Building material forming mould box

A technology for mold boxes and building materials, which is applied in ceramic molding machines, ceramic molding cores, ceramic molding mandrels, etc., can solve the common problems of high labor intensity of manual operation of end mold demoulding, manual mold box labor, etc., and achieves low manufacturing cost. The effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

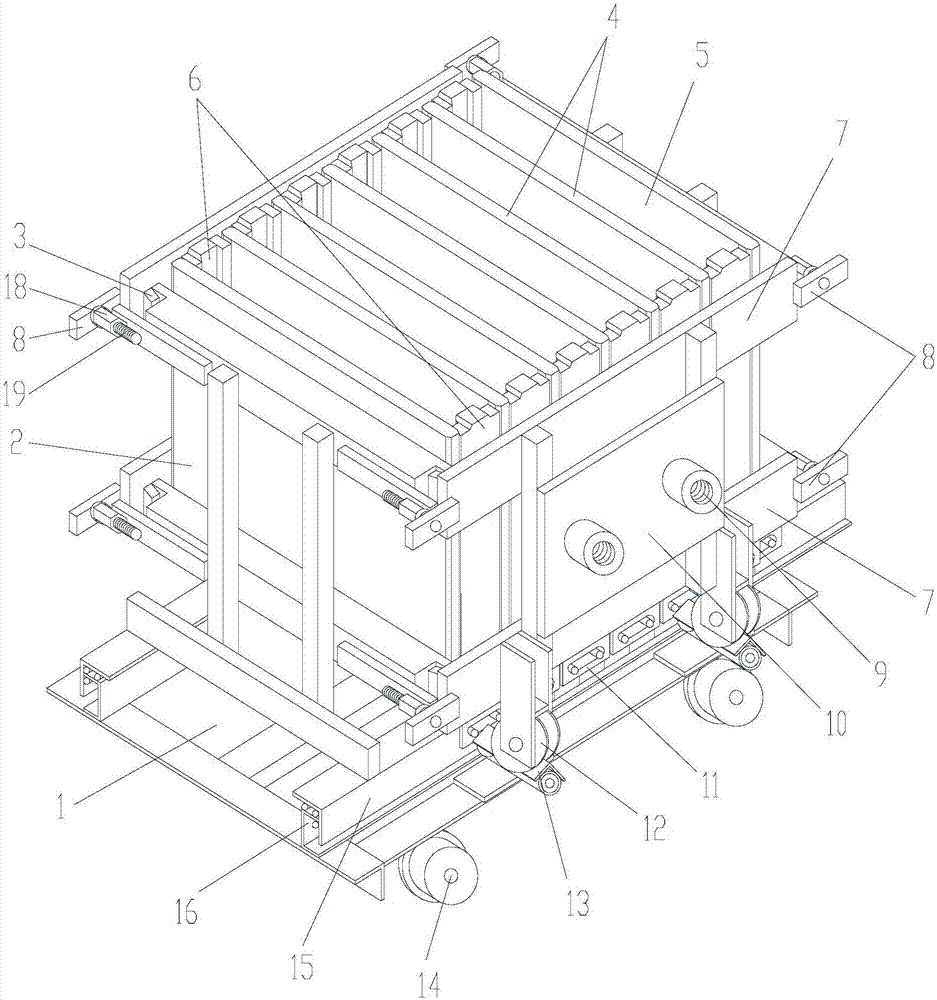

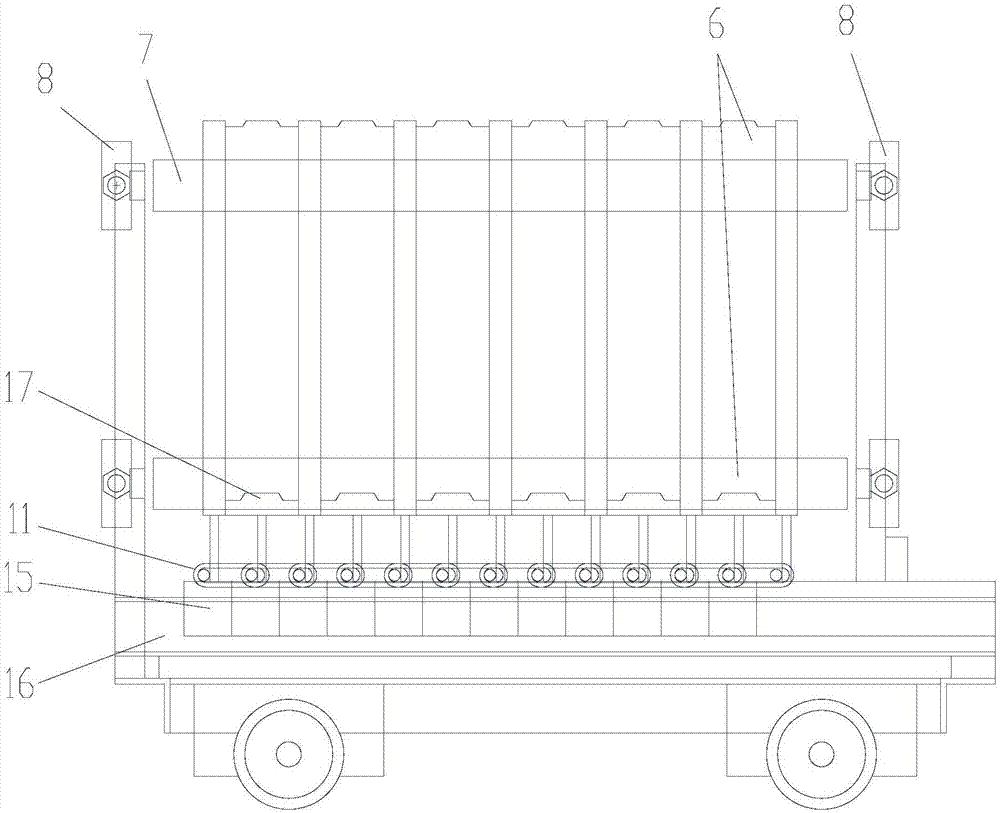

[0019] Example 1, such as figure 1 , 2 The building material molding mold box shown includes a mold box running on rails, and the chassis 1 of the mold box is provided with a front side formwork 2 and a rear side formwork 5 arranged in parallel to each other and arranged on the front side formwork 2 and the rear side. A plurality of partition molds 4 between the templates 5, the space between the front side template 2 and the rear side template 5 is divided into a plurality of mold cavities by the partition mold 4, and the left and right sides of the mold cavity are provided with end molds 6 (end molds 6 It consists of multiple pieces connected or a large block to seal several mold cavities), the bottom of the mold cavity is provided with a bottom mold 17; the chassis 1 is provided with front and rear guide rails 16 parallel to each other (the front and rear guide rails 16 have various shapes or structure), the front side template 2, the rear side template 5, the partition mo...

Embodiment 2

[0020] Embodiment 2, left and right guide rails 13 (the left and right guide rails 13 have various shapes or structures) are set on the underframe 1 in the described embodiment 1, the end module 7 is fixed on the end mold 6, and the pulley 12 (the pulley) is arranged below the end module 7. 12 rotate or do not rotate or other shapes or structures) slide back and forth on the left and right guide rails 13, and also drove the end die 6 to slide back and forth on the left and right guide rails 13 simultaneously, making the movement of the end die easy and accurate.

Embodiment 3

[0021] Embodiment 3, the end mold 6 and the bottom mold 17 in the above-mentioned embodiment 1 are provided with concave-convex tenons and tenon grooves, and the upper end of the end mold 6 is connected with the upper mold, so that there are concave-convex tenon and tenon grooves around the product produced .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com