Nickel base alloy submerged arc welding sintered flux and preparation method and application thereof

A nickel-based alloy, sintered flux technology, applied in arc welding equipment, welding equipment, welding equipment and other directions, can solve the problem of late start of research, and achieve the effects of improving purity, reducing metal oxygen content in welds, and reducing content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

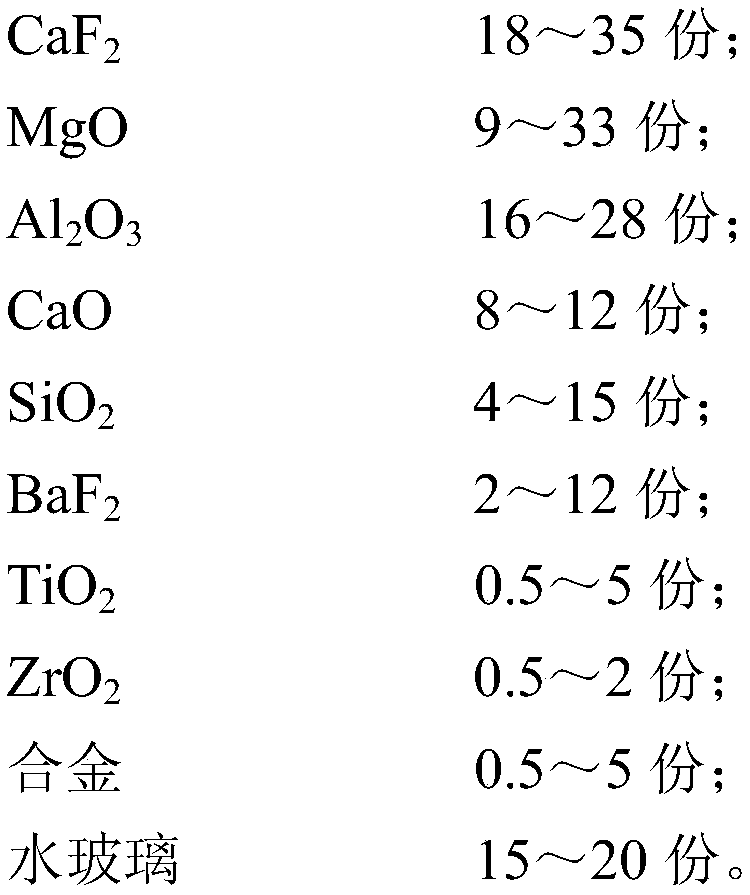

[0066] A nickel-based alloy submerged arc welding sintering flux, the main slag system is mainly composed of CaF 2 -MgO-Al 2 o 3 -CaO-BaF 2 -SiO 2 System composition, described nickel base alloy submerged arc welding sintering flux, comprises the following components by mass parts (each component chemical composition and particle size are shown in Table 1):

[0067]

[0068] The preparation method of described nickel-based alloy submerged arc welding sintering flux comprises the following steps:

[0069] (1) Mix the above-mentioned nickel-based alloy submerged arc welding sintering flux components (except potassium-sodium water glass) evenly, add potassium-sodium water glass for wet mixing, and obtain mixed powder;

[0070] (2) granulating the mixed powder prepared in step (1) in a granulation pan, with a particle size of 10 to 60 mesh; drying at 200° C. to obtain flux granules;

[0071] (3) sintering the flux particles prepared in step (2) at a high temperature of 720...

