Boring system of rotary dual jet flows under high pressure, and rotary dual jet flows nozzle under high pressure

A drilling method and double-jet technology, applied in the direction of drilling with liquid/gas jets, can solve the problems of rotary sealing resistance, consumption of jet energy and power, and low utilization efficiency of jet energy, so as to improve impact performance and utilization efficiency , the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

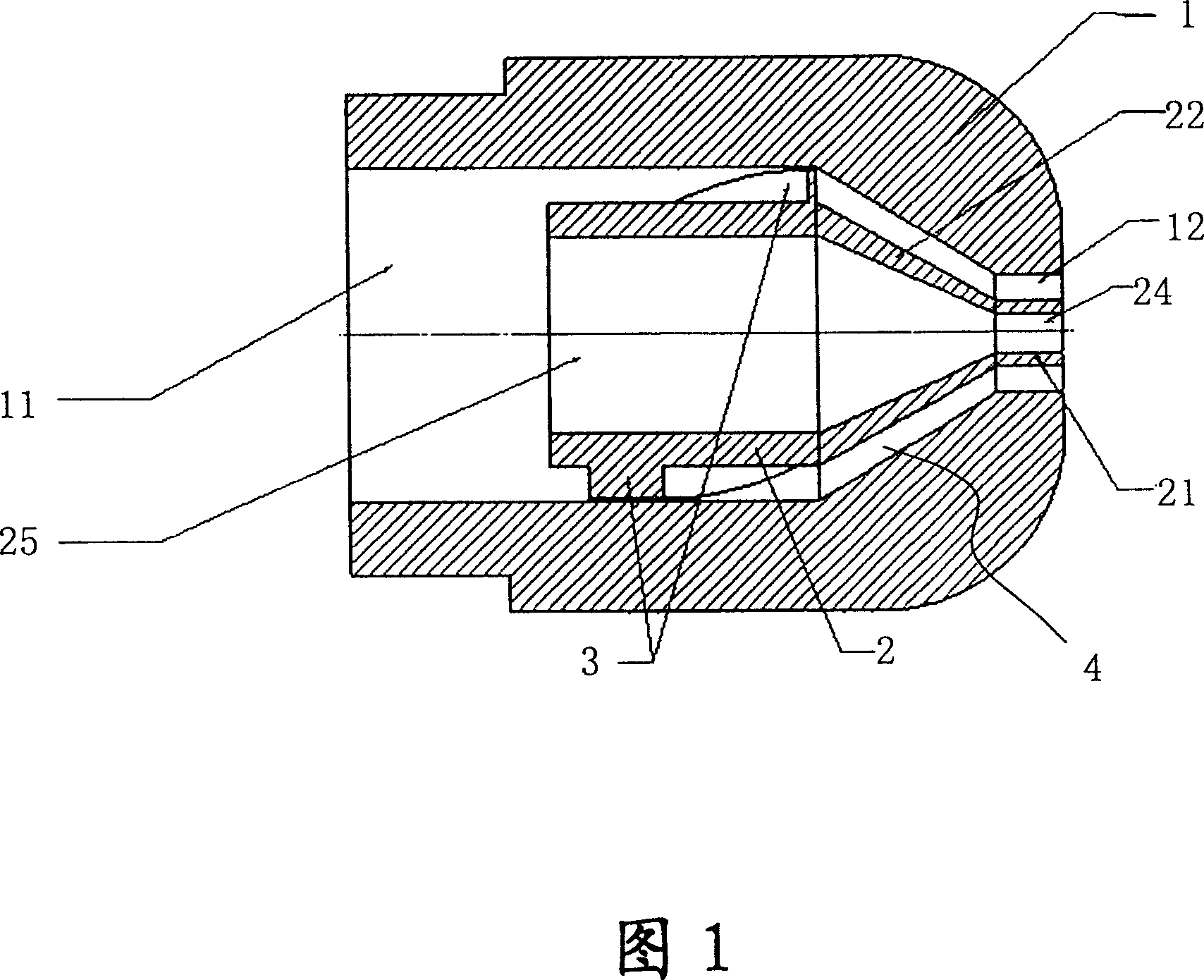

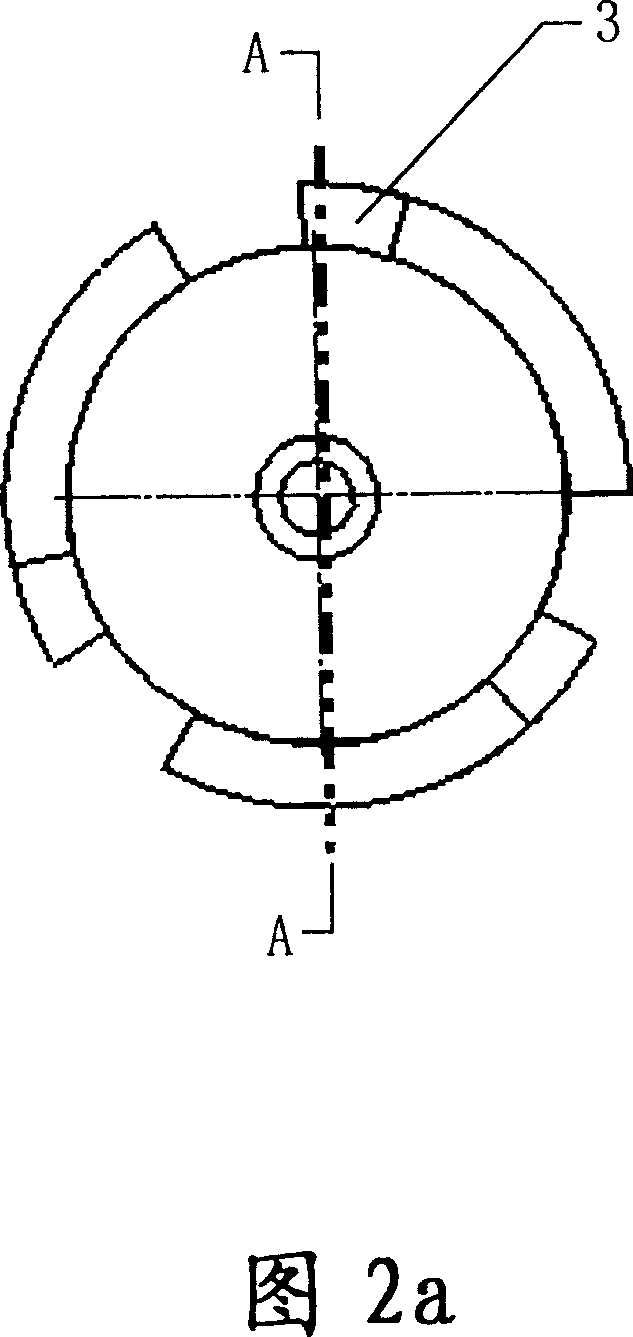

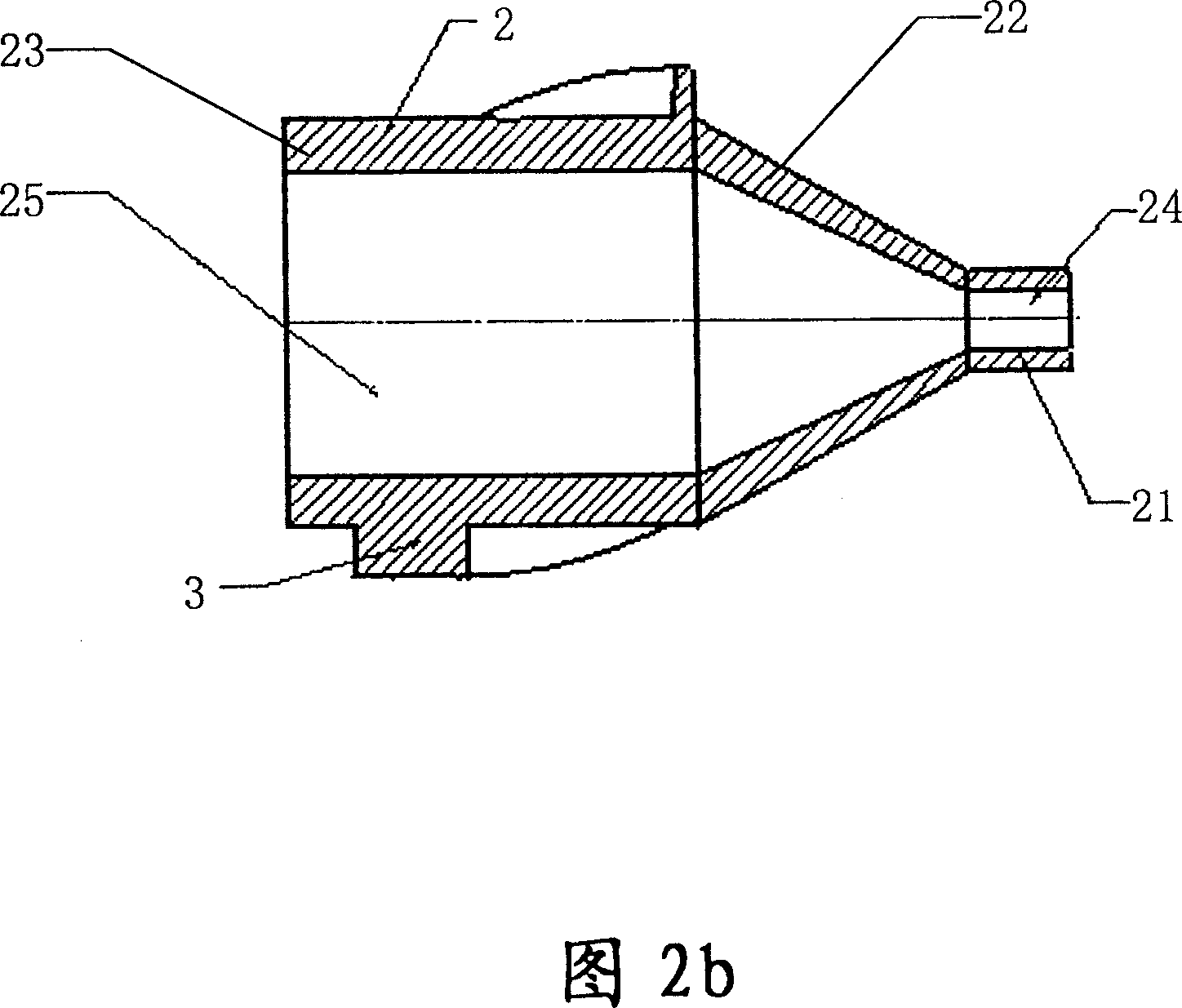

[0017] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so as to make the technical problems to be solved, features and technical effects achieved by the present invention more clear.

[0018] The high-pressure rotary double-jet drilling method of the present invention includes the rotary jet method and the direct jet method, the rotary jet method and the straight jet method are applied simultaneously, the rotary jet method forms a large energy transfer area in the target area, and the direct jet flow is in the center of the target area Partially form the energy transfer area area, the shear relationship between the two jets of the rotating jet method and the straight jet method, to make full use of the advantages of the large energy transfer area of the rotating jet and the long energy transfer distance of the straight jet, and use the rotating jet to shear and break rocks The mutual shearing of the two jet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com