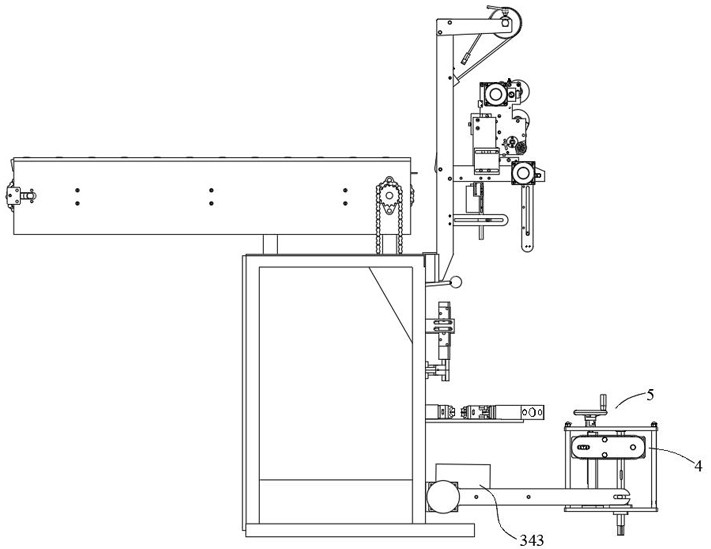

Medical needle box packaging machine capable of working continuously

A packaging machine and needle box technology, which is applied in the field of medical equipment, can solve the problems of time-consuming and laborious coating, the outer wall of the needle tip affects the surface smoothness, and is not good, and achieves the effect of convenient sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

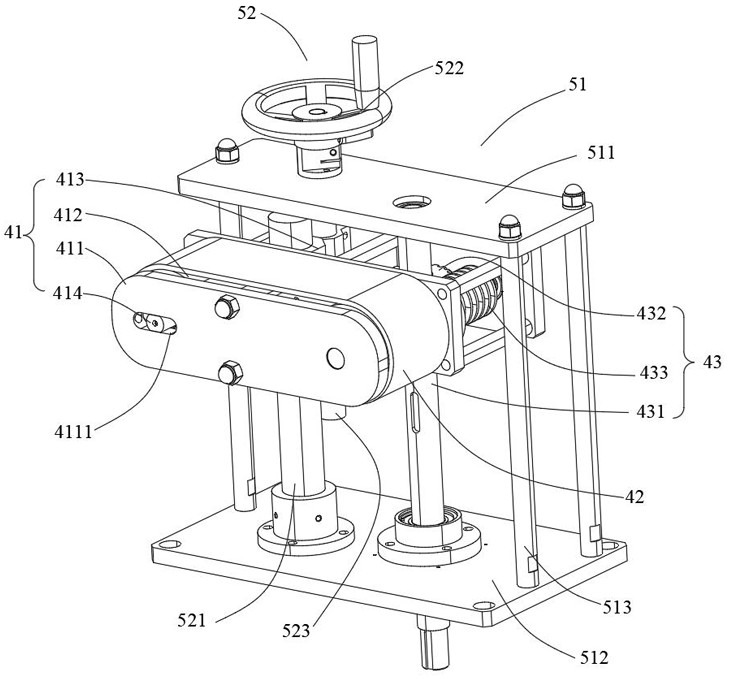

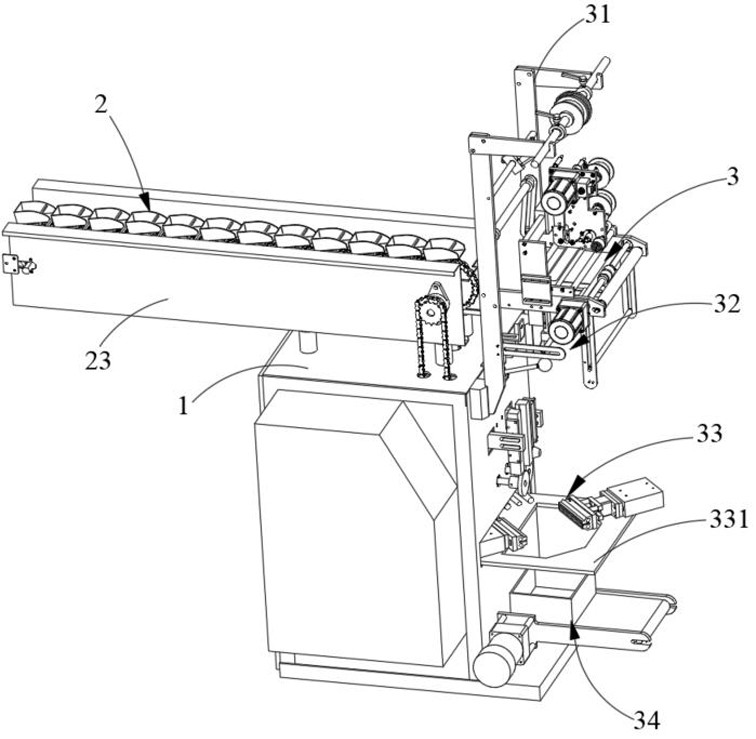

[0072] Embodiment 2: On the basis of Embodiment 1, this Embodiment 2 also provides a production process of a medical needle box packaging machine, including a medical needle box packaging machine as described in Embodiment 1, and the specific needle The box packaging machine is the same as that of Embodiment 1, and will not be repeated here.

[0073] After the workpiece is placed on the box body 253, the afterbody of the workpiece is against the gravity block 251 side wall of the inner bottom wall of the box body 253, and the front end of the workpiece is placed on the oil smearing plate 252. When the workpiece is placed on the oil smearing plate 252, it can Press the oiling plate 252 to rotate on the axis of the rotating column 2521 so that the upper surface of the oiling plate 252 fits with the outer wall of the front end of the workpiece, so that the oiling layer can contact the outer wall of the front end of the workpiece to smear oil; and the driving chain 21 drives The b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com