Arranging machine

A technology of aligning machines and racks, applied in the field of aligning machines, can solve the problems of slow transportation, pollution, affecting the safety of medicines, etc., and achieve the effect of fast bottle feeding and accurate counting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings:

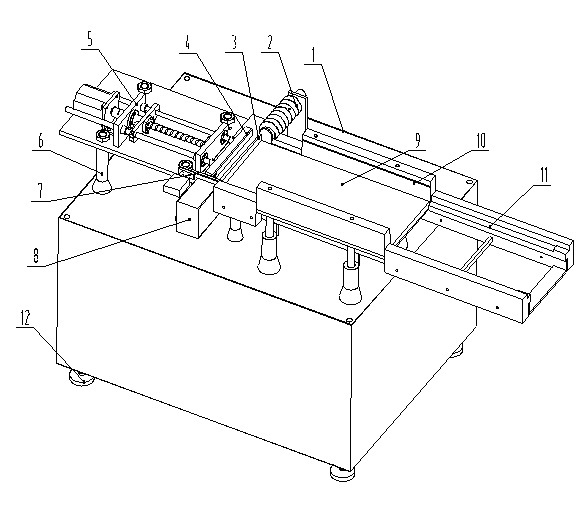

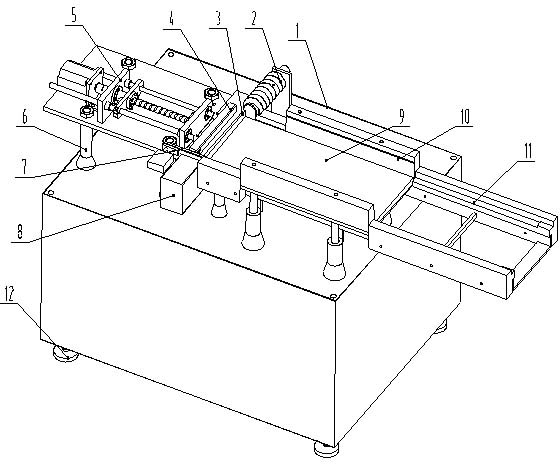

[0018] The present invention relates to a complete row machine, comprising a frame 1, on which a bottle storage area 9 is provided. The bottle storage area 9 is used to temporarily store the vials to be pushed into the freeze-drying tray. A bottle pushing mechanism is provided on one end of the length direction of 9, specifically, the bottle pushing mechanism includes a bottle pushing rod 4 and a bottle pushing power mechanism 5, and the bottle pushing power mechanism 5 includes a stepping motor and a screw rod. The stepping motor and the bottle pushing rod 4 are connected by a screw rod. A fixed plate is provided under the bottle pushing power mechanism. The fixed plate is supported by a column 6 and a column 6 is also provided below the bottle storage area 9. The height of the fixed plate is the same as the height of the bottle storage area to ensure the smooth operation of the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com