Method for dehydrogenating alkane

一种使烷烃、脱氢的技术,应用在使烷烃脱氢领域,能够解决转化率低、催化剂停留时间短等问题,达到降低氢分压、改进供热量、提高丙烯产量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

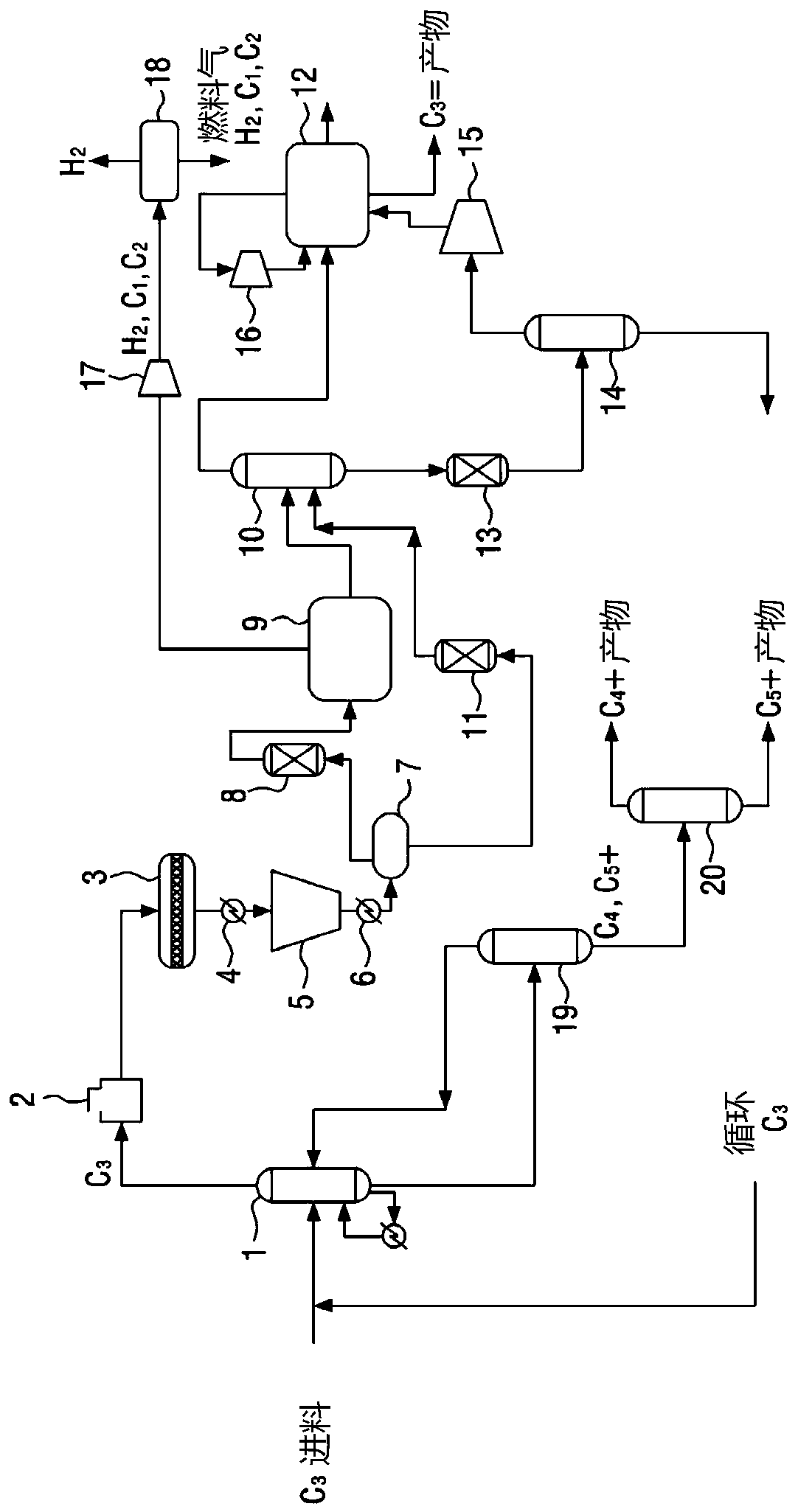

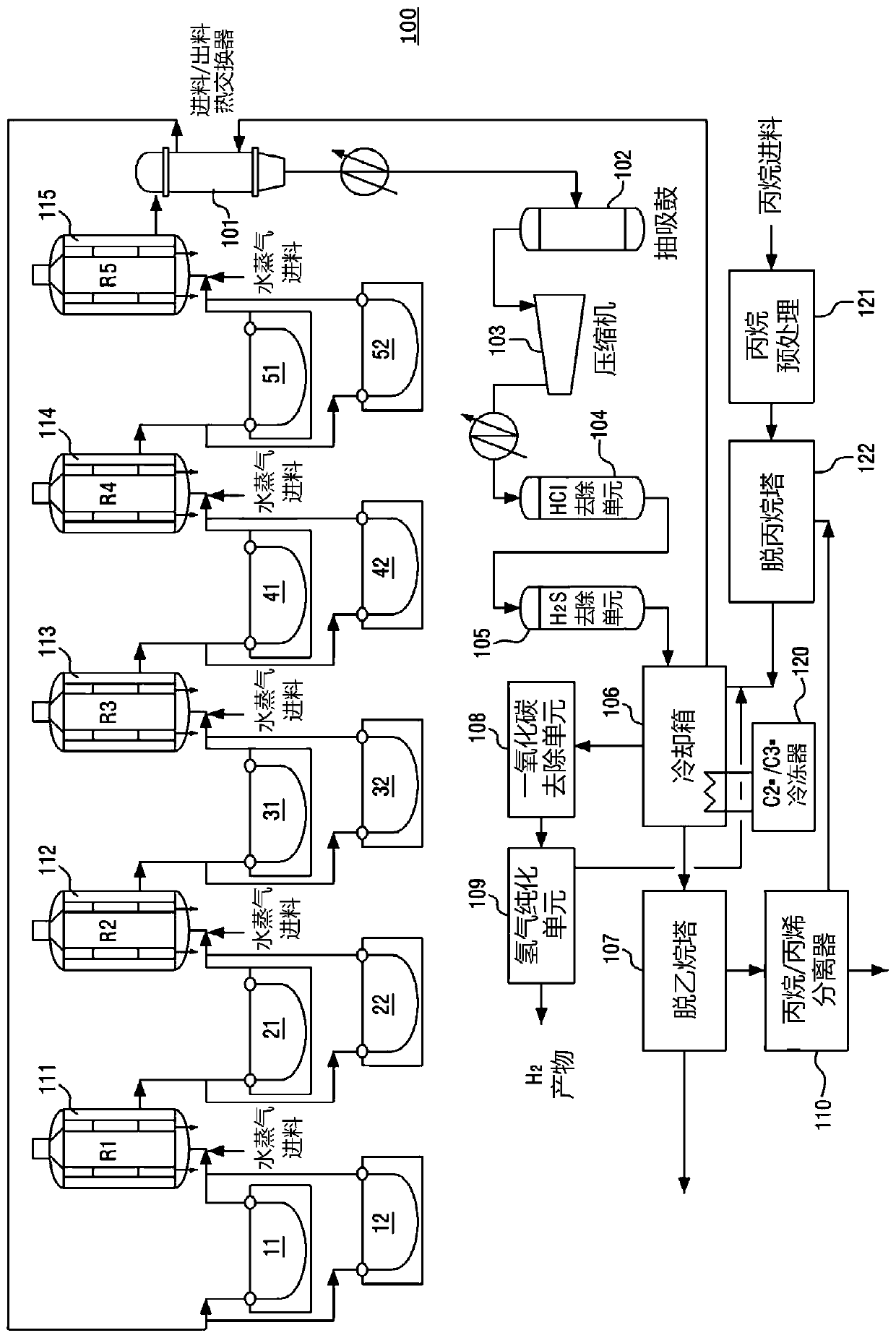

[0014] The present invention will be described in more detail below with reference to the accompanying drawings.

[0015] Although commonly-used terms widely used at present are selected as terms used in the present invention, terms randomly selected by the applicant are used in specific cases. In this case, the meaning of the term should be understood by considering the meaning described or used in the detailed description of the present invention, rather than simply considering the name of the term. Throughout the specification, the same reference symbols denote the same components.

[0016] Although the drawings depict a specific shape for the dehydrogenation reactor of the present invention, the dehydrogenation reactor may have various shapes suitable for the particular circumstances in which it is performed in a particular application. The broad applicability of the invention is not limited to the specific embodiments which will be described below. In addition, the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com