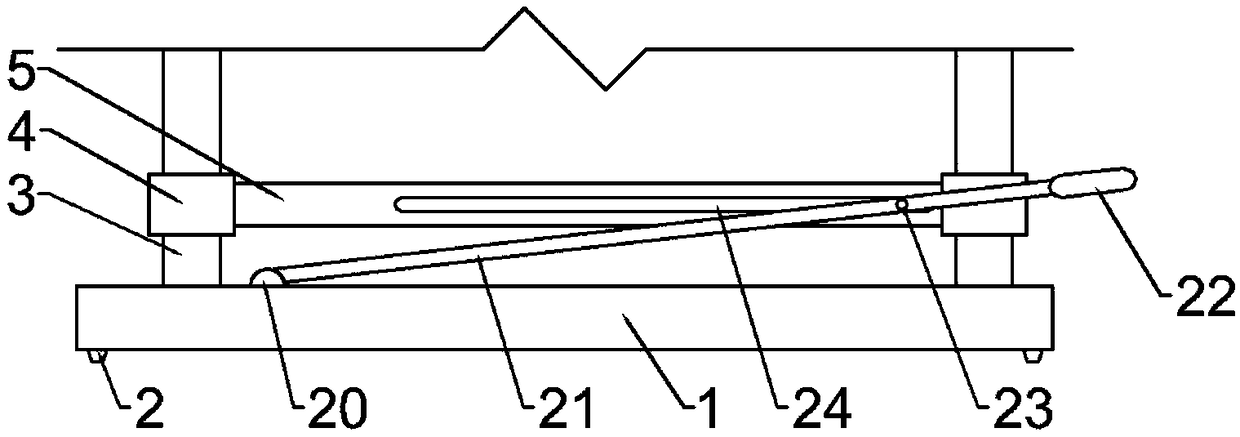

[0021] Example 1: Please refer to Figure 1-3 , a kind of drilling processing equipment for mechanical accessories, comprising a fixed base 1, a guide pillar 3 is fixedly connected symmetrically on the top of the fixed base 1, and a sliding sleeve 4 is connected to the outer side of the guiding pillar 3 symmetrically slidingly on the left and right, and the sliding sleeves 4 are fixed. Connected with a support base plate 5, the top of the guide pillar 3 is fixedly connected with a horizontal beam 6, and the upper side of the guide pillar 3 is slidably connected with an upper sliding sleeve 7, and the upper sliding sleeve 7 is connected with a drilling box 8 through a horizontal fixing rod 25;

[0022] When in use, the item to be drilled is placed on the support base plate 5, and then a suitable height adjustment method can be selected according to the quality of the item to be drilled for drilling;

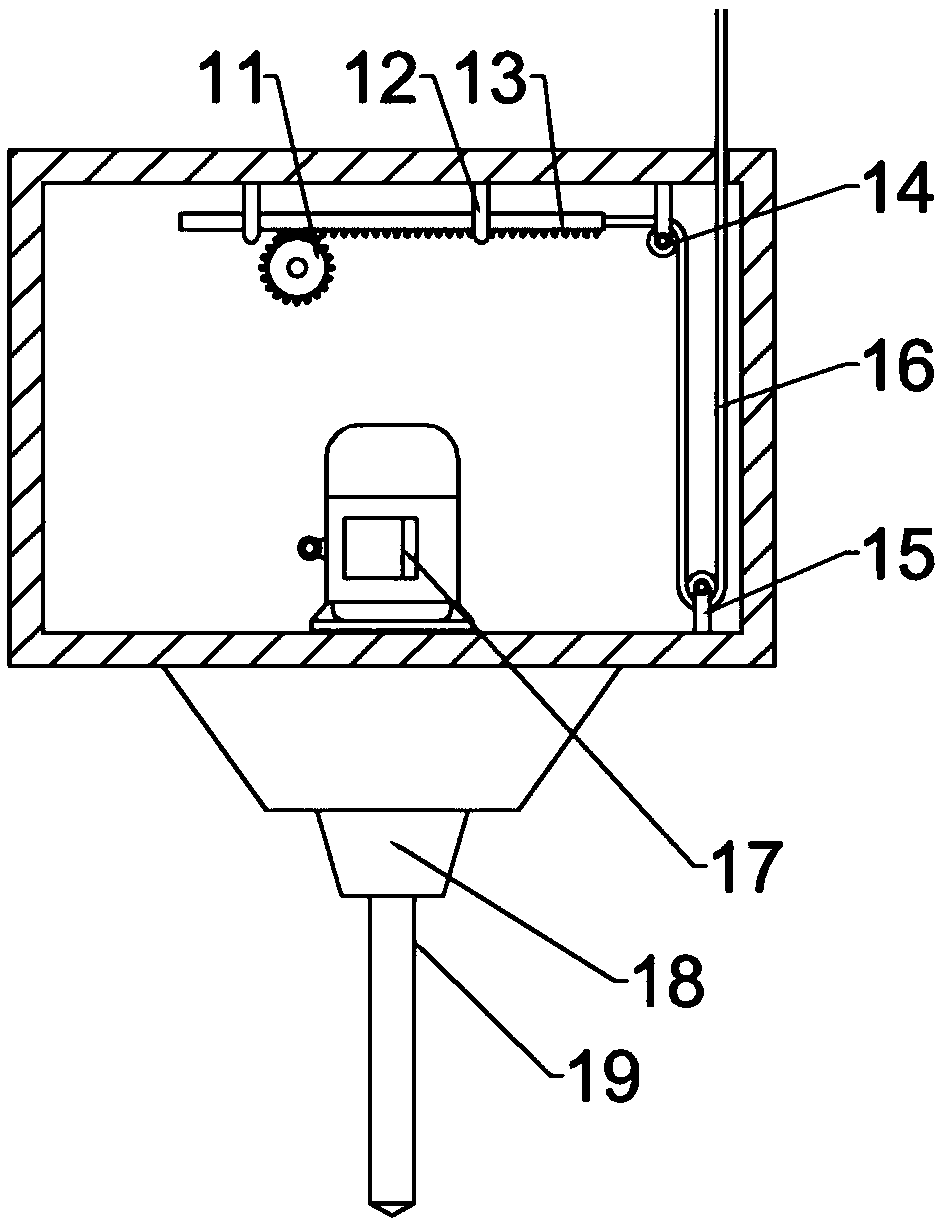

[0023] The front side wall of the drilling box 8 is rotatably connected with ...

Embodiment 2

[0035] Embodiment 2: The difference between this embodiment and the previous embodiment is that in this embodiment, electric telescopic rods are symmetrically arranged under the support base plate 5, and the up and down movement of the support base plate 5 is realized by electric drive, and the rotating shaft 9 is driven. It can also be driven by a motor. Although the cost of the device is increased, the full electric drive can effectively save manpower and speed up drilling.

[0036] The working principle of the present invention is: the present invention places the item to be drilled on the support base plate 5 during use, and then can select a suitable height adjustment method according to the quality of the item to be drilled for drilling, and then rotate the drilling box 8 The drive shaft 9 on the side, the rotation of the drive shaft 9 drives the inner transmission gear 11 to rotate, the rotation of the transmission gear 11 can drive the rack 13 to move to the left, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com