Magnetic biochar for rapidly removing methylene blue and preparation method and application thereof

A biochar and magnetic technology, applied in chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve the problems of unfavorable cost control, increased production cost, and many process steps, and achieve cost control and environmental protection , the effect of fewer process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A preparation method of magnetic biochar, comprising the steps of:

[0049] 1) bagasse is washed, crushed, dried, passed through a 100-mesh sieve, and stored for subsequent use;

[0050] 2) Add 10g of bagasse to 100mL of waste carbon steel pickling liquid, wherein the pH of the waste carbon steel pickling liquid is 1, the mass percentage of iron element is 12%, and the rotation speed is 100-150r / min. Stir for 6-12 hours, then centrifugally filter to obtain a solid mixture;

[0051]3) Put the solid mixture in a muffle furnace filled with nitrogen, calcinate at 600° C. for 0.5-2 hours, and pass through a 100-120 mesh sieve after cooling to obtain magnetic biochar.

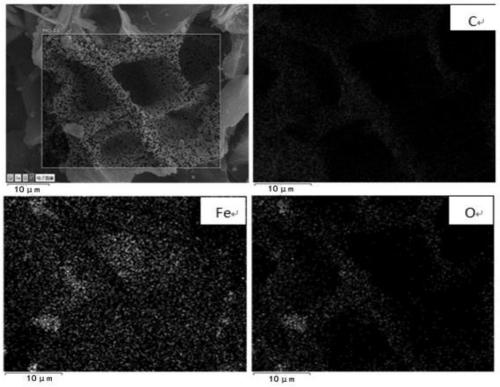

[0052] Depend on figure 1 It can be seen that the magnetic biochar has a porous structure with well-developed pore structure, and C, O and Fe elements are detected on its surface, and Fe elements are evenly distributed on the surface of the biochar and the wall of the biochar channel;

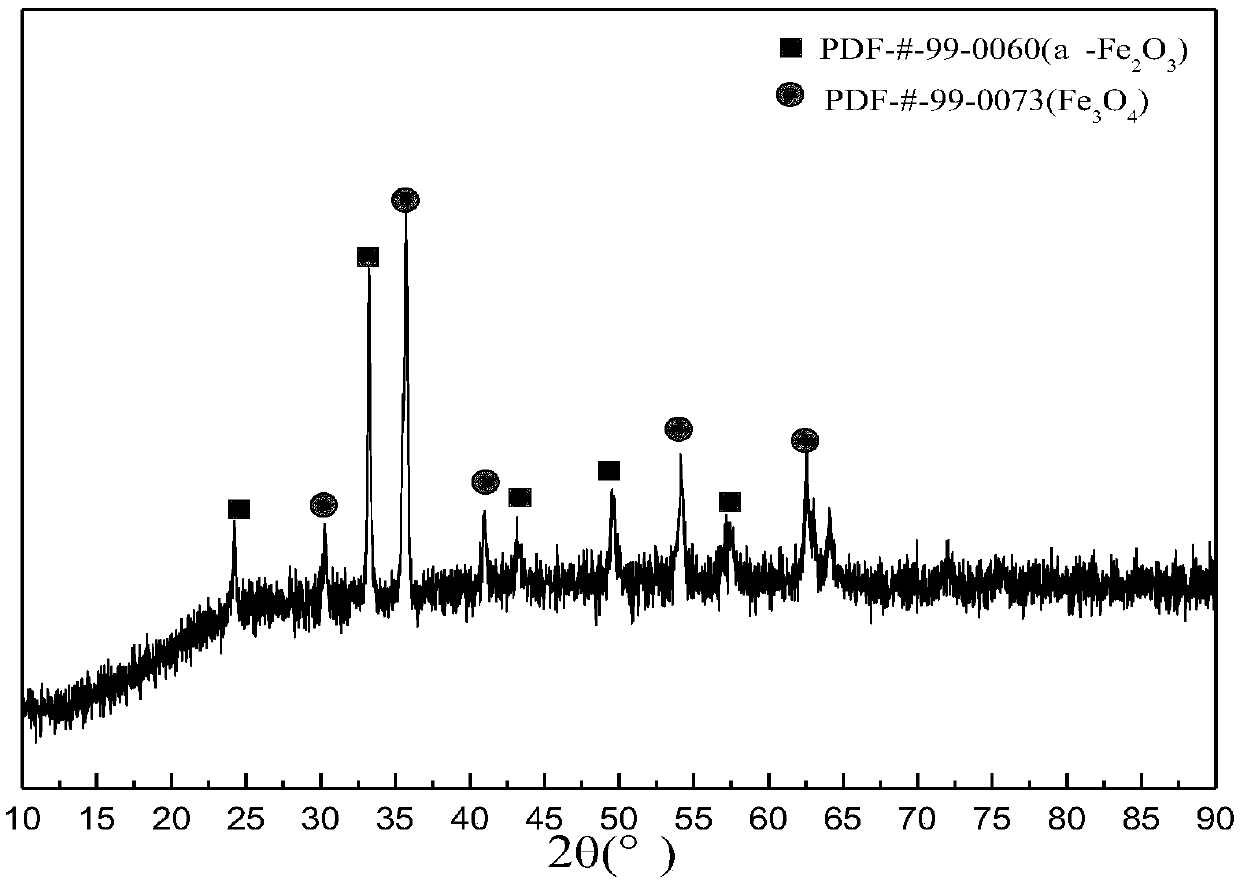

[0053] Depend on f...

Embodiment 2

[0060] A preparation method of magnetic biochar, comprising the steps of:

[0061] 1) bagasse is washed, crushed, dried, crushed and sieved, passed through a 100-mesh sieve, and stored for subsequent use;

[0062] 2) Add 10g of bagasse to 200mL carbon steel pickling waste liquid, wherein the pH of the carbon steel pickling waste liquid is 1.5, the mass percentage of iron element is 6%, and the rotation speed is 100-150r / min. Stir for 6-12 hours, then centrifugally filter to obtain a solid mixture;

[0063] 3) Put the solid mixture in a muffle furnace filled with nitrogen, calcinate at 600° C. for 0.5-2 hours, and pass through a 100-120 mesh sieve after cooling to obtain magnetic biochar.

Embodiment 3

[0065] A preparation method of magnetic biochar, comprising the steps of:

[0066] 1) bagasse is washed, crushed, dried, crushed and sieved, passed through a 100-mesh sieve, and stored for subsequent use;

[0067] 2) Add 10g of bagasse to 300mL carbon steel pickling waste liquid, wherein the pH of the carbon steel pickling waste liquid is 2, the mass percentage of iron element is 3%, and the stirring speed is 100-150r / min. ~12h, then centrifuged to obtain a solid mixture,

[0068] 3) The solid mixture is placed in a muffle furnace filled with nitrogen, pyrolyzed at 600° C. for 0.5-2 hours, cooled and passed through 100-120 sieves to obtain magnetic biochar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com