Safflower picking robot

A technology for picking robots and safflowers, which is applied in the direction of picking machines, harvesters, agricultural machinery and tools, etc., can solve the problems of manual picking such as high labor intensity, and achieve the effects of reducing labor intensity, saving human resources, and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

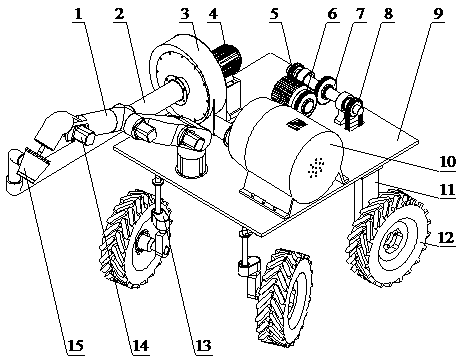

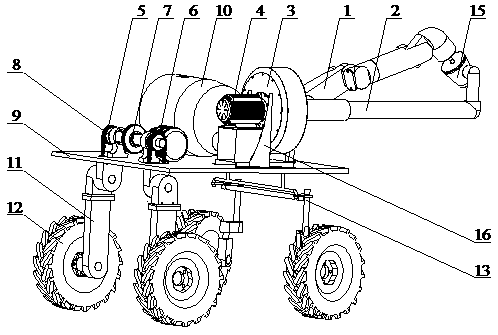

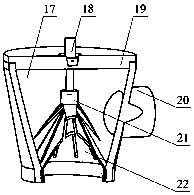

[0019] Embodiment 1: refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the present invention relates to a safflower picking robot, comprising a car body, a manipulator and a collection device, characterized in that the manipulator and the collection device are all installed on the car body, and are all located above the car body, and the manipulator is in front of the collection device . Described car body comprises vehicle body 9, running gear and driving device, and driving device is installed on the top of vehicle body 9, and running device is positioned at the below of vehicle body 9; The height of vehicle body 9 is higher than the height of safflower plant; Running gear comprises traveling wheel 12, Steering device 13, sprocket 5, gear 8 and housing 11, steering device 13 is connected with the road wheels 12 at the front end, drives the two road wheels 12 at the front end to perform steering action, sprocket 5 is connected with gear 8, and is ...

Embodiment 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the manipulator includes an end effector 14 and a robot arm 1 , and the end effector 14 is installed at the end of the wrist of the robot arm 1 .

Embodiment 3

[0021] Embodiment 3: The difference between this example and Embodiment 1 is that the collection device includes a flower conveying pipeline 2, a negative pressure fan 3, a motor 4 and a flower storage room 10, and the negative pressure fan 3 and the flower storage room 10 are all installed on the vehicle body 9, one end of the flower conveying pipeline 2 is connected with the suction port of the negative pressure fan 3, the flower inlet of the flower storage room 10 is connected with the air outlet of the negative pressure fan 3, and the motor 4 is installed on the vehicle body 9 through the motor base 16, Provide power for negative pressure blower 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com