Electromagnetic suspension type solar heat treatment furnace

An electromagnetic levitation and heat treatment furnace technology, applied in the direction of solar thermal energy, solar collectors, solar heating systems, etc., can solve the problems of high energy density, damage to the workpiece, and high local temperature of the workpiece, so as to ensure quality and efficiency, ensure heating, The effect of ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

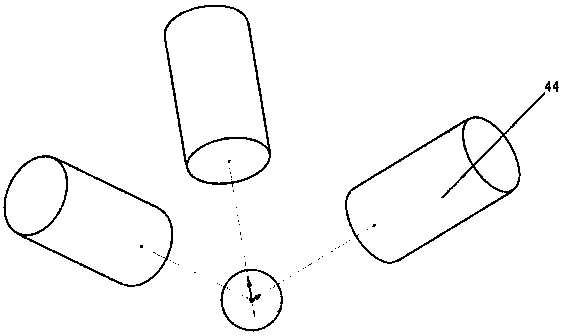

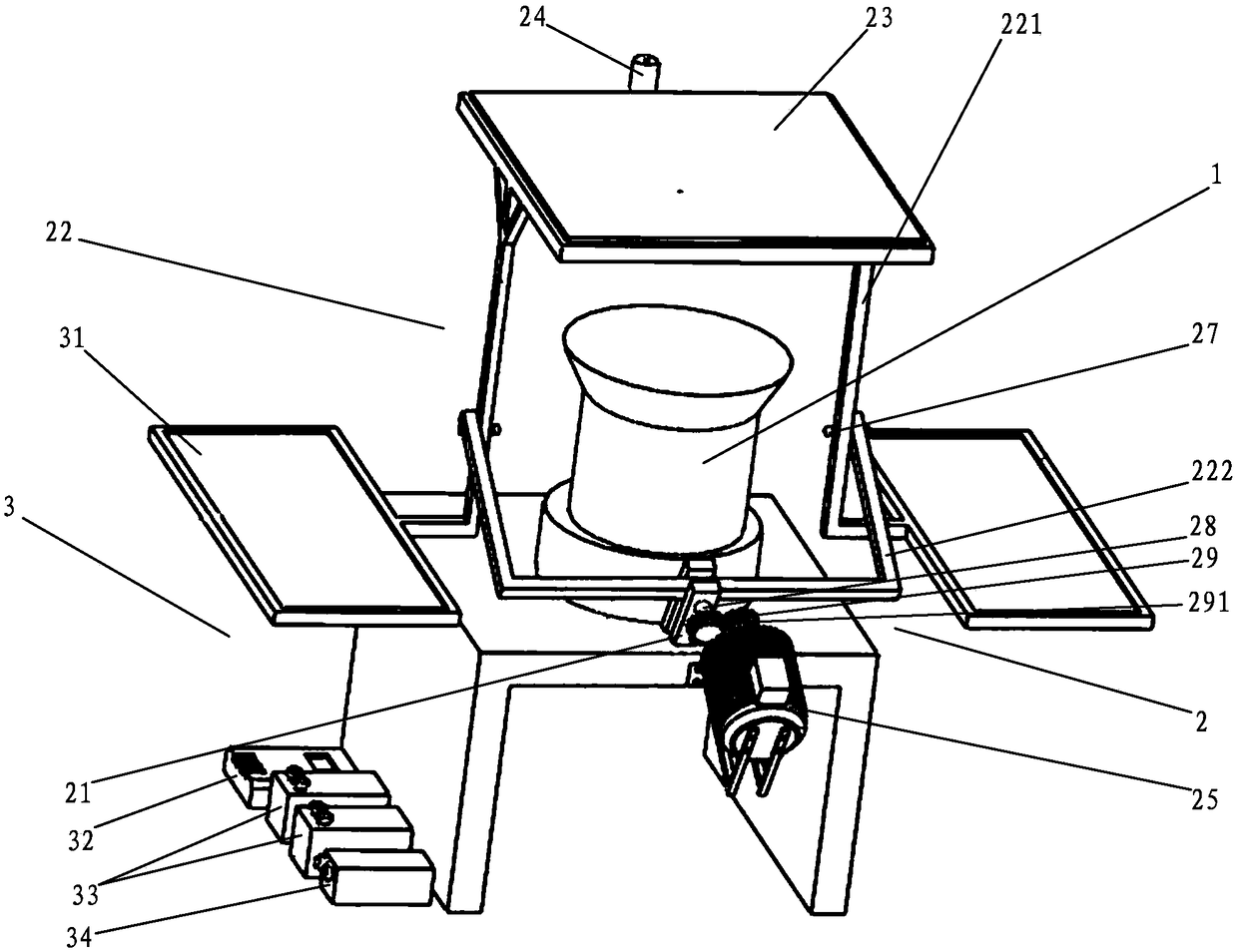

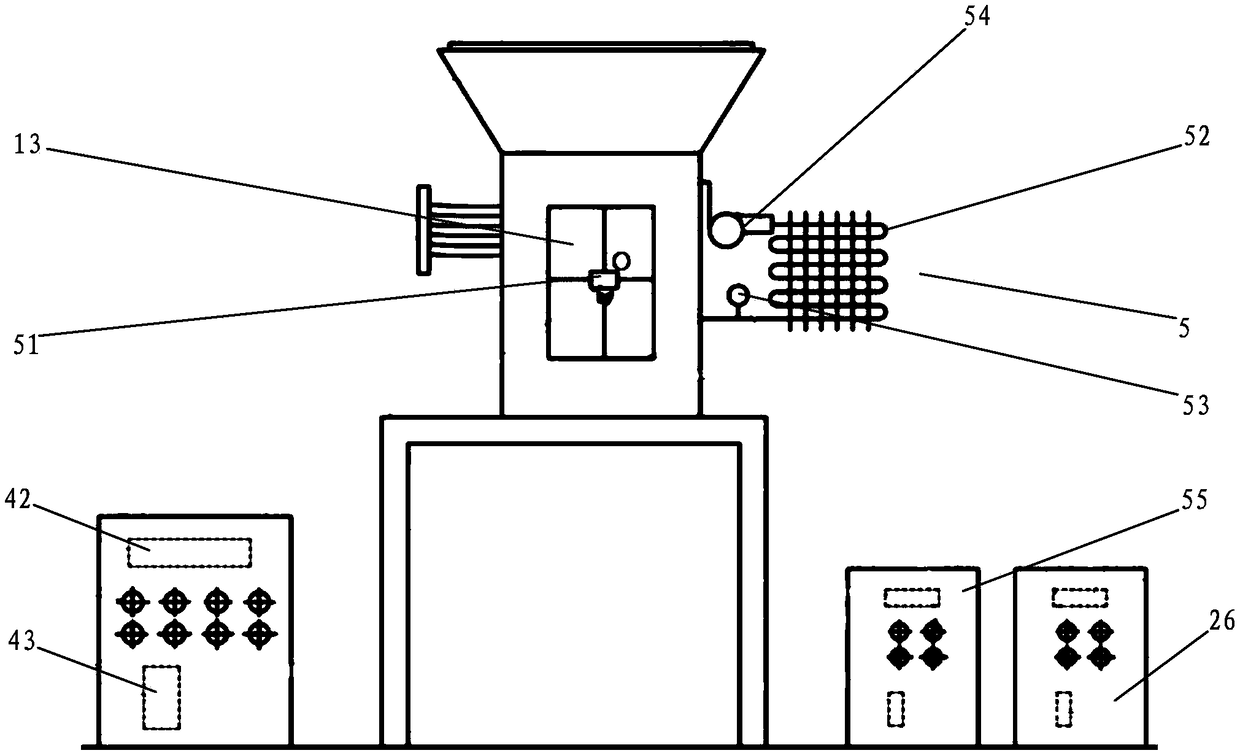

[0026] refer to Figure 1 to Figure 3 , this embodiment relates to a solar heat treatment furnace, including a furnace body 1, a solar automatic tracking heating system 2, a solar photovoltaic power supply system 3, an electromagnetic levitation system 4 and a temperature control system 5, the furnace body 1 is provided with workpieces to be processed, and the furnace body 1 is a sealed structure, and the upper surface of the furnace body 1 is a light-transmitting structure; the focus formed by the solar automatic tracking heating system 2 is located on the workpiece to be processed; the solar photovoltaic power supply system 3 receives sunlight and converts it into electrical energy, so The solar photovoltaic power supply system 3 provides electric energy for the solar automatic tracking heating system 2, the electromagnetic suspension system 4 and the temperature control system 5; the electromagnetic suspension system 4 generates multi-dimensional magnetic force to control th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com