Processing method for hard alloy extrusion mould

A technology of extrusion dies and hard alloys, which is applied in the field of processing and removal of leftover materials, can solve the problems of high cost, slow speed, low efficiency, etc., to reduce production costs, improve processing efficiency, and shorten the time for removal of remaining materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

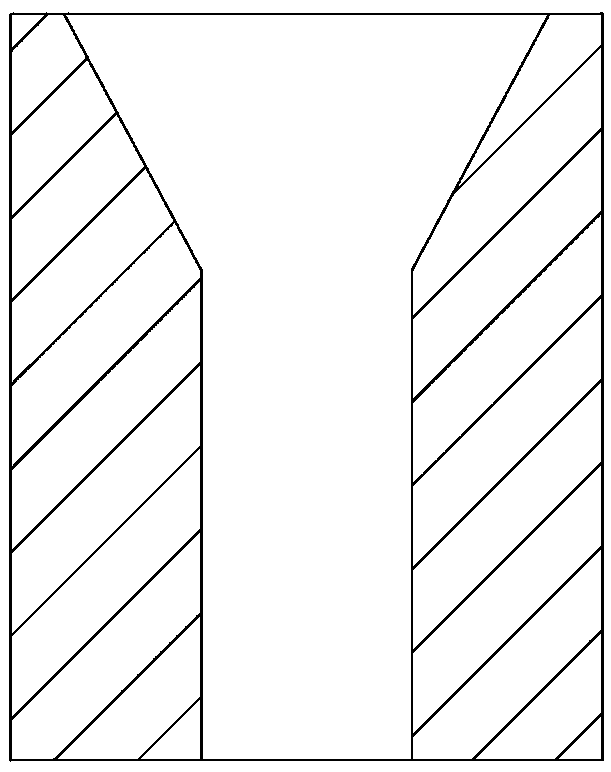

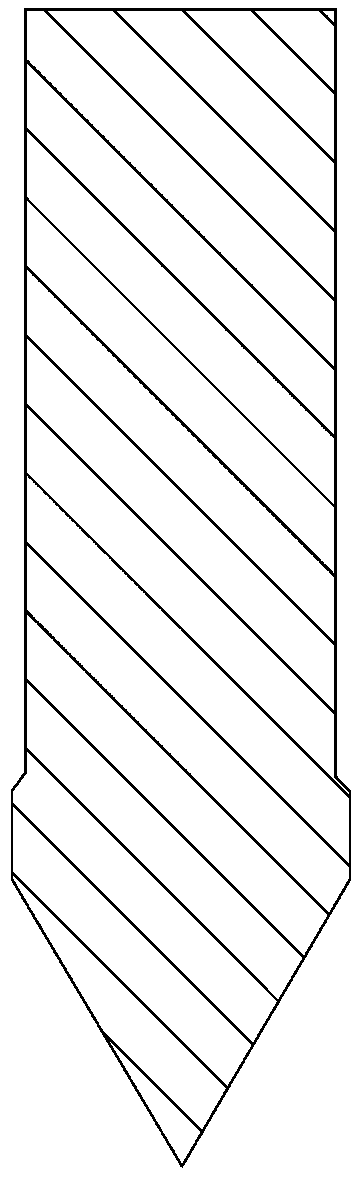

[0017] as attached figure 1 and 2 Shown, the present invention discloses a kind of processing method of cemented carbide extrusion die, comprises the following steps:

[0018] According to the shape of the tungsten carbide extrusion die, the corresponding matching shape of the electroplated diamond grinding wheel is designed. Grinding is carried out in the alloy extrusion die, and the clamping size of the electroplated diamond grinding wheel is determined according to the chuck size of the machining center or milling machine.

[0019] The electroplated diamond grinding wheel is set on the milling machine and the machining center, and the semi-finished product of the cemented carbide extrusion die is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com