Aluminum alloy vacuum standing, gas removal and smelting device

A vacuum static and aluminum alloy technology, which is applied in the field of aluminum alloy vacuum static degassing smelting devices, can solve the problems of unstable effect and low efficiency, and achieve the effects of strong hydrogen removal efficiency, reduced solubility, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

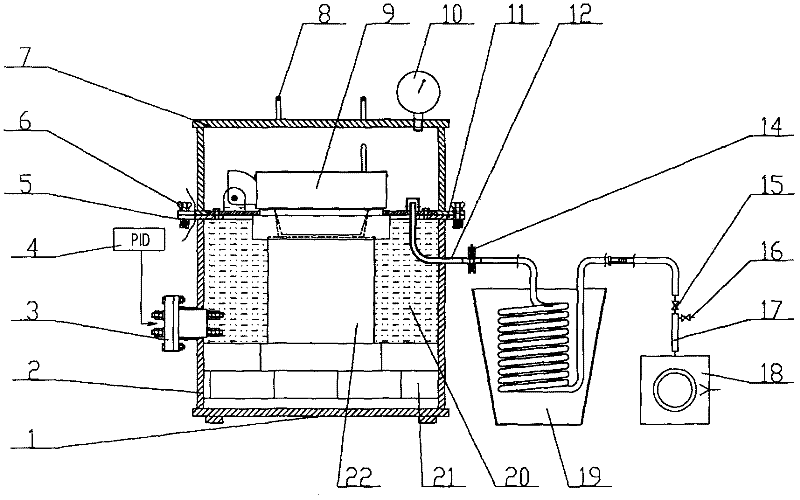

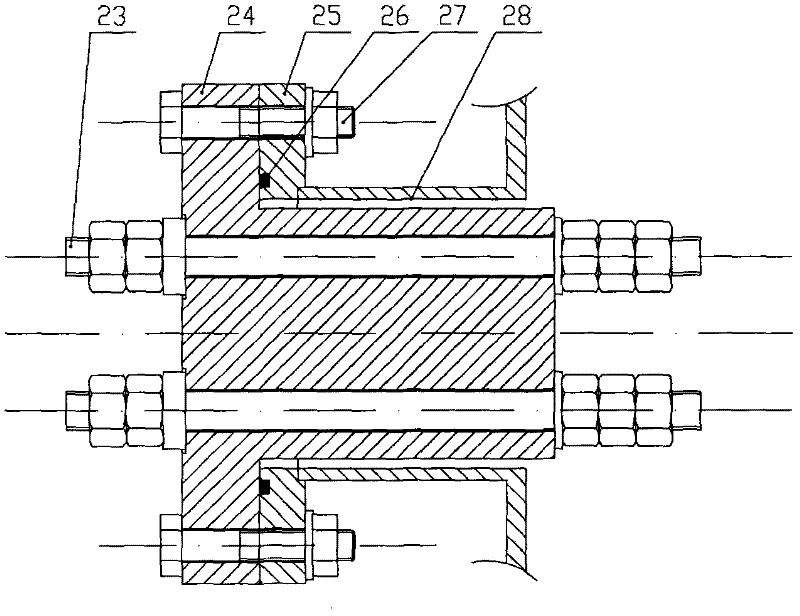

[0015] figure 1 As shown, the aluminum alloy vacuum static degassing smelting device includes a melting furnace body 1 mainly composed of a main furnace body 2 and a vacuum cover 7 matched with the main furnace body 2, and an exhaust pipe is arranged on the melting furnace body 1 12 and one end of the air extraction pipe 12 is located in the vacuum cover 7, the other end of the air extraction pipe 12 is connected with a cooling pipe 14, and the other end of the air extraction pipe 12 is connected with one end of the cooling pipe 14 through a vacuum quick release flange 13, cooling The other end of the pipe 14 is connected with a vacuum pump 18 through a rubber hose 17, and the rubber hose 17 is respectively provided with a vacuum valve 15 and a vacuum breaking valve 16.

[0016] The main furnace body 1 and the vacuum cover 7 are connected by a vacuum flange 5 and a slip bolt 6, an O-shaped sealing ring 11 is arranged between the two vacuum flanges 5, and the inside of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com