Two-stage hydrocracking method

A hydrocracking and two-stage hydrogenation technology, which is applied in the fields of hydrotreating process, hydrocarbon oil treatment, petroleum industry, etc., can solve the unrelated problems such as how to increase the yield of heavy naphtha in the second stage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

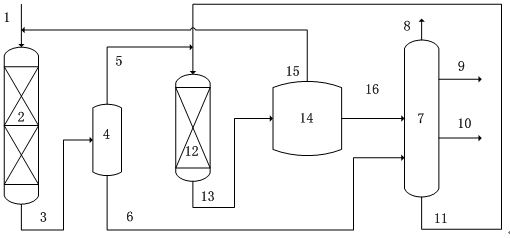

Method used

Image

Examples

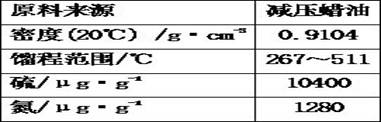

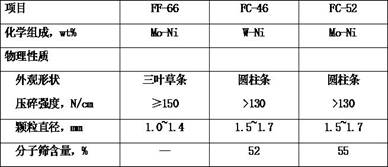

Embodiment 1

[0031] Process the raw materials in Table 1, use FF-66 hydrocracking pretreatment agent and FC-46 hydrocracking catalyst in the gradation of the first-stage reaction zone, the loading volume ratio of the two is 3:2, and the conversion rate of the first-stage control is 60% , the output liquid component enters the flash separator with an operating pressure of 13.5MPa and a temperature of 99°C. The liquid phase at the bottom of the separator enters the fractionation system, and the liquid phase at the bottom of the fractionation system and the gas phase at the top of the separator enter the second-stage reaction zone together. The second-stage filling uses FC-46 hydrocracking catalyst catalyst, and the single-pass conversion rate of the second stage is controlled. 60%, the liquid phase after the reaction enters the subsequent separation and fractionation system.

Embodiment 2

[0033] Process the raw materials in Table 1, use FF-66 and FC-46 hydrocracking catalysts in the reaction zone gradation of the first stage, the loading volume ratio of the two is 3:2, control the conversion rate of the first stage to 60%, and the liquid group of output The fraction enters the flash separator, whose operating pressure is 13.5MPa and temperature is 99°C. The liquid phase at the bottom of the separator enters the fractionation system, and the liquid phase at the bottom of the fractionation system and the gas phase at the top of the separator enter the second-stage reaction zone together. The second-stage filling uses FC-46 hydrocracking catalyst catalyst, and the single-pass conversion rate of the second stage is controlled. 70%, the liquid phase after the reaction enters the subsequent separation and fractionation system.

Embodiment 3

[0035] Process the raw materials in Table 1, use FF-66 and FC-46 hydrocracking catalysts in one-stage reaction zone gradation, the loading volume ratio of the two is 3:2, control the conversion rate of one-stage to 50%, and the liquid group of output The fraction enters the flash separator, whose operating pressure is 13.5MPa and temperature is 101°C. The liquid phase at the bottom of the separator enters the fractionation system, and the liquid phase at the bottom of the fractionation system and the gas phase at the top of the separator enter the second-stage reaction zone together. The second-stage filling uses FC-46 hydrocracking catalyst catalyst, and the single-pass conversion rate of the second stage is controlled. 60%, the liquid phase after the reaction enters the subsequent separation and fractionation system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com