Hydrogen manufacturing method for high-density culture and hydrogen production integration of platymanas subcordiformis

A technology for high-density cultivation of P. subcordiformis, which is applied in the field of hydrogen production integrating high-density cultivation and hydrogen production of P. subcordiformis. Destruction and other problems, to achieve the effect of increasing hydrogen production, eliminating product inhibition, and reducing manpower input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

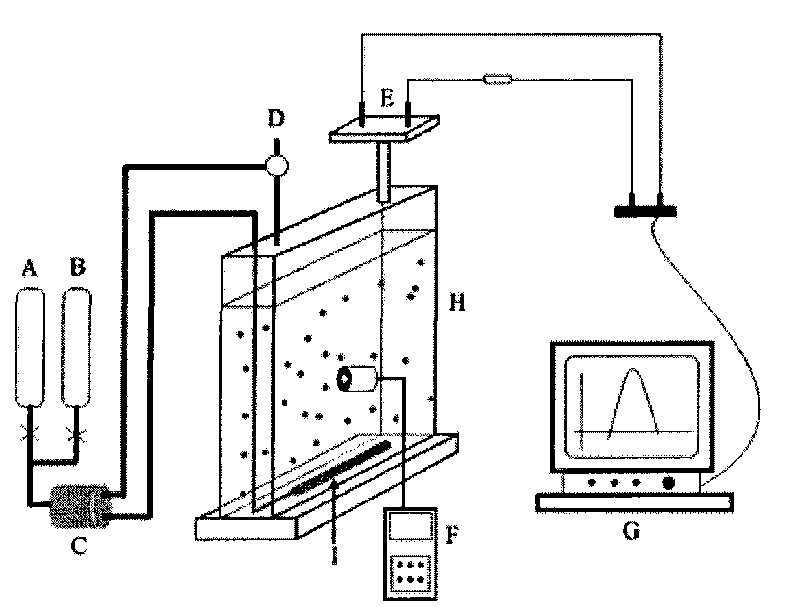

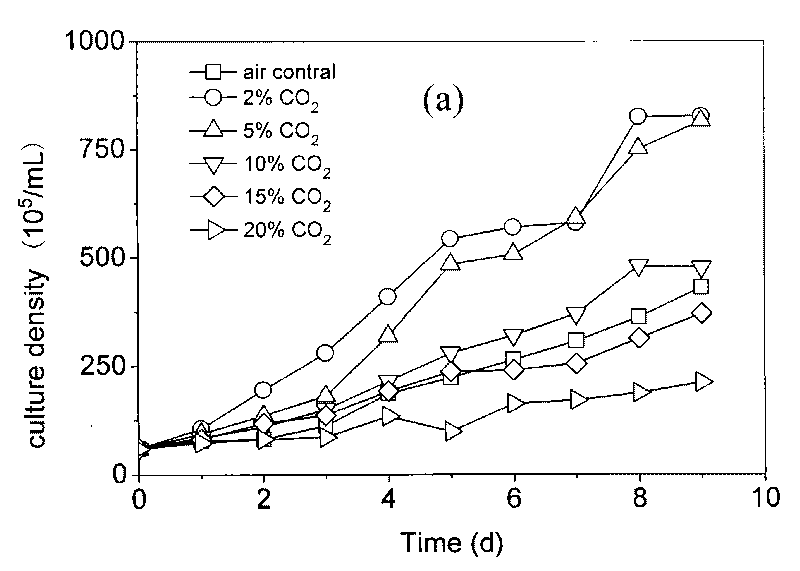

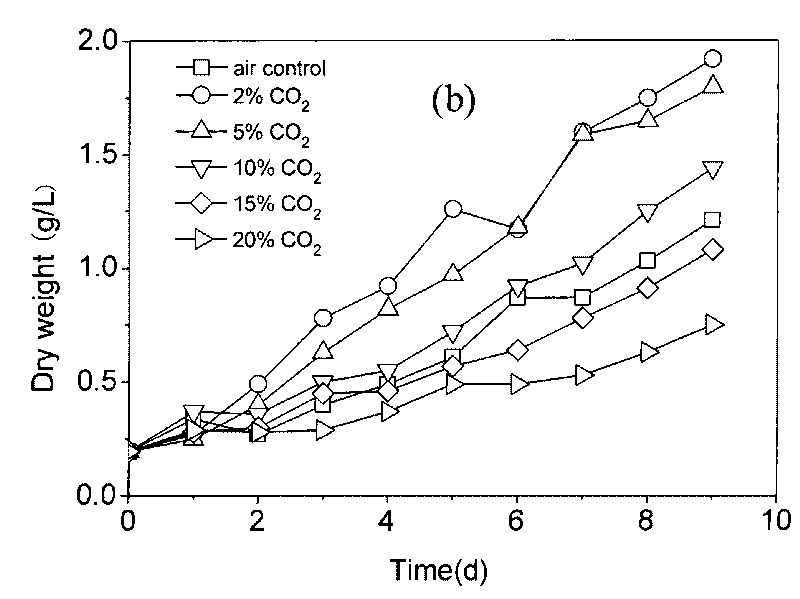

[0042] The reactor used is as figure 1 As shown, it is made of 3mm flat glass, the specification is 20cm*20cm*3cm, and the actual use volume is 1.5L. Platymonas subcordiformis required for the experiment was purified in the laboratory, cultured in a 2-liter Erlenmeyer flask with Kangweifang nutrient salt as the medium, and the initial inoculation density was 5×10 4 cell / mL, the volume of algae liquid is 1 liter; the culture temperature is 25°C; the light intensity is 50μE / m 2 .s -1 ; The light-to-dark ratio is 14:10. When the algae in shake flasks are in exponential growth phase, dilute to 10 6 cell / mL, inoculated in a plate reactor, the volume of algae liquid is 1.5L. During the cultivation process, different concentrations of CO 2 The algae liquid was aerated to investigate different concentrations of CO 2 Effects on the growth of flat algae, and find out the CO suitable for high-density cultivation of flat algae 2 concentration. Experimental results such as figure...

Embodiment 2

[0045] exist figure 1 In the reactor shown, when the algae density reaches 8×10 6 When cell / mL, close the CO 2 Cylinders, and keep the reactor dark. Then turn the gas conversion valve to N 2 Air valve, and open the nitrogen bottle, use nitrogen to purge the oxygen in the reactor, and the anaerobic state will be reached in the reactor after 10 minutes. Finally, the gas path switching valve was closed, and the reactor was placed in a dark place for 4 hours of dark induction. During this period, the micro-vacuum circulation pump should always be in an open state to stir the algae liquid. Before the light, inject 15 μL of CCCP into the reactor, and then carry out continuous light to produce hydrogen after 20 minutes, and the light intensity is 100 μE / m 2 .s -1 .

[0046] Figure 6 The results showed that the rapid light-induced curve decreased continuously with the passage of hydrogen production time, indicating that the ability of photosynthetic electron transfer (relativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com