Drilling device for tiny hole at needle end of medical suture needle with thread

A drilling device and suture needle technology, which is applied in boring/drilling, positioning devices, drilling/drilling equipment, etc., can solve the problems of low yield, high labor intensity, and low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

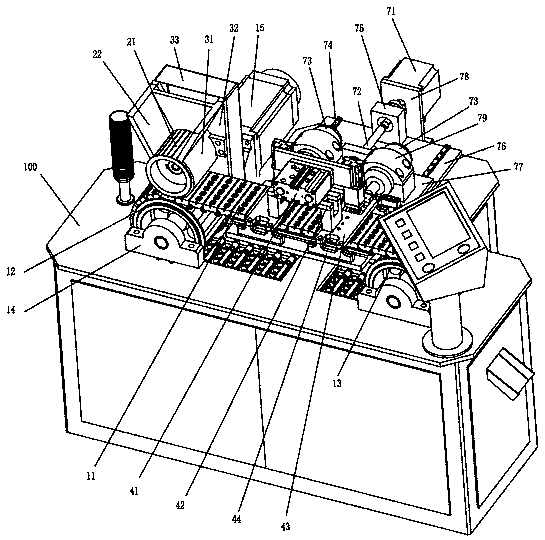

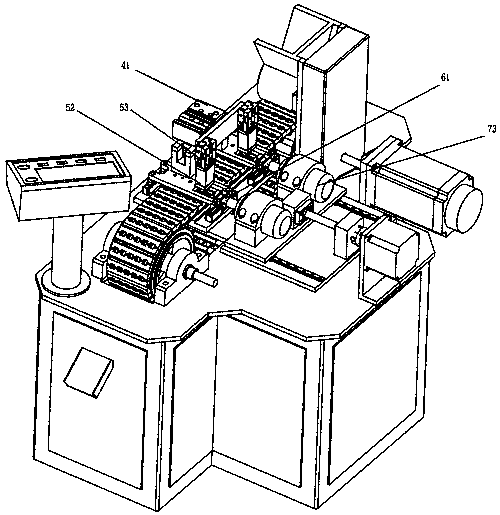

[0049] Such as figure 1 , figure 2 As shown, the micro-hole drilling device for the tail of a medical suture needle with thread of the present invention comprises a frame 100, a conveyor chain device is arranged on the frame 100, a feeding device is arranged above one end of the conveyor chain device, and the middle section of the conveyor chain device There is a clamping device on the top, and the clamping device is connected to the pushing device; one side of the conveyor chain device is provided with a drilling device;

[0050] Conveying chain device comprises conveying chain 11, and one end of conveying chain 11 connects driving wheel 12, and the other end of conveying chain 11 connects driven wheel 13; Driving wheel 12 and driven wheel 13 connect frame 100 by bearing seat 14; A servo motor 15 is driven to drive the conveyor chain 11 to move;

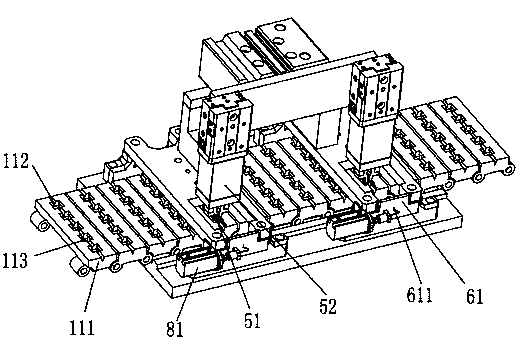

[0051] Such as image 3 As shown, the conveyor chain 11 is composed of a plurality of conveyor chain units 111; each conveyor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com