Variable diameter chamfering-based top plate high-directional drilling gas extraction device

A technology for directional drilling and gas drainage, which is applied in gas discharge, earth-moving drilling, safety devices, etc., can solve the problems of inability to cope with the geological environment, low efficiency, low drilling efficiency, etc., so as to improve drilling efficiency and improve drilling efficiency. Hole expansion efficiency and leakage avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

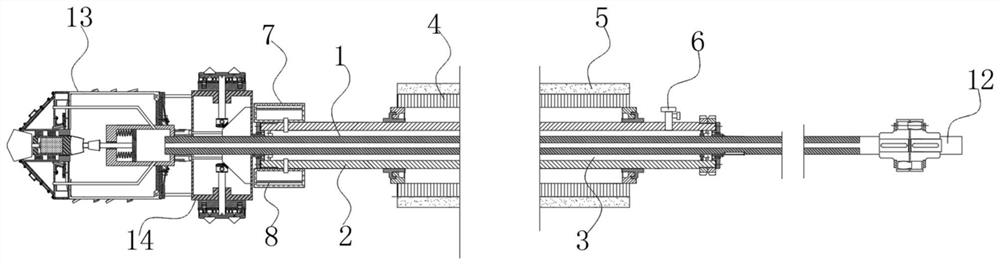

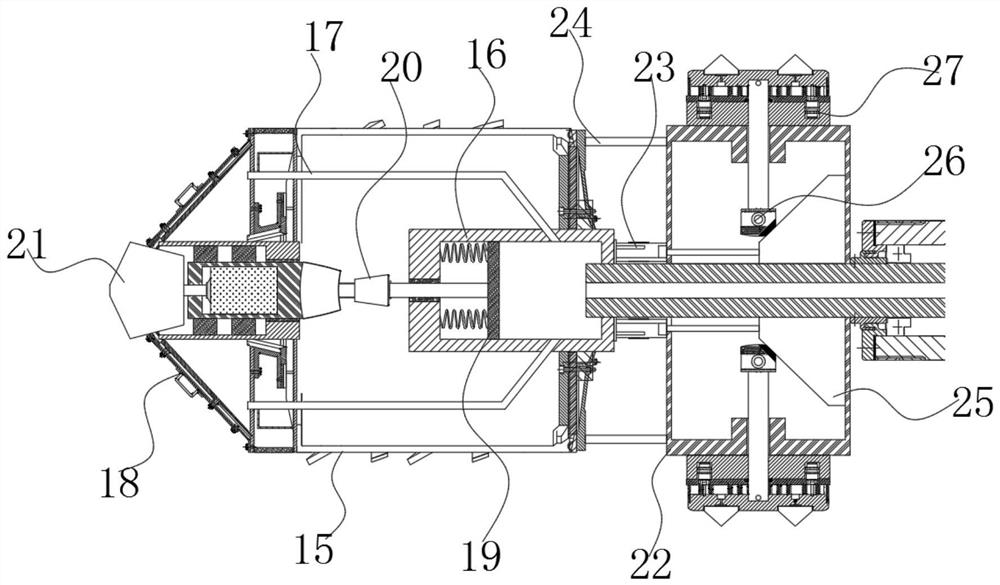

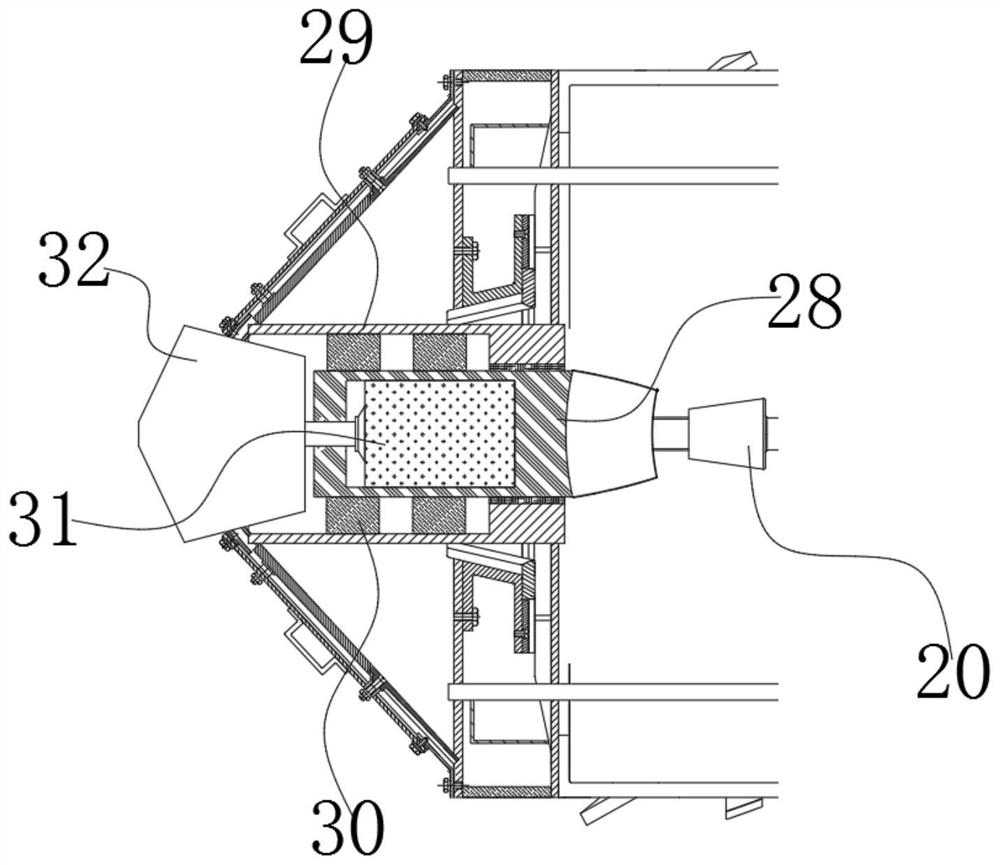

[0038] see Figure 1~5 , in an embodiment of the present invention, a roof high-position directional drilling gas drainage device based on variable-diameter reaming, which includes a drill pipe 1, a drainage cylinder 2, a drill assembly, a variable-diameter reaming assembly, and a support assembly, wherein the The central hole at one end of the drill pipe 1 far away from the drill hole is connected to the water supply pipeline 12 by a rotary joint, and the water supply pipeline 12 can provide flushing fluid for the central hole of the drill pipe 1,

[0039] The outer circumference of the drill pipe 1 located in the borehole is covered with a drainage cylinder 2. During drilling and reaming, the gas in the borehole can enter the drainage cylinder 2 and pass through the gas collection pipe. 6 Collected in an external storage tank to achieve pre-extraction and avoid gas leakage;

[0040] The drill rod 1 is installed in the extraction cylinder 2 in a sealed and rotating manner, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com