Industrial wastewater treatment equipment

A technology for treating equipment and industrial wastewater, which is applied in water/sewage treatment equipment, multi-stage water treatment, water/sewage treatment, etc. It can solve the problems of reduced water flow velocity, reduced treatment effect, filter blockage, etc., and can increase the rotation rate , improve the service life, increase the effect of the gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Such as Figure 1-Figure 6 Shown:

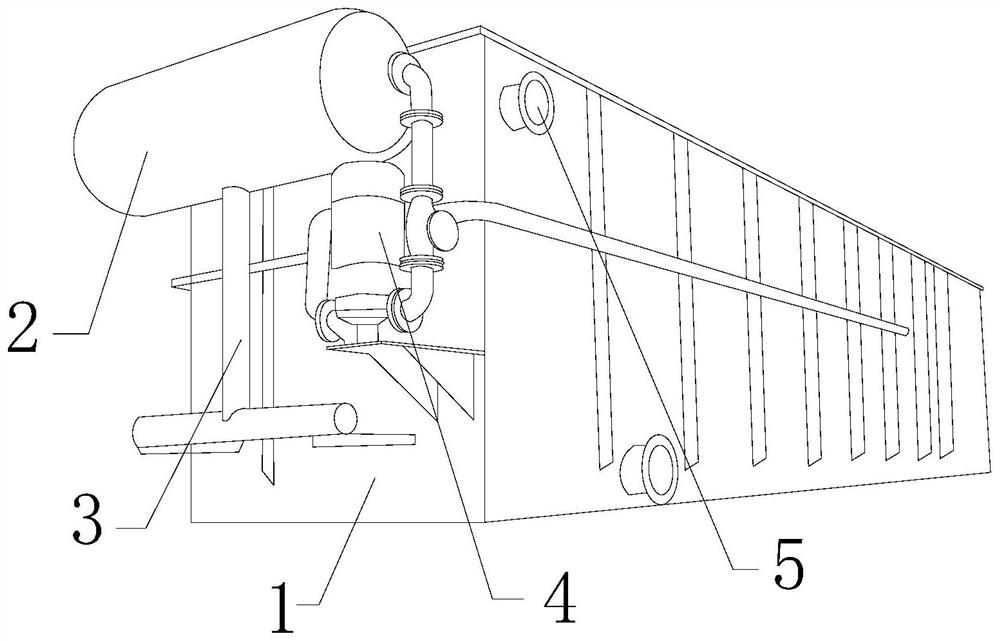

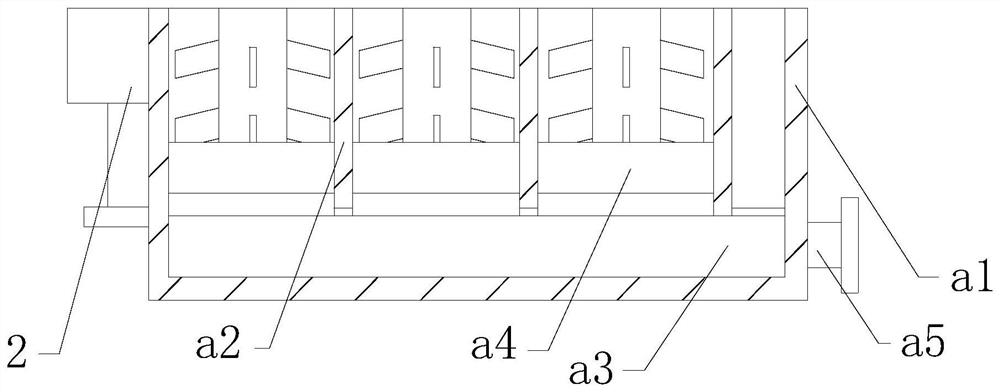

[0027] The present invention provides an industrial wastewater treatment equipment, the structure of which includes a treatment tank 1, a water supply tank 2, a connecting pipe 3, a converter 4, and an exhaust port 5, and the water supply tank 2 is embedded and connected to the treatment tank 1 with the converter 4 The front end, the exhaust port 5 is welded and connected to the position above the side of the treatment box 1, the connecting pipe 3 is flange-connected below the water supply tank 2, the connecting pipe 3 is screwed to the front end of the treatment box 1, and the treatment box 1 It mainly includes box a1, isolation plate a2, drain a3, treatment device a4, and drain pipe a5. The bottom of the inner wall of the box a1 is provided with a drain a3, and the treatment device a4 is embedded and connected to the upper side of the box a1. position, the isolation plate a2 is nested and connected between the processing devices a4...

