Method for replacing phosgene synthetic tower catalyst

一种合成塔、催化剂的技术,应用在光气合成塔催化剂更换领域,能够解决安全风险大、消耗大氮气、吹扫速度慢等问题,达到操作安全、提高工艺安全性、缩短光气脱除时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

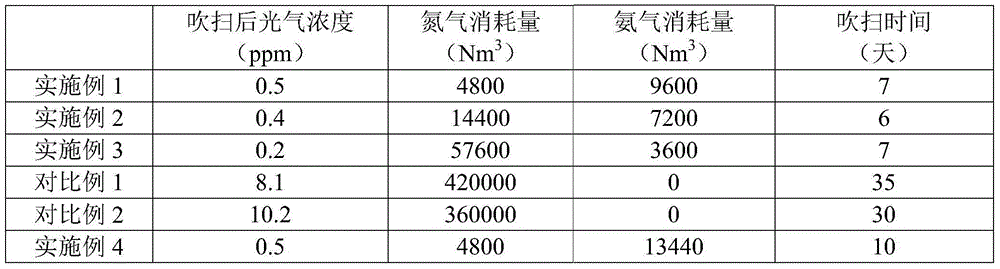

Embodiment 1

[0042] After the phosgene synthesis tower stops feeding, feed 100Nm from the bottom of the synthesis tower 3 The nitrogen of / h, nitrogen temperature is 100 ℃, and moisture content in nitrogen is 100ppm, and nitrogen pressure is 0.15MPa, and nitrogen continues to pass into 2 days, and the phosgene concentration of outlet of phosgene synthesis tower after measuring purging is 0.45% (v / v ). Then pass through the ammonia gas for purging, first pass through the ammonia gas to suppress the pressure, hold the pressure of the phosgene synthesis tower to 1MPa, hold the pressure for 2 hours, then open the outlet of the phosgene synthesis tower, and repeat the pressure suppression 8 times. Then continue to feed ammonia gas, the flow rate of ammonia gas is 80Nm 3 / h, the ammonia temperature is 40°C, the moisture content in the ammonia is 50ppm, the ammonia is purged for 5 days, and the phosgene concentration at the outlet of the phosgene synthesis tower is measured to be 0.5ppm. After ...

Embodiment 2

[0044] After the phosgene synthesis tower stops feeding, feed 200Nm from the bottom of the synthesis tower 3 The nitrogen of / h, the nitrogen temperature is 120 ℃, and the moisture content in the nitrogen is 300ppm, and the nitrogen pressure is 0.2MPa, and the nitrogen continues to feed for 3 days, and the phosgene concentration at the outlet of the phosgene synthesis tower after measuring and purging is 0.3% (v / v ). Ammonia gas is introduced first to suppress the pressure, the pressure of the phosgene synthesis tower is suppressed to 2 MPa, and the pressure is suppressed for 4 hours, then the outlet of the phosgene synthesis tower is opened, and the pressure is repeatedly suppressed 4 times. Then continue to pass into the ammonia purging, the ammonia flow rate is 100Nm 3 / h, the ammonia temperature was 60°C, and the ammonia gas was purged for 3 days, and the phosgene concentration at the outlet of the phosgene synthesis tower was measured to be 0.4ppm. After purging, the ph...

Embodiment 3

[0046] After the phosgene synthesis tower stops feeding, feed 400Nm from the bottom of the synthesis tower 3 The nitrogen of / h, the nitrogen temperature is 150 ℃, and the moisture content in the nitrogen is 200ppm, and the nitrogen pressure is 0.25MPa, and the nitrogen continues to feed for 6 days, and the phosgene concentration at the outlet of the phosgene synthesis tower after measuring and purging is 0.1% (v / v ). Then feed ammonia gas for purging, first feed ammonia gas to suppress the pressure, suppress the pressure of the phosgene synthesis tower to 3Mpa, hold the pressure for 5h, then open the outlet of the phosgene synthesis tower, and repeatedly suppress the pressure 5 times. Then continue to pass into the ammonia purging, the ammonia flow rate is 150Nm 3 / h, the ammonia temperature is 80°C, the ammonia gas is purged for 1 day, and the phosgene concentration at the outlet of the phosgene synthesis tower is measured to be 0.2ppm. After purging, the phosgene enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com