Reactor for preparing hydroanthraquinone and preparation method of hydroanthraquinone

A technology of hydrogen anthraquinone and reactor, which is applied in the field of hydrogen peroxide preparation by anthraquinone method, can solve the problems of low utilization rate of catalyst, low yield of anthraquinone hydrogenation, slow velocity of liquid through fluidized bed, etc., so as to improve selectivity and Effects of utilization rate, reduction of diffusion resistance, and reduction of catalyst dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

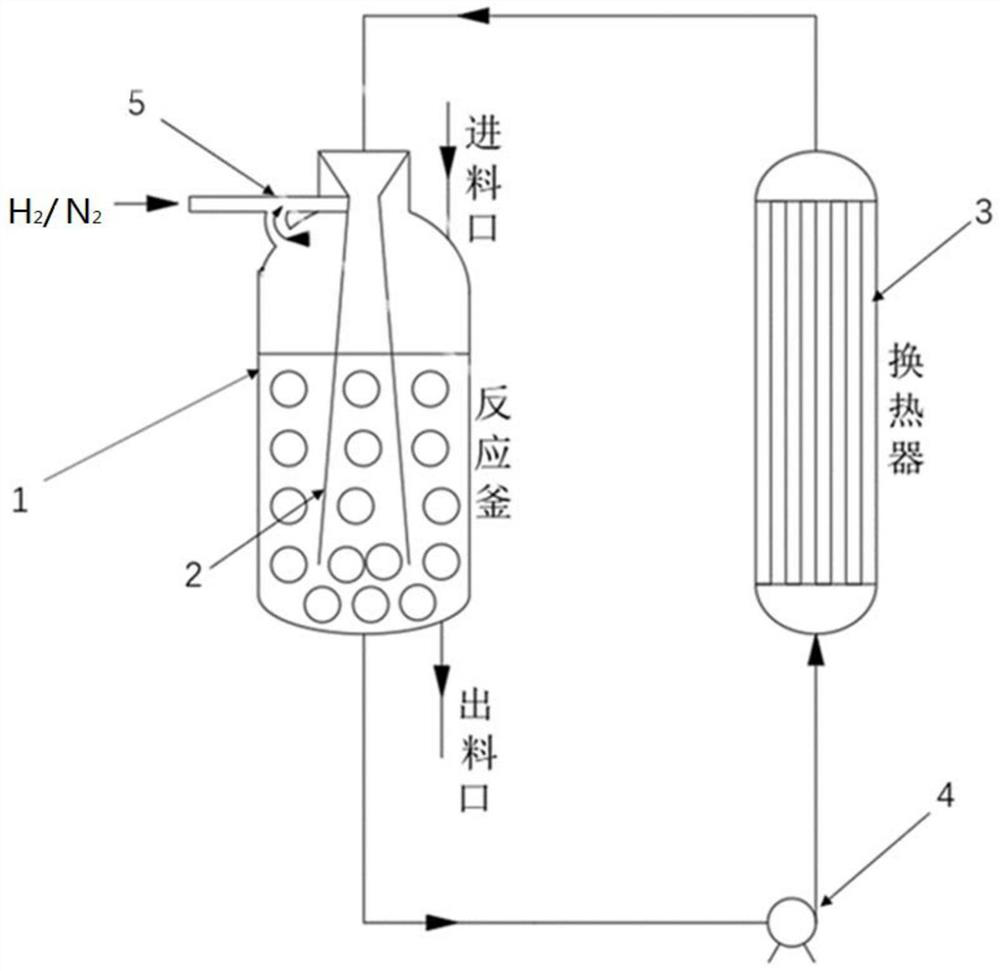

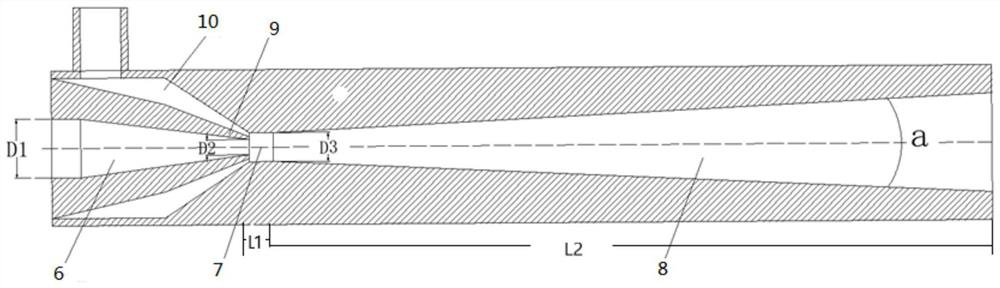

Method used

Image

Examples

preparation Embodiment A

[0056] Weigh the metered gas phase method SiO 2 Add the powder (silicon dioxide prepared by the gas phase method) into a custom-made glass container, and after evacuating for 1 hour, add a certain volume of the above-mentioned PdCl 2 Solution (SiO 2 The amount of powder added and PdCl 2 The amount of solution added is Pd: SiO 2 The mass ratio metering, controlled in Pd:SiO 2 For (0.1-0.3): 100, stirring and impregnating adsorption, stirring and impregnating adsorption, using 0.5mol / L sodium hydroxide solution to adjust pH = 9, reducing formaldehyde in a water bath at 80°C, and filtering and washing with ultrapure water until the end of the reduction The resistivity of the liquid is greater than or equal to 0.1MΩ·CM, and the filter cake is dried in a vacuum drying oven at 50°C, and the bulk density is 0.062-0.165g / cm3 when tested by a Scott density meter 3 .