Embodiment 2

[0035] Such as Figure 7-Figure 8 Shown:

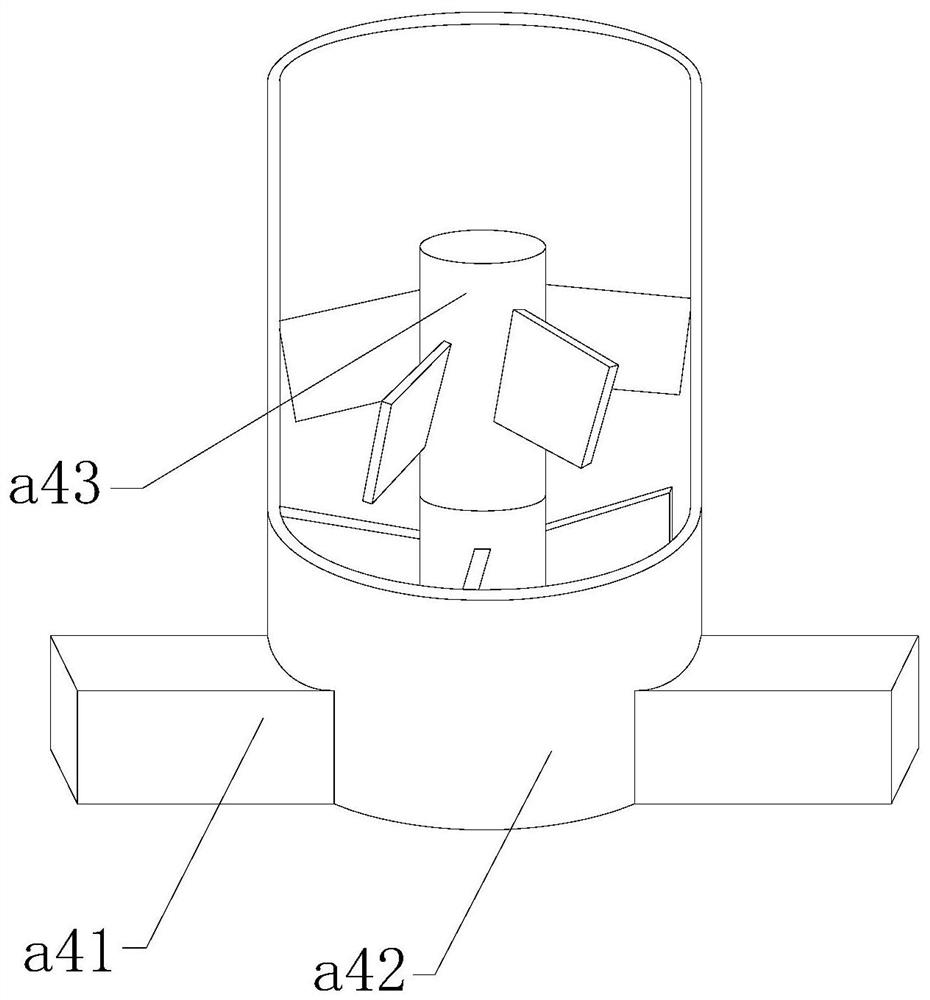

[0036] The present invention provides an industrial wastewater treatment equipment. The rotating filter tank a42 mainly includes a tank body a421, a filter plate a422, and a coupling shaft a423. The filter plate a422 is nested and connected at the bottom of the tank body a421. The axis a423 is embedded and connected to the center of the filter plate a422. The filter plate a422 has two layers and is installed in a symmetrical ring shape with the joint axis a423 as the center line, which can effectively improve the filtration efficiency and avoid the problem of dirty filtration.

[0037] Wherein, the combined shaft a423 mainly includes a support platform c1, an axis c2, a connecting plate c3, an elastic bar c4, and a contact block c5. The supporting platform c1 is embedded and connected between the filter plates a422, and the connecting plate c3 cooperates with The axis c2 is fixedly connected above the supporting platform c1, the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com