System for hydrogen purification and wax oil hydrogenation coupling in hydrogen from coal

A wax oil hydrogenation and coal-to-hydrogen technology, applied in the chemical industry, can solve the problems of difficult adsorbent regeneration, high energy consumption in cryogenic separation, and high investment costs, so as to reduce equipment investment and operating costs, reduce equipment investment, The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

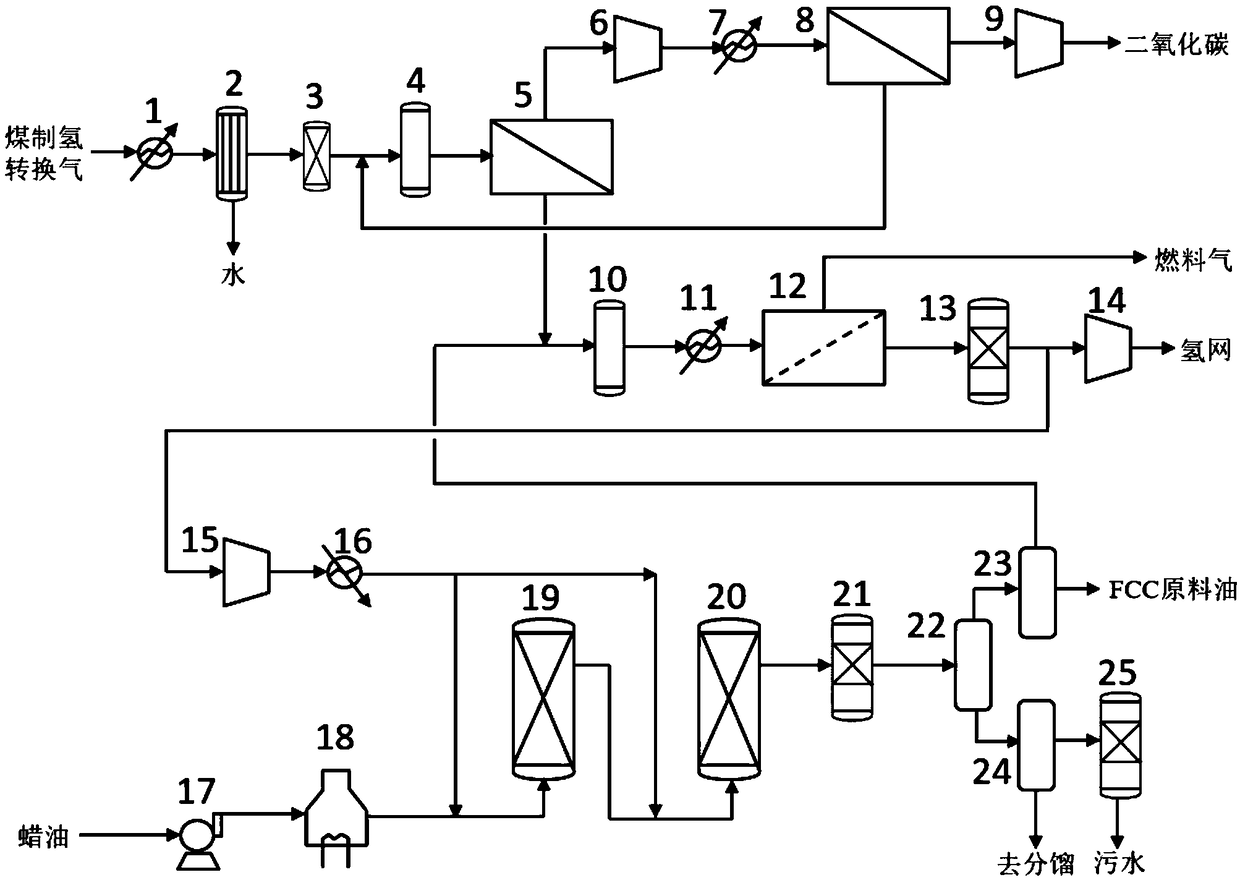

[0035] see figure 1 , the system of the present invention comprises a carbon dioxide separation unit, a hydrogen purification unit, a wax oil hydrorefining unit and an oil-gas separation unit;

[0036]The carbon dioxide separation unit is located at the beginning of the system. Firstly, the coal-to-hydrogen conversion gas is cooled from 300°C to 25°C and the pressure is 3MPa. After the water is discharged from the liquid separation tank, it enters the precision filter to filter out dust, water vapor, etc. to ensure The gas entering the membrane separator is pure, at this time the molar concentration of hydrogen is 55.12%, and the molar concentration of carbon dioxide is 40.02%. After being separated by the 1# carbon membrane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com