preparation Embodiment B

[0058] According to the method of embodiment A, gas phase method SiO 2 Change to Al 2 o 3 , all the other operating methods are the same as in Example A, and the bulk density is 0.894g / cm through the Scott density meter test 3 .

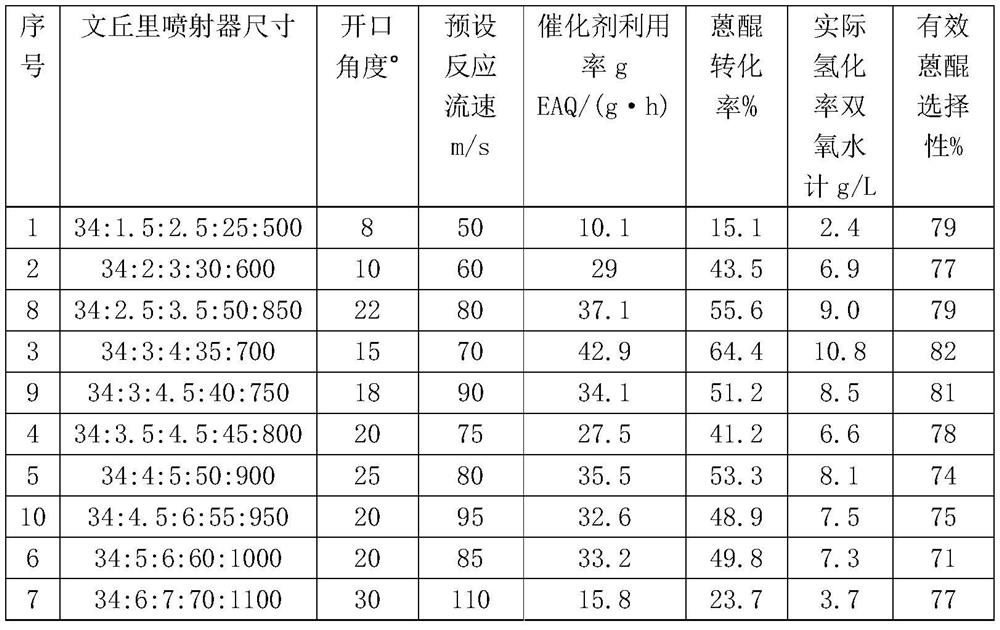

[0059] Example of Venturi Injector Size Screening

[0060] In the loop reactor of 5L (reactor volume 5L), add the EAQ working solution of 3kg 15% (the preparation of this working solution is as follows: heavy aromatics: trioctyl phosphate: 2-methylcyclohexyl acetate mass ratio is 70 :20:10 to prepare a mixed solution, add EAQ to the mixed solution to form an EAQ working solution, the mass concentration of EAQ in the EAQ working solution is 15%), add the Pd / SiO prepared by the catalyst preparation embodiment A 2 Catalyst powder (bulk density 0.083g / cm 3 ) is 1% of the mass of EAQ, where Pd:SiO 2=0.15:100, feed nitrogen into the reactor through the air inlet until the system pressure is 1MPa to vent and replace, and so cycle three times, nitrogen...

Embodiment 1

[0066] In the loop reactor of 5L (reactor volume 5L), add the EAQ working solution of 3kg 15%, add the Pd / SiO that catalyst preparation embodiment A prepares 2 Catalyst powder (bulk density 0.062g / cm 3 ) is 0.5% of the mass of EAQ, where Pd:SiO 2 =0.1:100, feed nitrogen into the reactor through the air inlet until the system pressure is 1MPa to vent and replace, so that the cycle is three times, and the nitrogen is switched to a hydrogen-nitrogen mixture (H 2 :N 2 =1:1) Fill the reactor to the reaction pressure of 0.3±0.05MPa, turn on the circulation pump to make the liquid in the kettle flow slowly, raise the temperature to the preset reaction temperature of 40°C (heating time is about 15min), adjust the circulation pump 4 to the flow rate of 60m / s, recorded as the reaction start time. During the reaction, the temperature of the connected reactor was controlled to be 40±1°C. After reacting for 3 hours, immediately reduce the flow rate of the circulation pump 4 and rapidl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com