Automatic material distribution machine

An automatic splitting machine and driving mechanism technology, which is applied in the field of casting splitting, can solve the problems of complex structure of the manipulator, inability to realize splitting operation, inconvenient operation, etc., and achieve the effect of saving cooling processing mechanism, less damage to the workpiece, and less damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present case will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

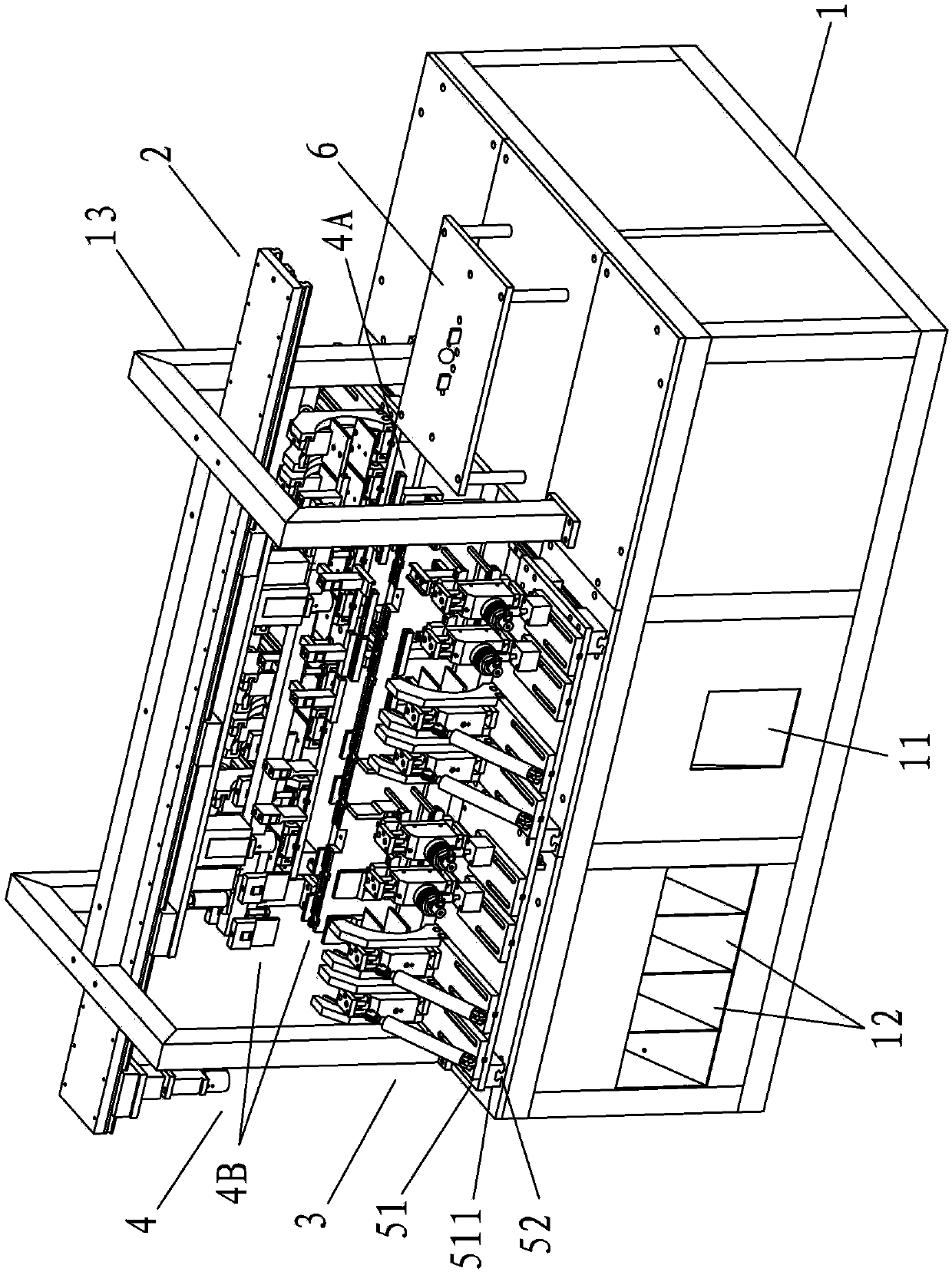

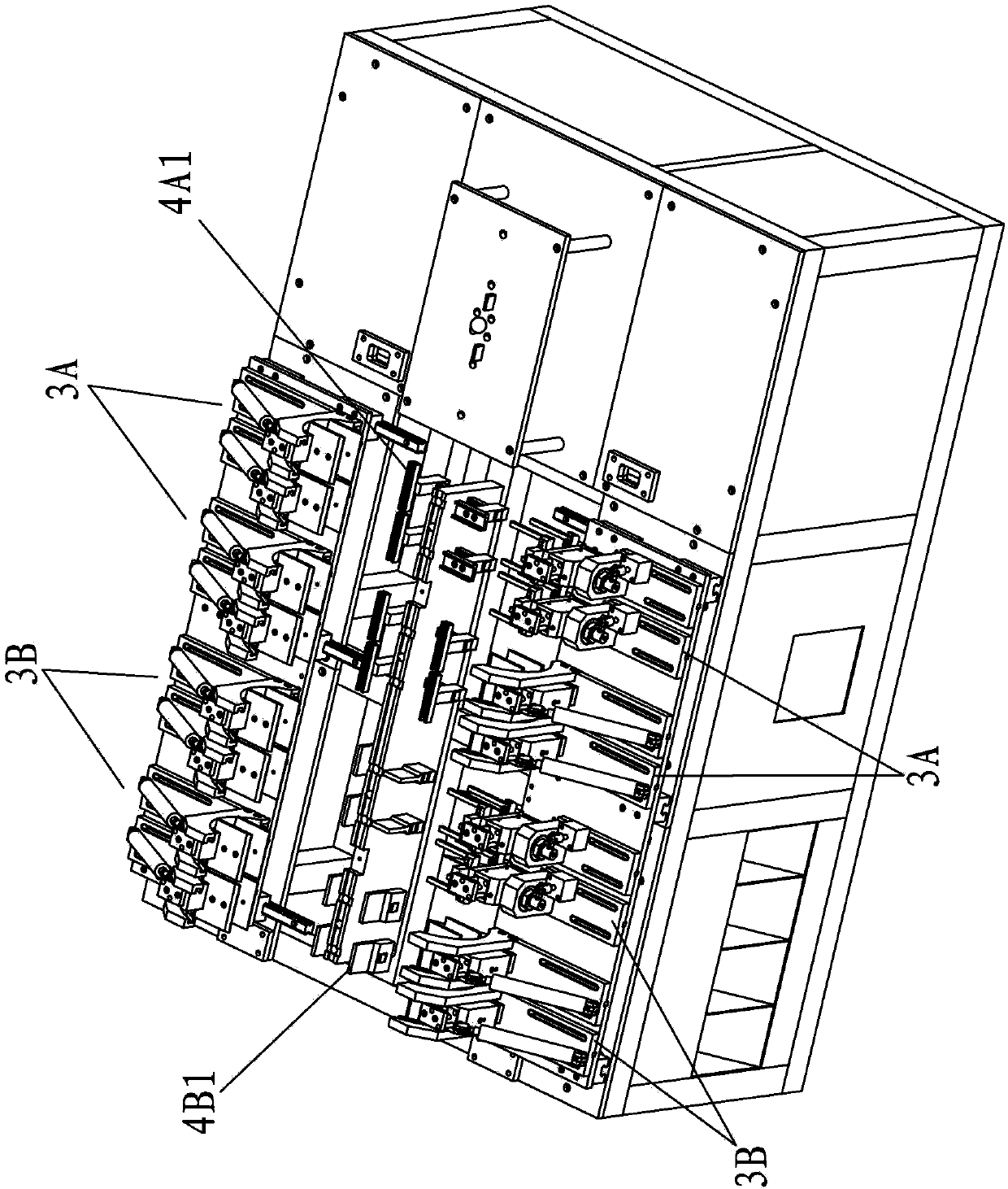

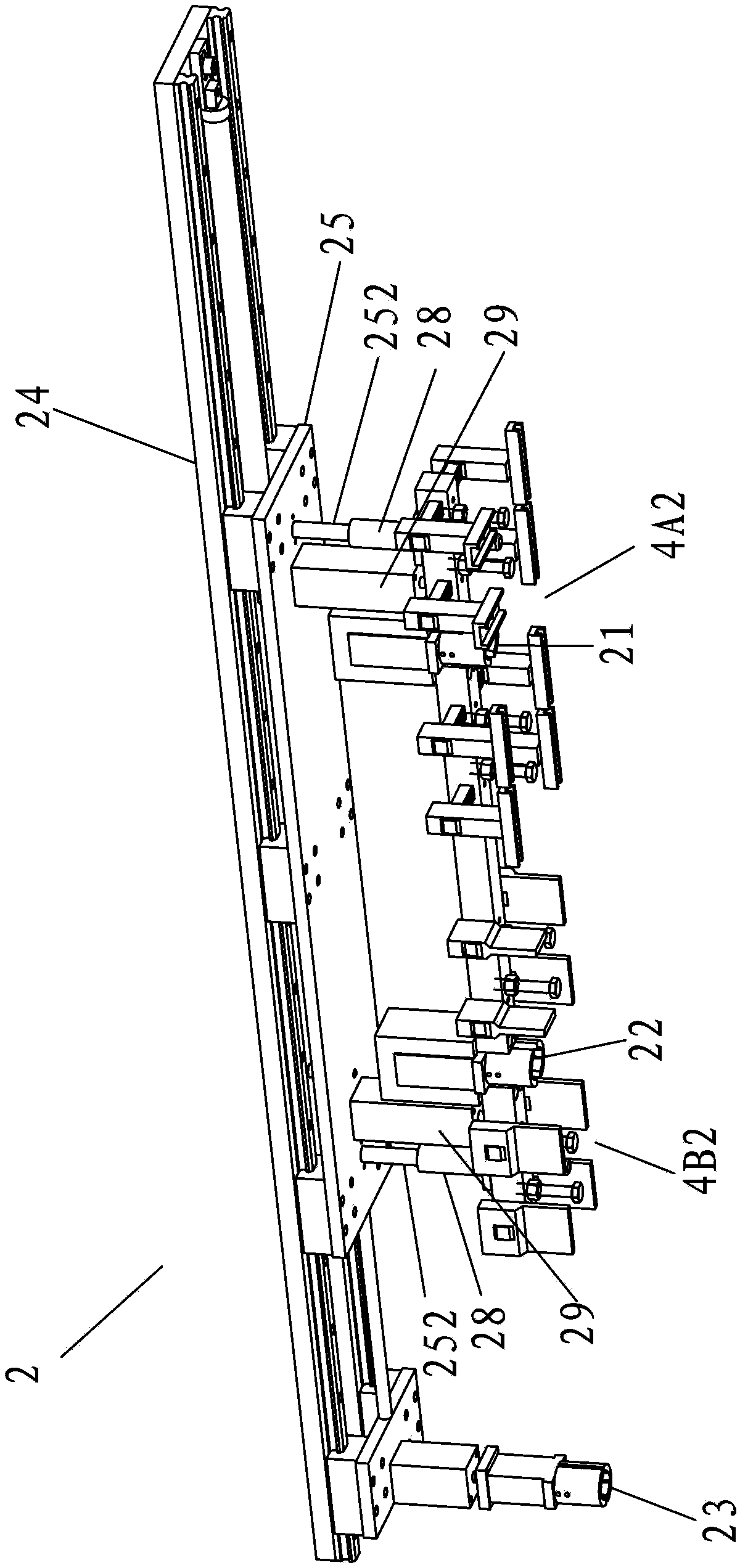

[0064] The present invention relates to a kind of automatic distributing machine, such as Figure 1-10 As shown, it mainly includes a main body 1 , a conveying device 2 , a manipulator device 3 and a pressing device 4 . Such as Figure 11 Shown is a schematic structural view of the existing casting 7 , including a flow channel body 71 , a workpiece 72 and a discharge material 73 . The workpieces 72 are divided into four groups and connected to the four branches of the flow channel body 71 , and the overflow material 73 corresponds to four groups, which are respectively connected to the four groups of workpieces 72 . Figure 11 Among them, the workpiece 72 has two kinds of arrangement structures, horizontal and vertical, and the corresponding overflow material 73 also has two kinds of arrangement structures, horizontal and vertical.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com