Crushing tool for powder coating production

A powder coating and cutting tool technology, applied in grain processing and other directions, can solve problems such as inconvenient disassembly, and achieve the effects of increasing work efficiency, improving stability, and increasing crushing area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

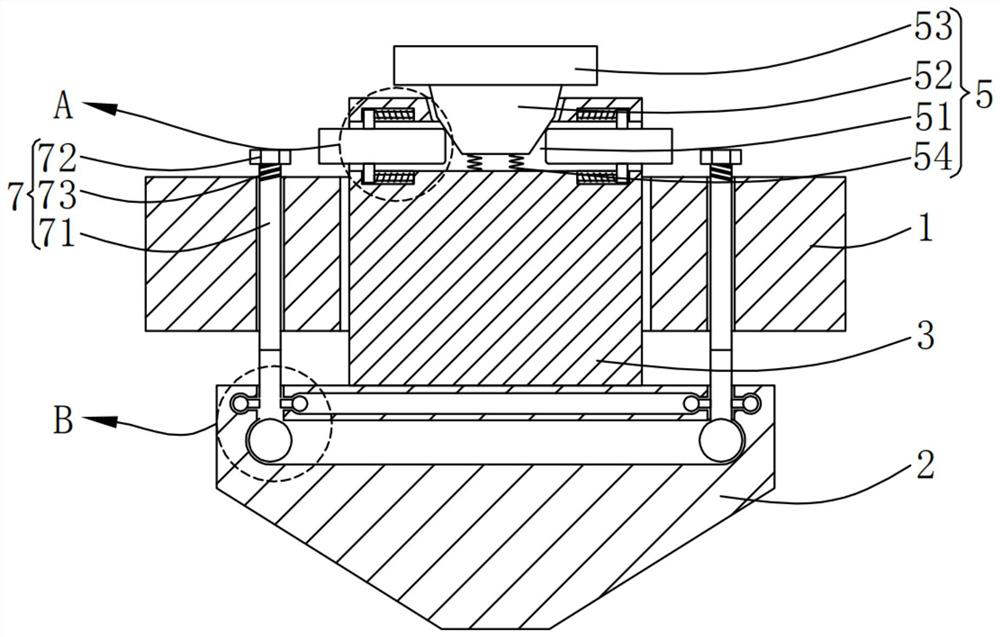

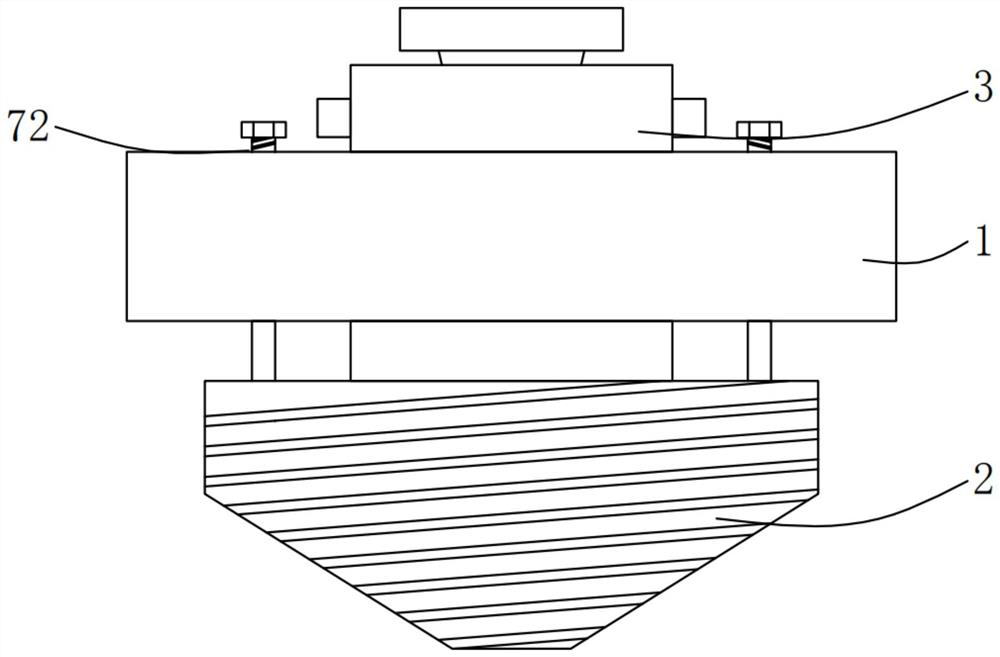

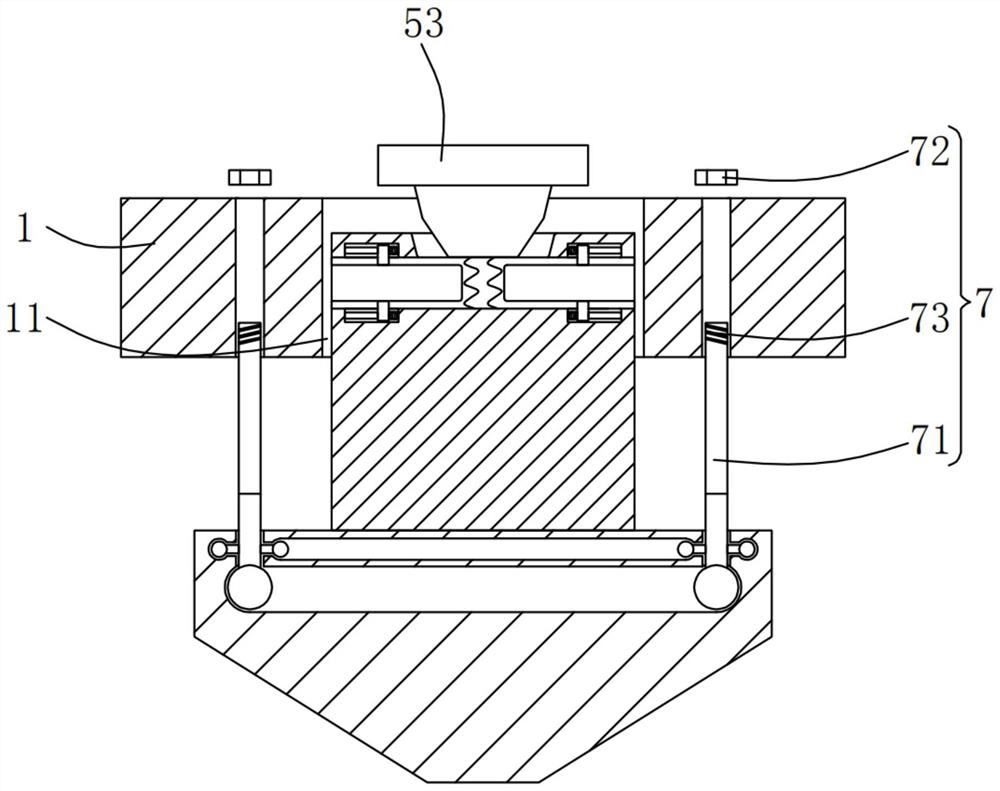

[0033] Please refer to Figure 1-Figure 5 ,in, figure 1 A schematic structural view of the first embodiment of the pulverizing tool produced by the powder coating provided by the present invention; figure 2 for figure 1 The appearance diagram shown; image 3 for figure 1 Schematic diagram of the structure during installation or disassembly; Figure 4 for figure 1 The enlarged schematic diagram of part A shown; Figure 5 for figure 1 The enlarged schematic diagram of part B is shown. The cutting tool for powder coating production includes: a base 1, a limiting assembly 6 and a connecting assembly 7, the limiting assembly 6 is arranged on the base 1 through the connecting assembly 7;

[0034] The first blade 2, the first blade 2 is arranged on the bottom of the base 1 through the positioning hole 11;

[0035] A connecting rod 3, the connecting rod 3 slides on the base 1, and the bottom end of the connecting rod 3 is fixedly connected with the first blade 2;

[0036] T...

no. 2 example

[0058] see Figure 6-Figure 7 , based on the pulverizing tool produced by powder coating provided in the first embodiment of the present application, the second embodiment of the present application proposes another kind of pulverizing tool produced by powder coating. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0059] Specifically, the difference between the pulverizing tool produced by the powder coating provided by the second embodiment of the present application is that the pulverized tool produced by the powder coating also includes: a rotating assembly 8, and the rotating assembly 8 includes a plurality of Rectangular slots 81 , the inner walls of the plurality of rectangular slots 81 are rotatably connected with rotating rods 82 , and the plurality of rotating rods 82 are fixedly connected with second blades 83 .

[0060] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com