Equipment for automatically dipping fastening piece and technological process

A fastener and dip coating technology, which is applied in the field of fastener automatic dip coating equipment and process flow, can solve the problems of large coating loss, uneven coating film, and large environmental pollution, and achieve improved drying effect and uniform coating film , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

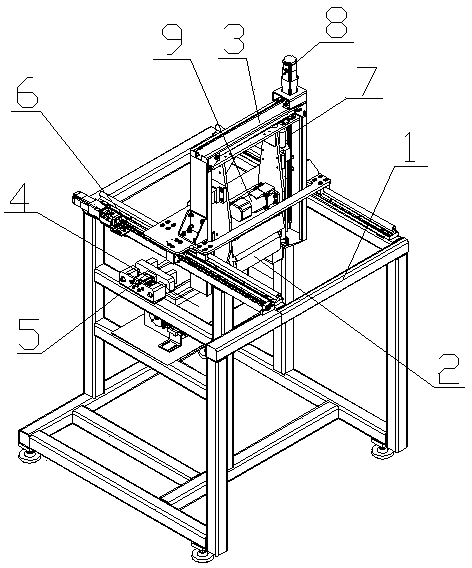

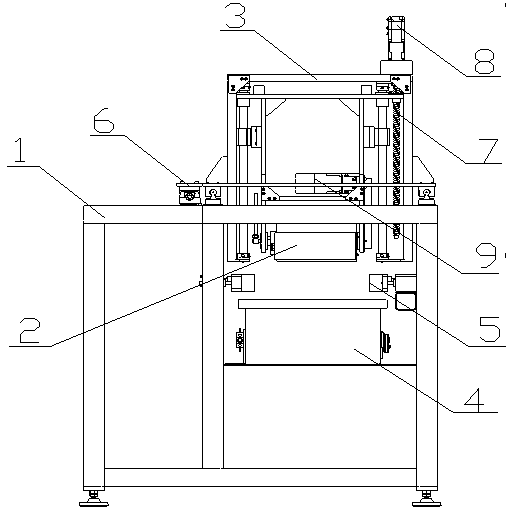

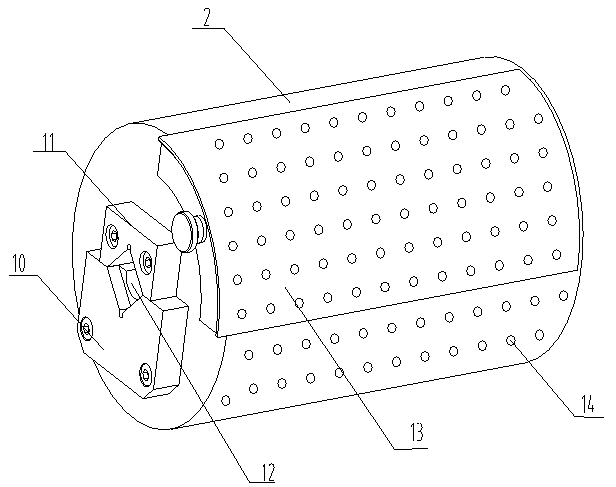

[0022] see figure 1 , figure 2 , image 3 , an automatic dipping equipment for fasteners, comprising a frame 1, a motor 9, a dipping moving vehicle 3 arranged on the frame 1, a horizontally arranged ball screw 7, a clamping mechanism 5 and a dipping tank 4, A trapezoidal screw rod is vertically arranged on the dip-coating moving car 3, and the dip-coating moving car 3 is connected with a ball screw 7; 2 rotates; the dip coating motion car 3 is also provided with a servo motor 8, and the servo motor 8 drives the ball screw 7 and the trapezoidal screw to drive the dip coating motion cart 3 to move, and the dip coating motion cart 3 drives the roller 2 to move horizontally and vertically ; The end face of the drum 2 is provided with a disassembly block 10, a transmission block 11 and a hot air duct opening 12, a drum door 13 is opened ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com