Food crushing and processing machine capable of preventing residues on inner wall

A processing machine and food technology, applied in the direction of cleaning hollow objects, cleaning methods and utensils, grain processing, etc., can solve the problems of unusable, food waste, inconvenient cleaning, etc., and achieve slip prevention, waste reduction, and stable force transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

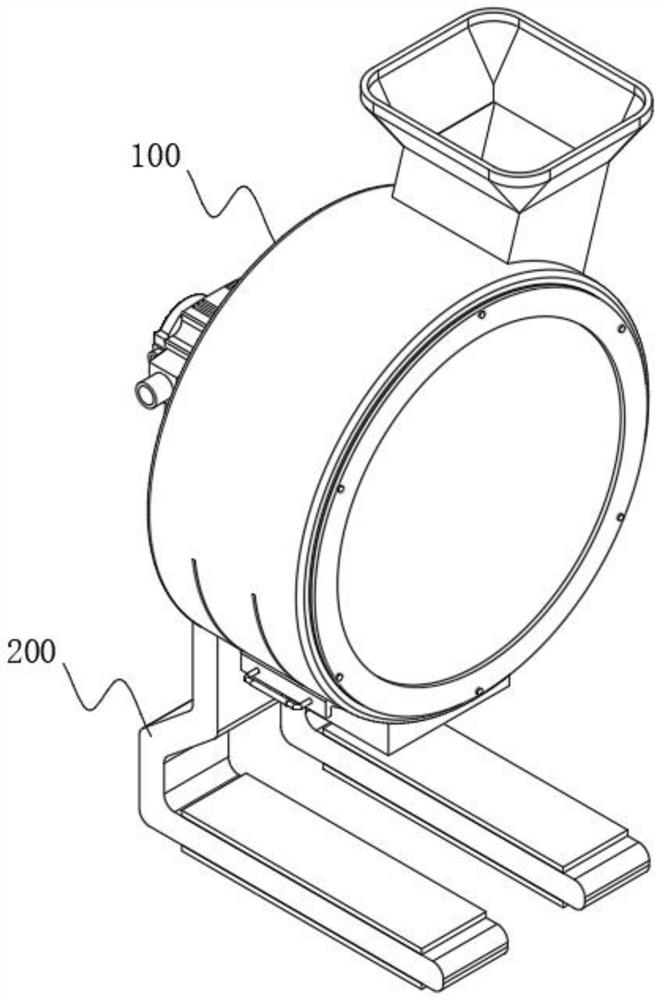

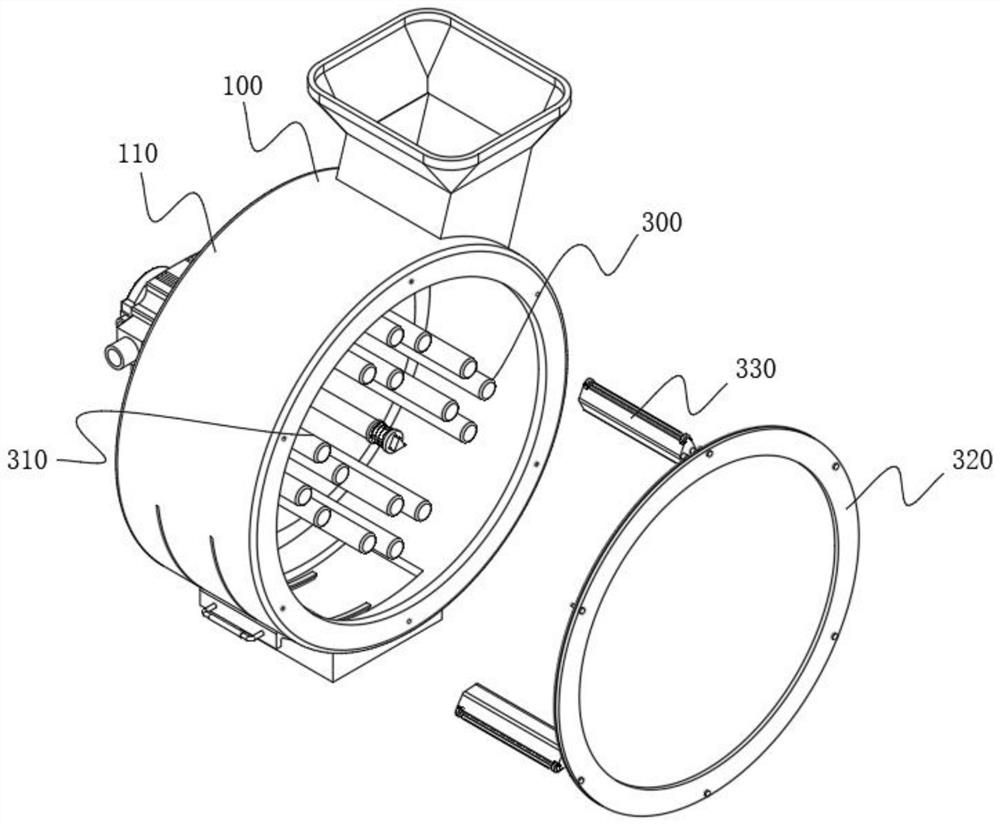

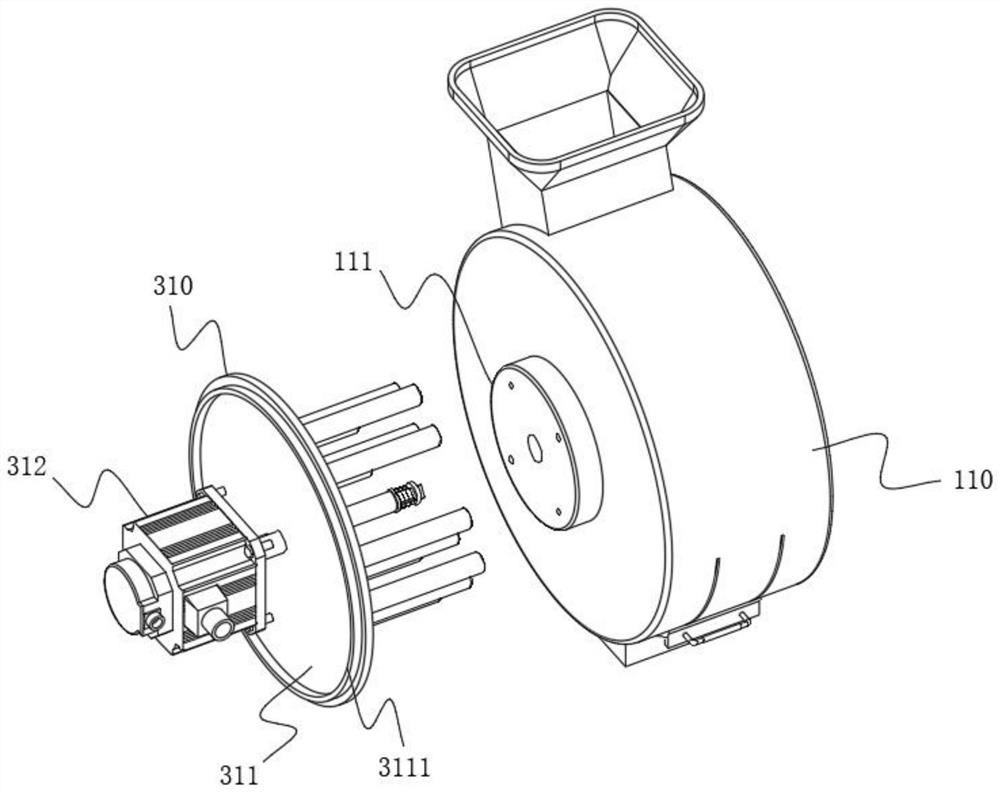

[0063] The present invention provides a food crushing machine that prevents residues on the inner wall, please refer to Figure 1-Figure 14 , including a crushing box 100 and a base 200 arranged at the bottom of the crushing box 100, the crushing box 100 includes a box body 110, a feeding chute 112 is provided at the top of the crushing box 100 near the left side, and a discharge chute 113 is opened at the bottom of the box body 110 , The front side of the box body 110 is provided with a crushing cavity, the crushing cavity is used to provide a working space for crushing, and a crushing mechanism 300 is arranged in the crushing cavity.

[0064] In addition, the crushing mechanism 300 at least includes a crushing device 310, the crushing device 310 includes a crushing disc 311, the rear side of the crushing disc 311 is provided with a motor 312, the transmission shaft on the front side of the motor 312 is the same circular axis as the crushing disc 311, and the crushing disc 311...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com