Method for removing dyes in water by utilizing magnetic metal-organic framework material

A technology of organic framework and magnetic metal, applied in the direction of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of complex process, high cost, low processing efficiency, etc., and achieve short removal time , conditions are easy to control, and the method is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Specific Embodiment 1: This embodiment is a method for removing dyes in water by using a magnetic metal-organic framework material, which is specifically completed according to the following steps:

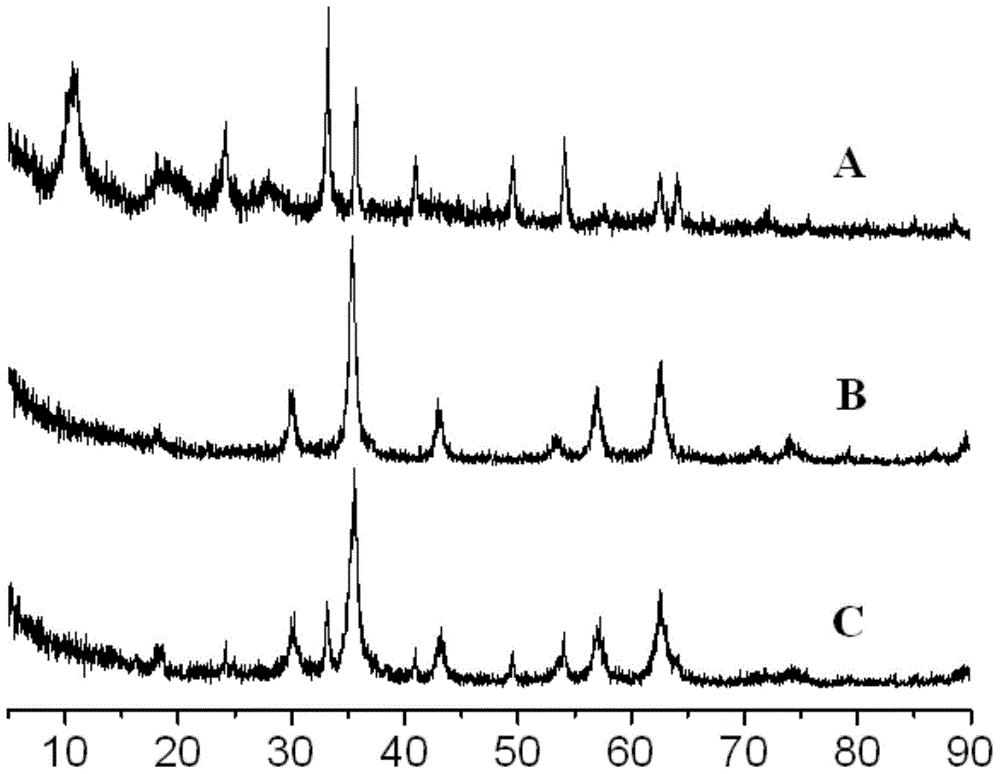

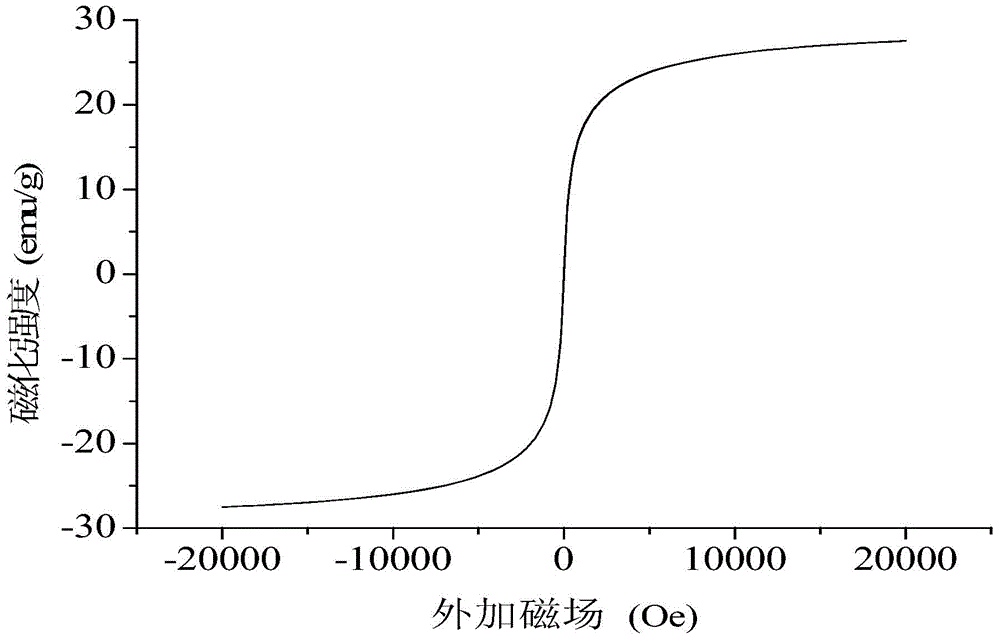

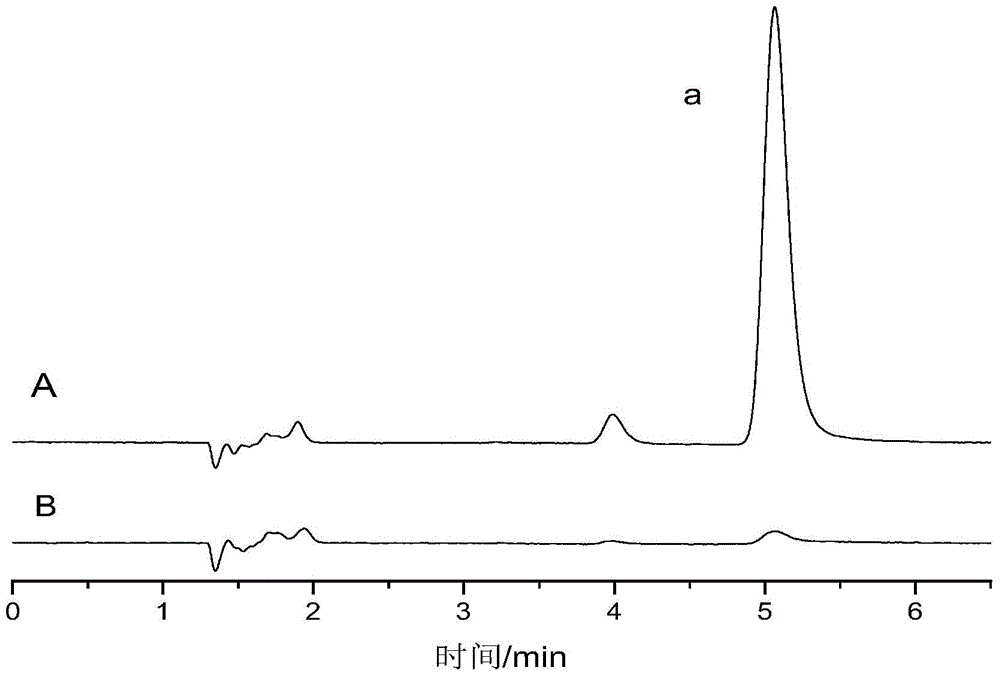

[0016] 1. Preparation of metal-organic framework materials: first, Fe(NO) 3 and 1,3,5-benzenetricarboxylic acid into a polytetrafluoroethylene liner, then add high-purity water to mix and stir evenly, cover it and transfer it to a stainless steel reaction kettle, and seal the stainless steel reaction kettle, then place it in an electric heating drum In an air constant temperature drying oven, react at a temperature of 190-220°C for 7h-10h, and then centrifuge at a speed of 5000rpm-7000rpm for 4min-7min to obtain a brick-red solid product. First, use N,N-dimethylformamide Wash the brick red solid product for 2 to 4 times, then wash with ethanol for 2 to 4 times, and finally wash with high-purity water for 2 to 4 times to obtain the washed product at a temperature of 50 to 70...

specific Embodiment approach 2

[0025] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: in step 1, react at a temperature of 200° C. for 8 hours, and then centrifuge at a speed of 6000 rpm for 5 minutes to obtain a brick-red solid product. Others are the same as the first embodiment.

specific Embodiment approach 3

[0026]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in Step 1, the washed product is vacuum-dried at 60° C. for 12 hours to obtain a metal-organic framework. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com