Embodiment 2

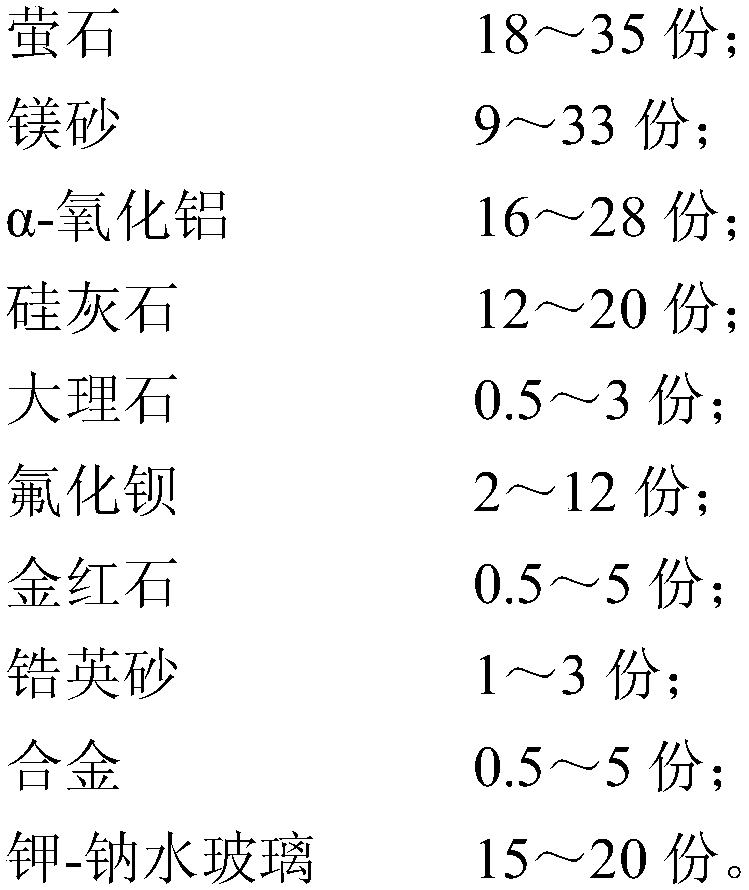

[0074] A nickel-based alloy submerged arc welding sintering flux, the main slag system is mainly composed of CaF 2 -MgO-Al 2 o 3 -CaO-BaF 2 -SiO 2 System composition, described nickel base alloy submerged arc welding sintering flux, comprises the following components by mass parts (each component chemical composition and particle size are shown in Table 1):

[0075]

[0076]

[0077] The preparation method of described nickel-based alloy submerged arc welding sintering flux comprises the following steps:

[0078] (1) Mix the above-mentioned nickel-based alloy submerged arc welding sintering flux components (except potassium-sodium water glass) evenly, add potassium-sodium water glass for wet mixing, and obtain mixed powder;

[0079] (2) granulating the mixed powder prepared in step (1) in a granulation pan, with a particle size of 10 to 60 mesh; drying at 200° C. to obtain flux granules;

[0080] (3) sintering the flux particles prepared in step (2) at a high temper...

Embodiment 3

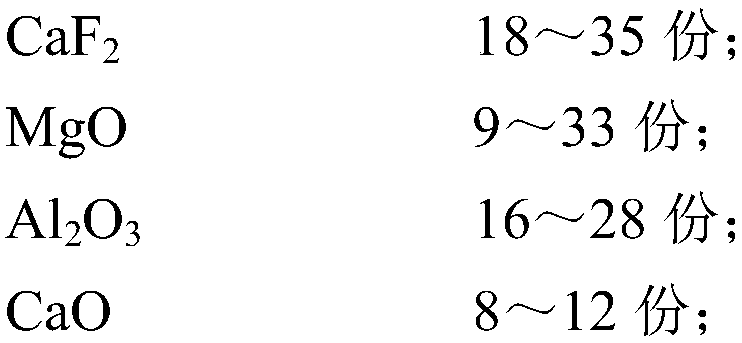

[0083] A nickel-based alloy submerged arc welding sintering flux, the main slag system is mainly composed of CaF 2 -MgO-Al 2 o 3 -CaO-BaF 2 -SiO 2 System composition, described nickel base alloy submerged arc welding sintering flux, comprises the following components by mass parts (each component chemical composition and particle size are shown in Table 1):

[0084]

[0085] The preparation method of described nickel-based alloy submerged arc welding sintering flux comprises the following steps:

[0086] (1) Mix the above-mentioned nickel-based alloy submerged arc welding sintering flux components (except potassium-sodium water glass) evenly, add potassium-sodium water glass for wet mixing, and obtain mixed powder;

[0087] (2) granulating the mixed powder prepared in step (1) in a granulation pan, with a particle size of 10 to 60 mesh; drying at 200° C. to obtain flux granules;

[0088] (3) sintering the flux particles prepared in step (2) at a high temperature of 720...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com