Assembly production line of hidden rail

A production line and assembly technology, used in assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of time-consuming workpieces, damage, disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

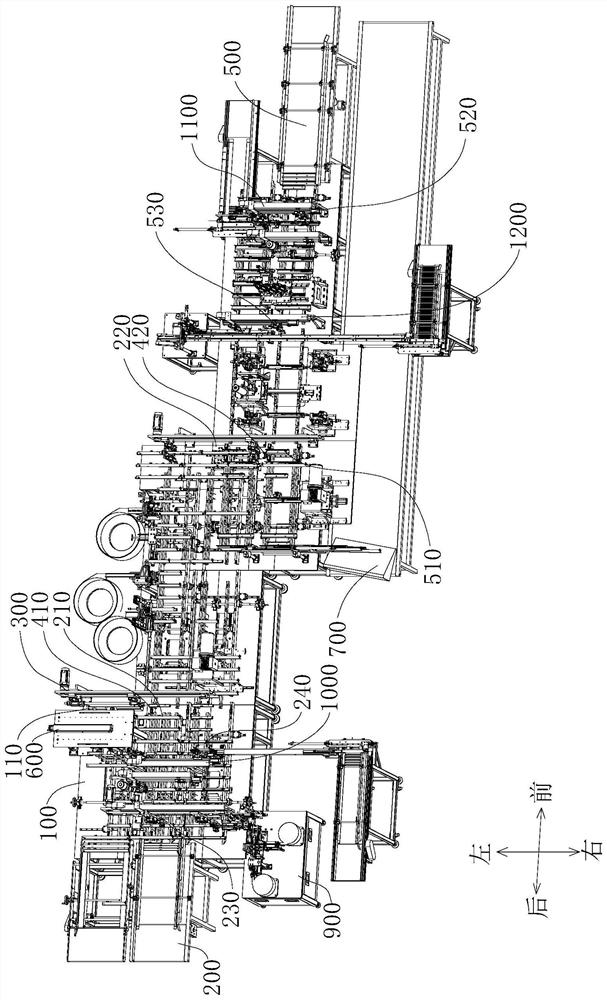

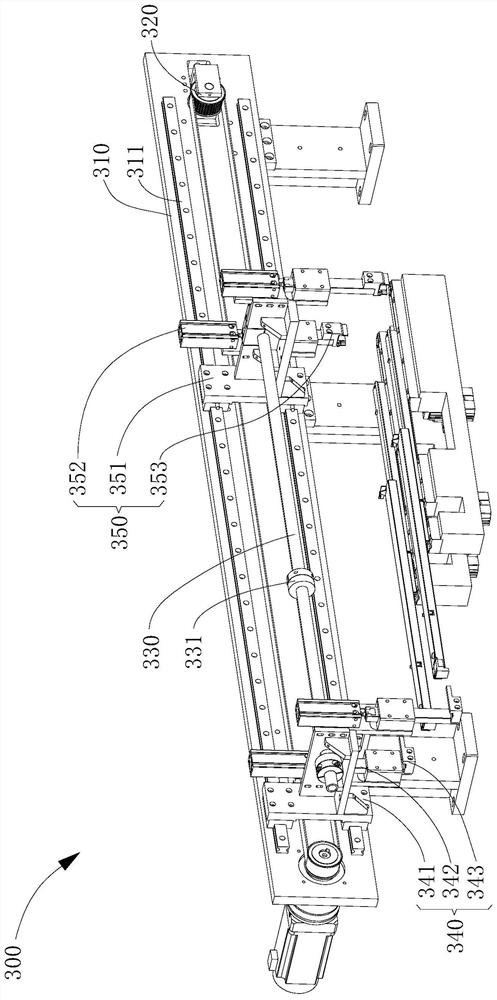

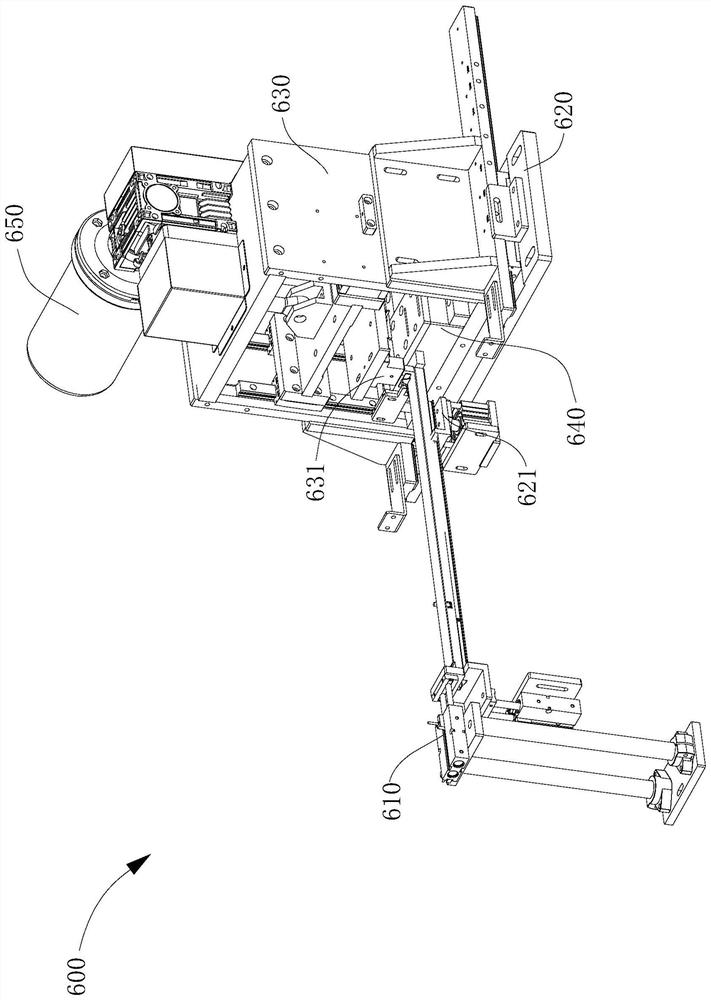

[0043] Example 1, see figure 1 and figure 2 , the embodiment of the present invention provides a hidden rail assembly production line, including: an upper rail conveying mechanism 100, a middle rail conveying mechanism 200, a lower rail conveying mechanism 500, a rail threading mechanism 300, a first limit cylinder 410 and a second limiter Position cylinder 420.

[0044] The upper rail conveying mechanism 100 is used for conveying the upper rail from back to front, the upper rail conveying mechanism 100 is provided with a first assembly station 110, the middle rail conveying mechanism 200 is used for conveying the middle rail from back to front, and the middle rail conveying mechanism 200 is used for conveying the middle rail from back to front. The rail conveying mechanism 200 is provided with a second assembly station 210. The first assembly station 110 and the second assembly station 210 are arranged opposite to each other and are arranged left and right, that is, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com