Metal surface rubber body removal method

A metal surface and rubber body technology, applied in recycling technology, plastic recycling, etc., can solve the problems of long removal time, difficult treatment of degumming waste liquid, high pollution of chemical solvents, etc., and achieve short removal time and low pollution Small, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

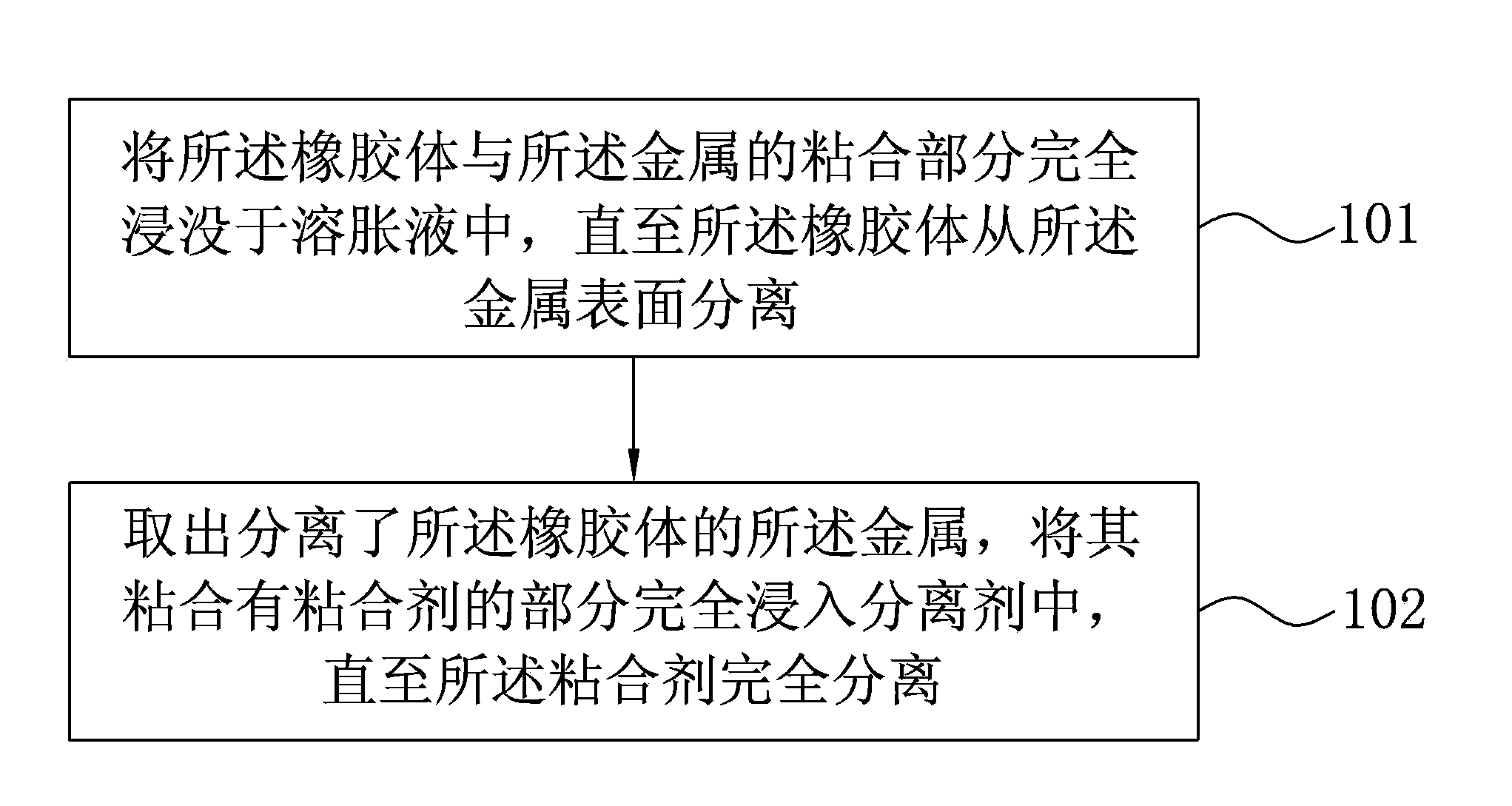

Image

Examples

Embodiment 1

[0036] The swelling separation solution may include the following components calculated according to mass fraction:

[0037] Dichloromethane 80%;

[0038] Absolute ethanol 20%.

Embodiment 2

[0040] The swelling separation solution may include the following components calculated according to mass fraction:

[0041] Dichloromethane 85%;

[0042] Absolute ethanol 15%.

Embodiment 3

[0044] The swelling separation solution may include the following components calculated according to mass fraction:

[0045] Dichloromethane 82%;

[0046] Absolute ethanol 18%.

[0047] Wherein, the reaction temperature in step 101 may be room temperature.

[0048] Wherein, the separating agent is N, N-dimethylformamide (also known as DMF; N, N-dimethylformamide

[0049] Formamide formic acid whose hydroxyl group is replaced by dimethylamino group) solution, the reaction time of the step 102 is 0.5-1 hour, and the reaction temperature of the step 102 can be room temperature.

[0050] In the method for removing the rubber body on the metal surface of the present invention, the adhesive is loosened by the swelling separation solution, softened and swollen and partially dissolved, and then separated from the rubber body, so as to achieve the bonding between the rubber body and the metal surface. Separation; taking out the metal and the rubber body, the swelling separation solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com